Just when I thought I had decided that my next challenge would be a reef tank instead of a planted discus tank . . .

Regardless which way I eventually go, both your examples are inspiring, @Broadfield

Regardless which way I eventually go, both your examples are inspiring, @Broadfield

IMG_1421

IMG_1421 IMG_1413

IMG_1413 IMG_1411

IMG_1411 IMG_1412

IMG_1412 IMG_1415

IMG_1415 IMG_1416

IMG_1416 IMG_1417

IMG_1417 IMG_1420

IMG_1420 IMG_1424

IMG_1424 IMG_1418

IMG_1418 IMG_1419

IMG_1419 IMG_1425

IMG_1425 IMG_1427

IMG_1427 IMG_1428

IMG_1428 IMG_1431

IMG_1431 IMG_1434

IMG_1434 IMG_1433

IMG_1433

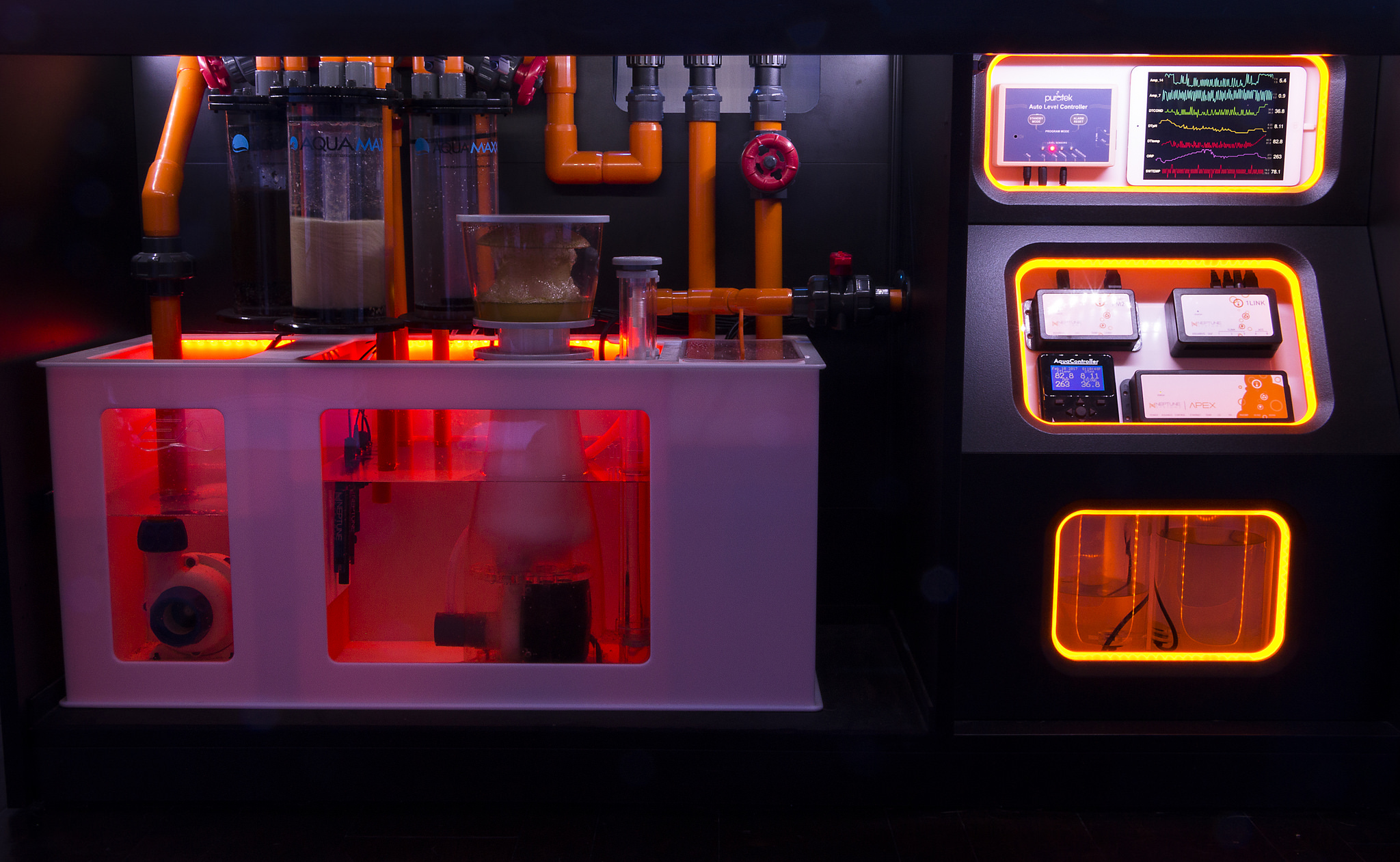

IMG_4609

IMG_4609 FTS

FTS FTS + Stand

FTS + Stand IMG_6030

IMG_6030 IMG_3820

IMG_3820 IMG_3819

IMG_3819 IMG_3825

IMG_3825 IMG_3826

IMG_3826 IMG_3899

IMG_3899 IMG_3887

IMG_3887 IMG_3937

IMG_3937 IMG_3978

IMG_3978