The VCA 134-Gallon Cube - Random Flow Generator Powered Mixed Reef!

The VCA 134-Gallon Cube - Random Flow Generator Powered Mixed Reef!The first of two new offices tanks are officially under way, and I can’t wait to share it here on Reef-2-Reef

Our goal with this tank is to build a mixed reef tank with a unique flow solution that utilizes just Random Flow Generator® Nozzles to flow the entire tank.

Here are the initial details:

The Display Tank – 134 Gallons

The Display Tank started out as a used Lemar 34x34x24 cube tank that we acquired from a local hobbyist - why build brand new when you can recycle – right?

The original configuration had the center overflow positioned on the back wall, with the standard three holes drilled in the bottom – two 1in holes for return lines and a single 1.5in hole for the drain.

The first task was to remove the back overflow box and prep the existing holes for the closed loop.

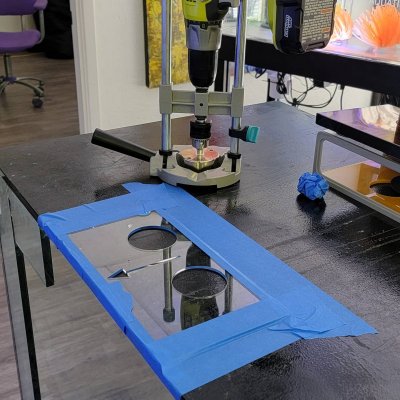

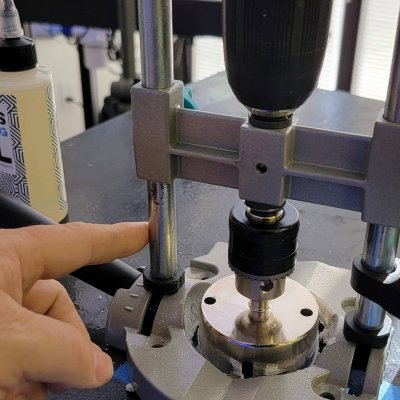

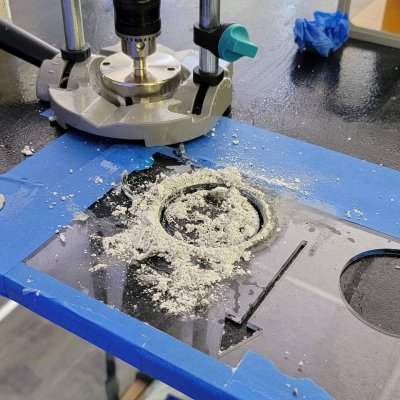

Next – we needed to drill 4 new holes – two for the returns and two for the EShopps Eclipse Overflow box. We did not have a way of running a continuous flow of water over the drill bit, without making a huge mess in the front lobby, so we use Glass Cutting Oil. Worked well. The process made some free sand. It if were not for the oil, I probably could have used it in a small nano tank.

The Custom Steel Stand

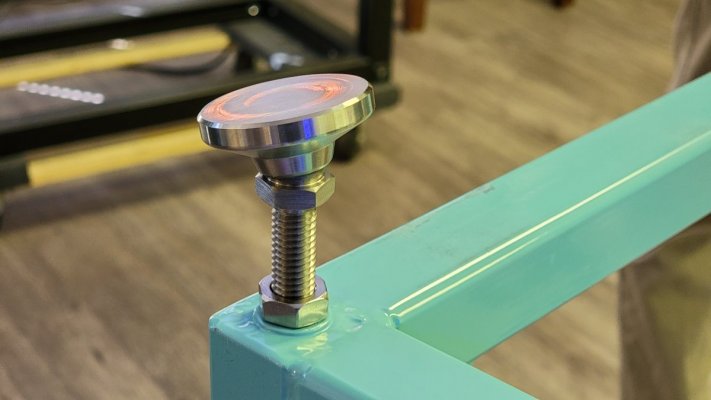

The Custom Steel StandThe stand is a custom steel stand constructed out of 1 1/2" tube steel with 3/8 inch wall thickness. It’s pretty heavy duty, while still maintaining a minimalist appearance. We had it powder coated with an Aqua Blue gloss finish.

We added a 3/4in Burch plywood base and platform. The floor in tour office suite is severely uneven. You can see it, but it because very obvious when you try and level a tank. So I designed the stand to use heavy duty leveling feet.

The first Challenge - the size of the tank vs the size of the door

One of the first challenges with this tank was the physical size of the tank in relationship to the size of the front door to our office. The maximum door width is 32 inches wide. The tank came in on its side with no problem. However, the stand had a limitation of 32 inches as a max dimension. As a result, the stand is a little shorter than I would have liked.

The height of the steel stand is 32 inches. The adjustable feet add another 3 inches to the overall height. The final height of the stand is 35in. Add to that the 3/4in birch board used as the base under the tank and the top of the tanks sits just shy of 60in tall.

The Dual Closed Loop - with Shared Drain

This build features a dual closed loop with shared drain. This will provide most of the flow in this tank and will be created using two of our 1in RFGS100LL Random Flow Generators®

This proved to be the second major challenge. The original design was to have the pumps mounted underneath the tank, upside down and out of the way. However, the sheer size of some of the plumbing fittings such as 1 1/2in elbows and Union Ball Valves made that nearly impossible.

The second challenge was being able to supply both pumps from a single drain. The drain is 1 1/2 inches which is more than enough for a single pump, but may be a bit restrictive for dual pumps. The biggest issue was friction caused by high velocity of flow through this pipe which could then lead to cavitation as the two pumps worked against one another for supply. To get around that and to minimize friction, we needed to reduce the velocity through the pipe.

With the help of friend who knows more than I do about friction and flow, we came up with this design that uses a 60 degree 3-way Y to split the drain and create two separate runs leading to each pump. This effectively reduces the velocity in the sections leading to the pumps and minimizes the chances of starving either of the pumps.

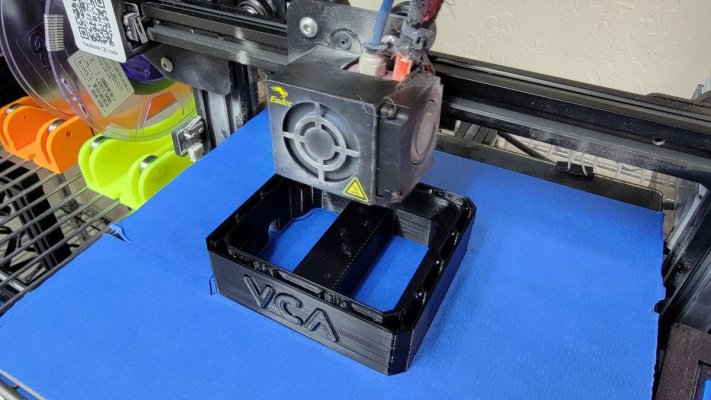

I mounted the pumps vertically to facilitate better flow into the inlet, but that presented a challenge. We didn't want to leave them dangling and unsupported. So, I designed and 3D printed these bases. The base helps to support the pumps and secure it in place. it also take stress off the plumbing. Once everything is done, I'll drill a hole underneath them and rout the wires underneath the platform so they are out of site.

In our initial testing, the dual closed loop with shared drain design seems to work quite well. Both pumps can be run at 100% without any apparent issue. We’ll share some flow numbers once we get the Apex hooked up. Here are some videos of the iniitial flow testing.

The Flow Plan

The primary flow will be handled with this dual close loop. Each side of the loop is powered by its own Cor20 return pump. These will then be controlled through a Neptune Apex to vary the speed of each loop. The plan here is to slowly alternate the power between the two pumps at opposite intervals. So for instance over the 12 hour period the left pump will ramp from 80% down to 20%, while the right side will ramp up from 20% to 80%.

This will hopefully create a sort of switching dominate current inside the tank. At the peak while the left side is at 80% and the right side is at 20%, the dominant current will be going in a general clockwise direction around the tank. Mid-day will be 50% power on both loops, so just chaotic randomized motion. Then towards the end of the day, the general flow direction will switch to a counter-clockwise direction.

A Reverse Check Valve Design

Returns are going to be kind of interesting because we want to feature another unique setup here a swell. We needed a way to run a undersized sump, and still be able to drop the return lines well below the water line without fear of back siphon and an overflow. Every 1 inch of water level in the display tank is approx 5 gallons of water. So we drew inspiration from Marc Levinson of Melev's reef reverse check valve design.

Reverse check valve is interesting because it will break the siphon almost instantly when power is cut to the return pump. But you need to configure it correctly to work. Basicly the main lien that feed the two returns needed to be ABOVE the returns, and the valve needs to be either inline or above that. Here's what i have planned:

Basically, you place a check valve in reverse at the highest point within your plumbing. Pressure from the return pump presses on the check valve and closes it allowing water to then be routed to the return line.

When power to the pumps is cut, the pressure releases and allows the check valve to then open. Once the valve opens, it draws in air and breaks the siphon.

This will allow me to accomplish the two things i needed

First I'll be able to drop the return lines, which will also have RFG nozzles as far below the waterline as I like.

Second it would allow me to run a slightly undersized sump, giving me more room for other equipment underneath the tank. This is important because a cube set up is generally a little more difficult to deal with than your more common rectangular setup in terms of placing equipment.

Stay Tuned

So that's where we're at so far. The tank sits at about 3/4 of the way full of water as we test the closed loops. Comment below and let me know what you think . And stay tuned as we progress with this build. Next up is the sump design

Last edited: