- Joined

- Apr 2, 2019

- Messages

- 4,654

- Reaction score

- 6,040

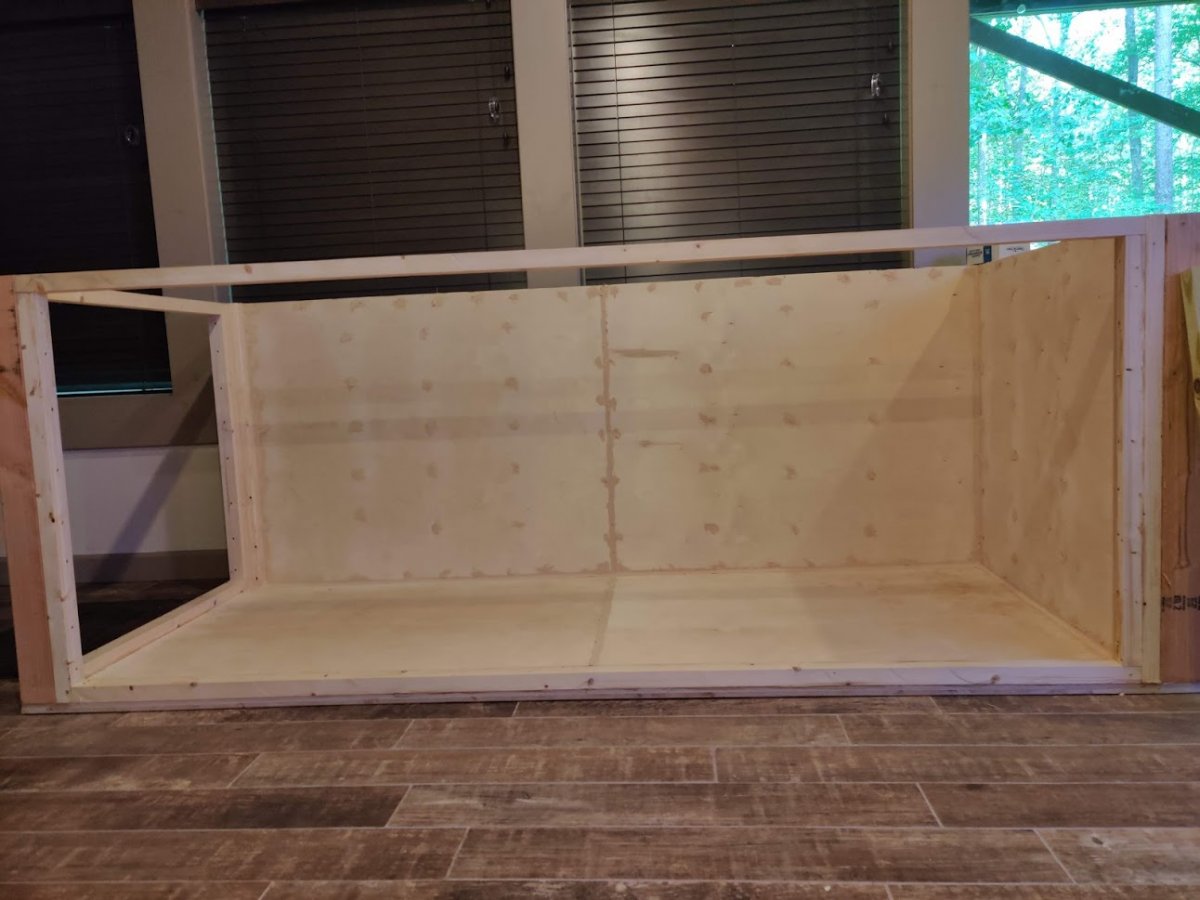

Right so last time I posted about the lighting system I built for the the new tank which is basically the only part of this build that is still functional. So, not a total loss!! But for the actual plywood part of the build we ended with box completion and it looked something like this:

The next step in a plywood build is to use bondo or epoxy filler to fill all the screw heads and seam gaps. For this I used JB weld wood epoxy which is a really cool 2 part putty product. It's like play-doh. It's a lot of fun to work with. It took about an hour to fill all the screw heads and seams and the buckets say to wait 24hrs before it's fully cured (I think it says you can paint and sand within a few hours, but I wasn't in a huge rush).

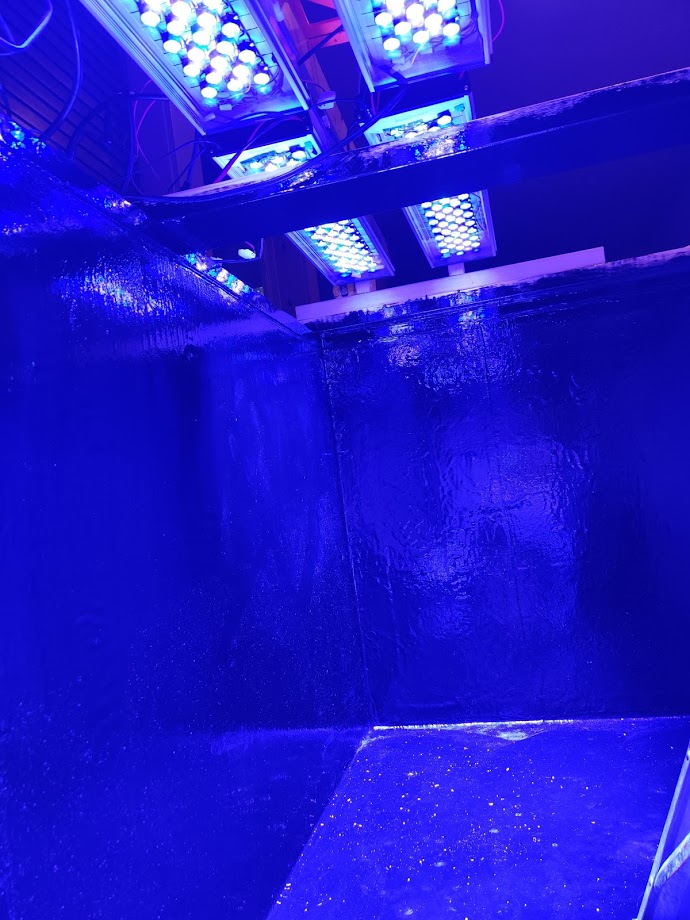

The next step after gap filling is the fun part: Fiberglassing. A lot of people who build plywood tanks only fiberglass the seams because those are the areas where there is the most stress. I have read a number of threads about epoxy water proofing products eventually getting microfissures and leaking within the panels. I didn't want to deal with that so I just fiberglassed the whole thing. I figured it was only an extra day of work and a couple hundred dollars more, so why not. And if it works for a canoe, it should work pretty well for a fish tank. I created a nice fiberglassing booth in my basement

And started the process of fiberglassing the tank with the sheets of 4oz mat that I had precut to fit each surface of the tank. I did the horizontal and vertical seams first and then overlapped the full panel sheets with those afterward.

Fiberglassing is actually pretty easy once you get the hang of it. A few simple rules though:

1) Before wetting out the fiberglass, spread epoxy over the wood surface. This will enhance the wetting out of the fabric. The wood will take up some amount of the epoxy so if you don't do this you can get spots in the fiberglass that don't wet out well and you have to spend a lot of time working epoxy into them. You don't want to do this when you only have 20 minutes or so of working time, especially if you're trying to lay more than one layer at a time (I was doing 2).

2) If you're doing a big section, roll the sheet up and the roll it out from left to right while covering with more epoxy. I tried to put the sheet on once just as a flat sheet and it wrinkled badly. It took a good 10 minutes to get it smoothed out, rolling it out gives you more time to work out the wrinkles before moving on to the next bit and makes the process go a whole lot more quickly

3) Get a good fiberglass roller. Rolling the fiberglass is the most important step! While doing this you introduce a ton of air bubbles into the epoxy and the fiberglass. if you don't roll them out they sit under the glass or in the epoxy and can pop or crack in the future. This is how leaks happen, so be sure you roll all the air bubbles out to prevent this from happening

4) Try to avoid rounded corners <3/4". Rounded corners make it almost impossible to remove air bubbles. The fiberglass just slides over the curved surface and this is especially bad on small radius corners. Try to keep any rounded corners at 3/4" or more if you must have them. I had a few 2x4 edges in my build and those were 1/4" corners. It was impossible to get a bubble free adhesion of the epoxy and fiberglass (the fiberglass does not bend well at all at that radius).

Once the fiberglassing was done I added pond shield pond armor for color. The tins for this product are covered in labels saying that it is non-toxic but it smells awful. The boat epoxy had no odor whatsoever, Pond Armor STINKS. If you're doing this in your house, get some fans and open a lot of windows!

Next came adding the acrylic windows. I picked these up from the local acrylic wholesaler with a uhaul and had a friend from work help me install the main window. The wisdom online said to rough up the sealing surfaces with 60 grit sand paper and liberally apply 3M 5200. We got there eventually after a lot of grunting and covering ourselves in 5200. Take it from me, wrestling a 250lb piece of 1.5" thick acrylic into a box is NOT a good time! I clamped it down and braced it, waiting 7 days for the cure before I installed the side window myself

In this picture you can see in the corner that I left about a 1/2" gap between the edge of the box and the window. This was eventually back filled with 3M 5200 with the expectation that the 5200 on the sealing surface and around the perimeter gap would be sufficient to keep water in the tank.

The side window was much easier to get in, half the thickness, 1.25" and about half the length!

Then came adding the top bracing

Building the light rack

And testing out my artificial Sun!

And as a final step I added the spa flex, bulkheads and got my wife to help me paint the exterior with some flat black enamel paint!

And at this point we were ready to go to install the Monster, which will be the highlight of the next post. The build process after my window mistake went surprisingly smoothly. Maybe I should have seen that as a warning, but at this point I was blissfully ignorant of the excitement I had ahead of me.

Bump?