I decided to finally quiet down my CPR CS90 overflow after years of the gurgling and sucking sound in the background. Wow! What a difference!? It only took about 10 minutes to build. Since I had to wait 24 hours for the glue to dry right for safety for the system, after building the Durso. I decided to use the Stockman standpipe first because no glue is needed.

Doing research, I found the Durso type standpipe first (LINK). I watched a couple of videos and decided to give it a try. A few hours later, I started putting my parts list together, then I discovered this thread here on R2R (LINK). I read through the thread, and it was suggested that the Stockman standpipe is quieter than the Durso standpipe. Then, I found a video on how to make a Stockman standpipe. I decided to stay with the Stockman standpipe because it worked.

Parts list for the Durso:

1” schedule 40 PVC 5” long cut in half, so that there is 2 x 2.5” sections, making sure the air intake is 1” above the overflow in the back the overflow box.

1” T-fitting

1” Street 90

1” Cap

A saw or PVC cutter, PVC glue, and a 13/64 drill bit for the air inlet hole.

One can adjust the flow by sticking some air line in the air inlet hole with an adjustable air line fitting

Picture of air line adjuster

Update 6/24/18

Switch the small airline adjuster out with a 1/4 waterline shut off because the sucking came back. This switch made a definite improvement and easier to adjust. My suggestion would be if the suckinng comes back then increase the line in to the top with a large line and fitting. For example if a 1/4 inch does not work then a 3/8 with shut off for adjustment. If that does not work the go larger.

Update 7/7/18 now more sucking noise after switching to the large shut off valve.

Picture of stand pipe

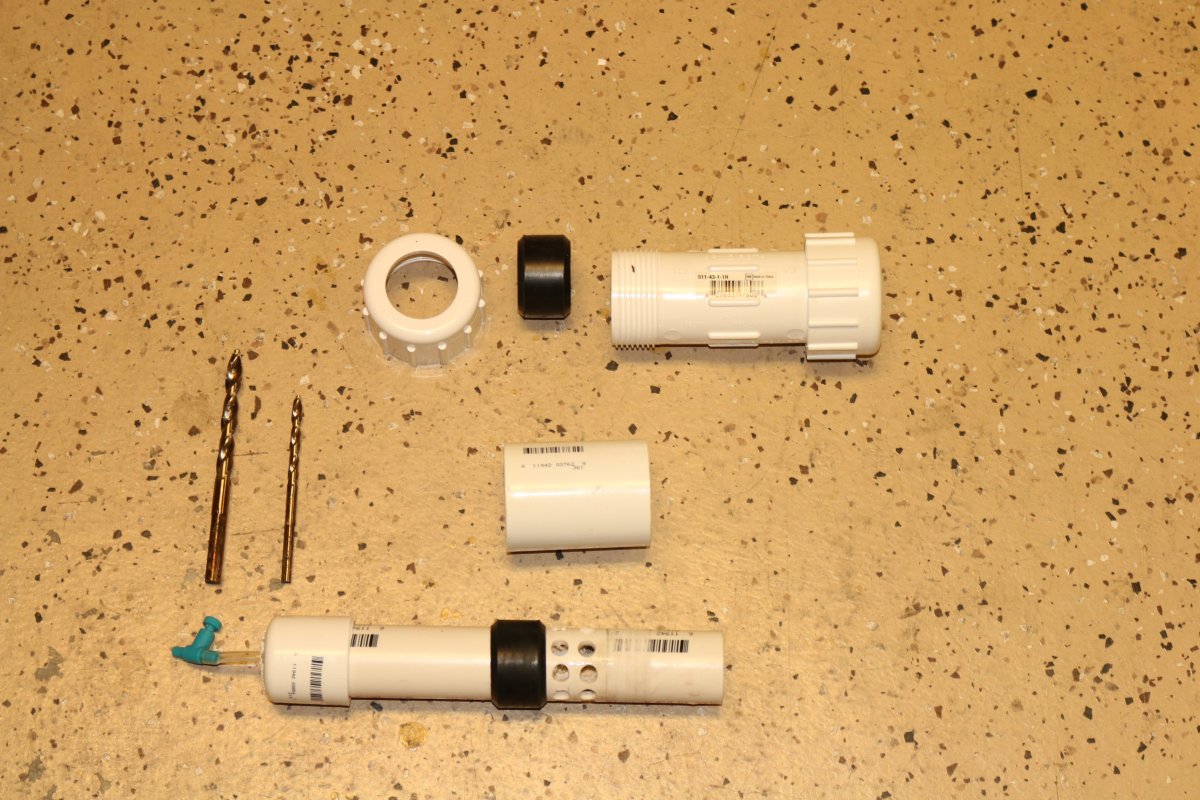

Parts list for the Stockman

1” schedule 40 PVC cut 7.5 inches long, making sure the air intake is 1” above the overflow in the back the overflow box.

1” repair compression coupling just for the rubber washer.

1 ¼ “coupling to fit over washer and drilled holes

1” cap

13/64 drill bit for air inlet hole

15/16 drill bit for water intake holes

Air line and air line adjustment fitting

I measured up two inches up from the bottom and made a line. Then measured up another inch to where my washer will be. I drilled 5/16 holes in the one-inch section randomly to let the water into the pipe. Slide the 1 ¼ fitting down over the washer to the two-inch mark. Drill a 13/64 hole in the top cap, push in your airline and adjuster. Place in overflow and adjust the flow with the airline adjuster. It will take a couple of tweaks but wow what a difference.

Picture of Stockman

Video of the noise reduction

Doing research, I found the Durso type standpipe first (LINK). I watched a couple of videos and decided to give it a try. A few hours later, I started putting my parts list together, then I discovered this thread here on R2R (LINK). I read through the thread, and it was suggested that the Stockman standpipe is quieter than the Durso standpipe. Then, I found a video on how to make a Stockman standpipe. I decided to stay with the Stockman standpipe because it worked.

Parts list for the Durso:

1” schedule 40 PVC 5” long cut in half, so that there is 2 x 2.5” sections, making sure the air intake is 1” above the overflow in the back the overflow box.

1” T-fitting

1” Street 90

1” Cap

A saw or PVC cutter, PVC glue, and a 13/64 drill bit for the air inlet hole.

One can adjust the flow by sticking some air line in the air inlet hole with an adjustable air line fitting

Picture of air line adjuster

Update 6/24/18

Switch the small airline adjuster out with a 1/4 waterline shut off because the sucking came back. This switch made a definite improvement and easier to adjust. My suggestion would be if the suckinng comes back then increase the line in to the top with a large line and fitting. For example if a 1/4 inch does not work then a 3/8 with shut off for adjustment. If that does not work the go larger.

Update 7/7/18 now more sucking noise after switching to the large shut off valve.

Picture of stand pipe

Parts list for the Stockman

1” schedule 40 PVC cut 7.5 inches long, making sure the air intake is 1” above the overflow in the back the overflow box.

1” repair compression coupling just for the rubber washer.

1 ¼ “coupling to fit over washer and drilled holes

1” cap

13/64 drill bit for air inlet hole

15/16 drill bit for water intake holes

Air line and air line adjustment fitting

I measured up two inches up from the bottom and made a line. Then measured up another inch to where my washer will be. I drilled 5/16 holes in the one-inch section randomly to let the water into the pipe. Slide the 1 ¼ fitting down over the washer to the two-inch mark. Drill a 13/64 hole in the top cap, push in your airline and adjuster. Place in overflow and adjust the flow with the airline adjuster. It will take a couple of tweaks but wow what a difference.

Picture of Stockman

Video of the noise reduction