Due to recent events, my 40 gallon sps tank had to shrink to a 20 gallon Inovative Marine Nuvo tank. I love the tank but I have every square inch covered with a piece of equipment (in the back). Apex probes, Doser lines, ATO, Cobalt heater, refuge on one side and ceramic media on the other with a filter sock. I have about 3” by 2” of space to place a skimmer. I did not want to have one in the display side due to micro bubbles and it’s ugly. I looked at the reefglass skimmer but I didn’t want to drop $110 for it with an air pump (mainly bc my wife was already ticked with the recent events regarding this tank). My goal was to design a skimmer that was cheap but worked and somehow get my C02 scrubber to work with it. This skimmer is designed for Nuvo tanks but can also work for other tanks in need of a nano skimmer, I will place recommendations for other tanks below. I purchased as much as I could from Amazon bc I love prime and it had the best deals. So here it goes:

Parts list:

1) Clear Polycarbonate tube 1 1/8” ID, 1 1/4” OD, 4’ length (smallest length on amazon) $10.00 Prime shipped. Clear Polycarbonate Tubing, 1-1/8" ID, 1-1/4" OD, 1/16" Wall, 4' Length https://www.amazon.com/dp/B000OMFLE4/ref=cm_sw_r_cp_api_1-JBAbYXK2S2H

2) #6 two hole rubber stopper with 5mm holes (3/16”) $5.75 shipped https://www.amazon.com/dp/B01318SOBO/ref=cm_sw_r_cp_api_naKBAbBPMFY3C

3) Uniclife UL-40 4-LPM adjustable air pump $14.98 Prime shipping. https://www.amazon.com/dp/B01EBXI7PG/ref=cm_sw_r_cp_api_udKBAb5HCB98A

4) LEE 2” wood air stone $6.85 Prime shipping.

https://www.amazon.com/dp/B0002APUP8/ref=cm_sw_r_cp_api_GfKBAbP2BDMHV

5) Standard airline, the link is what I purchased for another project but you don’t need $50 worth. Amazon has standard airline for $2.99. https://www.amazon.com/dp/B00TVNL9YI/ref=cm_sw_r_cp_api_EhKBAbMCME8TM

6) zip ties at least 6” length. $2-$3.

7) 1/2” ID vinyl tubing, 1’ ***not silicon, need it stiff. Usually around $1 from any hardware store. Home Depot, Lowe’s, ACE hardware, etc..

8) **Optional 1/4” acrylic tube, $2.49 from BRS. https://www.bulkreefsupply.com/1-4-clear-acrylic-tube-16-long.html

9) scrap piece of acrylic at least 2-3” by 3-4”.

10) Plastic container, I used a Bia drink bottle but soda bottle with a large base are perfect.

11) Aquarium safe silicone $3.99 from Lowe’s or Home Depot.

Tools needed or recommended:

1) preferred a table saw but if you don’t have one, go to a friends house or use a Dremel saw.

2) drill bits or dremel tool

3) something to cut zip ties

4) propane torch or butane torch or grill style lighter

5) oven mit

6) needle nose pliers preferably

I recommend everyone to be safe around power tools and torches or lighters. I won’t be healed liable for your use of the tools listed above.

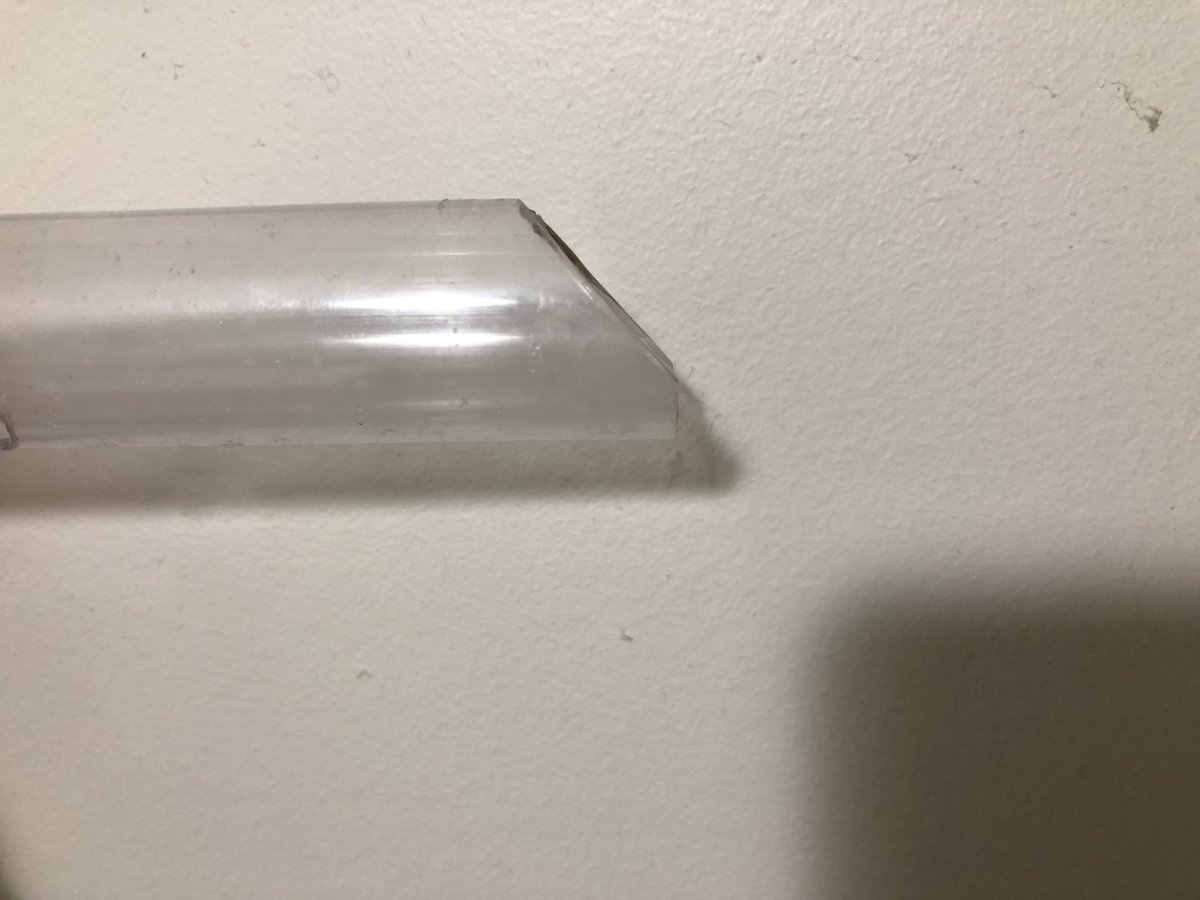

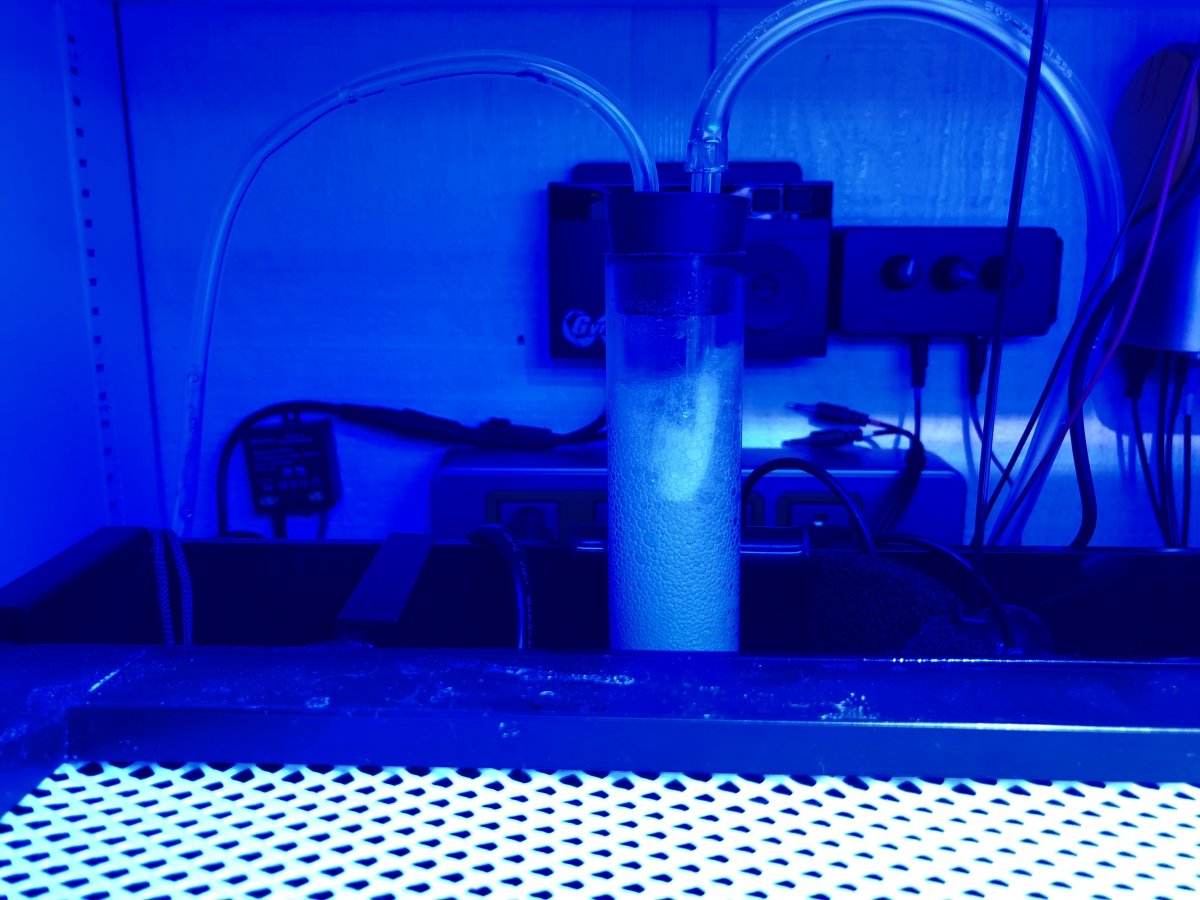

Step #1:

As previously mentioned, I designed this for a Nuvo tank but, some changes can be made on this step for other tanks. For Nuvo tanks, cut a piece of the Polycarbonate tubing to a length of 14” (reefglass has theirs at 11.5”, more contact the better). The goal is to have 5” of tube above the water line. This Nuvo 20 has a depth 8.5” of water in the area where the Skimmer will be placed. After you have cut a piece of Polycarbonate tubing, make another cut on the bottom at about a 45-30 degree angle but do not but across the whole tube. See the picture. The goal was to set the bottom of the tube on the bottom of the area where the Skimmer would be placed. The angle cut allows water to enter the Skimmer and the flat corner allows it to sit flat.

Step 2:

Cut a small piece of 1/2” ID vinyl tubing about 5-6” in length. Now, use a pair of pliers to hold one end of the tubing. Take a torch or other heating equipment and heat the tip of the tubing slowly, about 1.5” inches worth. You will start to see the tube becoming limp. When it is limp, using an oven mit on your hands, bend the tip of the tube at a 90 degree angle and hold it in place. Make sure that the tube does not pinch. When it cooled enough for me to handle it, I use my fingers to pinch the bend slightly to make sure I could allow as much water through as possible. Another trick I did is, while holding the 90 degree angle in place and pinching the bend, place it under cold water and this will quickly hold its shape. Once you the 90 degree bend, proceed to heat the shaft up to the bend. Once it is limp, make it as straight as you can. See pictures.

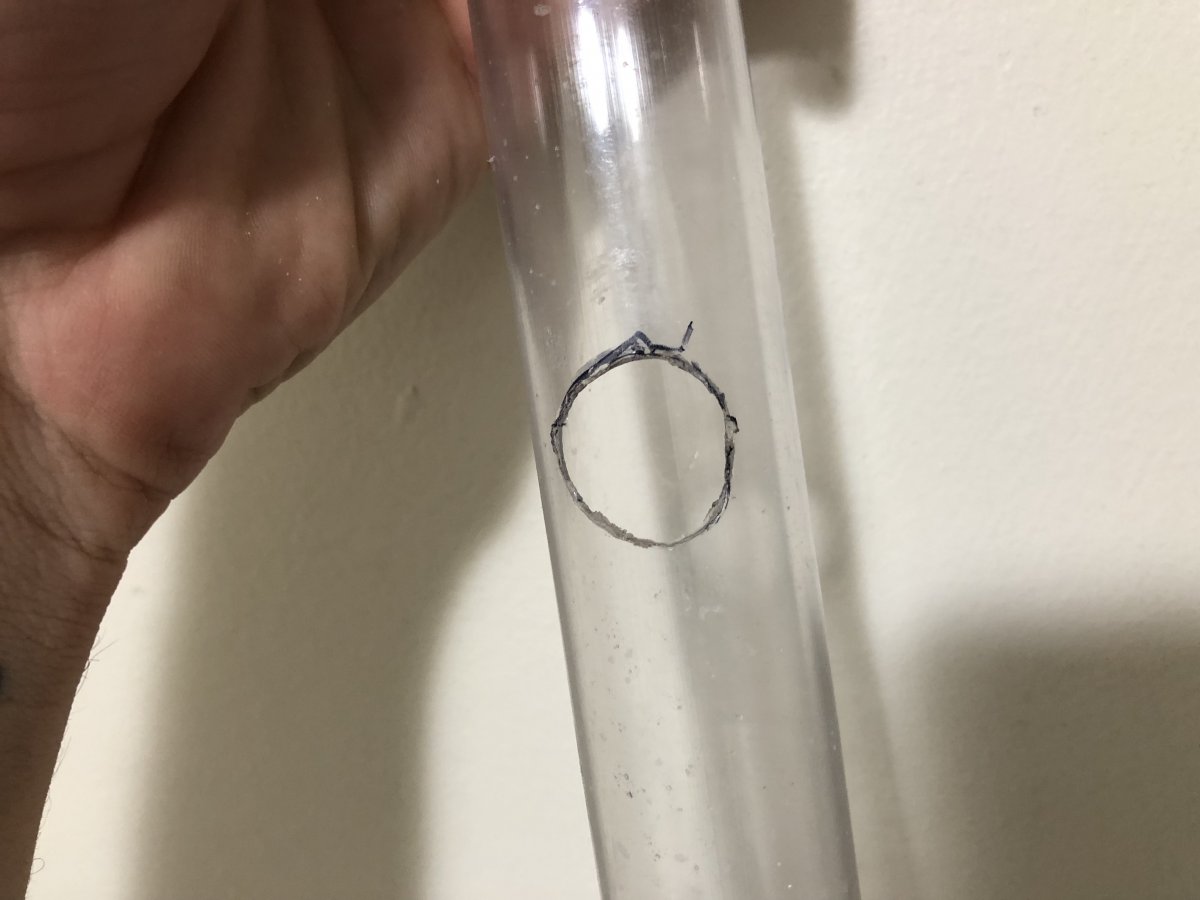

Step 3:

Carefully drill a hole in the side of the Polycarbonate tubing for the 1/2” ID vinyl tubing you bent or use a Dremel to make the hole. Go about 6” up from the base of the Skimmer (angle cut end). This tube will allow water to circulate as the air stone pulls the water in instead of the air stone working against itself. After you drill the hole, fit the vinyl tubing to check the placement. Make sure that the tube doesn’t protrude into the Polycarbonate tube past about 1/4”. Once the vinyl tube fits nice into the Polycarbonate tube, use two zip ties to hold the tube in place. Then use the silicone to seal around the vinyl tube going into the Polycarbonate tube.

Step 4:

The acrylic tube is optional for this step but is preferred. Now take the rubber stopper and push the 1/4” acrylic tub into the base of the stopper (only need about 1/4” pushed into the stopper). Then place the stopper in the top of the Polycarbonate tube. Now get an idea on how long you want the acrylic rod to be when it has the air stone on the end. Should be around 11-12” long. I attached the air stone to the acrylic rod for this step. I used a 3/8” piece of tube to attach the air stone to the acrylic rod. You don’t want the air stone sticking out the bottom of the tube. I placed mine right above the slit I cut into the Polycarbonate tube. The air stone should be below the hole you drilled into the Polycarbonate tube. If you chose to not use an acrylic tube, you can use your standard airline tubing. Just take note the air stone floats so you will need to make the tubing longer than you would the acrlic rod.

Step 5:

The mount. I had a scrap piece of black acrylic I used for this. Considering the Polycarbonate tube will be sitting on the bottom of the tank baffle area, you just need to hold the Skimmer in place and prevent it from moving. Using the same technique as bending the vinyl tubing, I bent the top of the piece of acrylic so that it held onto the top of the glass lip of the tank. I then drilled two holes in the side of the acrylic where I then wrapped a zip tie around the Skimmer and through the holes, holding it into place. If you do not have a piece of acrylic, you might have to get creative or find a way to zip tie it to something that won’t move.

Step 6:

Drill a hole in the soda bottle lid to fit the standard airline tubing (drill in center of the lid). Now drill 4-5 other holes around the center airline hole to allow the air to escape.

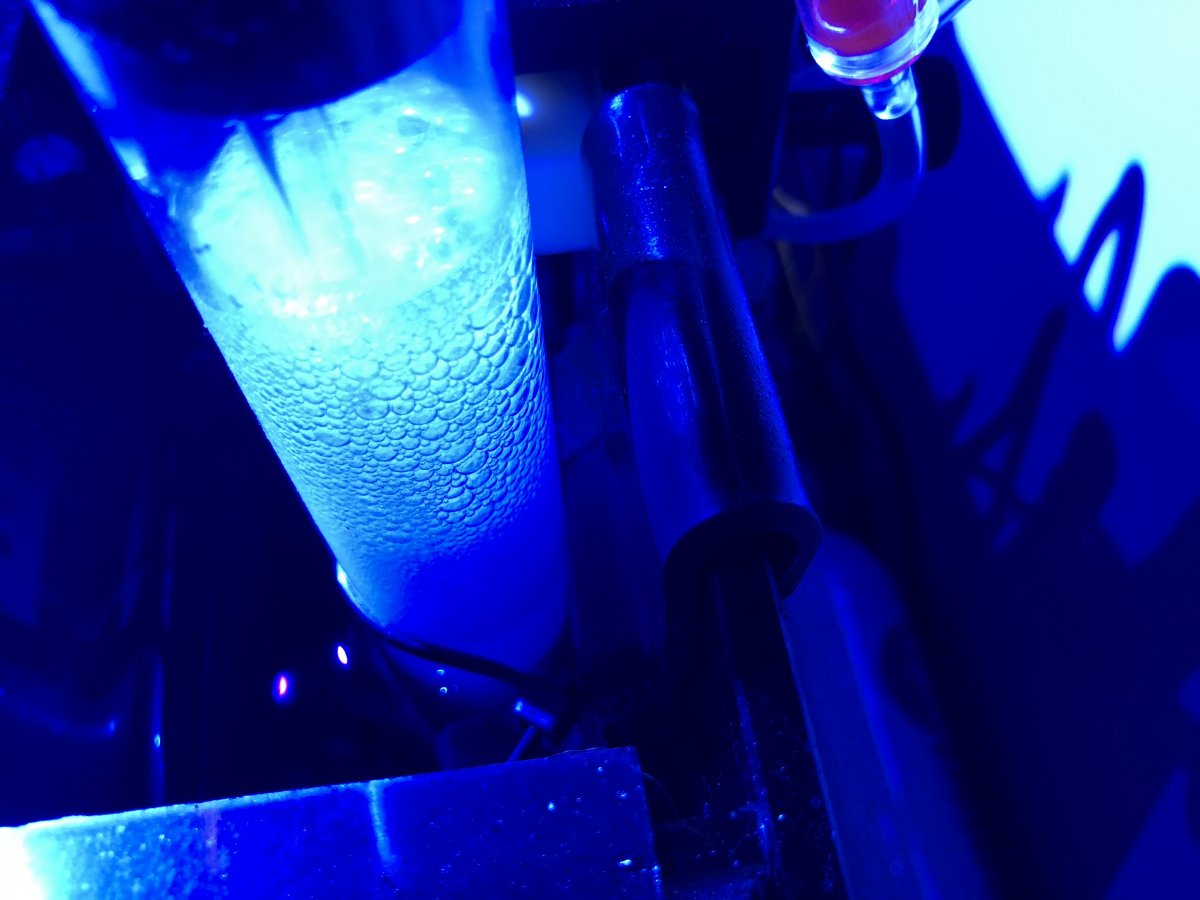

Step 7:

Put the Skimmer together by placing the stopper in the top of the Skimmer with the air stone attached. Now push a 6” piece of airline tubing into the top of the stopper at the same hole that the acrylic rod with the air stone is connected. Now attach one of the airline check valves that came with the pump to the airline you just pushed into the top of the stopper. Now attach a piece of airline tubing to the other hole on the top of the stopper. This line will run to the waste bottle where you drilled all the holes a few minutes ago. Make sure the bottle is below where the Skimmer will be placed. Now mount the Skimmer into place. Hook up the Skimmer to the air pump. Make sure you use both airline outs for the Skimmer. I then turn it on with the output adjusted at its lowest. Slowly increase until the bubbles are about 2” below the stopper. It will take a few days to break in and get everything adjusted correctly. I will tag a separate post where I will include how I made a C02 scrubber work with this. Enjoy!

Parts list:

1) Clear Polycarbonate tube 1 1/8” ID, 1 1/4” OD, 4’ length (smallest length on amazon) $10.00 Prime shipped. Clear Polycarbonate Tubing, 1-1/8" ID, 1-1/4" OD, 1/16" Wall, 4' Length https://www.amazon.com/dp/B000OMFLE4/ref=cm_sw_r_cp_api_1-JBAbYXK2S2H

2) #6 two hole rubber stopper with 5mm holes (3/16”) $5.75 shipped https://www.amazon.com/dp/B01318SOBO/ref=cm_sw_r_cp_api_naKBAbBPMFY3C

3) Uniclife UL-40 4-LPM adjustable air pump $14.98 Prime shipping. https://www.amazon.com/dp/B01EBXI7PG/ref=cm_sw_r_cp_api_udKBAb5HCB98A

4) LEE 2” wood air stone $6.85 Prime shipping.

https://www.amazon.com/dp/B0002APUP8/ref=cm_sw_r_cp_api_GfKBAbP2BDMHV

5) Standard airline, the link is what I purchased for another project but you don’t need $50 worth. Amazon has standard airline for $2.99. https://www.amazon.com/dp/B00TVNL9YI/ref=cm_sw_r_cp_api_EhKBAbMCME8TM

6) zip ties at least 6” length. $2-$3.

7) 1/2” ID vinyl tubing, 1’ ***not silicon, need it stiff. Usually around $1 from any hardware store. Home Depot, Lowe’s, ACE hardware, etc..

8) **Optional 1/4” acrylic tube, $2.49 from BRS. https://www.bulkreefsupply.com/1-4-clear-acrylic-tube-16-long.html

9) scrap piece of acrylic at least 2-3” by 3-4”.

10) Plastic container, I used a Bia drink bottle but soda bottle with a large base are perfect.

11) Aquarium safe silicone $3.99 from Lowe’s or Home Depot.

Tools needed or recommended:

1) preferred a table saw but if you don’t have one, go to a friends house or use a Dremel saw.

2) drill bits or dremel tool

3) something to cut zip ties

4) propane torch or butane torch or grill style lighter

5) oven mit

6) needle nose pliers preferably

I recommend everyone to be safe around power tools and torches or lighters. I won’t be healed liable for your use of the tools listed above.

Step #1:

As previously mentioned, I designed this for a Nuvo tank but, some changes can be made on this step for other tanks. For Nuvo tanks, cut a piece of the Polycarbonate tubing to a length of 14” (reefglass has theirs at 11.5”, more contact the better). The goal is to have 5” of tube above the water line. This Nuvo 20 has a depth 8.5” of water in the area where the Skimmer will be placed. After you have cut a piece of Polycarbonate tubing, make another cut on the bottom at about a 45-30 degree angle but do not but across the whole tube. See the picture. The goal was to set the bottom of the tube on the bottom of the area where the Skimmer would be placed. The angle cut allows water to enter the Skimmer and the flat corner allows it to sit flat.

Step 2:

Cut a small piece of 1/2” ID vinyl tubing about 5-6” in length. Now, use a pair of pliers to hold one end of the tubing. Take a torch or other heating equipment and heat the tip of the tubing slowly, about 1.5” inches worth. You will start to see the tube becoming limp. When it is limp, using an oven mit on your hands, bend the tip of the tube at a 90 degree angle and hold it in place. Make sure that the tube does not pinch. When it cooled enough for me to handle it, I use my fingers to pinch the bend slightly to make sure I could allow as much water through as possible. Another trick I did is, while holding the 90 degree angle in place and pinching the bend, place it under cold water and this will quickly hold its shape. Once you the 90 degree bend, proceed to heat the shaft up to the bend. Once it is limp, make it as straight as you can. See pictures.

Step 3:

Carefully drill a hole in the side of the Polycarbonate tubing for the 1/2” ID vinyl tubing you bent or use a Dremel to make the hole. Go about 6” up from the base of the Skimmer (angle cut end). This tube will allow water to circulate as the air stone pulls the water in instead of the air stone working against itself. After you drill the hole, fit the vinyl tubing to check the placement. Make sure that the tube doesn’t protrude into the Polycarbonate tube past about 1/4”. Once the vinyl tube fits nice into the Polycarbonate tube, use two zip ties to hold the tube in place. Then use the silicone to seal around the vinyl tube going into the Polycarbonate tube.

Step 4:

The acrylic tube is optional for this step but is preferred. Now take the rubber stopper and push the 1/4” acrylic tub into the base of the stopper (only need about 1/4” pushed into the stopper). Then place the stopper in the top of the Polycarbonate tube. Now get an idea on how long you want the acrylic rod to be when it has the air stone on the end. Should be around 11-12” long. I attached the air stone to the acrylic rod for this step. I used a 3/8” piece of tube to attach the air stone to the acrylic rod. You don’t want the air stone sticking out the bottom of the tube. I placed mine right above the slit I cut into the Polycarbonate tube. The air stone should be below the hole you drilled into the Polycarbonate tube. If you chose to not use an acrylic tube, you can use your standard airline tubing. Just take note the air stone floats so you will need to make the tubing longer than you would the acrlic rod.

Step 5:

The mount. I had a scrap piece of black acrylic I used for this. Considering the Polycarbonate tube will be sitting on the bottom of the tank baffle area, you just need to hold the Skimmer in place and prevent it from moving. Using the same technique as bending the vinyl tubing, I bent the top of the piece of acrylic so that it held onto the top of the glass lip of the tank. I then drilled two holes in the side of the acrylic where I then wrapped a zip tie around the Skimmer and through the holes, holding it into place. If you do not have a piece of acrylic, you might have to get creative or find a way to zip tie it to something that won’t move.

Step 6:

Drill a hole in the soda bottle lid to fit the standard airline tubing (drill in center of the lid). Now drill 4-5 other holes around the center airline hole to allow the air to escape.

Step 7:

Put the Skimmer together by placing the stopper in the top of the Skimmer with the air stone attached. Now push a 6” piece of airline tubing into the top of the stopper at the same hole that the acrylic rod with the air stone is connected. Now attach one of the airline check valves that came with the pump to the airline you just pushed into the top of the stopper. Now attach a piece of airline tubing to the other hole on the top of the stopper. This line will run to the waste bottle where you drilled all the holes a few minutes ago. Make sure the bottle is below where the Skimmer will be placed. Now mount the Skimmer into place. Hook up the Skimmer to the air pump. Make sure you use both airline outs for the Skimmer. I then turn it on with the output adjusted at its lowest. Slowly increase until the bubbles are about 2” below the stopper. It will take a few days to break in and get everything adjusted correctly. I will tag a separate post where I will include how I made a C02 scrubber work with this. Enjoy!