@atomic081 Thank you they're fun to create and I hope they help others see my vision. I plan to share some how I use that information from the topography in the future.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

400 Gal SPS Dominant + 265 Gal Mix Reef in a 1000 Gallon system.

- Monster Build

- Thread starter Breakbeats2334

- Start date

- Tagged users None

MOUNTING BACKBOARD FOR CONTROLLERS AND BATTERIES

It took us 8 to 12 weeks to obtain the desired look of this backboard with two redo after not liking what we saw. Here are the steps we took.

Step 1: BACKBOARD: Bought a half inch sheet of plywood, cut it to 7’x2.5’ and anchored it to the studs on the wall behind the 400G tank. Now we have a blank canvas and the world was our oyster.

Step 2: MOUNT BATTERIES: Installed the backup batteries to the backboard in a location above the controllers and low enough to be seen. We have always embraced the redundancy approach for peace of mind, knowing we are minimizing the possibilities of ‘Murphian disappointments’. Three of the batteries are connected to the external lifelines of the system 24/7. The other two are connected when we are leaving town for extended periods. One to an internal MP40 pump in the 400G and the same for the 265G on the other floor.

TIP: Tape the inputs of the batteries not in use to prevent corrosion

on the connectors. After a few years, this the corsion lead

to the death of a new unused battery.

Step 3: HOOKS FOR TRANSFORMERS. The original plan was to have the D.C. transformers for all the pumps, lights, and equipment together and beautifully displayed. That desire went out the door as the length of cords and proximity to equipment became a limitation. The desire to not have the spaghetti cords in the pictures made it painfully obvious we needed a solution for the wires. We ended up using brass hooks below each controller. Wrap each wire around its transformer, zip tie it for neatness and then hung it on the hook directly below its controller and out of view with the camera.

Step 4: COLOR CODE WIRES: With multiple pumps, lights, and controllers, all on route to this backboard, the task of managing the spaghetti of wires became rather challenging. When it took almost forever to rejoin a disconnected wire to its rightful place, it dawned on us we needed to devise a system where each wire could easily be identified by its type, which of the many like it and its destination. The blessings of this system came home when it was time to connect them all to the energy bars on the control center in the Utility Room. More on this subject at a later date.

Step 5: ACCESS HOLE: Access holes through the wall were needed for wires going from the tank room to the utility room. The entrance hole from one room and the exit hole in the other room were required to be inconspicuous or at least minimal viewing in the pictures. We had wires up high for the lights, wires in the middle for the internal pumps, wires at the bottom for the external pumps, and wires for equipment here, wires there, and what seems to have been wires everywhere. We settled with three 3” diameter furniture hole covers. One up top by the ceiling, the second in the middle for the internal pumps, and the third near the floor for the external pumps. We needed the holes to be big enough for the wires and also with enough room for each plug to go through.

Step 6: MOUNT DRIVERS: Finally, we mounted the drivers to the backboard. The mounting brackets for the internal and external pump drivers were all the same. We looked at the space allocated, divided it by the number of drivers to install, added the minimum space desired, verify we were comfortable with the look and then went to town mounting them. The height on the board chosen was to see all the controllers when standing before the tank while minimize seeing the cords that lead to them.

Last edited:

That wire coding system is genius and so simple... I’ll be pinching that idea, thanks

MOUNTING BACKBOARD FOR CONTROLLERS AND BATTERIES

It took us 8 to 12 weeks to obtain the desired look of this backboard with two redo after not liking what we saw. Here are the steps we took.

Step 1: BACKBOARD: Bought a half inch sheet of plywood, cut it to 7’x2.5’ and anchored it to the studs on the wall behind the 400G tank. Now we have a blank canvas and the world was our oyster.

Step 2: MOUNT BATTERIES: Installed the backup batteries to the backboard in a location above the controllers and low enough to be seen. We have always embraced the redundancy approach for peace of mind, knowing we are minimizing the possibilities of ‘Murphian disappointments’. Three of the batteries are connected to the external lifelines of the system 24/7. The other two are connected when we are leaving town for extended periods. One to an internal MP40 pump in the 400G and the same for the 265G on the other floor.

TIP: Tape the inputs of the batteries not in use to prevent corrosion

on the connectors. After a few years, this the corsion lead

to the death of a new unused battery.

Step 3: HOOKS FOR TRANSFORMERS. The original plan was to have the D.C. transformers for all the pumps, lights, and equipment together and beautifully displayed. That desire went out the door as the length of cords and proximity to equipment became a limitation. The desire to not have the spaghetti cords in the pictures made it painfully obvious we needed a solution for the wires. We ended up using brass hooks below each controller. Wrap each wire around its transformer, zip tie it for neatness and then hung it on the hook directly below its controller and out of view with the camera.

Step 4: COLOR CODE WIRES: With multiple pumps, lights, and controllers, all on route to this backboard, the task of managing the spaghetti of wires became rather challenging. When it took almost forever to rejoin a disconnected wire to its rightful place, it dawned on us we needed to devise a system where each wire could easily be identified by its type, which of the many like it and its destination. The blessings of this system came home when it was time to connect them all to the energy bars on the control center in the Utility Room. More on this subject at a later date.

Step 5: ACCESS HOLE: Access holes through the wall were needed for wires going from the tank room to the utility room. The entrance hole from one room and the exit hole in the other room were required to be inconspicuous or at least minimal viewing in the pictures. We had wires up high for the lights, wires in the middle for the internal pumps, wires at the bottom for the external pumps, and wires for equipment here, wires there, and what seems to have been wires everywhere. We settled with three 3” diameter furniture hole covers. One up top by the ceiling, the second in the middle for the internal pumps, and the third near the floor for the external pumps. We needed the holes to be big enough for the wires and also with enough room for each plug to go through.

Step 6: MOUNT DRIVERS: Finally, we mounted the drivers to the backboard. The mounting brackets for the internal and external pump drivers were all the same. We looked at the space allocated, divided it by the number of drivers to install, added the minimum space desired, verify we were comfortable with the look and then went to town mounting them. The height on the board chosen was to see all the controllers when standing before the tank while minimize seeing the cords that lead to them.

@Mortie31 As the number of plugs in the system increase your appreciation for identification at a quick glance will increase tenfold.

R2R Water Storage, Exchange and Capacity

This 1000G System has a 100gallon Salt water container and a 100Gallon tank, being feed by a BRS 7stage 150G/Day RODI unit. The ATO(Auto Top Off) and water exchange system is controlled by a Genesis STORM and RENEW unit. Instead of large monthly water changes, we exchange a gallon of water every 8 hours(12 in winter months). With a 0.1% water change over an 8 hour period, this approach minimizes the livestock needs to adjust their biology to compensate for our changes and is believed to promote better mortality rates.

WATER STORAGE, USAGE, and EXCHANGE.

GENESIS, RENEW and STORM

The Renew is a water exchange system that swaps water continuously, per day or week, in gallon intervals. Seven years ago we bought this ATO system, and since then it has been serving us well.

It uses a gallon bucket for new salt water and a second bucket for the old water from the system. While suspending the activities of the ATO float switch, it adds the new salt water to the system and dumps the old water to the sink.

The Genesis STORM is an ATO (Auto Top Off) System. It replaces evaporated water when the float switch in the 150 gallon sump is activated. The pump is operational between 1 to 99 seconds, so depending on the settings, one can replenish ounces or gallons of evaporated waster. If for whatever reason the replenished water was not enough to reset the float switch, the timer will run a second time and if that does not reset the float switch, the system will shut off. We use 1.3 gallons for each occurrence and that is more than enough to reset the float switch.

7 STAGE BRS RODI

This water filter station comes with a liquid water pressure gauge and three TDS(Total Dissolved Solids) particle counters.

The water enters the first chamber (bottom left) a 1micron sediment filter, then into two 1micron carbon block filters, then up top to the two 75Gallons/Day membrane and then finally to the two mixed bed color changing deionization resin filters on the far right. The desired end result from the inline TDS particle counter is 0 parts/1,000 going to the storage tank. The booster pump increase the water pressure and back flushes the system occasionally for better efficiencies.

This 1000G System has a 100gallon Salt water container and a 100Gallon tank, being feed by a BRS 7stage 150G/Day RODI unit. The ATO(Auto Top Off) and water exchange system is controlled by a Genesis STORM and RENEW unit. Instead of large monthly water changes, we exchange a gallon of water every 8 hours(12 in winter months). With a 0.1% water change over an 8 hour period, this approach minimizes the livestock needs to adjust their biology to compensate for our changes and is believed to promote better mortality rates.

WATER STORAGE, USAGE, and EXCHANGE.

| SYSTEM 1000Gallons(3785L) | SALT WATER | RODI Water |

| CAPACITY | 100 Gallons(378L) | 100 Gallons(378L) |

| SUMMER USAGE - %Volume Exchanged/Month - Tank Refill Frequency | 3Gal(11L)/Day. 9%/Month 1Month to Refill | 5Gal(19L)/Day. 16%/Month 0.7Month to Refill |

| WINTER USAGE - %Volume Exchanged/Month - Tank Refill Frequency | 2Gal(8L)/Day. 6%/Month 1.5Month to Refill | 3Gal(11L)/Day. 9%/Month 1Month to Refill |

| Genesis RENEW | Exchange system water for new salt water. | N/A |

| Genesis STORM | N/A | Replace evaporated water with RODI. (Auto Top Off) |

GENESIS, RENEW and STORM

The Renew is a water exchange system that swaps water continuously, per day or week, in gallon intervals. Seven years ago we bought this ATO system, and since then it has been serving us well.

It uses a gallon bucket for new salt water and a second bucket for the old water from the system. While suspending the activities of the ATO float switch, it adds the new salt water to the system and dumps the old water to the sink.

The Genesis STORM is an ATO (Auto Top Off) System. It replaces evaporated water when the float switch in the 150 gallon sump is activated. The pump is operational between 1 to 99 seconds, so depending on the settings, one can replenish ounces or gallons of evaporated waster. If for whatever reason the replenished water was not enough to reset the float switch, the timer will run a second time and if that does not reset the float switch, the system will shut off. We use 1.3 gallons for each occurrence and that is more than enough to reset the float switch.

7 STAGE BRS RODI

This water filter station comes with a liquid water pressure gauge and three TDS(Total Dissolved Solids) particle counters.

The water enters the first chamber (bottom left) a 1micron sediment filter, then into two 1micron carbon block filters, then up top to the two 75Gallons/Day membrane and then finally to the two mixed bed color changing deionization resin filters on the far right. The desired end result from the inline TDS particle counter is 0 parts/1,000 going to the storage tank. The booster pump increase the water pressure and back flushes the system occasionally for better efficiencies.

@Blue Tang Clan

Thanks for the kind words, we are documenting the journey and it has been quite a challenge but real rewarding when I get feedback from you guys. This week we will have more photos with stories to share now that we are getting to the equipment side of things.

Thanks for the kind words, we are documenting the journey and it has been quite a challenge but real rewarding when I get feedback from you guys. This week we will have more photos with stories to share now that we are getting to the equipment side of things.

SKIMMERS, FILTERING and the IMPOSSIBLE SCHOOL OF TANGS

This 1,000Gal(3,785L) predominant SPS System would prefer to thrive in pristine clean waters, however they share this eco system with over 60 fishes in two tanks(400 and 265Gal). As if gluttons for SPS blasphemy, over the last three years, the system has grown from 18 to 25 tangs starting from 1.75” and now ranging from 3.5 to 5.5” in length. Among the variety of fish in the 265Gal, it had a school of 14 beautiful Hawaiian yellow tangs.

WATER CLEANING

Primary contributors to the cleaning are

MANAGING THE UNMANAGEABLE

The task off keeping 4 yellow tangs for 6 months without them slowly killing each other has been deemed as most challenging for many. We added a school of 14 beautiful Hawaiian yellow tangs in the 265Gal (1000L). Over the next 4 months, we have witnessed the entire school harassing the targeted weakest to death, and at a later date choose the next victim from among themselves.

Then there is peace and quiet for a while and with no obvious reason, they would take on the next victim. The remaining gang of 11 lived in reasonable harmony for over 2 years until after an 8day vacation we lost 4 on the return, that was painful. The early targeting harassment on a single yellow tang began again, maybe not enough feeding.

SKIMMER BOX

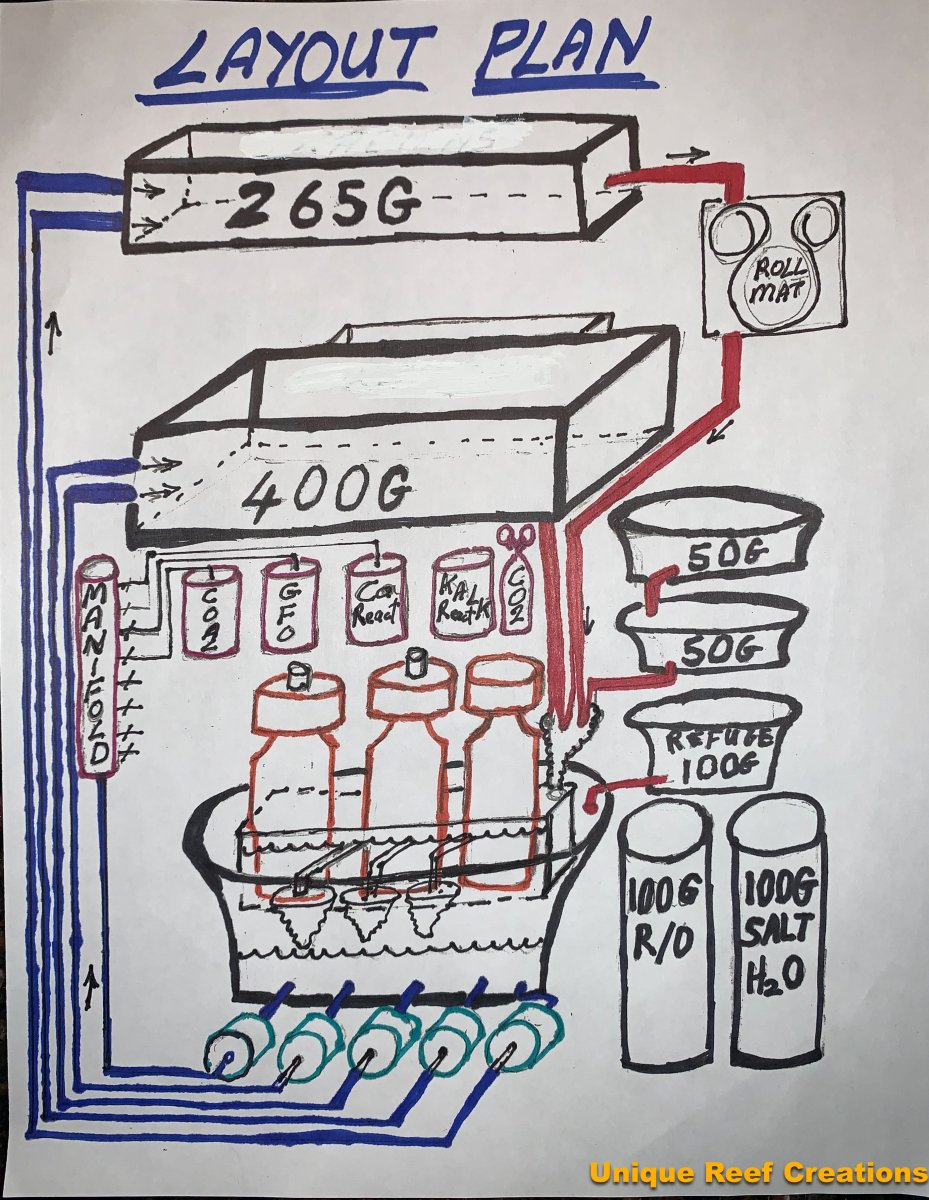

The three skimmers sit in a skimmer box with drains that keep the water height at 9”(23cm). Before when the height fluctuated, the first two skimmers would sometimes overflow. With 5 variable external pumps and ongoing aquascaping activities, the annoyance increased. The solution for it was a skimmer box with four 1.5” overflow holes. Here is a schematic of the early layout plan with the skimmer box, and since then we have made a few changes as we moved from hoses to red PVC.

ROLLER MAT

The majority of the water returning from the 265 Gal tank is filtered through a roller mat before going to the skimmers for additional cleaning. This equipment has been hailed by some as one of the most significant recent addition to the hobby, and yes it scrubs the water very well. After the cleaning of the roller mat and the three skimmers, the water exits the skimmer box into three 50micron filter socks and then to the sump.

FILTER SOCKS

At first without the Roller Mat, it took

The 100G(380L) refugium is lit by three Kessil H380 growing lights to do some additional scrubbing of phosphates from the water and keep the algae growth in the tanks to a minimum, thus leaving a quantity behind thats manageable by the army of tangs.

This 1,000Gal(3,785L) predominant SPS System would prefer to thrive in pristine clean waters, however they share this eco system with over 60 fishes in two tanks(400 and 265Gal). As if gluttons for SPS blasphemy, over the last three years, the system has grown from 18 to 25 tangs starting from 1.75” and now ranging from 3.5 to 5.5” in length. Among the variety of fish in the 265Gal, it had a school of 14 beautiful Hawaiian yellow tangs.

WATER CLEANING

Primary contributors to the cleaning are

- 3 Skimmers with 5 pumps, (1+2+2)

- 2 Skimmer cup neck cleaners (1+1+0)

- 1 Roller Mat, 6"wide over a 10” wheel

- 3 filter socks, 50micron, 6”diaX16”tall

- 100Gal(380L) Refugium

MANAGING THE UNMANAGEABLE

The task off keeping 4 yellow tangs for 6 months without them slowly killing each other has been deemed as most challenging for many. We added a school of 14 beautiful Hawaiian yellow tangs in the 265Gal (1000L). Over the next 4 months, we have witnessed the entire school harassing the targeted weakest to death, and at a later date choose the next victim from among themselves.

Then there is peace and quiet for a while and with no obvious reason, they would take on the next victim. The remaining gang of 11 lived in reasonable harmony for over 2 years until after an 8day vacation we lost 4 on the return, that was painful. The early targeting harassment on a single yellow tang began again, maybe not enough feeding.

SKIMMER BOX

The three skimmers sit in a skimmer box with drains that keep the water height at 9”(23cm). Before when the height fluctuated, the first two skimmers would sometimes overflow. With 5 variable external pumps and ongoing aquascaping activities, the annoyance increased. The solution for it was a skimmer box with four 1.5” overflow holes. Here is a schematic of the early layout plan with the skimmer box, and since then we have made a few changes as we moved from hoses to red PVC.

ROLLER MAT

The majority of the water returning from the 265 Gal tank is filtered through a roller mat before going to the skimmers for additional cleaning. This equipment has been hailed by some as one of the most significant recent addition to the hobby, and yes it scrubs the water very well. After the cleaning of the roller mat and the three skimmers, the water exits the skimmer box into three 50micron filter socks and then to the sump.

FILTER SOCKS

At first without the Roller Mat, it took

- 7Days to clog 2Socks, then

- 6Days to clog 3Socks, and now every

- 4Days to clog 3socks with the addition of the Roller Mat.

The 100G(380L) refugium is lit by three Kessil H380 growing lights to do some additional scrubbing of phosphates from the water and keep the algae growth in the tanks to a minimum, thus leaving a quantity behind thats manageable by the army of tangs.

Given that you have three different brands of skimmers on the one system, would love to hear your thoughts as to performance between them. And interesting information on the yellow tangs!

@GBRsouth The Nyos skimmer takes out the most particulates and is also the least sensitive to overflows. The Reef Octopus skimmer is the second best and rarely overflows. The Vertex skimmer draws out the least, the most sensitive to overflows, and is adjusted towards wet skimming. All three skimmer cups lead to a sealed 5 gallon container which limits the drainage to 5 gallons before the float switches are activated.

TIP: It's possible we haven't tuned the vertex skimmer correctly resulting in its lower performance.

Its advised not to lead the skimmer cup drain hose directly to an open sink/container, because if the skimmer is compromised it could drain your system.

@MatnNatsReef @C. Eymann Thanks for joining us.

TIP: It's possible we haven't tuned the vertex skimmer correctly resulting in its lower performance.

Its advised not to lead the skimmer cup drain hose directly to an open sink/container, because if the skimmer is compromised it could drain your system.

@MatnNatsReef @C. Eymann Thanks for joining us.

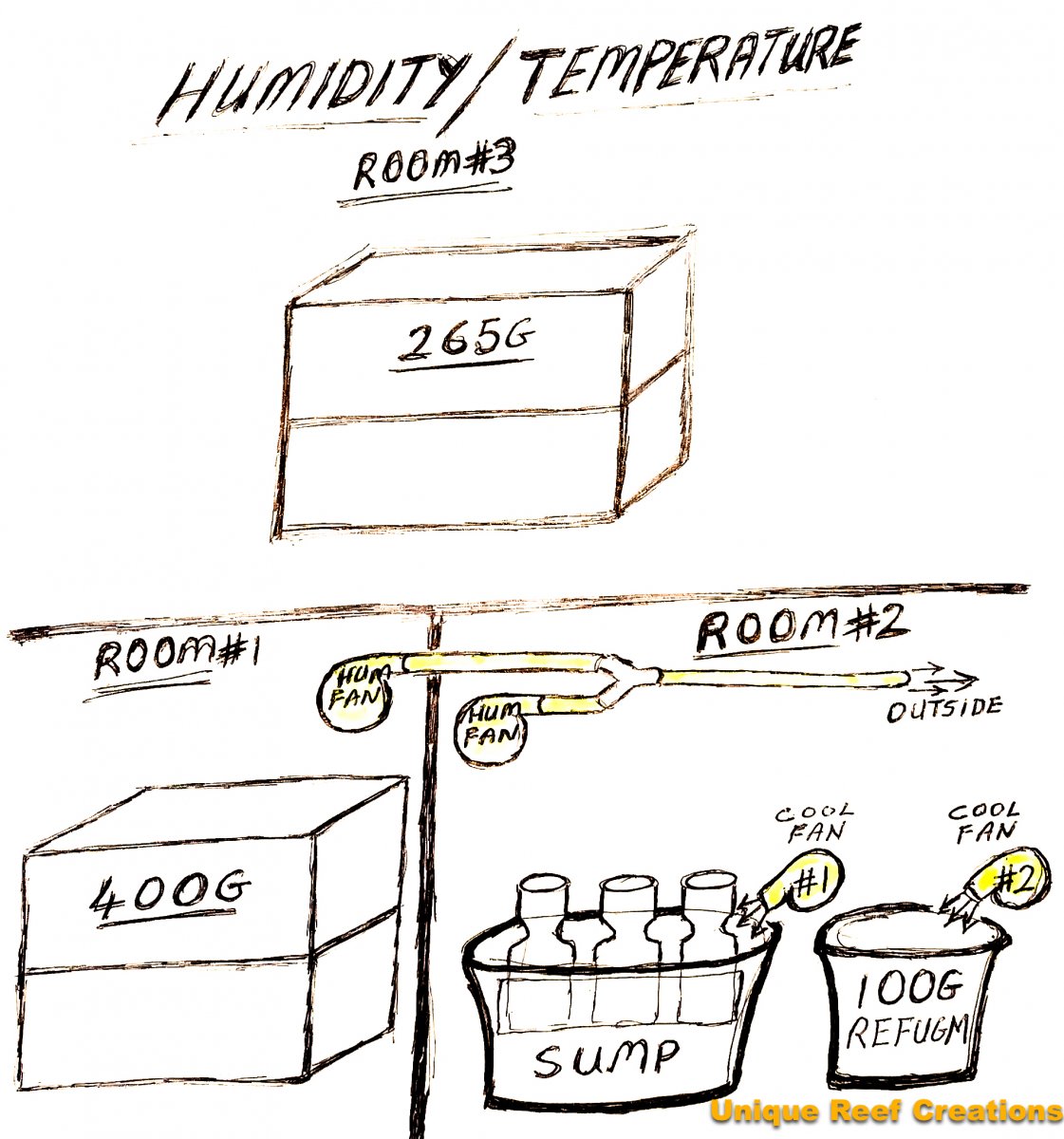

Fish Temp Humidity Heating and cooling

The humidity in a home with a 1000G(3800L) system became unmanageable as we grew from the humble beginnings of a 220G(830L) system. The efficiency of the cooling fans during the summer would push the unmanageable humidity towards the rain forrest conditions that would threaten the life of every nearby electronic equipment. The air condition and a humidity exhaust fan took care of the humidity challenge.

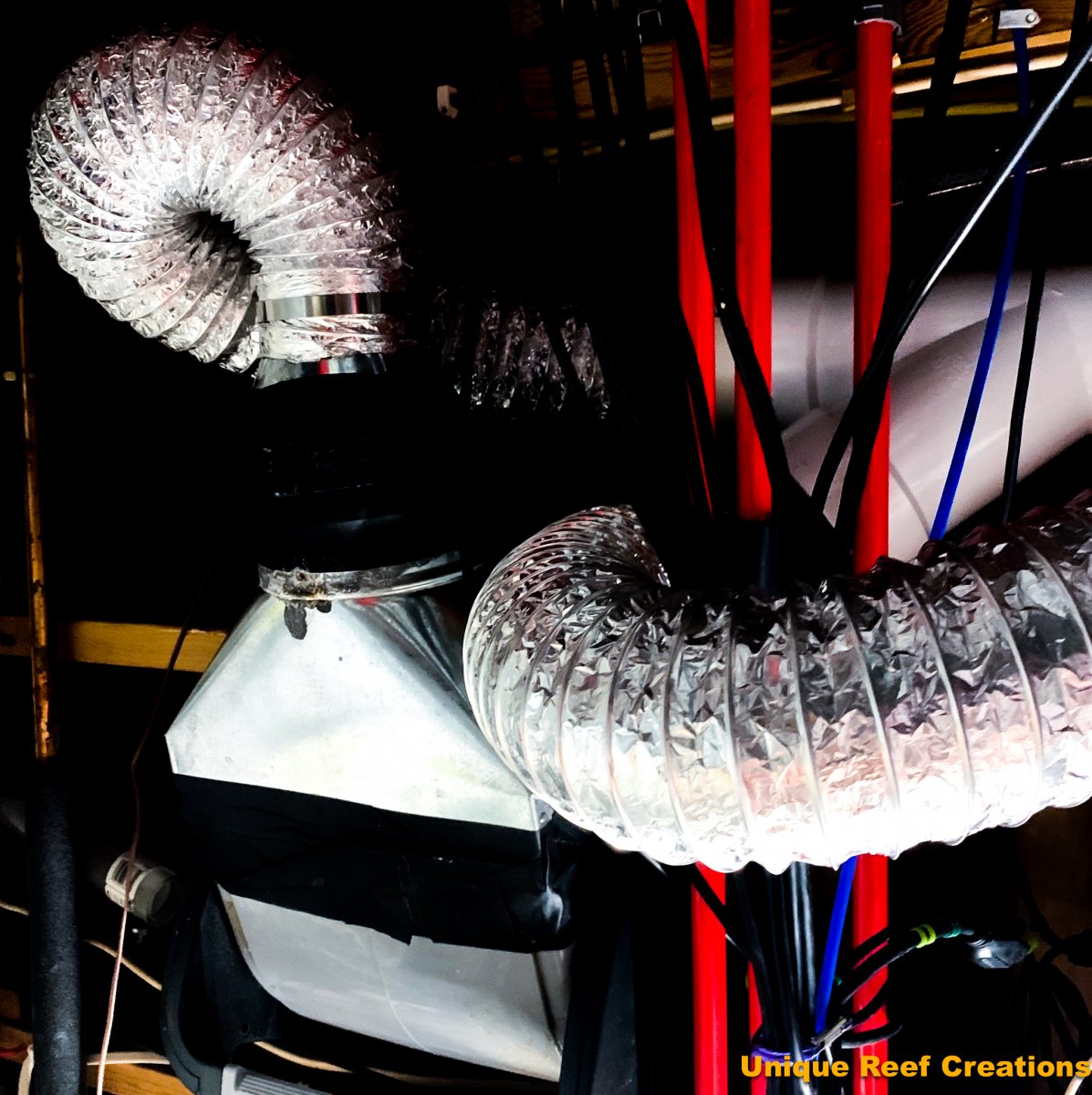

EXHAUST FANS

With the most open water surfaces in Room#2, we installed an exhaust fan and vented it outside. We later added a 2nd quiet exhaust fan over the 400G tank in ROOM#1 and added it to the other venting line. We used two 6”(15cm) clothes dryer hoses from the fans leading to a Y-Shaped one way PVC connector vented outside.

The following winter cancelled some of our summer humidity successes as the reality of bringing humid winter air inside to solve a humidity problem came with more challenges.

TEMPERATURE & HUMIDITY STATION

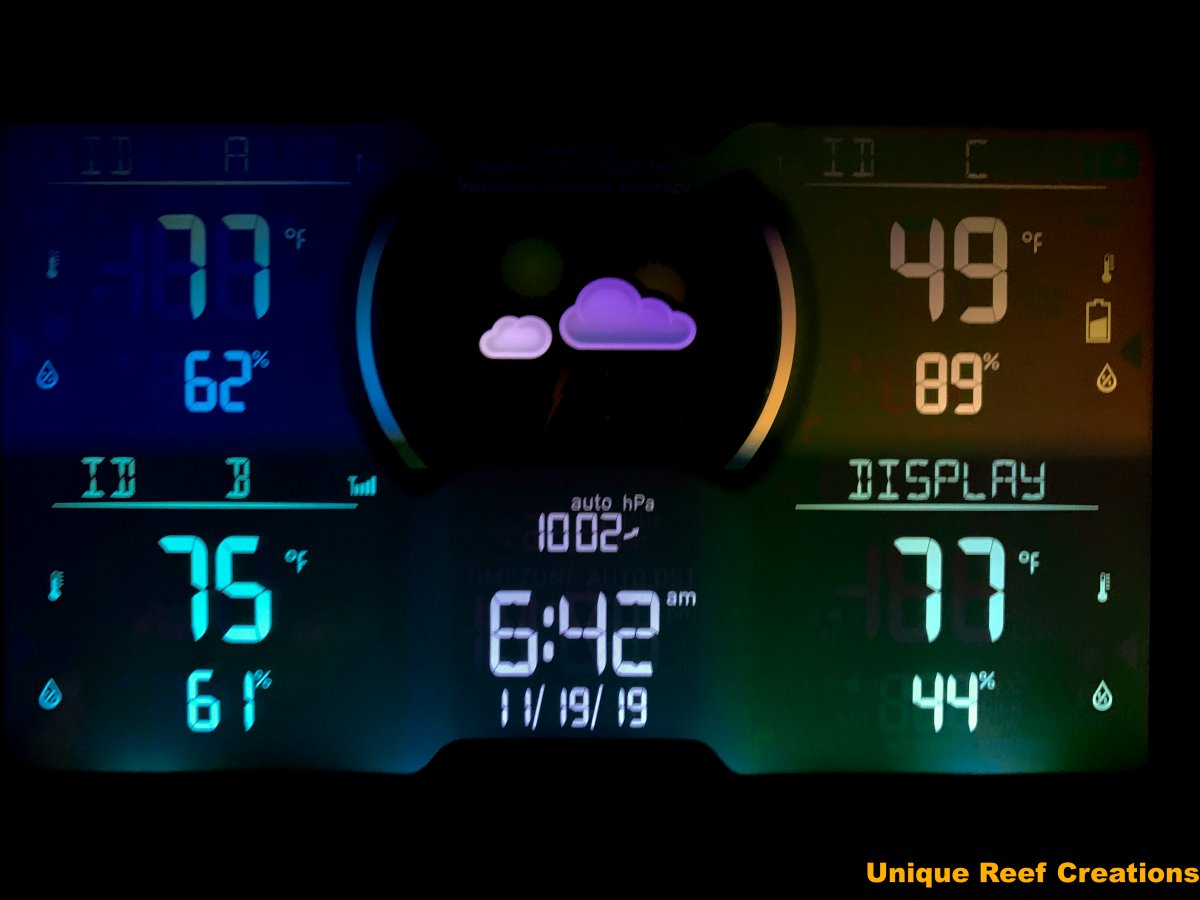

A four stage temperature and humidity station by AcuRite, with wireless probes, gave us the T&H conditions in the three rooms of interest along with the outside conditions.

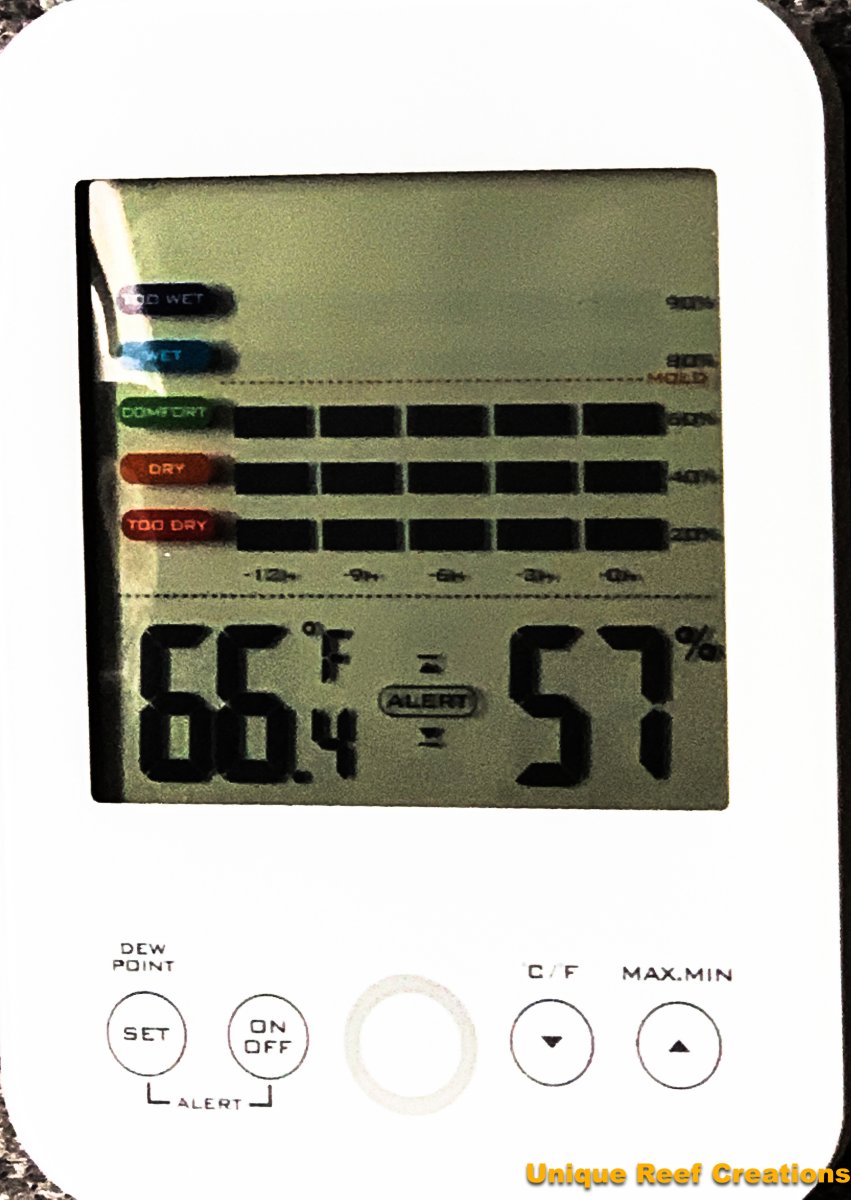

We also used a PT720 Thermo-Hygrometer that gave the current Temp/humidity along with humidity levels over the past 12 hours in that room and guidance for mold avoidance humidity levels(<62%Humidity).

HEATING

A single Temperature probe in the sump drives the three heaters for a 0.5°F increase when summoned. 400W in the sump, 300W in skimmer box and 300W in the 265G tank. When the system temperature drops by 0.5°F below the lower operating limit, we would change the oldest (or failed) heater in the group.

The system is programmed to operate in a 3°F range, 79.0°F+/-1.5(77.5-80.5°F). Both heaters and cooling fans are set to move the system 0.5°F towards the desired settings when summoned.

COOLING FANS

In a few minutes, the two power house fans blowing across the sump and the refugium could easily drop the system by 1.0°F, however to lower the humidity spike in the room, we use 0.5°F increments.

HEATER FAILURE & REDUNDANCY

If the system temperature drifts beyond the operating limits, the early warning beepers are sounded followed by a text of the condition. If the temperature falls 0.5F below the operating limit we either replace the failed heater or the oldest of the three. The three heaters are on three different fuses and the controller with the temperature probe is on a fourth.

LIGHTS HEATING

The primary drivers of the system temperature are the tank lights and the daily outside temperature cycle. Before the LED lights, the metal halide lamps would demand far more management as they would uncomfortably raise the temperature of the the rooms they were in. Homes with the forced hot air heating system distributes the temperature and humidity around the house within a tighter range than the ones with the baseboard heat, the (type we currently use).

LIGHT SCHEDULE

The humidity in a home with a 1000G(3800L) system became unmanageable as we grew from the humble beginnings of a 220G(830L) system. The efficiency of the cooling fans during the summer would push the unmanageable humidity towards the rain forrest conditions that would threaten the life of every nearby electronic equipment. The air condition and a humidity exhaust fan took care of the humidity challenge.

| ROOMS | WATER FLOWING |

| Upstairs Room#3 | 265G NoFans |

| Downstairs Room#1 | 400G + 1HumFan |

| Downstairs Room#2 Sump& Refugium | 300G + 1HumFan. + 2CoolingFans |

| Outside | DRY ...... Summers HUMID .. Winter/rain |

EXHAUST FANS

With the most open water surfaces in Room#2, we installed an exhaust fan and vented it outside. We later added a 2nd quiet exhaust fan over the 400G tank in ROOM#1 and added it to the other venting line. We used two 6”(15cm) clothes dryer hoses from the fans leading to a Y-Shaped one way PVC connector vented outside.

The following winter cancelled some of our summer humidity successes as the reality of bringing humid winter air inside to solve a humidity problem came with more challenges.

TEMPERATURE & HUMIDITY STATION

A four stage temperature and humidity station by AcuRite, with wireless probes, gave us the T&H conditions in the three rooms of interest along with the outside conditions.

We also used a PT720 Thermo-Hygrometer that gave the current Temp/humidity along with humidity levels over the past 12 hours in that room and guidance for mold avoidance humidity levels(<62%Humidity).

HEATING

A single Temperature probe in the sump drives the three heaters for a 0.5°F increase when summoned. 400W in the sump, 300W in skimmer box and 300W in the 265G tank. When the system temperature drops by 0.5°F below the lower operating limit, we would change the oldest (or failed) heater in the group.

The system is programmed to operate in a 3°F range, 79.0°F+/-1.5(77.5-80.5°F). Both heaters and cooling fans are set to move the system 0.5°F towards the desired settings when summoned.

COOLING FANS

In a few minutes, the two power house fans blowing across the sump and the refugium could easily drop the system by 1.0°F, however to lower the humidity spike in the room, we use 0.5°F increments.

HEATER FAILURE & REDUNDANCY

If the system temperature drifts beyond the operating limits, the early warning beepers are sounded followed by a text of the condition. If the temperature falls 0.5F below the operating limit we either replace the failed heater or the oldest of the three. The three heaters are on three different fuses and the controller with the temperature probe is on a fourth.

LIGHTS HEATING

The primary drivers of the system temperature are the tank lights and the daily outside temperature cycle. Before the LED lights, the metal halide lamps would demand far more management as they would uncomfortably raise the temperature of the the rooms they were in. Homes with the forced hot air heating system distributes the temperature and humidity around the house within a tighter range than the ones with the baseboard heat, the (type we currently use).

LIGHT SCHEDULE

| 265G ROOM#3 | 400G ROOM#1 | FRAG& FUGE ROOM#2 | TOTAL | |

| 9am-2pm | 6 Lights | 6Lights | ||

| 2p-9pm | 6 Lights | 10 Lights | 16Lights | |

| 9pm-12 | 10 Lights | 10Lights | ||

| 12-9am | 4 Lights. 3 Kessill/Fuge | 4 Lights 3 Kessill |

This is awesome. I'll definitely be following around. This is the dream bro, you're making it happen!

@GBRsouth The Nyos skimmer takes out the most particulates and is also the least sensitive to overflows. The Reef Octopus skimmer is the second best and rarely overflows. The Vertex skimmer draws out the least, the most sensitive to overflows, and is adjusted towards wet skimming. All three skimmer cups lead to a sealed 5 gallon container which limits the drainage to 5 gallons before the float switches are activated.

TIP: It's possible we haven't tuned the vertex skimmer correctly resulting in its lower performance.

Its advised not to lead the skimmer cup drain hose directly to an open sink/container, because if the skimmer is compromised it could drain your system.

@MatnNatsReef @C. Eymann Thanks for joining us.

Thank you for this information! I was headed in the direction of the Nyos for my future system, so this is great confirmation for me!

Similar threads

- Replies

- 3

- Views

- 94

- Replies

- 38

- Views

- 2,224

- Replies

- 1

- Views

- 78

- Replies

- 2

- Views

- 273