- Joined

- Sep 13, 2018

- Messages

- 851

- Reaction score

- 976

Hello everyone, I figured it would be good to start my own build thread for several reasons. I got a lot of ideas and help from various folks on R2R, so I would like to pay it back even a bit if I can. Also, it would be neat to see progress for myself and how things evolve and change.

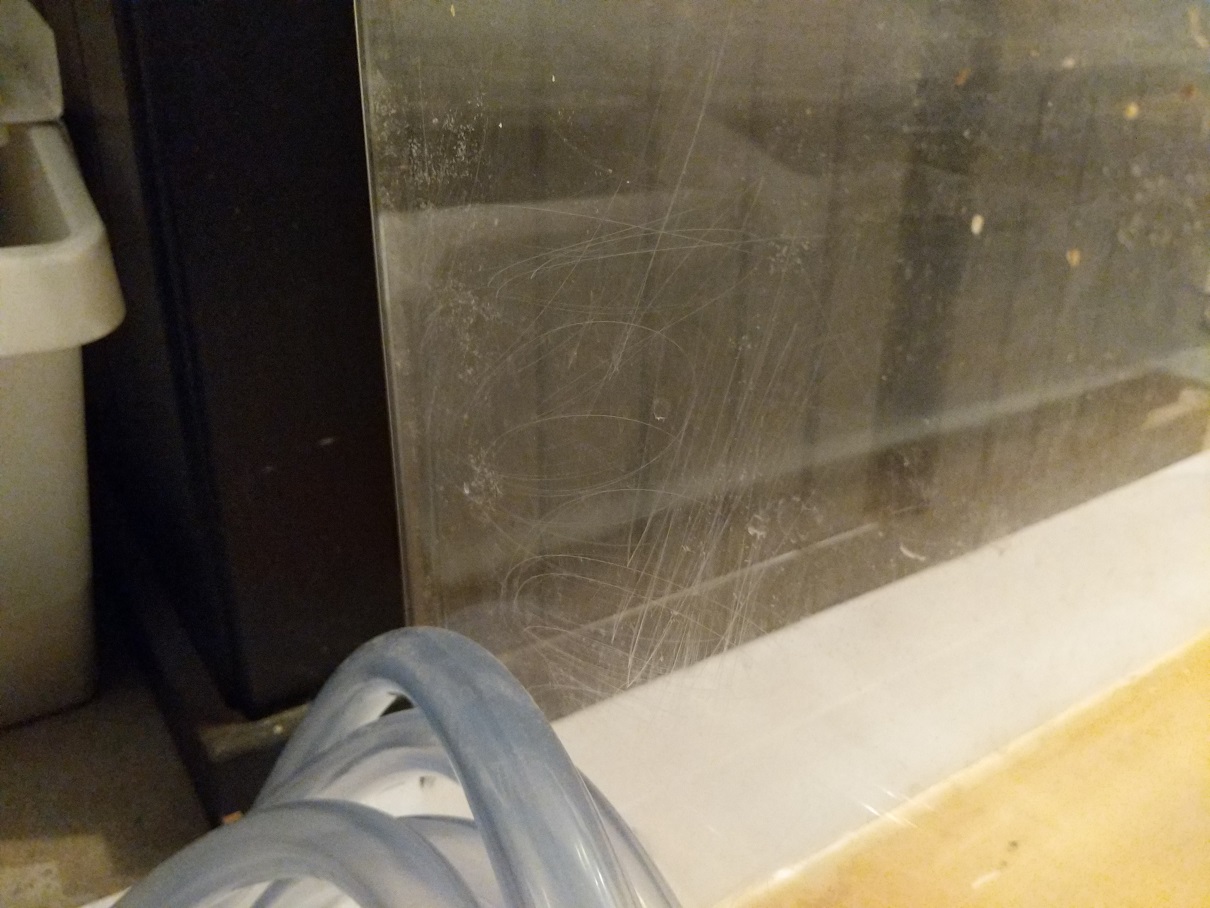

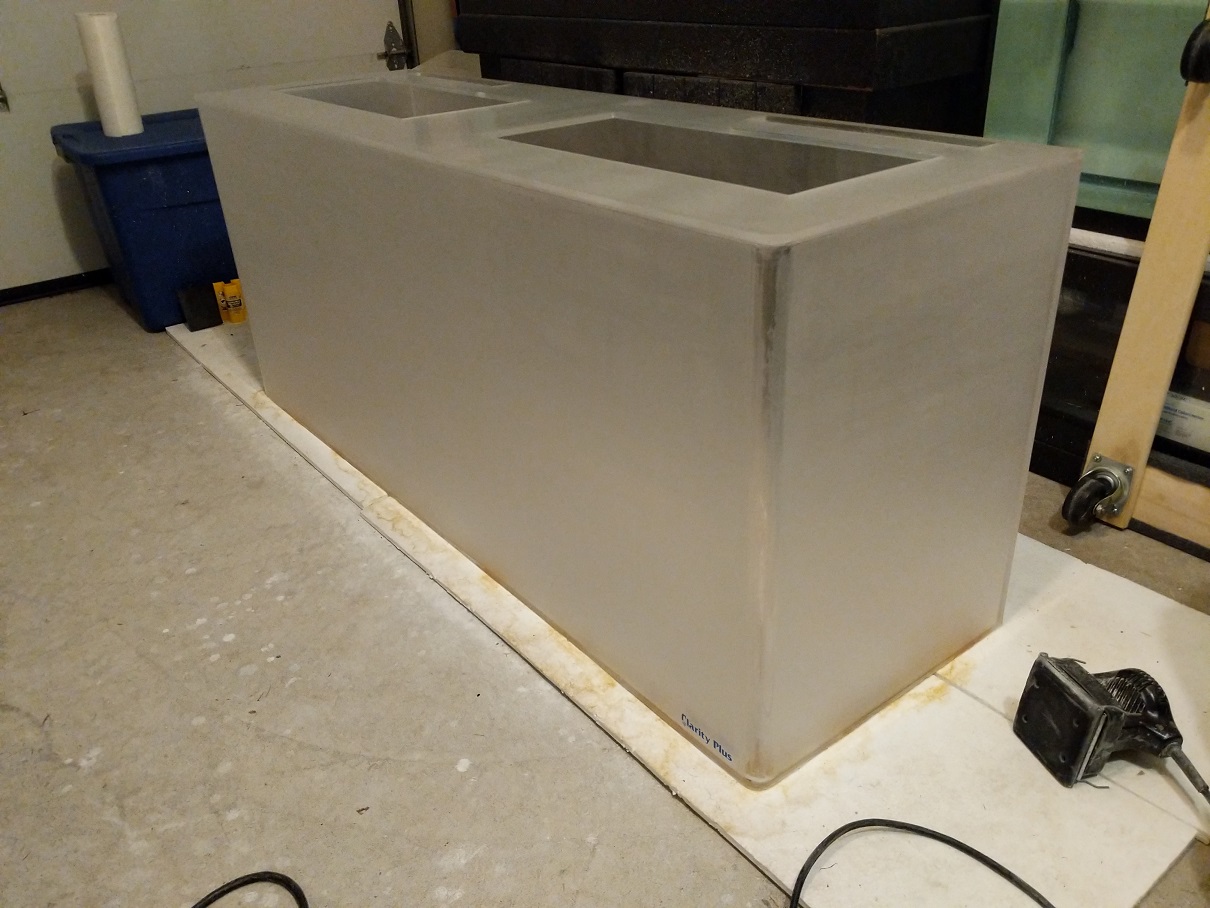

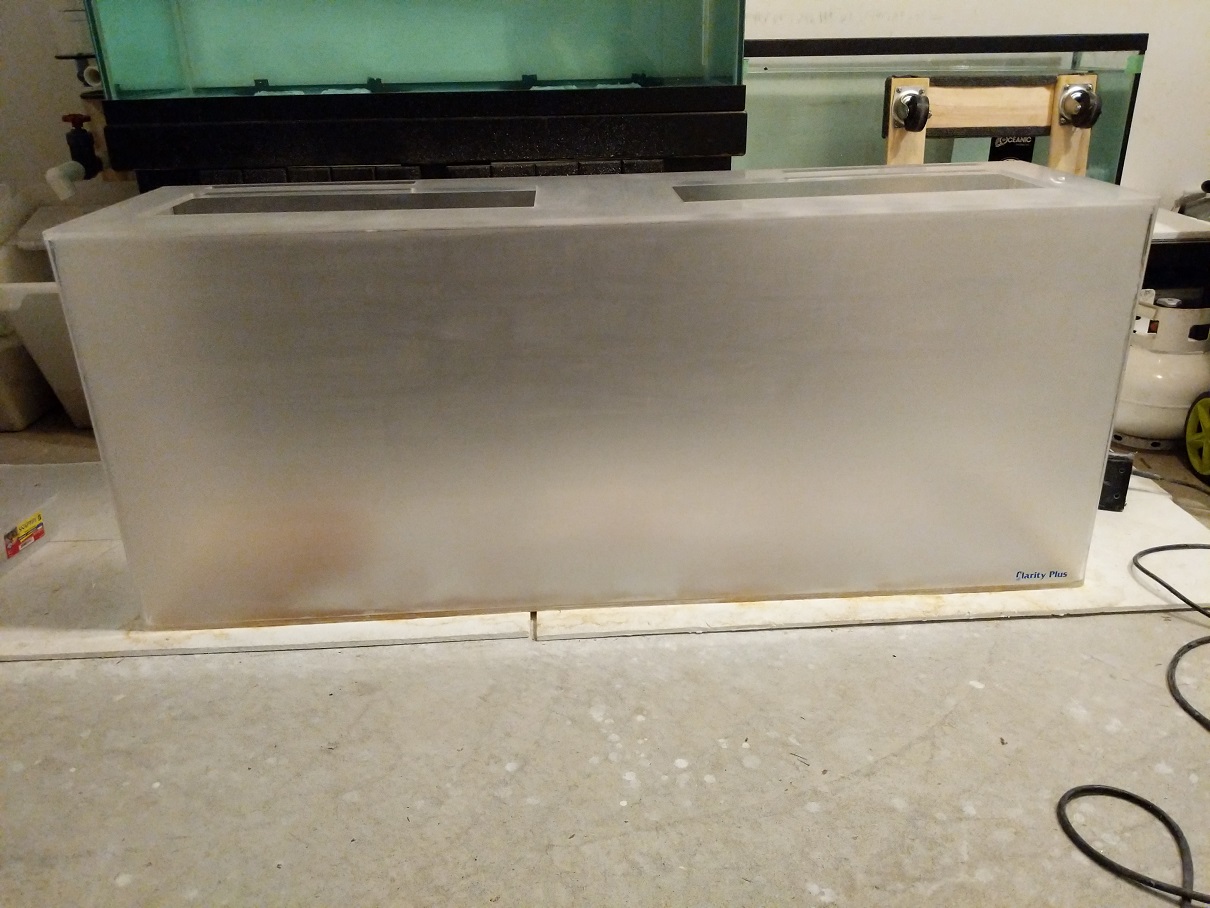

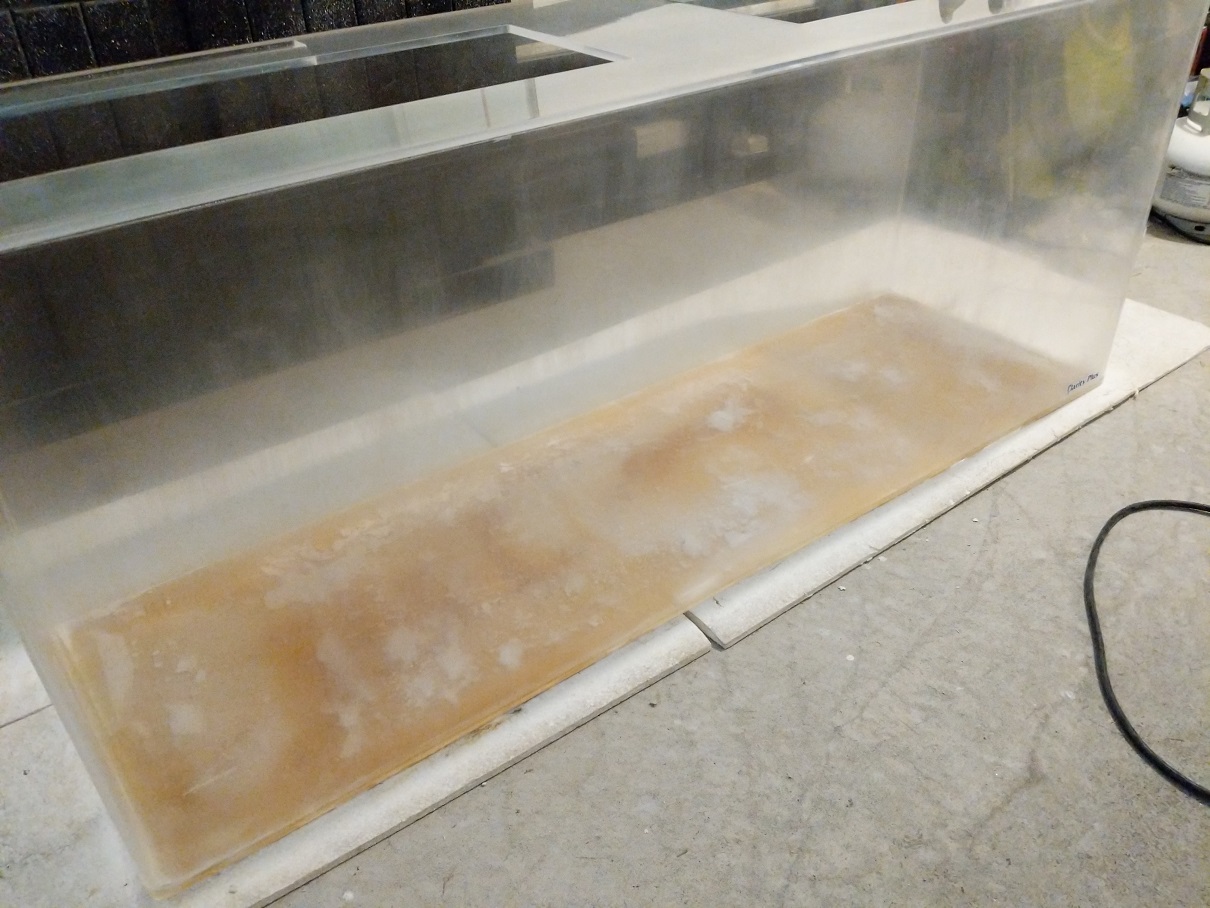

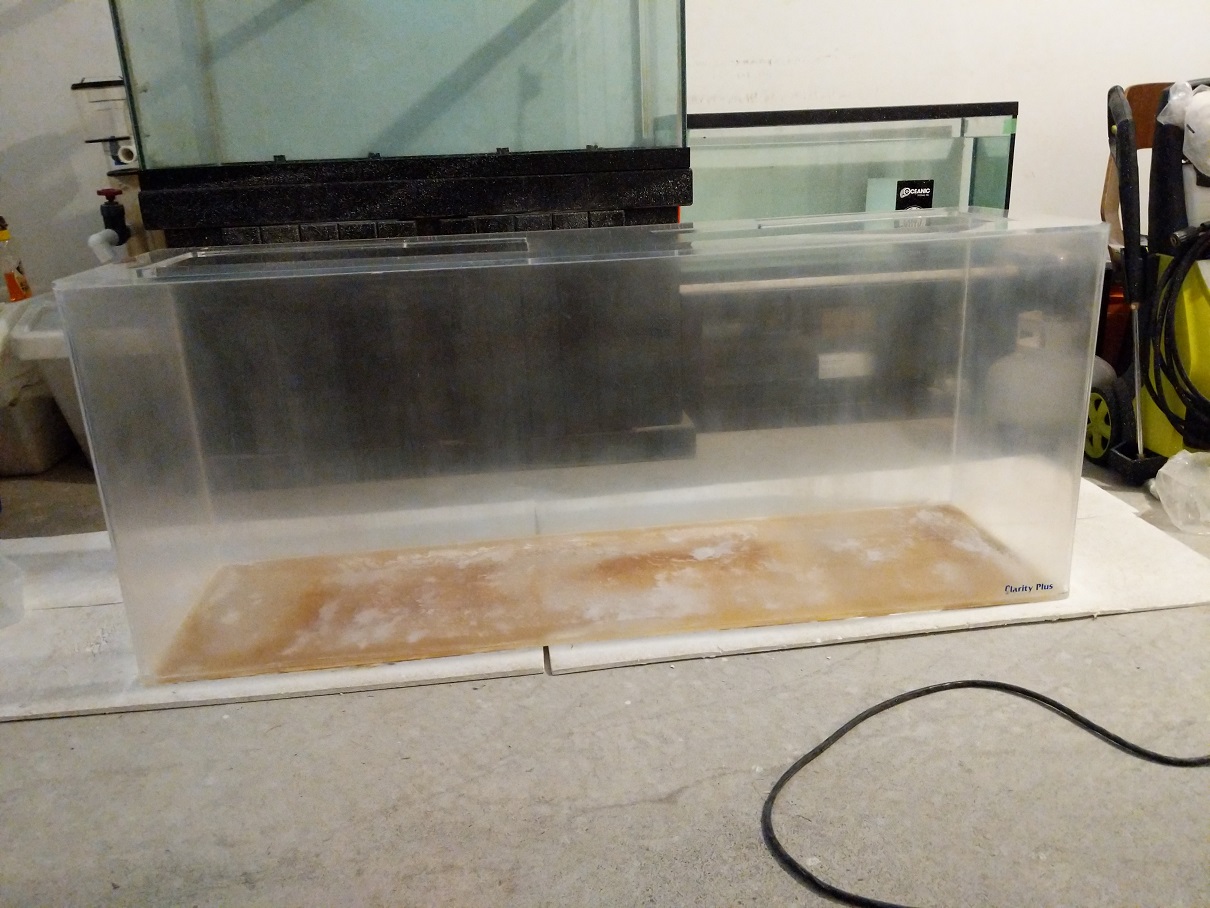

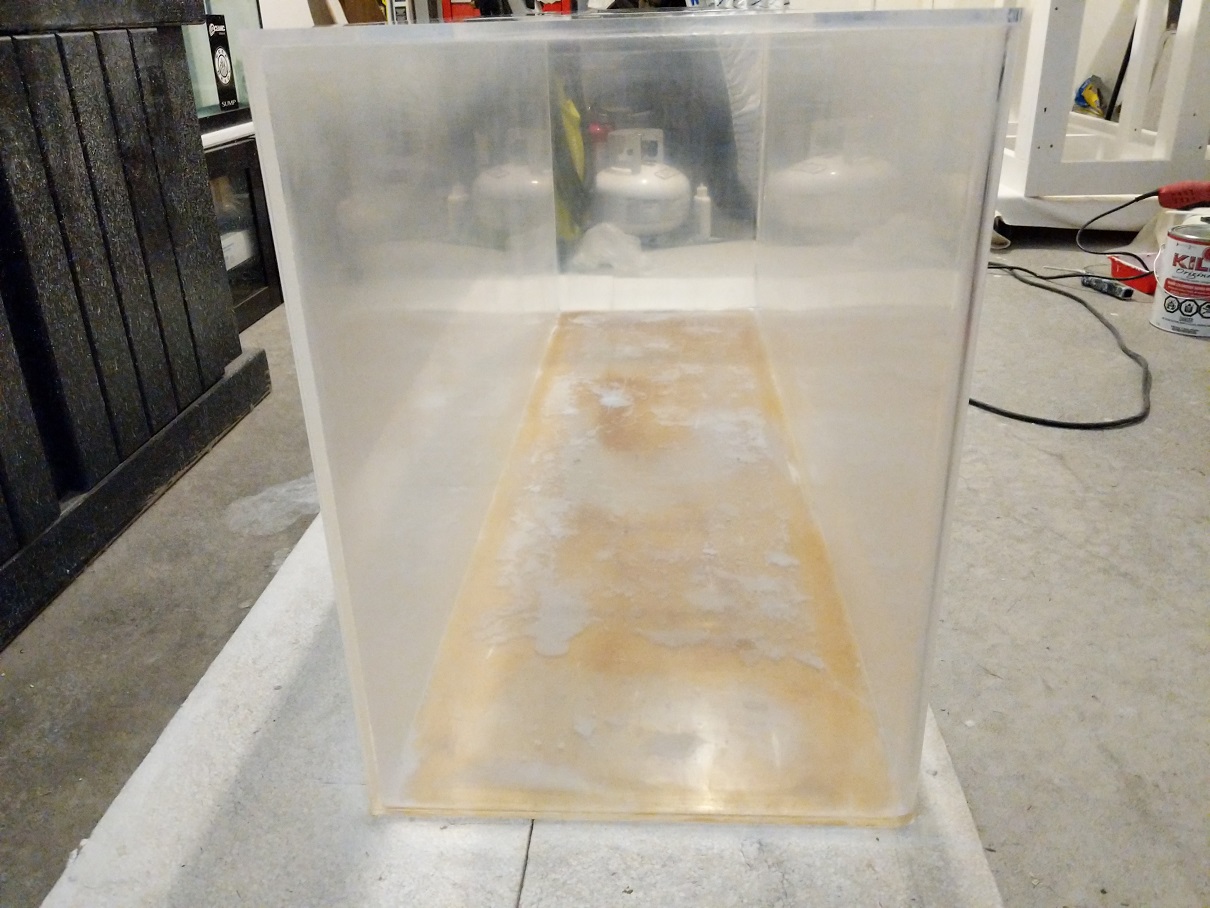

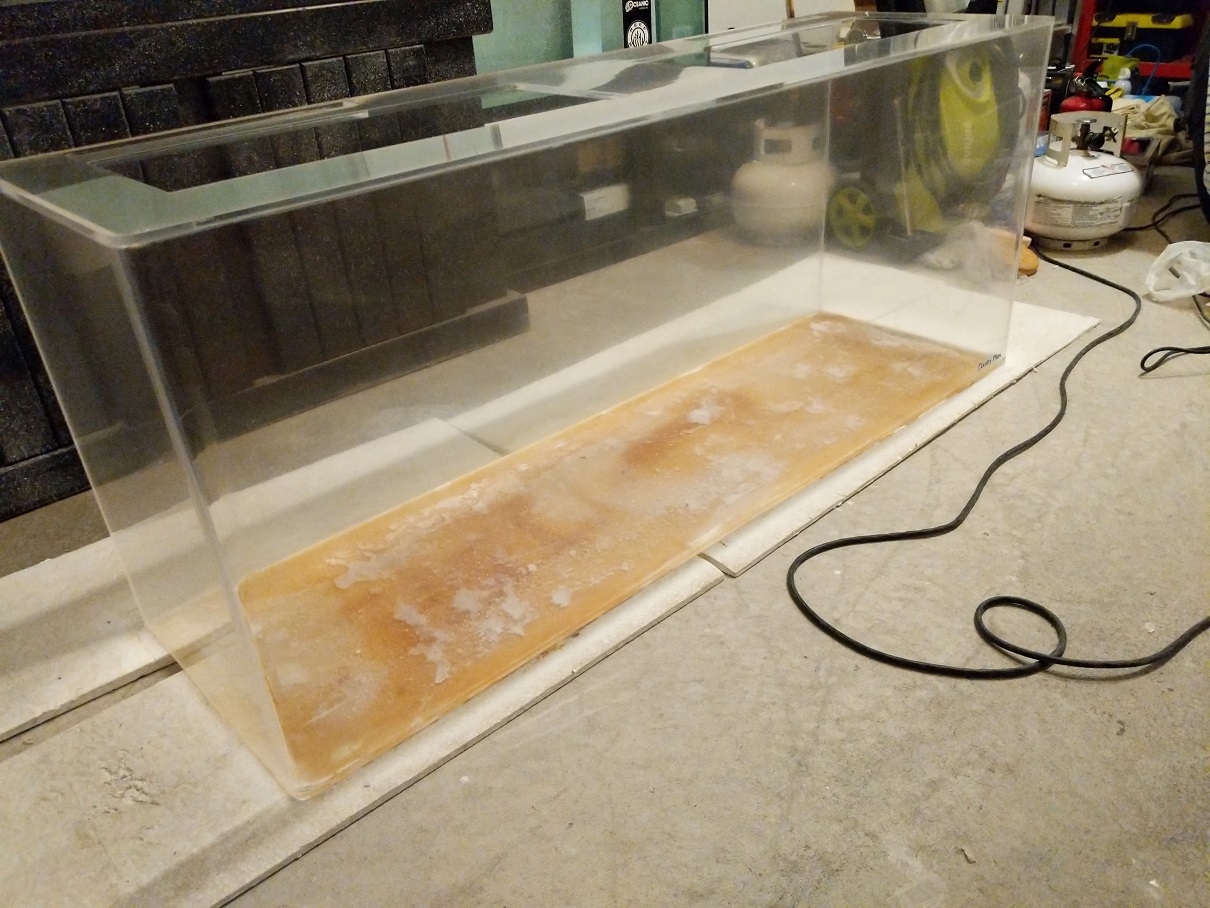

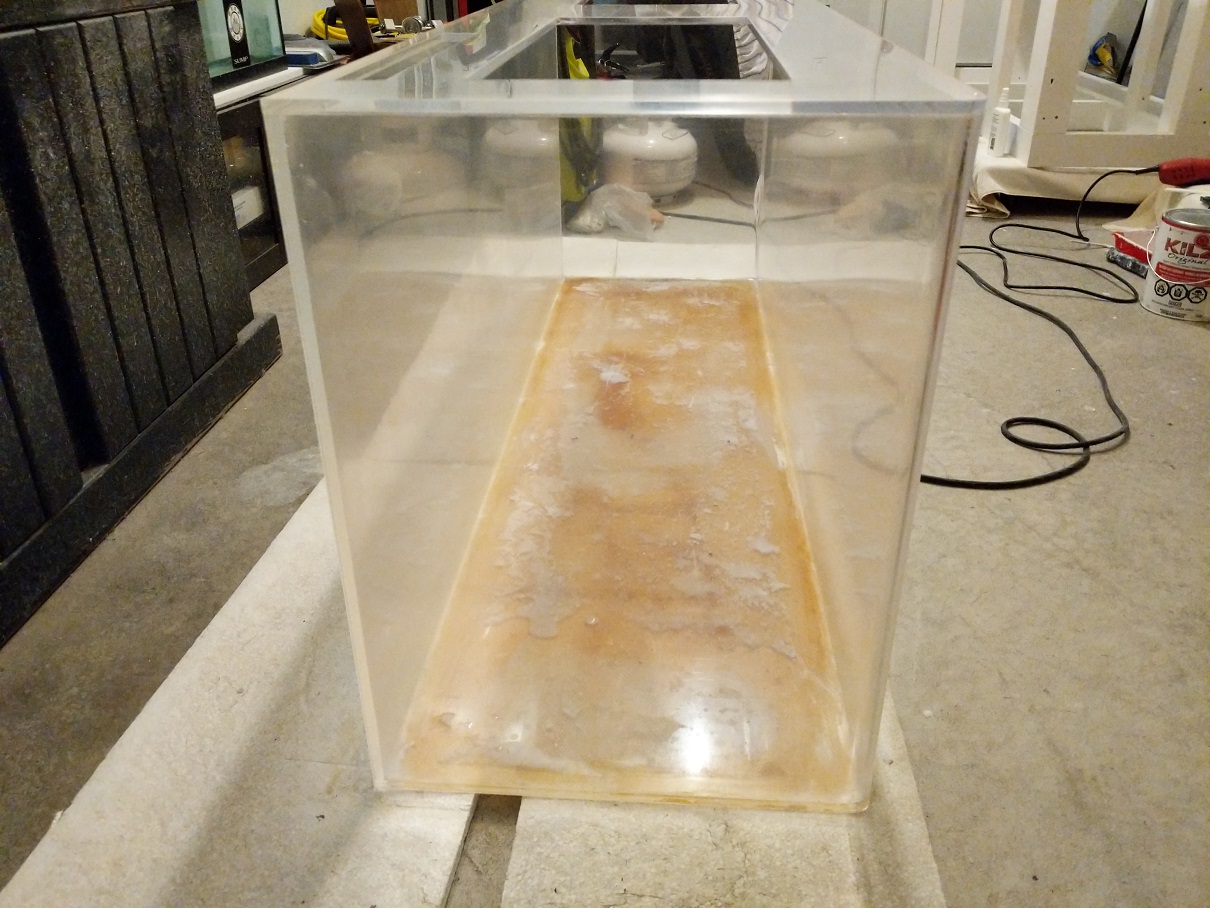

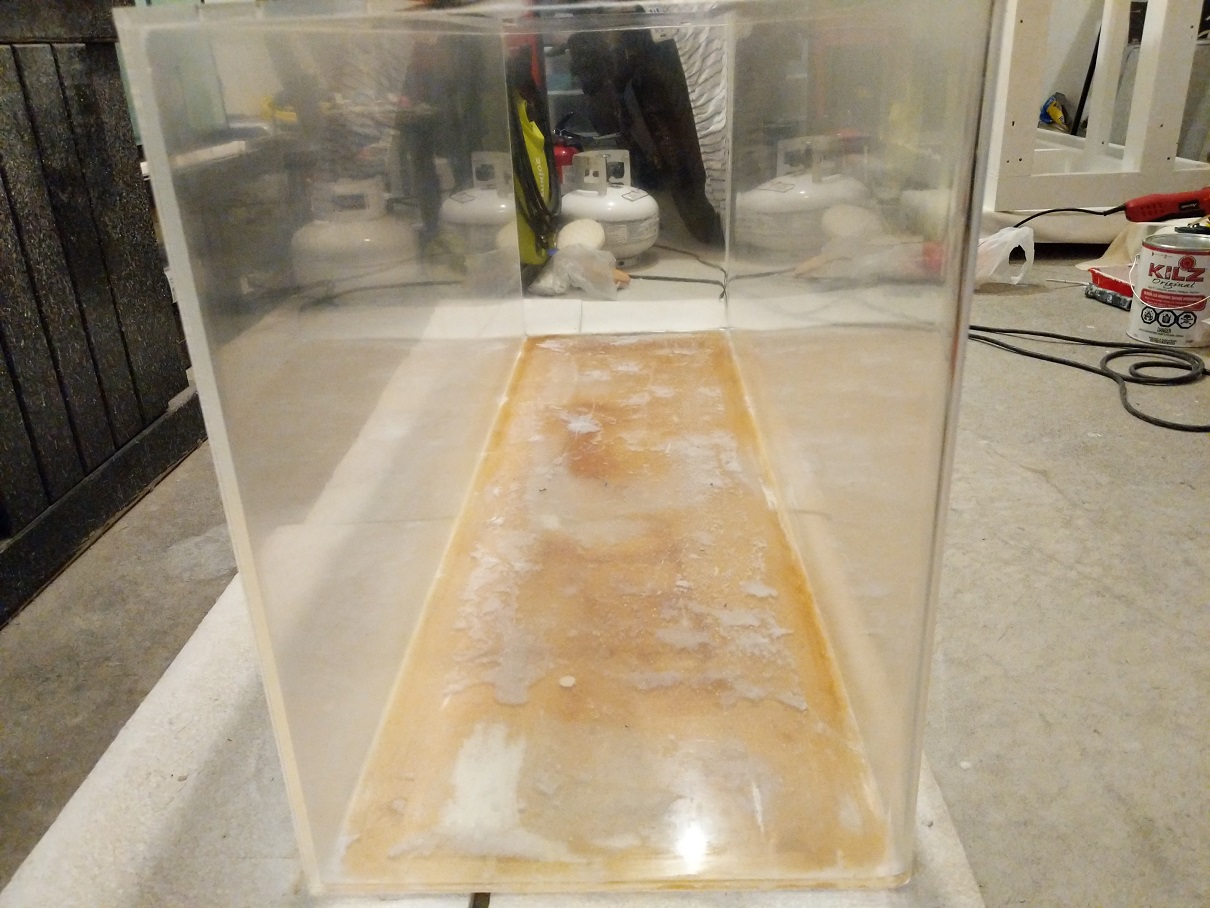

I picked up acrylic (5 foot x 18" x 24") 110 gallon tank several months ago. This is what it looked like when I got it

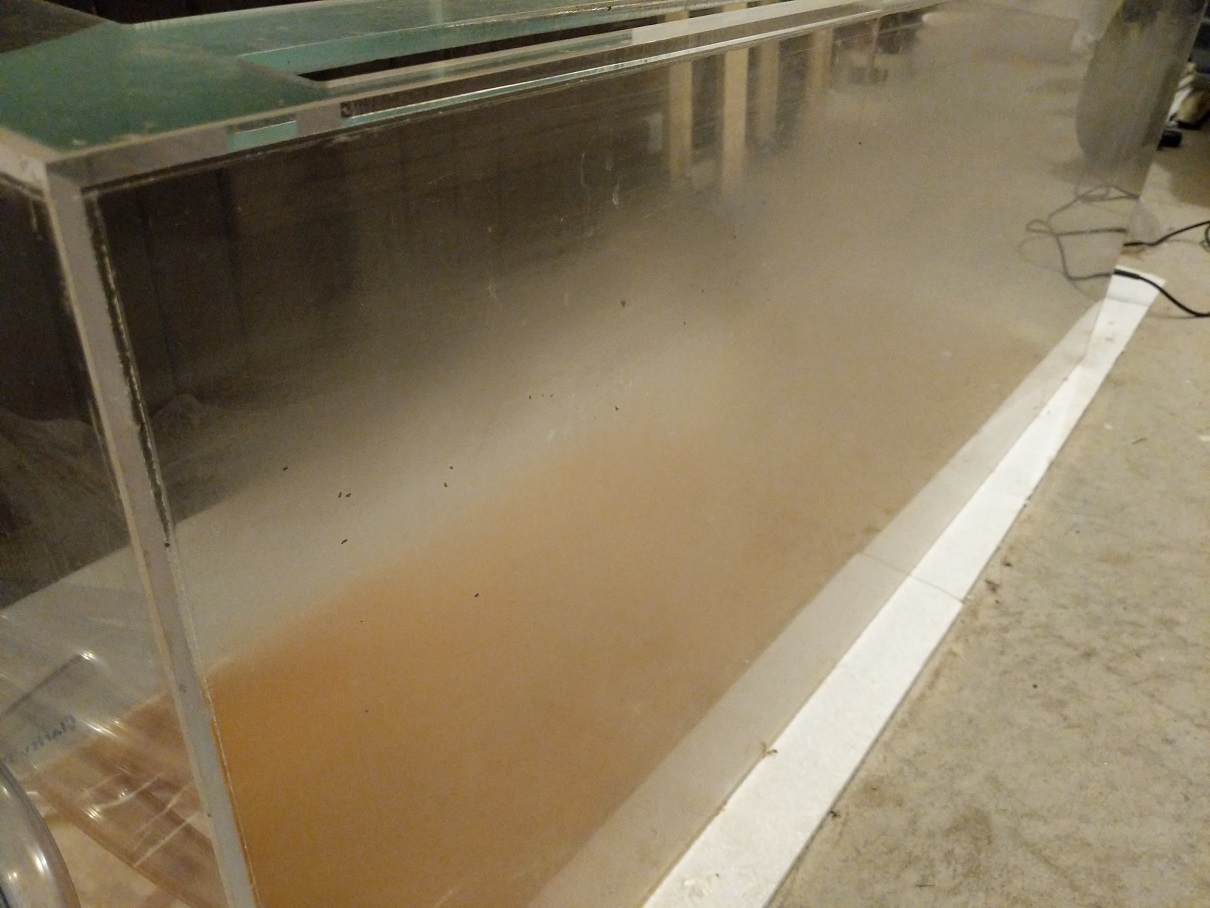

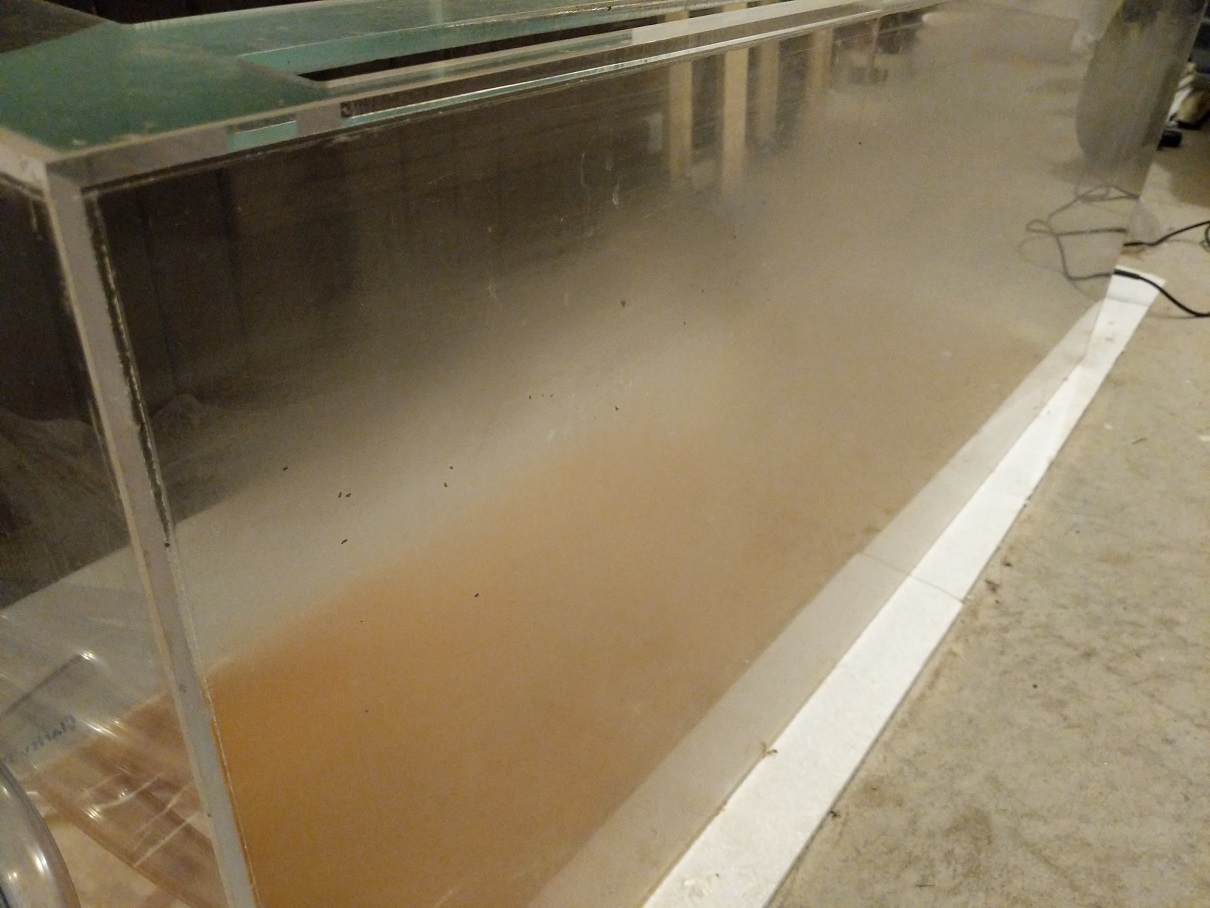

As you can see it was in a somewhat rough shape, but all seams were looking good and it held water fine. After week long water test I cleaned up algae with Mr Clean eraser. This stuff is magic. I could now see what I was actually working with.

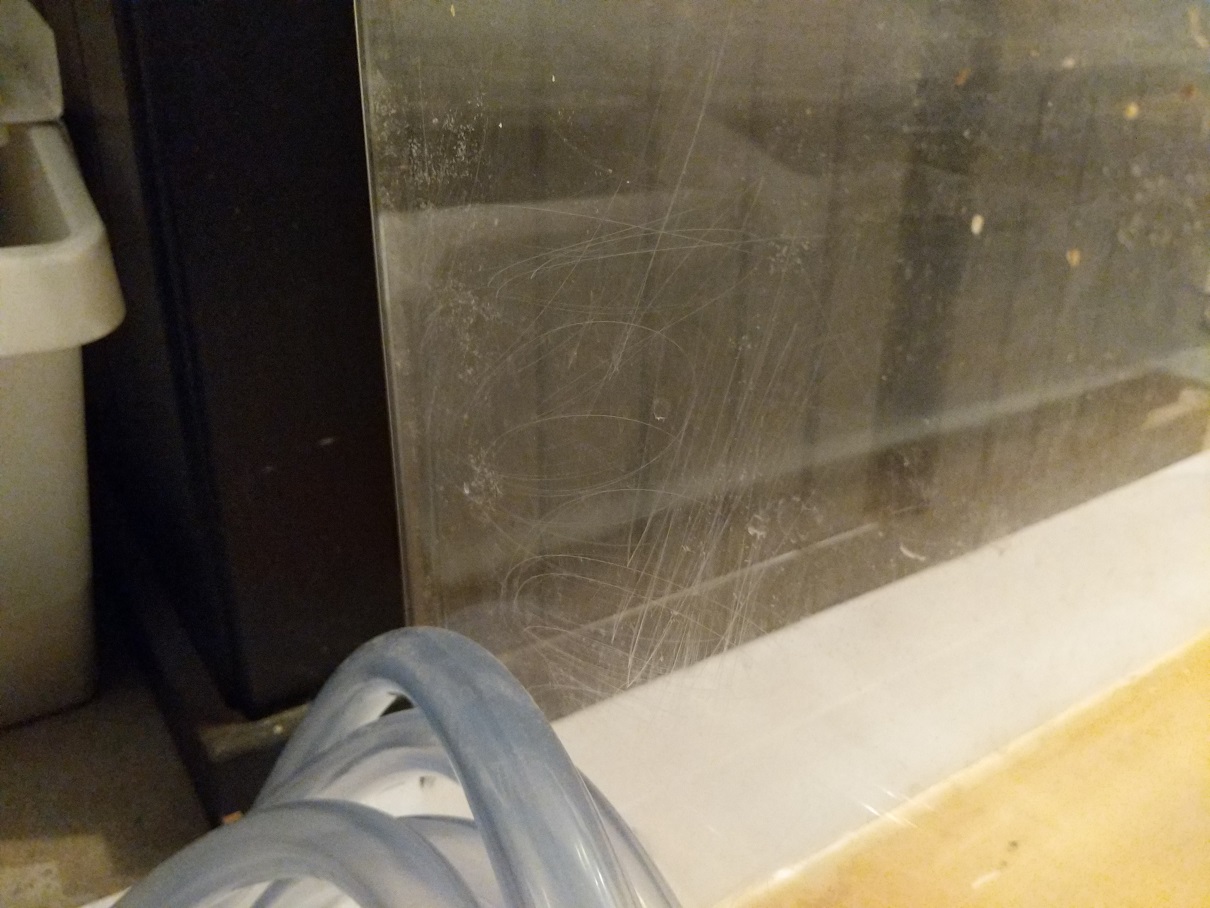

I am guessing PO tried to buff out scratches, used higher grit sand paper and then gave up.

Lots of scratches everywhere.

I picked up acrylic (5 foot x 18" x 24") 110 gallon tank several months ago. This is what it looked like when I got it

As you can see it was in a somewhat rough shape, but all seams were looking good and it held water fine. After week long water test I cleaned up algae with Mr Clean eraser. This stuff is magic. I could now see what I was actually working with.

I am guessing PO tried to buff out scratches, used higher grit sand paper and then gave up.

Lots of scratches everywhere.