Build Confession: I am a hobby plagiarist and anything that Ratkiller does I can do too! (Just smaller....and with fewer wet sleeves)

Tank #4 (48 gallon) Current FTS (JUL-2023)

FTS (SEP-2022):

The Ratkiller aspirational-I'll-get-there-someday-but-not-get-my-armpits-wet tank -130-ish 165 gallon (whoops!) Starfire custom in-wall, 300 gallon total system volume of gloriousness and basketball sized Tort colonies:

Tank #1 (2017 to 2020: Illumin8's 8 gallon AIO TOTM on NanoReef) - loved this tank, upgraded for that fat, bloodthirsty, lightning maroon clown shark:

Tank #2 (2020 to 2021 - semi-cursed 24 gallon acrylic AIO) - 3 x the fun of the 8 gallon and 3 x the blood drawn by the lightning maroon clown shark:

Tank #3 (2021 to Aug 2022 36 gallon): Moar space! Moar coral! Moar I-really-need-a-sump-and-Ca-reactor......

(guess who the fish trap was for.... he got a sweet upgrade to an anemone tank all his own and still gets regular visits from his first source of human flesh)

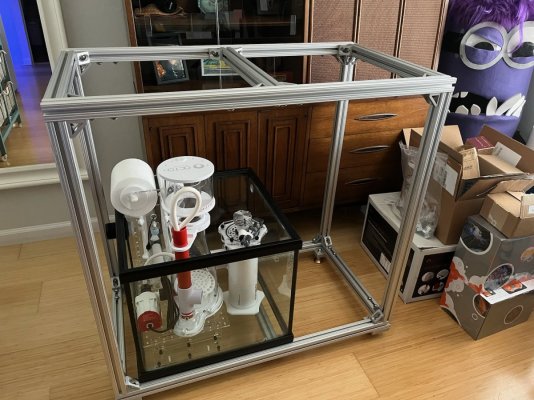

Tank #4 (June 2022 to ??? 48 gallon w/ sump): Just getting started, so 4th time's the charm?

Remaining Tank #4 To-do List:

| Item | Name | Details |

|---|---|---|

| Tank | ADA 90P | 48 gallon |

| Sump | Custom cube (21 x 21 x 21) | 40 gallon (25 gallon fill volume) |

| Overflow | Modular Marine | 800 gph custom white acrylicz, 1/2" bean animal |

| Display Flow | EcoTech | |

| Return Plumbing | 1/2" | |

| Return Flow | Ecotech Vortech | S2 |

| Manifold plumbing | ||

| Manifold Flow | Ecotech Vortech | |

| Filtration | Clarisea | SK5000 |

| Algae Reactor | PaxBellum | ARID n18 |

| Skimmer | Reef Octopus | Elite |

| Lighting | Radion G3 | XR15 x 2 |

| Dosing | Geo's Reef | CR618 with Platinum Blue DC pump (silent) Carbon Doser CO2 Control |

| Misc. | UV | Pentair Smart 18W |

| Controller | Apex A2 (pH x 2 & temp), EB8, EB4, 2 x FMM | |

| Testing | Hanna (PO4), Salifert (Ca2+, KH, NO3) |

Tank #4 (48 gallon) Current FTS (JUL-2023)

FTS (SEP-2022):

The Ratkiller aspirational-I'll-get-there-someday-but-not-get-my-armpits-wet tank -

Tank #1 (2017 to 2020: Illumin8's 8 gallon AIO TOTM on NanoReef) - loved this tank, upgraded for that fat, bloodthirsty, lightning maroon clown shark:

Tank #2 (2020 to 2021 - semi-cursed 24 gallon acrylic AIO) - 3 x the fun of the 8 gallon and 3 x the blood drawn by the lightning maroon clown shark:

Tank #3 (2021 to Aug 2022 36 gallon): Moar space! Moar coral! Moar I-really-need-a-sump-and-Ca-reactor......

(guess who the fish trap was for.... he got a sweet upgrade to an anemone tank all his own and still gets regular visits from his first source of human flesh)

Tank #4 (June 2022 to ??? 48 gallon w/ sump): Just getting started, so 4th time's the charm?

Remaining Tank #4 To-do List:

- Install MP40 thin spacers so the dang pumps quit jumping off the glass....

- Figure out a skin for the stand

- Option 1: Magnet attached panels - plastic (PVC? Acrylic?) panels with wood veneer or MDF?

- Option 3: Hinged MDF custom cabinet doors/panels

- Tear down the 36 gallon

- Move 48 gallon to final location

- Remove Radion mounts - yay no cords visible through the back panel!!

- Program current lights to 48 gallon schedule

- Build Apex and controller drawer insert

Last edited: