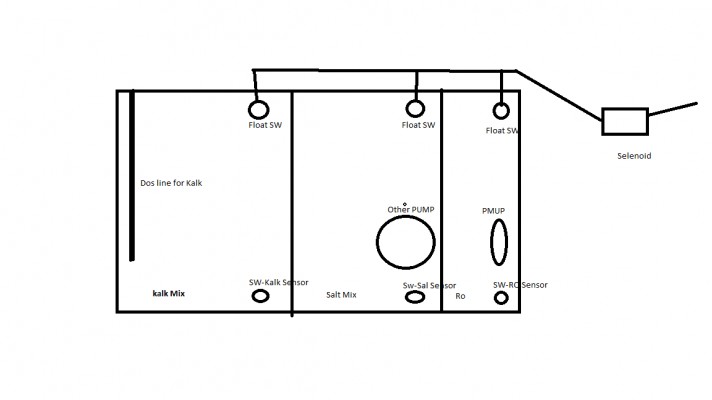

So I need a little bit of help with the programming of my apex. I built a three stage acrylic container where I can have RO/Salt Water Mix/Kalk Mix. All three containers are behind a single solenoid. I have a sensor on each container letting me know when the container has run out of water(mix) and a float switch so that the container won’t overflow. I’ve had float switch go bad on me, I want to use the solenoid as protection. I want the solenoid to turn on for a period of time and then turn off and remain off.

The issue that I’m having is with the PMUP. When the container runs out of water, air goes inside of the PMUP and even if the container fills up with water, the PMUP won’t pump water due to the air in the motor. I have to suck the air out through the hose and the PMUP starts working again.

I’m trying to write a code that when the water sensor is opened, to stop the pump and to open the solenoid to fill the container with water.

So I have a sensor, a virtual outlet and of course an outlet for each chamber. What I have programed and re-program and program again trying different logic; was that if the water sensor is opened, it will turn on the virtual outlet and keep it turned on for a time period until the container is filled again. Trying different things, I just left the outlet as basic as if switch on then on with no DEFER or no MIN TIME. That seems to work best but still not what I need. The issue that I’m having now is when the virtual ATO outlet is on, it has a DEFER and doesn’t allow the PMUP from stopping, so it keeps the pump running until it runs dry and then when the container is filled with water the PMUP won’t pump water due to the air in the pump.

I was thinking of using the WHEN command to see if I can manually turn off the virtual outlet and then turn it back on another way (which I’m not familiar how to set it back to automatic; I think that may be a bit out of my scope of programming…

Here’s what I have so far.

Sensor

Name - Sw_RO

Virtual Outlet – Name Vir-Ro

Set OFF

If Sw_RO OPEN Then ON

Min Time 018:00 Then ON

Virtual Outlet – Name ATO-Virtual

Fallback OFF

Set OFF

If Sw-Low CLOSED Then ON

Min Time 002:00 Then ON

If Sw_RO OPEN Then OFF (This is not stopping the outlet because of the MinTime)

Selenoid – Name ATO-Pump

Set OFF

If Sw-Hig OPEN Then OFF

If Output Vir-Ro = ON Then ON

If Output Vir-Sal = ON Then ON

Again, The issue that I’m having is when the PMUP runs out of water, it turns off, but I think air goes into the pmup and when the container is filled back up with water, It won’t pump water out again. I have to suck water out through the hose pulling the air that’s in the pump in order for the pump to continue to work.

Hope this is not so complicated to you all as it is to me…..

Thanks in advance.

The issue that I’m having is with the PMUP. When the container runs out of water, air goes inside of the PMUP and even if the container fills up with water, the PMUP won’t pump water due to the air in the motor. I have to suck the air out through the hose and the PMUP starts working again.

I’m trying to write a code that when the water sensor is opened, to stop the pump and to open the solenoid to fill the container with water.

So I have a sensor, a virtual outlet and of course an outlet for each chamber. What I have programed and re-program and program again trying different logic; was that if the water sensor is opened, it will turn on the virtual outlet and keep it turned on for a time period until the container is filled again. Trying different things, I just left the outlet as basic as if switch on then on with no DEFER or no MIN TIME. That seems to work best but still not what I need. The issue that I’m having now is when the virtual ATO outlet is on, it has a DEFER and doesn’t allow the PMUP from stopping, so it keeps the pump running until it runs dry and then when the container is filled with water the PMUP won’t pump water due to the air in the pump.

I was thinking of using the WHEN command to see if I can manually turn off the virtual outlet and then turn it back on another way (which I’m not familiar how to set it back to automatic; I think that may be a bit out of my scope of programming…

Here’s what I have so far.

Sensor

Name - Sw_RO

Virtual Outlet – Name Vir-Ro

Set OFF

If Sw_RO OPEN Then ON

Min Time 018:00 Then ON

Virtual Outlet – Name ATO-Virtual

Fallback OFF

Set OFF

If Sw-Low CLOSED Then ON

Min Time 002:00 Then ON

If Sw_RO OPEN Then OFF (This is not stopping the outlet because of the MinTime)

Selenoid – Name ATO-Pump

Set OFF

If Sw-Hig OPEN Then OFF

If Output Vir-Ro = ON Then ON

If Output Vir-Sal = ON Then ON

Again, The issue that I’m having is when the PMUP runs out of water, it turns off, but I think air goes into the pmup and when the container is filled back up with water, It won’t pump water out again. I have to suck water out through the hose pulling the air that’s in the pump in order for the pump to continue to work.

Hope this is not so complicated to you all as it is to me…..

Thanks in advance.