Here is my current DIY project, it is still in the early stages:

Any Guesses?

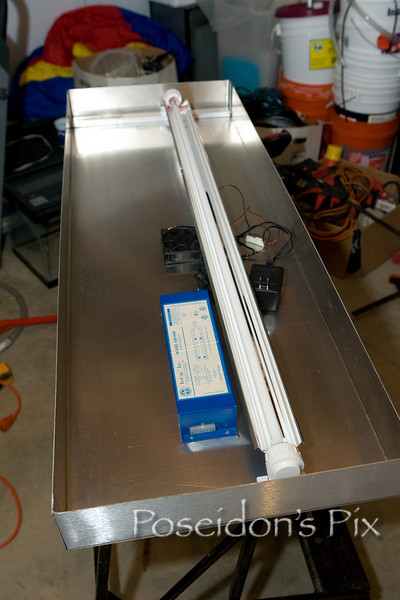

This should give it away....

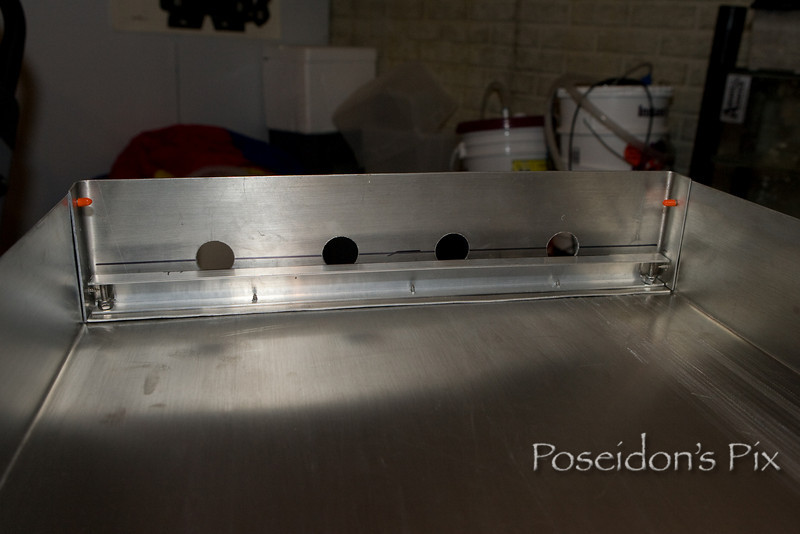

Vent holes:

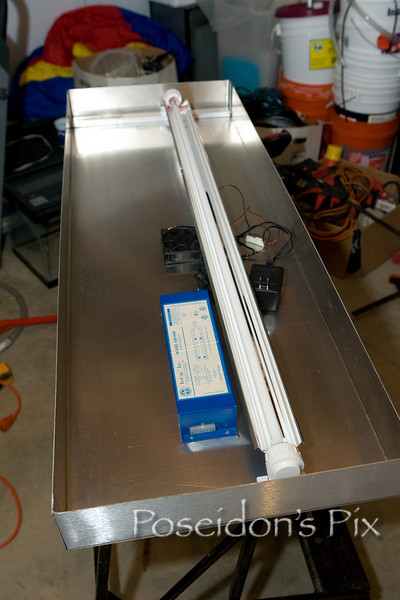

Nothing has been attached yet, but that will happen today I think! I have stainless steel hardware for all the screws and nuts, and I am going to add a thin black fabric to the vents, so that light doesn't leak out so much.

The fixture will be suspended over my tank with sun lifts, and it will have 2 3" fans for active cooling. I'll post more pictures later... (When I have more to show!)

Any Guesses?

This should give it away....

Vent holes:

Nothing has been attached yet, but that will happen today I think! I have stainless steel hardware for all the screws and nuts, and I am going to add a thin black fabric to the vents, so that light doesn't leak out so much.

The fixture will be suspended over my tank with sun lifts, and it will have 2 3" fans for active cooling. I'll post more pictures later... (When I have more to show!)