- Joined

- Feb 23, 2015

- Messages

- 349

- Reaction score

- 50

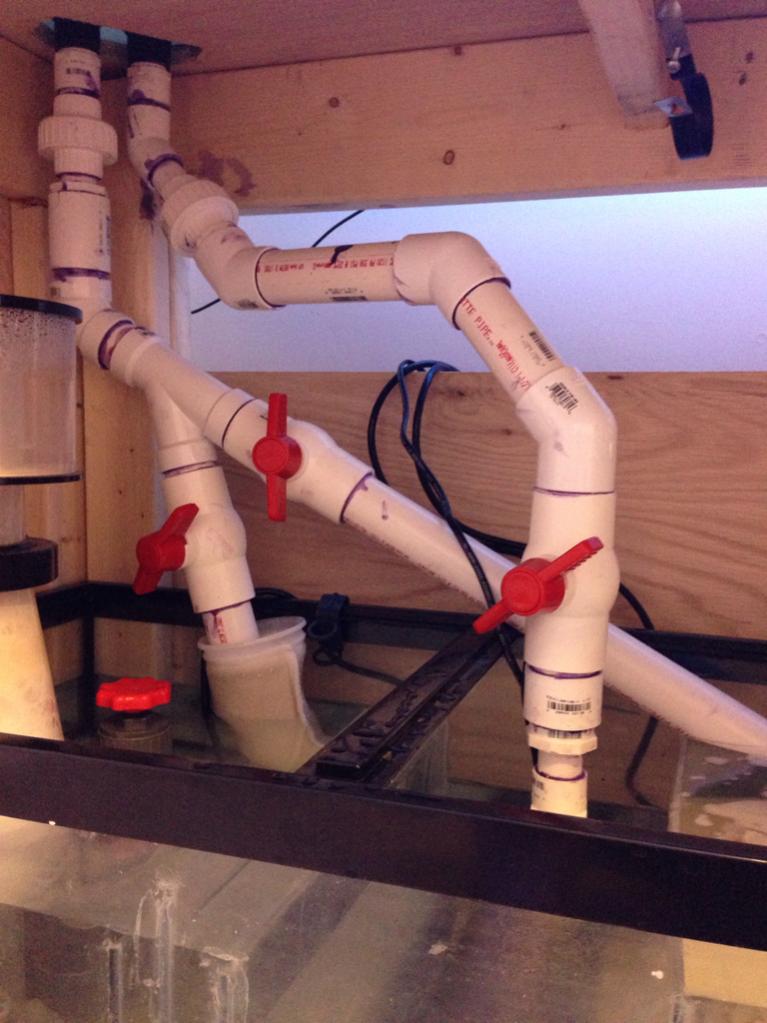

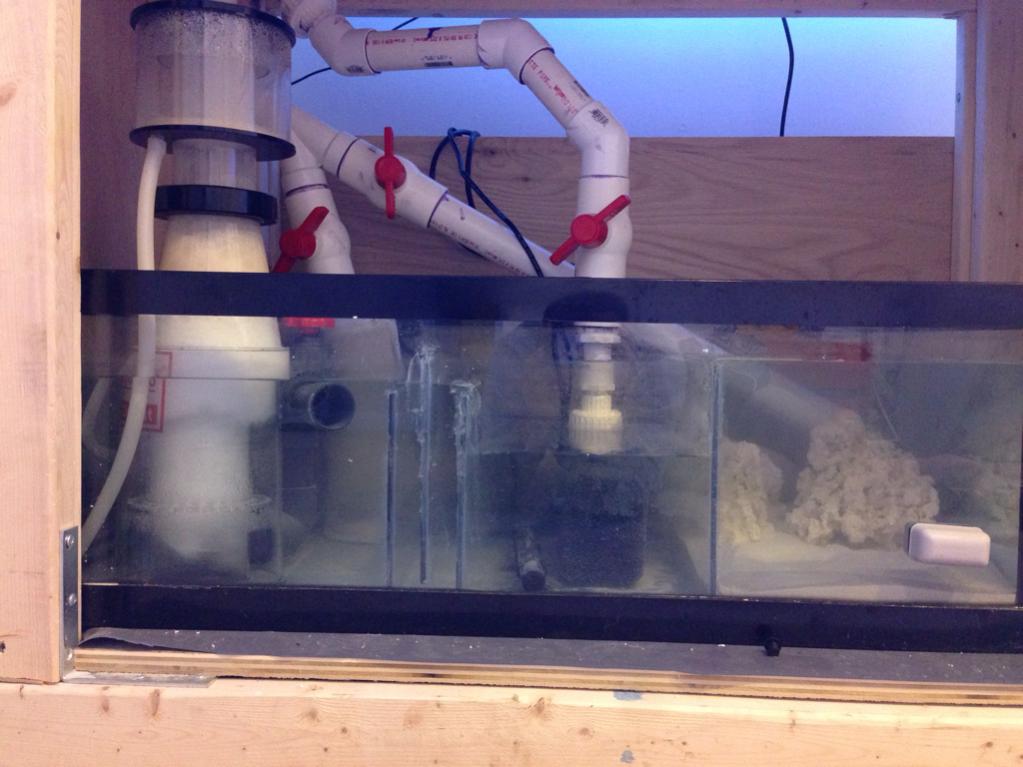

Just got this system dialed in yesterday, it's a 120 with 1.5"drain & return leading to the 40 breeder sump. The drain is split direct to refugium and skimmer compartment, central compartment with a mag 9.5 return pump and heater.

Super Reef Octopus 2000 INT skimmer, Aqueon Pro 200 heater, x2 Kessil a360w with controller. Maxspectre Gyre XF-150

Still trying out new things with the LED controller. Setting up the program levels and intervals.

Roughly, very roughly, 100lbs of reef saver rock. 2-3" live sand bed

The rock work is combination putty/epoxy and drilled pieces stacked on thick PVC tubing. The towers do not sway or teeter they are rigid. There is about 10-20lbs In the fuge as well.

What do you think?

Super Reef Octopus 2000 INT skimmer, Aqueon Pro 200 heater, x2 Kessil a360w with controller. Maxspectre Gyre XF-150

Still trying out new things with the LED controller. Setting up the program levels and intervals.

Roughly, very roughly, 100lbs of reef saver rock. 2-3" live sand bed

The rock work is combination putty/epoxy and drilled pieces stacked on thick PVC tubing. The towers do not sway or teeter they are rigid. There is about 10-20lbs In the fuge as well.

What do you think?