here is a step by procedure for building a seamless custom acrylic tank.....

i will try to explain it the best i can...this was built for the owner of my companies son....sometimes it pays to be slow at work lol..... the tank will be used for freshwater so there is no overflows etc.....so here we go let the pics begin.....

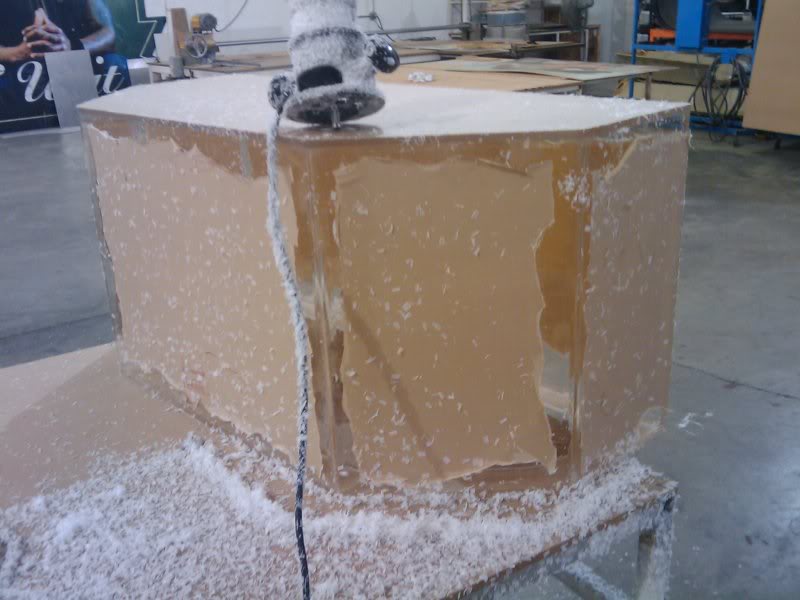

first step is the layout and mark your material where you would like to bend it....i choose half inch because this is a 100gal hex front.....after you have your layout set it up on a table and i perfer 1"medite or mdf some call it to keep the material flat while it is heated clamp the material in place leaving a 1" gap between for the material to heat and bend....i use a infared heater used to bake paint for my bending, each bend is heated for 2 hours very slowly to prevent problems such as crazing while you glue it....it is the best way to get a nice clean bend without alot of stress on the material if you heat it fast it will severly weaken the material...each bend was at a 45deg....

i will try to explain it the best i can...this was built for the owner of my companies son....sometimes it pays to be slow at work lol..... the tank will be used for freshwater so there is no overflows etc.....so here we go let the pics begin.....

first step is the layout and mark your material where you would like to bend it....i choose half inch because this is a 100gal hex front.....after you have your layout set it up on a table and i perfer 1"medite or mdf some call it to keep the material flat while it is heated clamp the material in place leaving a 1" gap between for the material to heat and bend....i use a infared heater used to bake paint for my bending, each bend is heated for 2 hours very slowly to prevent problems such as crazing while you glue it....it is the best way to get a nice clean bend without alot of stress on the material if you heat it fast it will severly weaken the material...each bend was at a 45deg....