The most Askoll motor blocks such as the Fluval SP4 and 6 have built in circuitry. It’s not new they have been doing this for a while. I think most manufacturers have decided to add a power supply and controller to make it low voltage and controllable . The issue with the Sicce SDC is that they are not the smoothest running pumps unlike the other well known Asian manufacturers . The Fluval on the other hand is a very quiet and doesn’t have the vibration issues as the Sicce.Ok yep, I definitely hear you on the traditional style of bidirectional 'dumb' reluctance blocks and concede their inherent lack of efficiency. But I do have to disagree on the point about not being able to take advantage of a directional impeller in a bump start or electronic start design. (Btw the pump whose impeller I posted a pic of is definitely a 2 pole reluctance motor and does not have a bump start- it's electronic). If we go with your assertion that there's no advantage to using a directional impeller on a fixed speed AC pump - assuming you can bump it or electronically start it in 1 direction, why does nearly every pump that turns in 1 direction use such an impeller? And I'll take it one step further and argue that a DC pump impeller and volute, while optimized, are less efficient in their peak efficiency point than a comparable fixed speed impeller and volute precisely because they have to be somewhat of a compromise across the whole range of the pump's operating rpm.

The ADV pumps are actually the first 'AC' pumps I suspected might be a bldc motor with on board controls- hence my keen interest in them. Do you think the onboard bldc controls will last as long as a traditional reluctance block would? I'd consider giving them a trial run if the potted components are going to last for 5+ years.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BRS - what's up with Sicce Syncra ADV pumps?

- Thread starter don_chuwish

- Start date

-

- Tags

- syncra adv

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

Exactly. The askoll is a perfect example of a 2 pole AC driven reluctance motor with electronic directional start circuitry and an optimized impeller/volute that is smooth and quiet.The most Askoll motor blocks such as the Fluval SP4 and 6 have built in circuitry. It’s not new they have been doing this for a while. I think most manufacturers have decided to add a power supply and controller to make it low voltage and controllable . The issue with the Sicce SDC is that they are not the smoothest running pumps unlike the other well known Asian manufacturers . The Fluval on the other hand is a very quiet and doesn’t have the vibration issues as the Sicce.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

I hope I didn't give the impression there was no advantage to a directional impeller. The issue as I see it is if the the improved performance is worth the trade off in reliability or noise.If we go with your assertion that there's no advantage to using a directional impeller on a fixed speed AC pump - assuming you can bump it or electronically start it in 1 direction, why does nearly every pump that turns in 1 direction use such an impeller?

To the best of my knowledge there are 4 common ways to do directional start in a reluctance motor. The most basic is the bump start. You can add parking magnets into the stator to force the rotor to stop in a known position where it will start in the correct direction. You can use at least 4 poles with an offset in how they are physically installed so they are not evenly spaced or you can use an electronic controller which we typically call DC pumps. I will admit it's been over 10 years since I did design work for a motor shop so it is possible something new was developed. I've tried keeping up with the technology but it isn't always the easiest now that I've moved almost exclusively to high voltage power distribution and protection.

This I will completely agree with. Strictly from a pump perspective, a well designed single speed pump will outperform a variable speed pump design. A true AC motor operated at max speed will always be more efficient than a DC (or AC variable speed) motor. As soon as you introduce an electronic speed controller to a motor you lose at least 3% to 7% efficiency and up to around 20% for a poorly designed system.And I'll take it one step further and argue that a DC pump impeller and volute, while optimized, are less efficient in their peak efficiency point than a comparable fixed speed impeller and volute precisely because they have to be somewhat of a compromise across the whole range of the pump's operating rpm.

I do still do protection settings for our larger water pump motors (typically 400hp through 1800hp). We strive to use the most energy efficient pumps as possible for the obvious cost savings. For our most efficient systems we either need to use a soft start, VFD, or a mechanical bypass to allow the induction motors to get up to speed without stalling. This issue would be magnified due to the poor starting torques on reluctance motors. If the gain in efficiency isn't worth this additional cost, we will use a less efficient pump design. These same considerations come into play with hobbyist pumps they just aren't custom designed. What is changing rapidly is how cheap the electronics have become. A speed control circuit that cost $100+ as little as 5 years ago now sells for under $5.

I hope I didn't give the impression there was no advantage to a directional impeller. The issue as I see it is if the the improved performance is worth the trade off in reliability or noise.

To the best of my knowledge there are 4 common ways to do directional start in a reluctance motor. The most basic is the bump start. You can add parking magnets into the stator to force the rotor to stop in a known position where it will start in the correct direction. You can use at least 4 poles with an offset in how they are physically installed so they are not evenly spaced or you can use an electronic controller which we typically call DC pumps. I will admit it's been over 10 years since I did design work for a motor shop so it is possible something new was developed. I've tried keeping up with the technology but it isn't always the easiest now that I've moved almost exclusively to high voltage power distribution and protection.

This I will completely agree with. Strictly from a pump perspective, a well designed single speed pump will outperform a variable speed pump design. A true AC motor operated at max speed will always be more efficient than a DC (or AC variable speed) motor. As soon as you introduce an electronic speed controller to a motor you lose at least 3% to 7% efficiency and up to around 20% for a poorly designed system.

I do still do protection settings for our larger water pump motors (typically 400hp through 1800hp). We strive to use the most energy efficient pumps as possible for the obvious cost savings. For our most efficient systems we either need to use a soft start, VFD, or a mechanical bypass to allow the induction motors to get up to speed without stalling. This issue would be magnified due to the poor starting torques on reluctance motors. If the gain in efficiency isn't worth this additional cost, we will use a less efficient pump design. These same considerations come into play with hobbyist pumps they just aren't custom designed. What is changing rapidly is how cheap the electronics have become. A speed control circuit that cost $100+ as little as 5 years ago now sells for under $5.

Yep agreed. We are definitely on the same page now. I believe Elio Marioni actually patented a a system for starting 2 pole reluctance motors.

Its over my head, but I get the gist of it. I think this link is the patent, but idk for sure cause he has a gazillion patents lol. If I remember the abstract correctly its a pretty elegant and ingenious design.

https://patents.google.com/patent/EP0574823A2

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

I had no idea that Askoll held the patent for this. Very cool!Yep agreed. We are definitely on the same page now. I believe Elio Marioni actually patented a a system for starting 2 pole reluctance motors.

Its over my head, but I get the gist of it. I think this link is the patent, but idk for sure cause he has a gazillion patents lol. If I remember the abstract correctly its a pretty elegant and ingenious design.

https://patents.google.com/patent/EP0574823A2

It is a fantastic design. I haven't come across it professionally since most of the reluctance motors I deal with are 3 phase but I am familiar with it. It combines the offset windings I mentioned in the previous post with a simple electronic controller to produce a directional soft start. This design has 2 big advantages. The control signal for the electronics comes from a sensing device mounted in the motor so no outside input or control is needed. It also removes the offset windings from the circuit once up to speed which reduces the vibration in the motor when running. The only downside I'm aware of is a slight loss of efficiency from magnetic interaction with the offset starting windings.

I can't help but wonder what a Triac cost in 1992 when the patent was filed as opposed to what it costs today. I'm guessing that was a $100+ control circuit when it was designed that can now be made for under $2.

We build permanent magnet motors, and we buy 250kw fancy vector controlled motor drives for $10k. Imagine what that would have cost 10 years ago!I had no idea that Askoll held the patent for this. Very cool!

It is a fantastic design. I haven't come across it professionally since most of the reluctance motors I deal with are 3 phase but I am familiar with it. It combines the offset windings I mentioned in the previous post with a simple electronic controller to produce a directional soft start. This design has 2 big advantages. The control signal for the electronics comes from a sensing device mounted in the motor so no outside input or control is needed. It also removes the offset windings from the circuit once up to speed which reduces the vibration in the motor when running. The only downside I'm aware of is a slight loss of efficiency from magnetic interaction with the offset starting windings.

I can't help but wonder what a Triac cost in 1992 when the patent was filed as opposed to what it costs today. I'm guessing that was a $100+ control circuit when it was designed that can now be made for under $2.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

We used to pay almost $4k for 15kw vector drive controllers back in the mid 90's. Now they are well under $1k and have a ton more features.We build permanent magnet motors, and we buy 250kw fancy vector controlled motor drives for $10k. Imagine what that would have cost 10 years ago!

Did they have auto-tune that actually works like the Yaskawa drives?We used to pay almost $4k for 15kw vector drive controllers back in the mid 90's. Now they are well under $1k and have a ton more features.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

I've never used a Yakawa drive. I will say that I have yet to find an inertia based auto-tune that I thought works well. But again, I've been removed from much of that for the last 10 or so years, so it may have improved.Did they have auto-tune that actually works like the Yaskawa drives?

The only one that works on our motors is Yaskawa. We have a control systems PHD for all the other drives.I've never used a Yakawa drive. I will say that I have yet to find an inertia based auto-tune that I thought works well. But again, I've been removed from much of that for the last 10 or so years, so it may have improved.

That would be super cool, or maybe BRS doesn’t have to do it. They could just Skype, nerd out, record it and put it on YouTube.This has been a fascinating and informative thread.

I thing BRStv should have an episode about pumps with @Brew12 and @rockskimmerflow on the show

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

And all 18 people who actually care about the topic that much could watch.This has been a fascinating and informative thread.

I thing BRStv should have an episode about pumps with @Brew12 and @rockskimmerflow on the show

Let's face it. Most hobbyists just want a pump to pump water. They may look at efficiencies but they don't care enough about the concepts we discusses to see how it applies to them. I could see them liking a BRS video testing the efficiencies, but they aren't going to watch a video of a technical discussion on why the results are what they are.

I agree ! But perhaps also educated the basics of a flow curve so that when the purchase a pump they won’t be disappointed and which pump might suit their applications. How many times do we see customers purchasing a pump and are disappointed by the flow rate!

Anyhow I think BRS should consider something along this line.

@randyBRS #AskBRStv

Anyhow I think BRS should consider something along this line.

@randyBRS #AskBRStv

I did a bit of numbers game today and this is what annoys me.

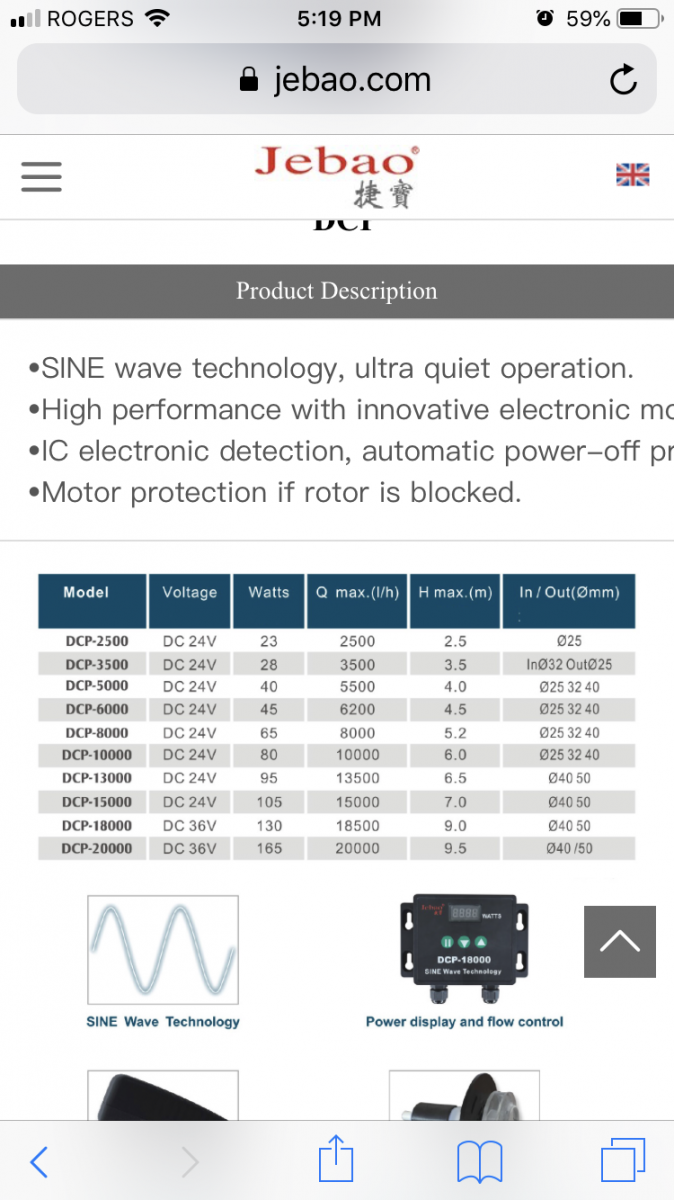

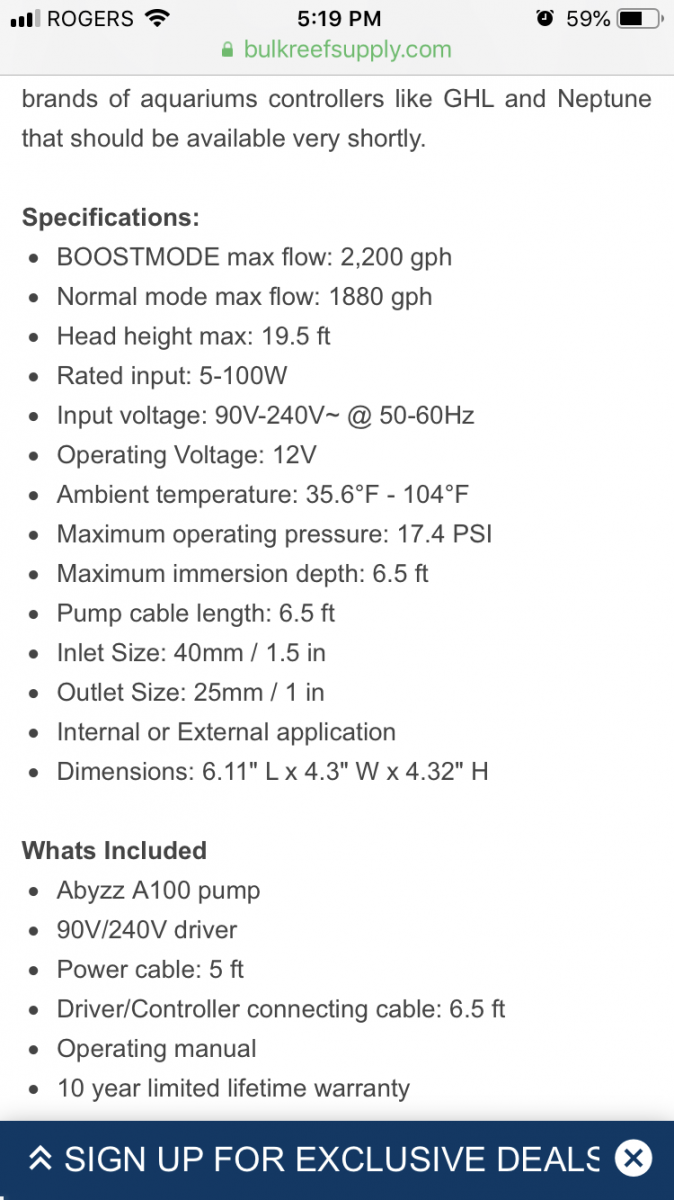

Here is a spec sheet of Jebao and Abyzz.

The Jebao on paper outperforms the Abyzz, but at what cost reliability, maintenance eg. (tighter tolerances between stator and rotor) or simply inaccurate ratings. BTW the Abyzz uses neodymium magnets.

Here are some specs

Here is a spec sheet of Jebao and Abyzz.

The Jebao on paper outperforms the Abyzz, but at what cost reliability, maintenance eg. (tighter tolerances between stator and rotor) or simply inaccurate ratings. BTW the Abyzz uses neodymium magnets.

Here are some specs

- Joined

- Jan 3, 2018

- Messages

- 833

- Reaction score

- 699

My experience is in selecting industrial pumps from a process standpoint. I have always suspected that the power improvement of aquarium DC pumps comes largely from their ability to spin at slower speeds rather than any improved electrical efficiency. Aquarium applications are relatively high flow and low head which strongly favors 1800 or 1200 rpm pumps with larger diameter impellers. A lower speed pump will generally have much better hydraulic efficiency. I would say a 40-70% efficiency is typical of a 3600 rpm industrial pump compared to 80-90% for a 1200-1800 RPM pump. It would not surprise me if these ADV pumps are simply using a different means to reduce the pump speed as I think has been suggested. Lower speed also reduces the noise.

In practical industrial applications that's likely true. However, it's always been my understanding that higher rotational speed actually increases hydraulic efficiency in a centrifugal pump (just the pump, not necessarily the electric drive motor). High flow/low head generally takes a mixed or axial flow impeller/screw with a large intake and outlet aperture. Totally agree on the lower rpm reducing noise potential. The SDC and ADV pumps should actually have higher rpms since they aren't sporting significantly large diameter impellers compared to other units and yet they are spec'd quite favorably. They are spec'd to produce relatively high head pressure vs comparably sized AC models and higher rpms are the only way to do it given similar impeller diameter - they don't appear to have noticeably larger volutes/impellers than any other common aquarium pumps.My experience is in selecting industrial pumps from a process standpoint. I have always suspected that the power improvement of aquarium DC pumps comes largely from their ability to spin at slower speeds rather than any improved electrical efficiency. Aquarium applications are relatively high flow and low head which strongly favors 1800 or 1200 rpm pumps with larger diameter impellers. A lower speed pump will generally have much better hydraulic efficiency. I would say a 40-70% efficiency is typical of a 3600 rpm industrial pump compared to 80-90% for a 1200-1800 RPM pump. It would not surprise me if these ADV pumps are simply using a different means to reduce the pump speed as I think has been suggested. Lower speed also reduces the noise.

So I’m running the ADV 5.5 on my tank, throttled back about 10%. According to my Apex, I’m drawing a mere 33 watts. Runs quietly too, comparable to a Fluval SP noise wise... or should I say, lack there of!

Needless to say, I’m quite happy with my pump and it’s AC reliability.

Needless to say, I’m quite happy with my pump and it’s AC reliability.

The only DC pump I’ve run/tested was a Tunze 1073.050 and I’d say it’s similar noise wise. I owned a Vectra M1 but never ran it... ended up selling it because I wanted AC reliability. Sold the Tunze because I wanted more flow.

Last edited:

Similar threads

- Price: $30 - $350

- Shipping Available

- Replies

- 19

- Views

- 566

- Replies

- 8

- Views

- 409

- Price: $160

- Shipping Available

- Replies

- 4

- Views

- 212

- Price: $65 Shipped

- Shipping Available

- Replies

- 2

- Views

- 215

- Price: $240-$375

- Shipping Available

- Replies

- 1

- Views

- 263