- Joined

- Feb 15, 2009

- Messages

- 313

- Reaction score

- 322

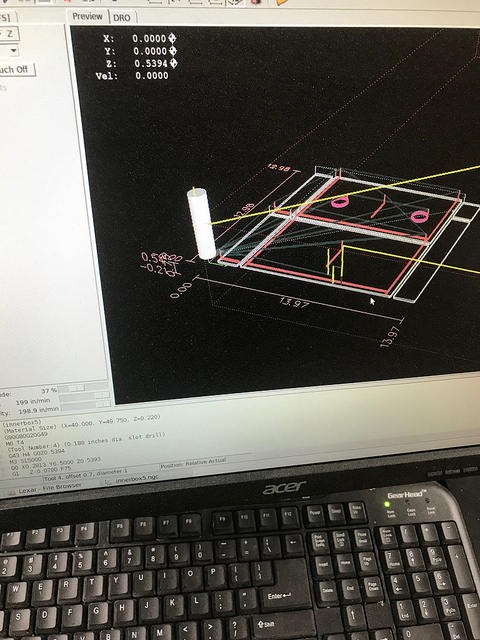

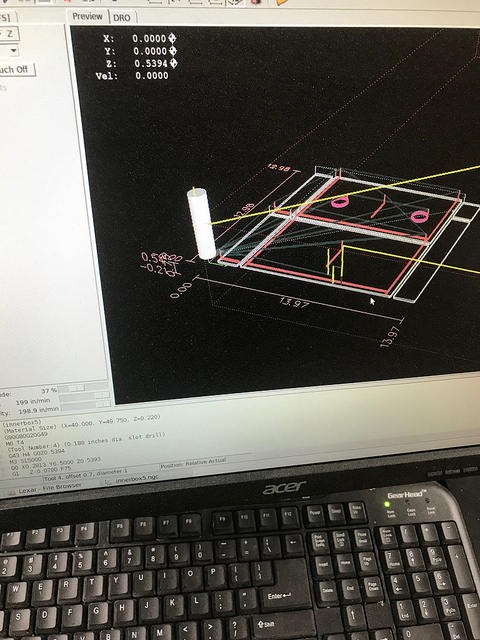

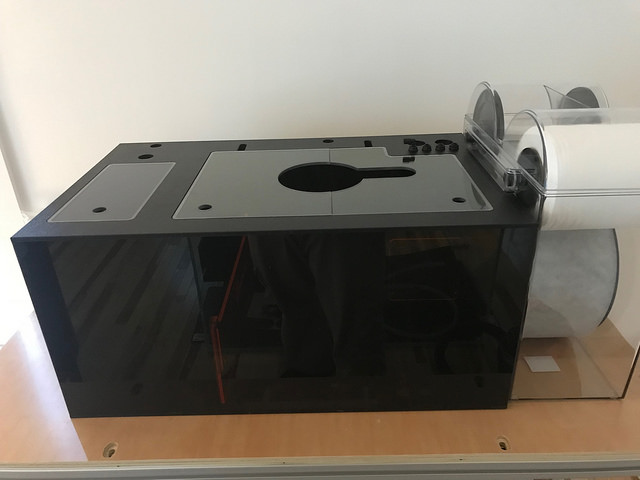

messin around in the workshop and got the inner box finished for the most part..

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr

box is only 1.5" i think it will work.. but i may try and go thinner maybe 1" any drawbacks to that idea?

Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickr Untitled by shaun s., on Flickr

Untitled by shaun s., on Flickrbox is only 1.5" i think it will work.. but i may try and go thinner maybe 1" any drawbacks to that idea?

Untitled

Untitled Untitled

Untitled

Untitled

Untitled Untitled

Untitled

Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled

Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled