With my great luck, the following day after the Wrasse was added, he jumped out of the tank. Luckily my cat spotted the fish and got my attention. After about 12 hours, the fish was back to normal and happy. Lucky escape.

So now the tank is rocking this mesh screen top from IM.

I must say, that this screen kit is quite terrible. I previously purchased a small one from Red Sea for my nano and it was miles better. The IM kit is bulkier, painted worse, the rubber ribbing material is terrible, the clips for corners are pretty atrocious, and it doesnt even come with the tools. Lucky for me, I had the tools from the Red Sea kit, as well as some practice on the previous one, so I was able to make this one work.

The kit is designed to go inside the tank borders and hang on the corner tabs but I do not trust it hanging with its own weight :/ So I decided to not cut the kit and keep it full size. So as not to scratch the tank, I picked up some rubber feet from Home Depot and stuck them to the rails. Another benefit now, is the rubber feet actually make the screen "stick" to the tank better.

This kit will have to do until I do my research and settle on a custom cover.

As the days and weeks passed where I waited for the tank to adjust after moving each fish (3 have been moved in total now), I continued to work on various small parts of the tank.

First order of business was running a second layer of silicone along one edge of the tank which didnt settle properly the first time, leaving small gaps where water could pass through. So off to tape the lines again, and fill it with more silicone.

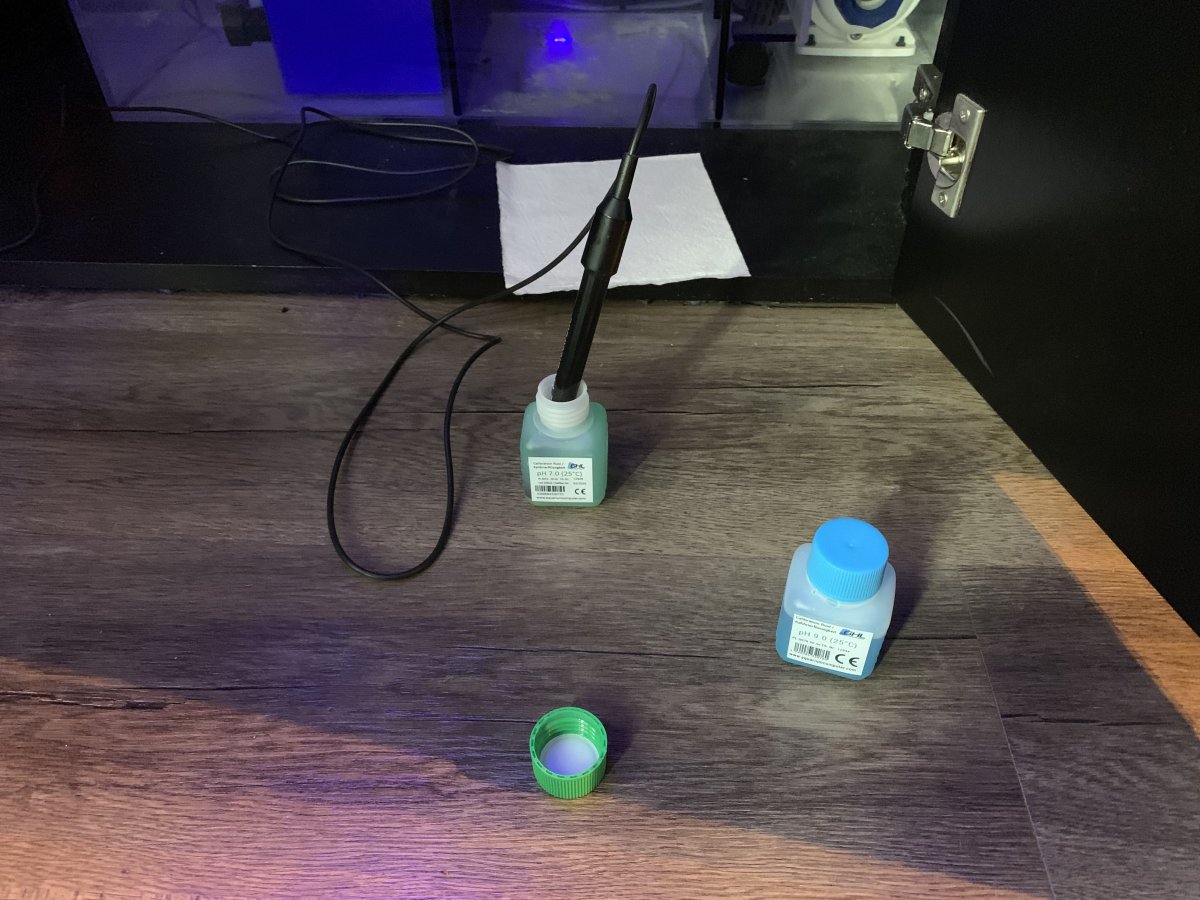

Next I attached, ran, and calibrated more probes (pH and Conductivity).

Finally, a very small change, but I think cool one, was tweaking the colors of the GHL Profilux Touch to match the rest of the aquarium color scheme... Blue and Black.

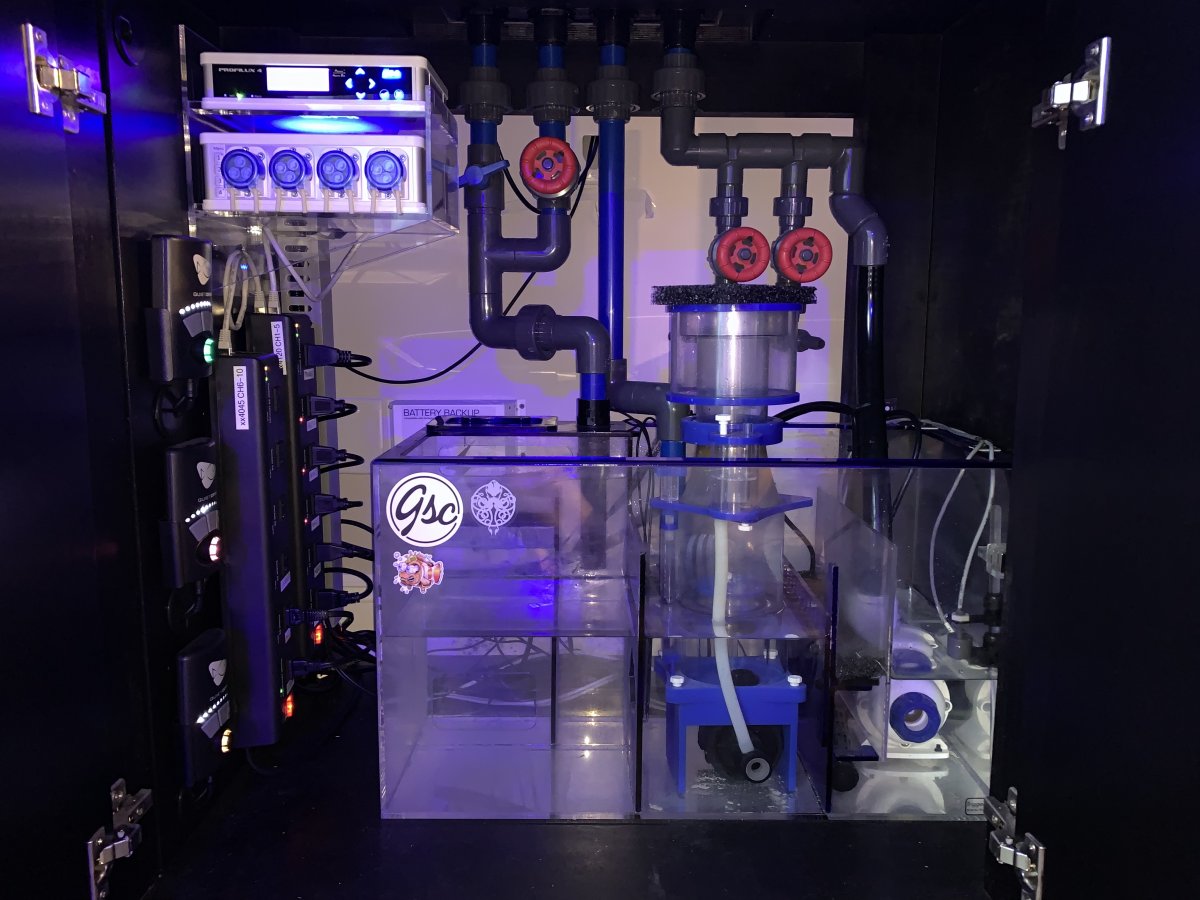

Current state of the sump area where all the stuff is still in the works. Soon the skimmer will be updated, and a few other pieces of equipment added.

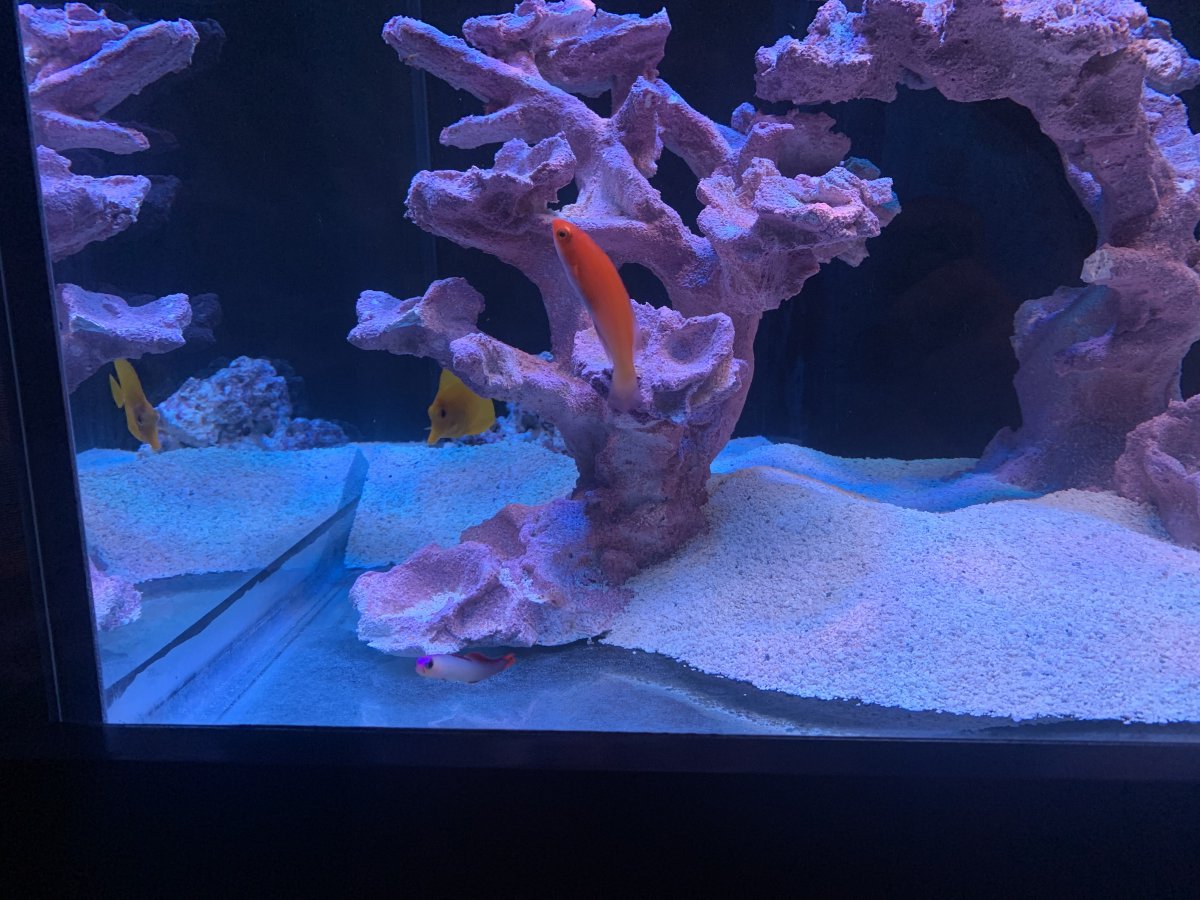

Here's a picture of the inhabitants now of the tank! I have the Cherry Wrasse, Purple Firefish, and Yellow Tang which were all successfully relocated from the small tank to this one.

So now the tank is rocking this mesh screen top from IM.

I must say, that this screen kit is quite terrible. I previously purchased a small one from Red Sea for my nano and it was miles better. The IM kit is bulkier, painted worse, the rubber ribbing material is terrible, the clips for corners are pretty atrocious, and it doesnt even come with the tools. Lucky for me, I had the tools from the Red Sea kit, as well as some practice on the previous one, so I was able to make this one work.

The kit is designed to go inside the tank borders and hang on the corner tabs but I do not trust it hanging with its own weight :/ So I decided to not cut the kit and keep it full size. So as not to scratch the tank, I picked up some rubber feet from Home Depot and stuck them to the rails. Another benefit now, is the rubber feet actually make the screen "stick" to the tank better.

This kit will have to do until I do my research and settle on a custom cover.

As the days and weeks passed where I waited for the tank to adjust after moving each fish (3 have been moved in total now), I continued to work on various small parts of the tank.

First order of business was running a second layer of silicone along one edge of the tank which didnt settle properly the first time, leaving small gaps where water could pass through. So off to tape the lines again, and fill it with more silicone.

Next I attached, ran, and calibrated more probes (pH and Conductivity).

Finally, a very small change, but I think cool one, was tweaking the colors of the GHL Profilux Touch to match the rest of the aquarium color scheme... Blue and Black.

Current state of the sump area where all the stuff is still in the works. Soon the skimmer will be updated, and a few other pieces of equipment added.

Here's a picture of the inhabitants now of the tank! I have the Cherry Wrasse, Purple Firefish, and Yellow Tang which were all successfully relocated from the small tank to this one.

Last edited: