- Joined

- Feb 9, 2020

- Messages

- 167

- Reaction score

- 111

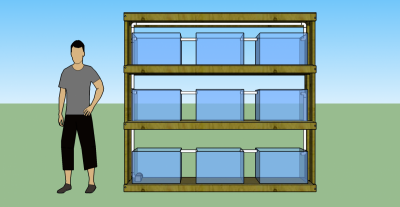

Here's the rundown for the tanks, hardware and lumber:

So the idea was to build a system which, in theory, could be portable. It's hard to move tanks larger than 75 gallons, and certainly a 75gal with a nice sump is a contender. This model proposes using standard 20 gallon tanks because they are cheap, reliable, and fairly sturdy.

The idea with the stand was to make it simple with minimal tools required. For example, a drill bit for the 5/8" bolts only needs to be about 6" long (because the longest piece that needs drilling is the 4.5" filler piece on the top).

Other thoughts I had about this build would be to add a bracket and bolt it to the wall (into a stud)... especially if there are kids/animals around bent on doing some climbing.

I haven't planned out what equipment goes where in the sump. The protein skimmer will probably be the tightest fit. I guess I could add 5" to the overall height and make more space above the bottom row.... or.... I could switch to a couple of 20gal long tanks....

Very interested to hear everyone's thoughts/ideas/opinions/warnings/reactions to the above!

| Aquarium 20g high $26.79 each at PetCo 9 tanks ~ 180 gallons total volume | $241.11 |

| 2x4x8 studs $4.32 each at Home Depot 23 pieces | $99.36 |

| Sanded Plywood 11/32 in. x 4 ft. x 8 ft. Home Depot $38.83 each 2 sheets | $77.66 |

| 5/8" x 16" Hex Bolt - galvanized $4.42 each at BoltDepot - 8 bolts total | $35.36 |

| Total | 453.49 |

|

| Front view of the system. Nine 20gal high aquariums are plumbed in series. The bottom left tank holds the return pump and pushes water to the top right tank. The bottom row can hold a fuge, skimmer, baffles, ato etc. 1/2" plywood provides shear stability and strength and dresses up the build. The plywood also can be waterproofed to catch any leaks and allow for drainage to the bottom. |

|

| Side view with the plywood removed. 16" carriage bolts bolt through 5 (horizontal) and 2 (vertical) 2x4 studs. The top uses a 4.5" filler piece and so has only 2 (horizontal) and 2 (vertical) 2x4 studs. |

|

| The system with all the wood removed. 1" PVC was used for the model. Unions would probably be a good addition to each connection and would increase the cost as would the bulkhead fittings. I only priced out the "aquarium and stand". |

|

| Another view from the side. The height for the whole system takes into consideration adequate space (hopefully!) for lighting each tank and space on the bottom row for adding/removing equipment. The width is 8 foot, to maximize use of plywood and lumber. Lighting, internal flow, etc could be customized for each tank depending on the needs of that tank's inhabitants. |

So the idea was to build a system which, in theory, could be portable. It's hard to move tanks larger than 75 gallons, and certainly a 75gal with a nice sump is a contender. This model proposes using standard 20 gallon tanks because they are cheap, reliable, and fairly sturdy.

The idea with the stand was to make it simple with minimal tools required. For example, a drill bit for the 5/8" bolts only needs to be about 6" long (because the longest piece that needs drilling is the 4.5" filler piece on the top).

Other thoughts I had about this build would be to add a bracket and bolt it to the wall (into a stud)... especially if there are kids/animals around bent on doing some climbing.

I haven't planned out what equipment goes where in the sump. The protein skimmer will probably be the tightest fit. I guess I could add 5" to the overall height and make more space above the bottom row.... or.... I could switch to a couple of 20gal long tanks....

Very interested to hear everyone's thoughts/ideas/opinions/warnings/reactions to the above!