This is my first attempt at building anything like this. I'm working on building a small acrylic frag tank (20" x 16" x 6"). I had the 1/2" cast acrylic cut with a router at the acrylic shop and sanded the edges down with a sanding block.

Last night I welded the sides together with Weldon 3 using the pin method and ran into a couple of issues.

First on one of the seems I got a couple of bubbles that I couldn't get out and also each end of that same seem didn't seem to take the cement all the way. Where the rest of it turned clear as the cement went in there is about a 1/8" area that didn't turn clear no matter how much cement I was squirting in. Are these concerns and if so, is there a way to remedy them?

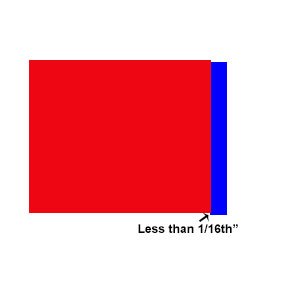

Also, on one of the sides, the edges were shifted very slightly so they are mis-aligned by less than 1/16". I'm guessing when I sit the sides on the bottom panel there will be the slightest gap between the wall and the bottom. I've attached an image to show what I mean. Is there a way to make this work?

Thanks!

Last night I welded the sides together with Weldon 3 using the pin method and ran into a couple of issues.

First on one of the seems I got a couple of bubbles that I couldn't get out and also each end of that same seem didn't seem to take the cement all the way. Where the rest of it turned clear as the cement went in there is about a 1/8" area that didn't turn clear no matter how much cement I was squirting in. Are these concerns and if so, is there a way to remedy them?

Also, on one of the sides, the edges were shifted very slightly so they are mis-aligned by less than 1/16". I'm guessing when I sit the sides on the bottom panel there will be the slightest gap between the wall and the bottom. I've attached an image to show what I mean. Is there a way to make this work?

Thanks!