Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Feb 15, 2009

- Messages

- 313

- Reaction score

- 322

this is steel?

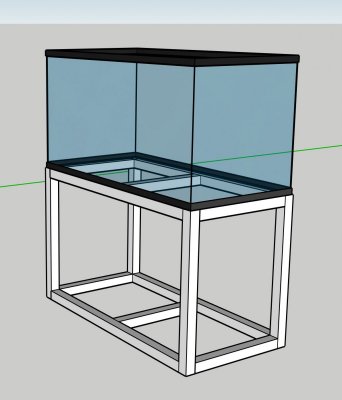

thats going to be a great thread to see what others have done with steel! IMO it will be fine... i would change one thing though. i would put your top horizontals on top of your vertical legs.

Lets see those steel stands! - Page 51 - Reef Central Online Community

Page 51- Lets see those steel stands! Do It Yourself

www.reefcentral.com

thats going to be a great thread to see what others have done with steel! IMO it will be fine... i would change one thing though. i would put your top horizontals on top of your vertical legs.

Last edited:

OP

OP

member 99594

Guest

View BadgesYes, steel and powder coated after.this is steel?

Lets see those steel stands! - Page 51 - Reef Central Online Community

Page 51- Lets see those steel stands! Do It Yourselfwww.reefcentral.com

thats going to be a great thread to see what others have done with steel! IMO it will be fine... i would change one thing though. i would put your top horizontals on top of your vertical legs.

- Joined

- Sep 3, 2019

- Messages

- 961

- Reaction score

- 1,050

I would have it fabricated differently then you show. I would have 2 frames made using mitered corners and then put the legs between them. That way the load goes directly into the legs from the horizontals.

I think welders will tell you that once welded, it really doesn't matter if the horizontal is a butt joint or resting on top, mitered, or whatever. It's all one piece of metal after welding. I would want a 3/4" sheet of plywood on top just to give you a 'ceiling' inside the stand - handy for screwing things, hanging, etc. Best thing I did on my last stand is put formica on the plywood.

With 1/8 2x2 you could park a car on it. You could EASILY get by with 1/16th thick steel. I literally drove half of my tundra on a steel 1/8 frame with the same load design as yours. (4' span).

Cheers.

Cheers.

It will make it much easier to get a level surface if you make two frames with mitered corners and the legs between them.I mentioned the horizontals on top of the verticals as more of a deflection thing... but with .125 it really doesn't matter I guess lol!

I would have it fabricated differently then you show. I would have 2 frames made using mitered corners and then put the legs between them. That way the load goes directly into the legs from the horizontals.

Ahh, I looked at the drawing and see what you are saying. Struturally it should be about the same but that is absolutely how i would go about building it. You weld up two frames on a nice flat surface, then weld the legs between them.

so im a welder for the us army like stated above you want the tank as flat as possible who ever welds it make sure they either miter the corners and grid flush or leave the top of the joint unwelded. you can even use 1/8 alum for that size tank. if you have any question just ask.

Similar threads

- Replies

- 1

- Views

- 146

- Replies

- 24

- Views

- 727