Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Canopy and Stand Build for 42 Gallon Hex Tank

Thank you, but I have a good day job that would be hard to beat. I am a maintenance technician for ion implanters in a semiconductor factory.Man, this is an awesome thread...you should do this for a living!! what a great build.

Not much has been happening lately. Everything has been going smoothly in the tank. We lost power today during a storm. The power company came out and changed a fuse on the transformer up on the pole. They said it was lightning that caused it. So far the only thing we lost was a PC4 power bar that was in the garage. I replaced it with my backup and reprogrammed the channels on the backup to take the place of the the PC4 that was replaced. The PC4 will not communicate with either my Archon or the RKE, but myReef will see it when it is hooked to the SID. You can also manually turn the outputs on or off. I re flashed the firmware, but still no help. I guess I will have to get a new PB4 as a backup. It could have been a lot worse. I may find other things around the house that are not working, but so far that is the only thing I have noticed. The power was only out for about three hours thanks to the fast service from PEC. I do have a backup battery for my two MP10's so the tank would be good for several hours.

Last edited:

Some photos taken today of the tank. Not much going on. The candy cane has 4 heads now. I added another fish yesterday. It is a yellow goby, but is still a little shy.

Fresh Salt Water Storage and Mix Tank Control via the Archon

So I wanted a fresh saltwater storage tank and a separate mixing tank that was somewhat automated. My goal was to have the mixing tank ready to replenish the storage tank when it went empty. Then the mixing tank would auto fill with DI ready to add the salt mix for the next batch. I already have the auto water change running. I purchased two 20 gallon Brute trash cans for this. So far I have only put enough holes in the lids to add a full and empty float switch in each tank along with a fill input on the mix tank and a output on the storage tank to the auto water change pump. I will need to get 3 pumps for this. Two for the mixing tank, one for mixing and one for transfer. I will need another for the storage tank to dispense into another container when needed for other than the normal water changes. So far I have programmed and tested the mixing and transfer control using a couple of spare pumps I have. It seems to work correctly so far. To do this I used the relay output and two switch inputs of a SW5 module. I hooked the relay contact outputs to switch input D. This was to latch the output to use as a signal to confirm the water in the mix tank is ready to go. This is accomplished by pressing a push button switch connected to switch input C of the SW5. Input B will also have a push button switch to dispense fresh saltwater from the storage tank on demand into another container.

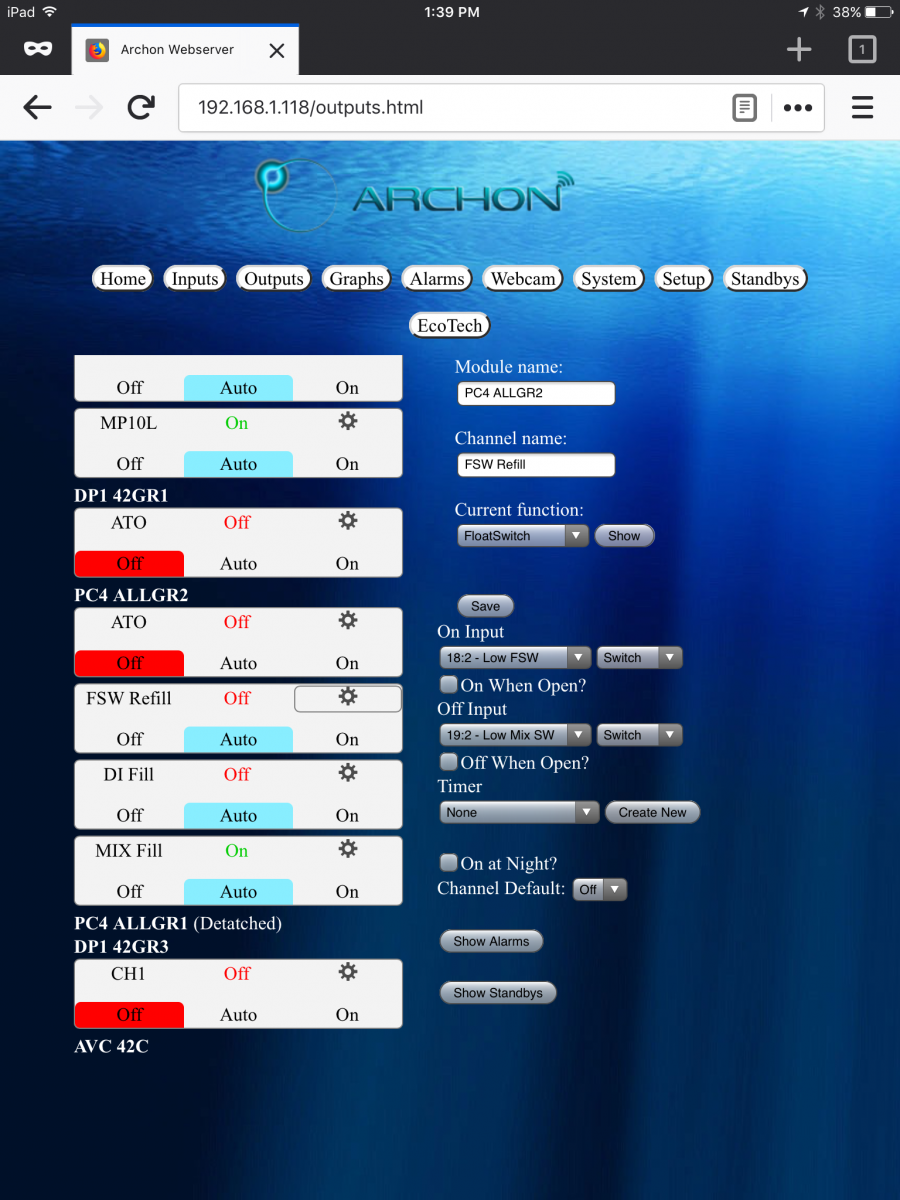

On to the programming. First the transfer pump output programming. It uses the float switch function and uses the empty float on the storage tank to start the pump. The empty float in the mix tank stops the pump. The mix tank empty to full volume is set a little less than the storage tanks full to empty volume.

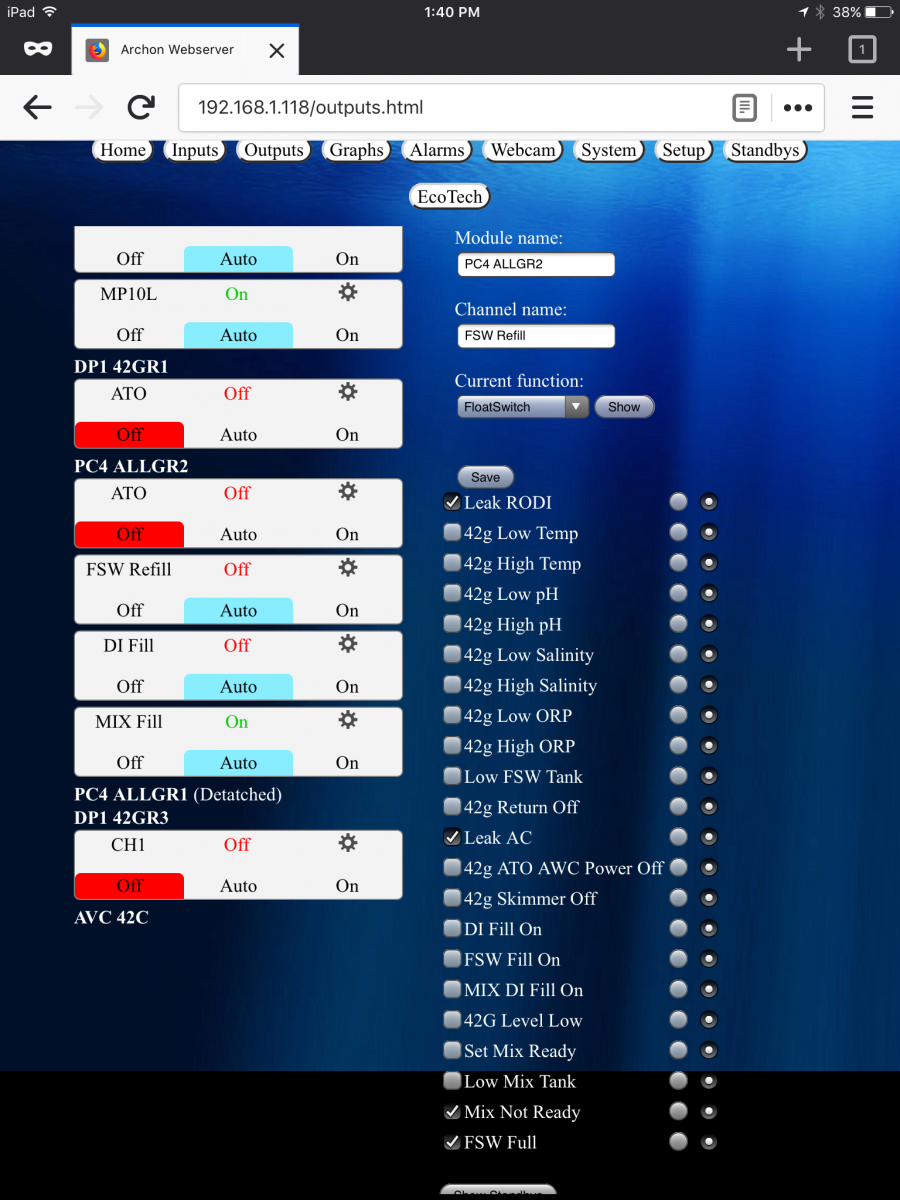

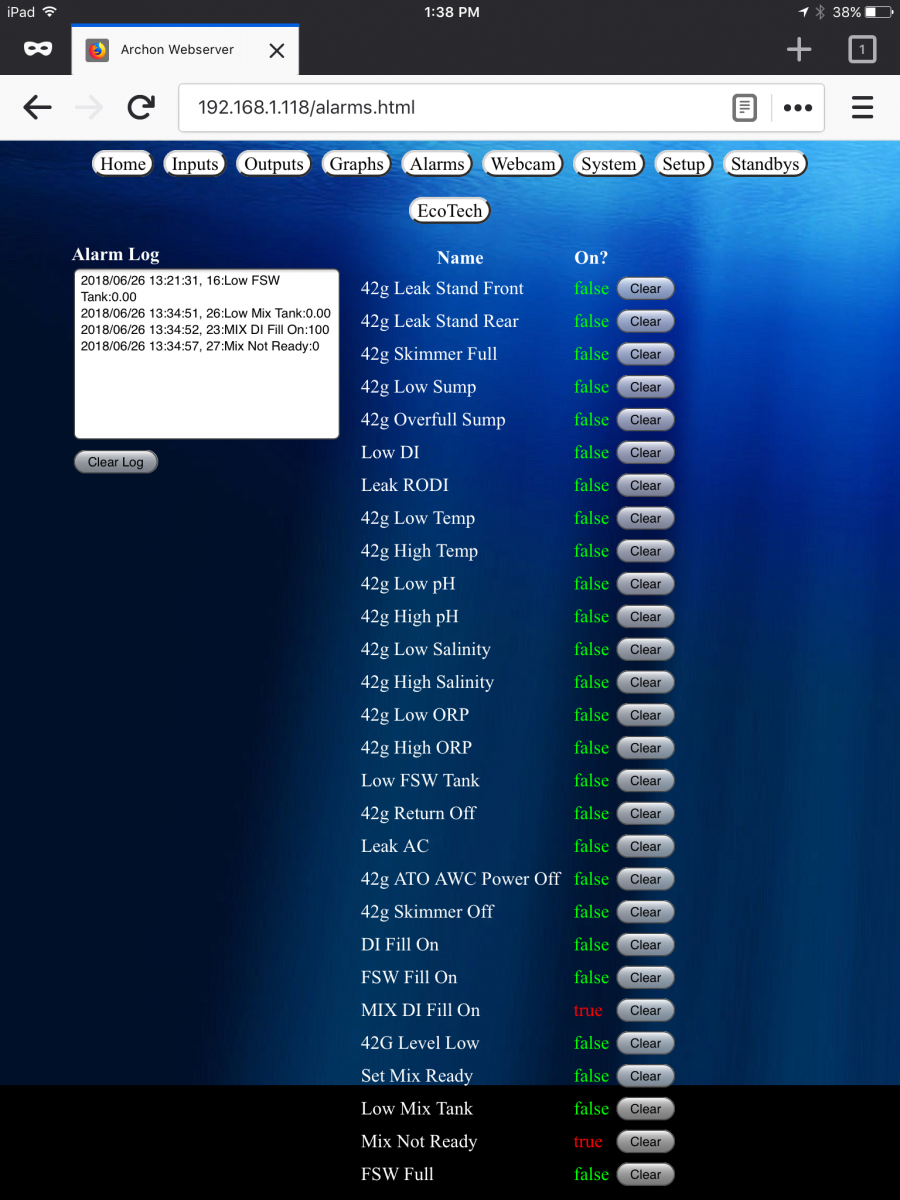

The alarms used on this output are Leak RODI, Leak AC, Mix Not Ready and FSW Full. The two leak detectors are near the storage tanks. If there is a leak I do not want the pump to run since it might be the cause. The FSW Full alarm is set if the storage tank is full. I want it to stop in this condition so it does not overfill the storage tank. Mix Not Ready is an alarm that is set if the ready push button has not been pushed. I plan on adding a SL2 module with a salinity probe also as a precaution in the future.

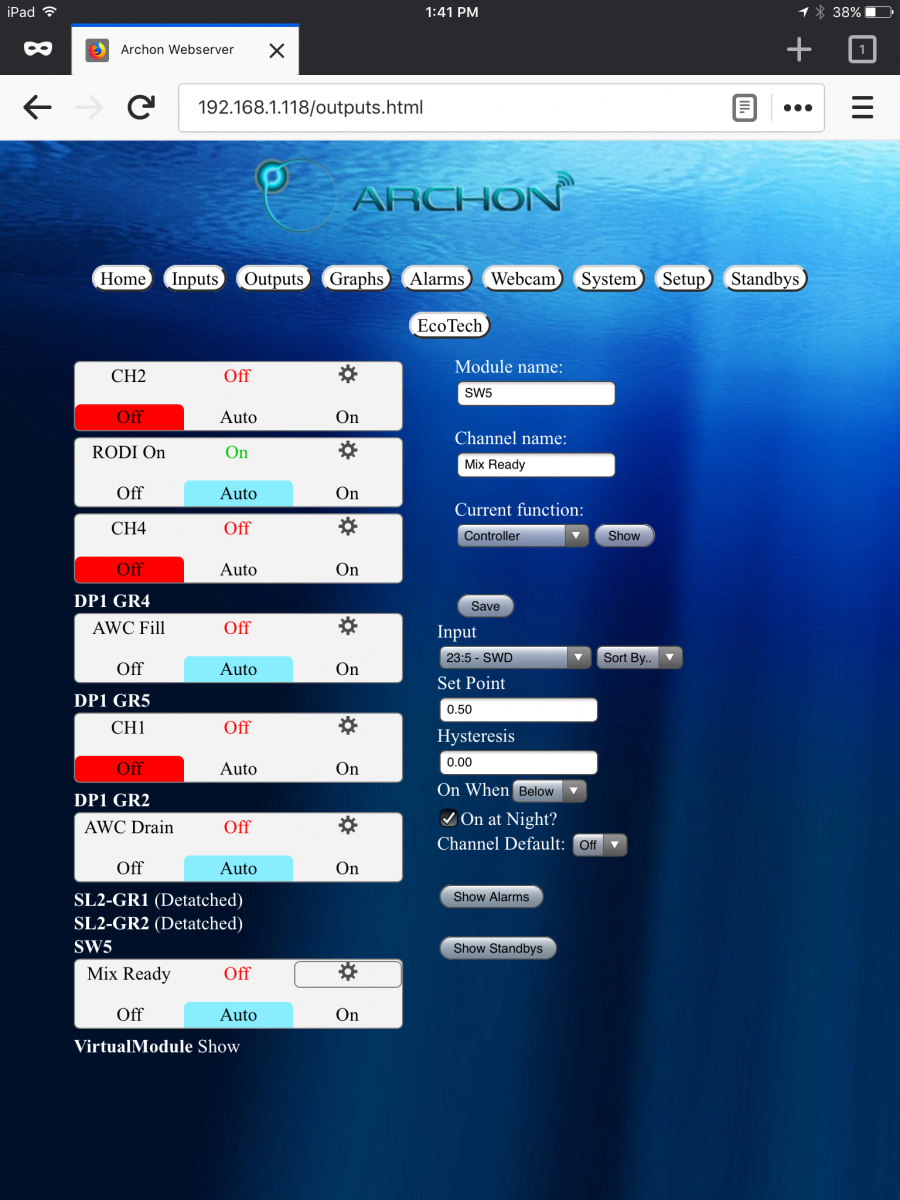

Below is a screenshot of the programming for the SW5 relay output. It uses the controller function and the SW5 D switch input as the trigger. This creates a latch once the relay is activated. I will use an alarm to activate the output. The push button hooked to switch input C will activate the alarm (Set Mix Ready) used to activate the relay causing it to latch on. This output is used to trigger the Mix Not Ready alarm.

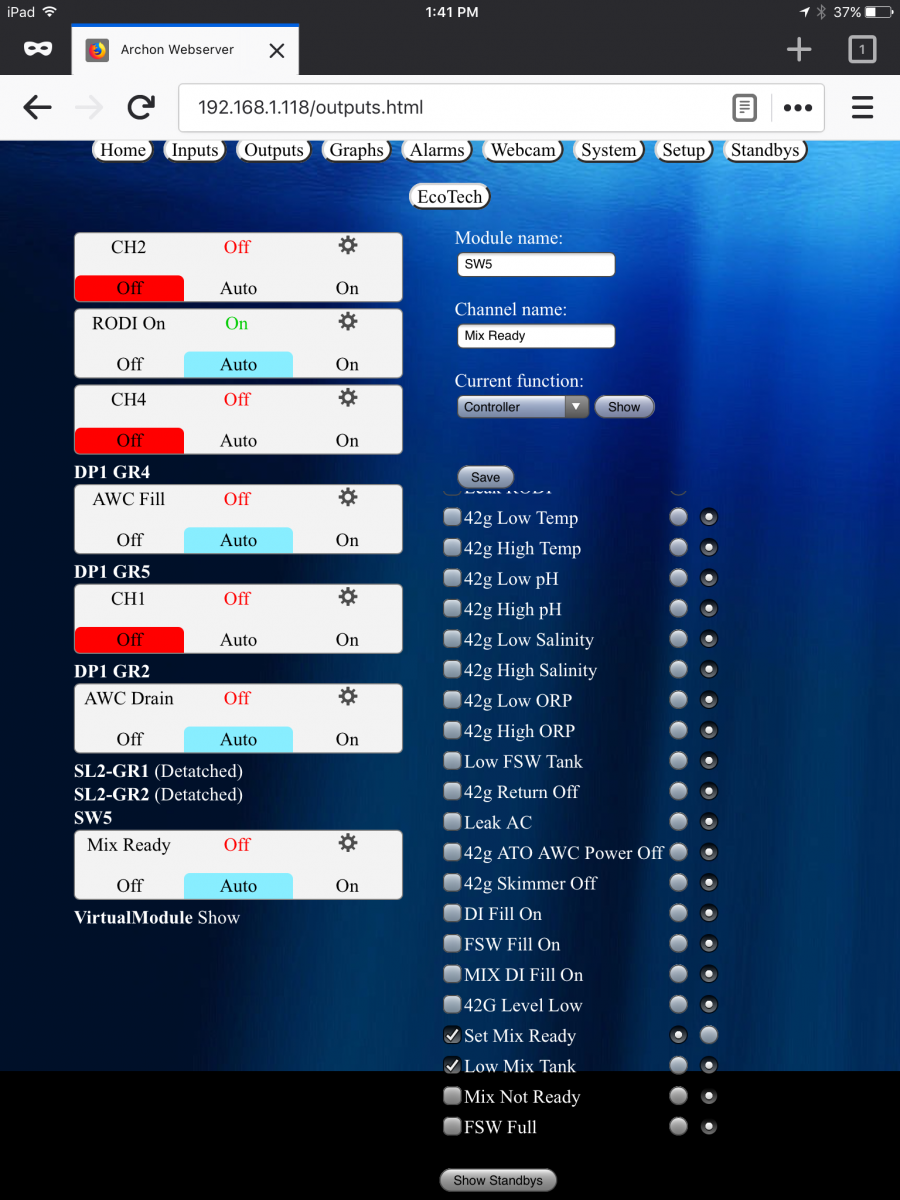

Below is the Alarm settings screenshot for the relay output. Most alarms are used to turn off an output, but the Set Mix Ready is used to turn on the output in this instance. In this case once the alarm is triggered turning on the relay output it latches and it will not matter about the push button switch it will remain on until the Low Mix Tank alarm is triggered turning off the output. I could have made an external circuit to latch a switch input to do the same thing but doing it this way I was trying minimize any DIY hardware.

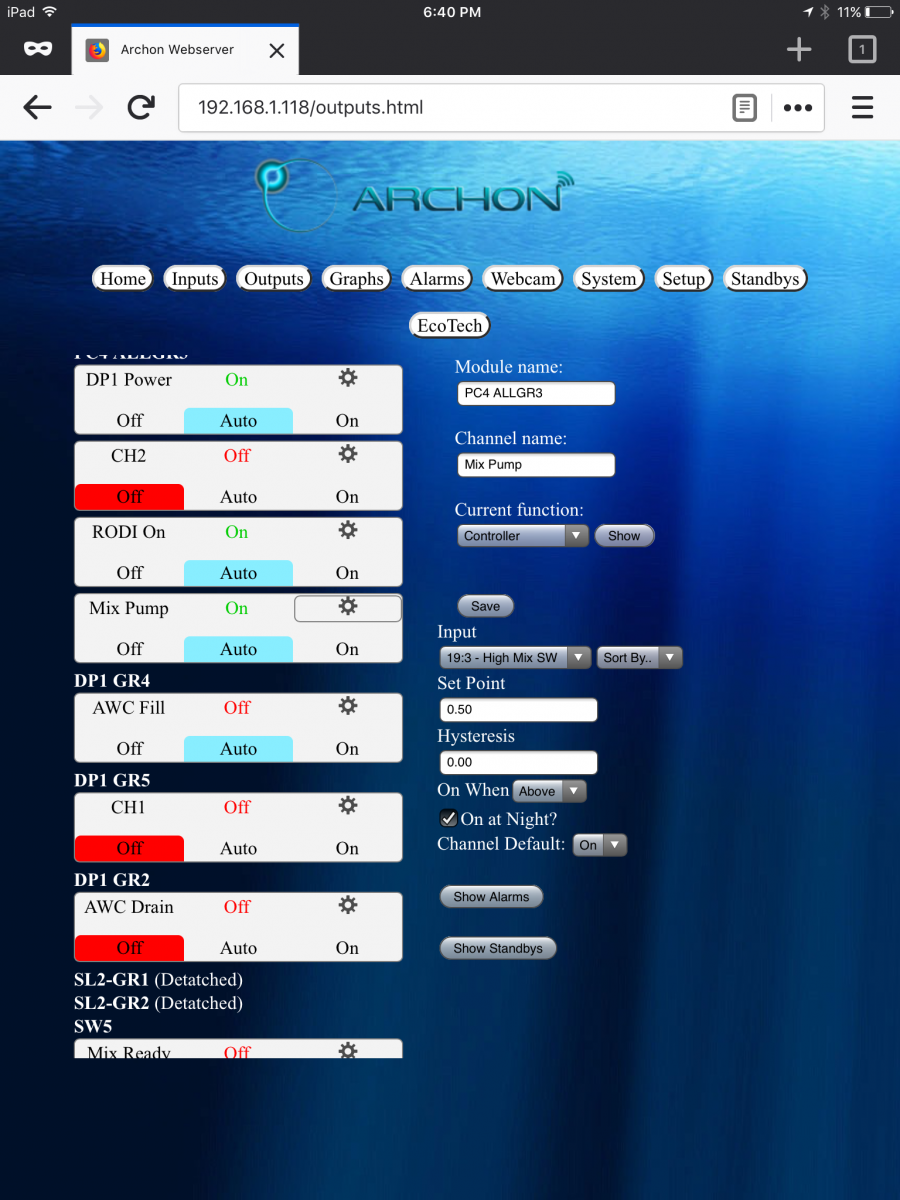

The mix pump programming is in the screenshot below. It uses the controller function using the High Mix switch input to control it. If the tank is full the mix pump will be on otherwise it is turned off. I have no alarms set for this output.

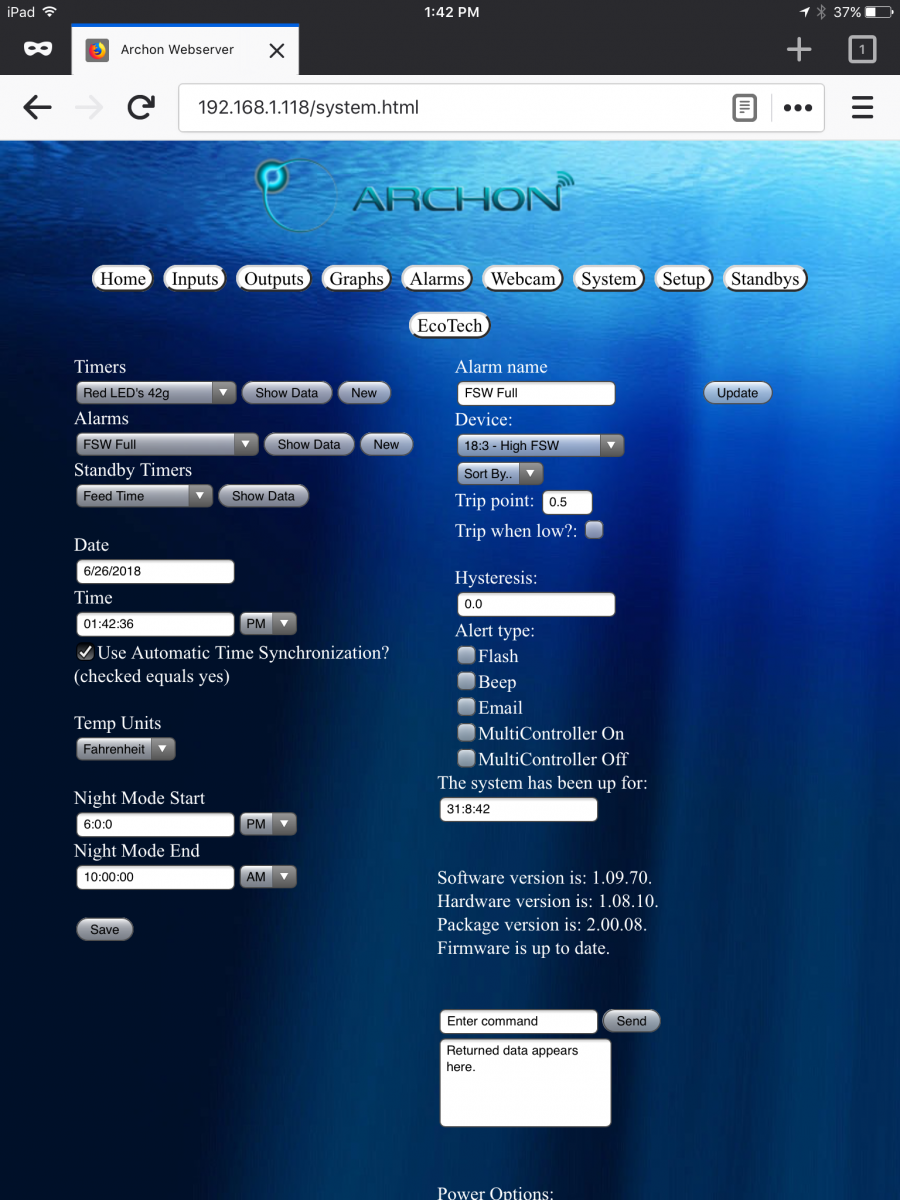

Now on to the alarms needed to do this. Most of the time alarms are used to alert you of an issue with something that is not right, but in this case I am using alarms to help control outputs. The alarm in the screenshot below is used to set the relay output to on when the push button switch it pressed momentarily. It uses the C input of the SW5 to trigger the alarm. No alerts are checked, but it will still show on the alarm log if triggered. More on this later.

The next alarm setup in the screenshot below is Low Mix Tank. This will turn off the relay when the mix tank goes empty. The mix tank empty float also starts the DI fill to refill this tank and since it will no longer have the correct salinity we do not want the transfer tank to run.

The alarm in the screenshot below uses the relay output off condition to trigger. This signals that the water in the mix tank is not ready to use for water changes. If you were not aware of this you can use a output to trigger an alarm along with its normal output function.

The alarm in the screenshot below uses the FSW Full float switch to trigger the alarm. This alarm is used as a backup in the instance the transfer pump were to overfill the fresh salt water storage tank. This is very unlikely to happen but was added just in case it does.

So I will go over the sequence of event. For this both tanks are full and the mix tank is ready. Once the fresh salt water storage tank goes empty two things will happen. One both water change pumps will stop. The transfer pump will turn on providing the mix ready signal is on. Once it is filling the fresh saltwater storage tank both water change pumps will continue their normal programming. The transfer pump will run until the mix tank empty float triggers or the FSW Full alarm is triggered. If the alarm was triggered the pump will continue once this alarm is off. Once the mix tank empty float triggers it starts the mix DI fill output. The mix tank full float switch stops the fill. There is also a float valve for a backup if for some reason the float switch were to fail. Once I add the salt mix to the mix tank and it has had time to completely mix and is the right salinity then I press the push button to set the mix ready relay. I guess I have not wen over the mix tank fill output. It is the same as the DI tank fill output but I will go over it later along with the salt water dispense fill output. For the test I did not have the dispense output programmed. More on this later. This is too large to do in one post.

Below is a screenshot of the alarm log after a empty fresh saltwater tank empty event.

So I wanted a fresh saltwater storage tank and a separate mixing tank that was somewhat automated. My goal was to have the mixing tank ready to replenish the storage tank when it went empty. Then the mixing tank would auto fill with DI ready to add the salt mix for the next batch. I already have the auto water change running. I purchased two 20 gallon Brute trash cans for this. So far I have only put enough holes in the lids to add a full and empty float switch in each tank along with a fill input on the mix tank and a output on the storage tank to the auto water change pump. I will need to get 3 pumps for this. Two for the mixing tank, one for mixing and one for transfer. I will need another for the storage tank to dispense into another container when needed for other than the normal water changes. So far I have programmed and tested the mixing and transfer control using a couple of spare pumps I have. It seems to work correctly so far. To do this I used the relay output and two switch inputs of a SW5 module. I hooked the relay contact outputs to switch input D. This was to latch the output to use as a signal to confirm the water in the mix tank is ready to go. This is accomplished by pressing a push button switch connected to switch input C of the SW5. Input B will also have a push button switch to dispense fresh saltwater from the storage tank on demand into another container.

On to the programming. First the transfer pump output programming. It uses the float switch function and uses the empty float on the storage tank to start the pump. The empty float in the mix tank stops the pump. The mix tank empty to full volume is set a little less than the storage tanks full to empty volume.

The alarms used on this output are Leak RODI, Leak AC, Mix Not Ready and FSW Full. The two leak detectors are near the storage tanks. If there is a leak I do not want the pump to run since it might be the cause. The FSW Full alarm is set if the storage tank is full. I want it to stop in this condition so it does not overfill the storage tank. Mix Not Ready is an alarm that is set if the ready push button has not been pushed. I plan on adding a SL2 module with a salinity probe also as a precaution in the future.

Below is a screenshot of the programming for the SW5 relay output. It uses the controller function and the SW5 D switch input as the trigger. This creates a latch once the relay is activated. I will use an alarm to activate the output. The push button hooked to switch input C will activate the alarm (Set Mix Ready) used to activate the relay causing it to latch on. This output is used to trigger the Mix Not Ready alarm.

Below is the Alarm settings screenshot for the relay output. Most alarms are used to turn off an output, but the Set Mix Ready is used to turn on the output in this instance. In this case once the alarm is triggered turning on the relay output it latches and it will not matter about the push button switch it will remain on until the Low Mix Tank alarm is triggered turning off the output. I could have made an external circuit to latch a switch input to do the same thing but doing it this way I was trying minimize any DIY hardware.

The mix pump programming is in the screenshot below. It uses the controller function using the High Mix switch input to control it. If the tank is full the mix pump will be on otherwise it is turned off. I have no alarms set for this output.

Now on to the alarms needed to do this. Most of the time alarms are used to alert you of an issue with something that is not right, but in this case I am using alarms to help control outputs. The alarm in the screenshot below is used to set the relay output to on when the push button switch it pressed momentarily. It uses the C input of the SW5 to trigger the alarm. No alerts are checked, but it will still show on the alarm log if triggered. More on this later.

The next alarm setup in the screenshot below is Low Mix Tank. This will turn off the relay when the mix tank goes empty. The mix tank empty float also starts the DI fill to refill this tank and since it will no longer have the correct salinity we do not want the transfer tank to run.

The alarm in the screenshot below uses the relay output off condition to trigger. This signals that the water in the mix tank is not ready to use for water changes. If you were not aware of this you can use a output to trigger an alarm along with its normal output function.

The alarm in the screenshot below uses the FSW Full float switch to trigger the alarm. This alarm is used as a backup in the instance the transfer pump were to overfill the fresh salt water storage tank. This is very unlikely to happen but was added just in case it does.

So I will go over the sequence of event. For this both tanks are full and the mix tank is ready. Once the fresh salt water storage tank goes empty two things will happen. One both water change pumps will stop. The transfer pump will turn on providing the mix ready signal is on. Once it is filling the fresh saltwater storage tank both water change pumps will continue their normal programming. The transfer pump will run until the mix tank empty float triggers or the FSW Full alarm is triggered. If the alarm was triggered the pump will continue once this alarm is off. Once the mix tank empty float triggers it starts the mix DI fill output. The mix tank full float switch stops the fill. There is also a float valve for a backup if for some reason the float switch were to fail. Once I add the salt mix to the mix tank and it has had time to completely mix and is the right salinity then I press the push button to set the mix ready relay. I guess I have not wen over the mix tank fill output. It is the same as the DI tank fill output but I will go over it later along with the salt water dispense fill output. For the test I did not have the dispense output programmed. More on this later. This is too large to do in one post.

Below is a screenshot of the alarm log after a empty fresh saltwater tank empty event.

Last edited:

Just ran another test with the refill of fresh salt water tank from the mixing tank without issues. Now to get the plumbing and hardware to make a permanent instalation in the tanks. Right now I am just using a couple of spare pump I had. Also took some photos of the tank today. Have a small issue with some cyano but otherwise looking good.

I took some photos this morning just after the lights came on. This is 8% intensity. I took some photos of full tank and stand.

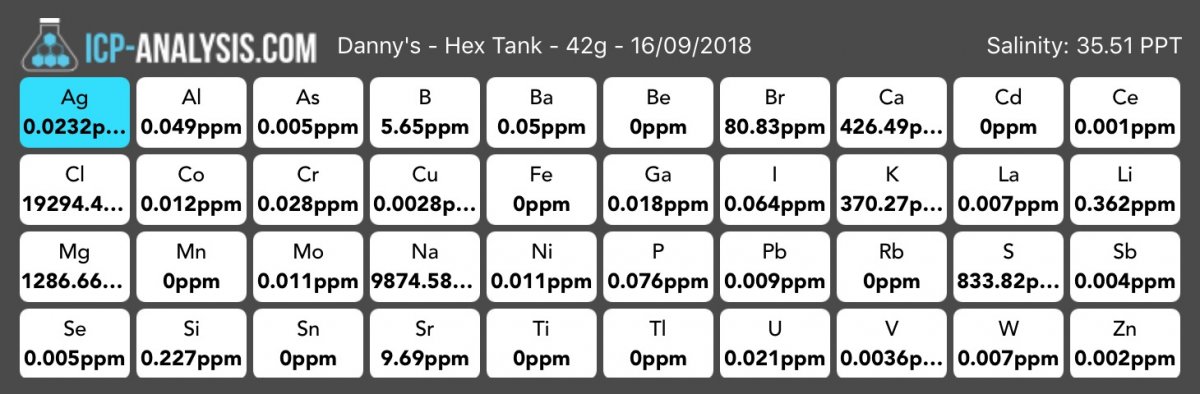

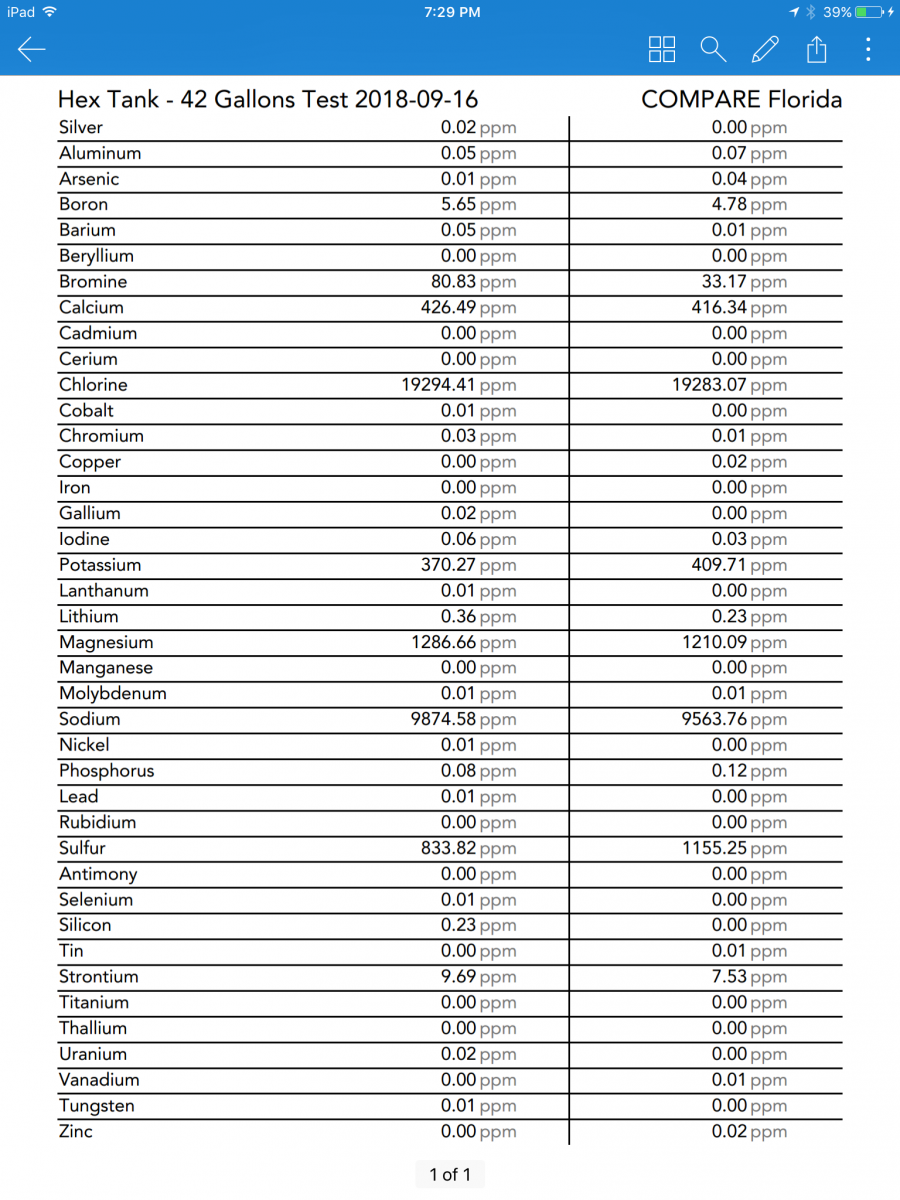

When I was at MACNA I ran across ICP-Anaylisis.com at one of the booths. This company is in the US so no need to send the sample out of the country. They were selling water test kits for $20 at the event. They are normally $30. I got one and sent the sample off Monday and got the results on Friday. The results are listed below. All values are listed in ppm.

On the same day as the sample I tested the following. They do seem close to my results. I did not expect them to match.

Salinity on The Archon .. 34.9ppt

Calcium Nyos kit ............ 435ppm

Magnesium Nyos kit ...... 1305ppm

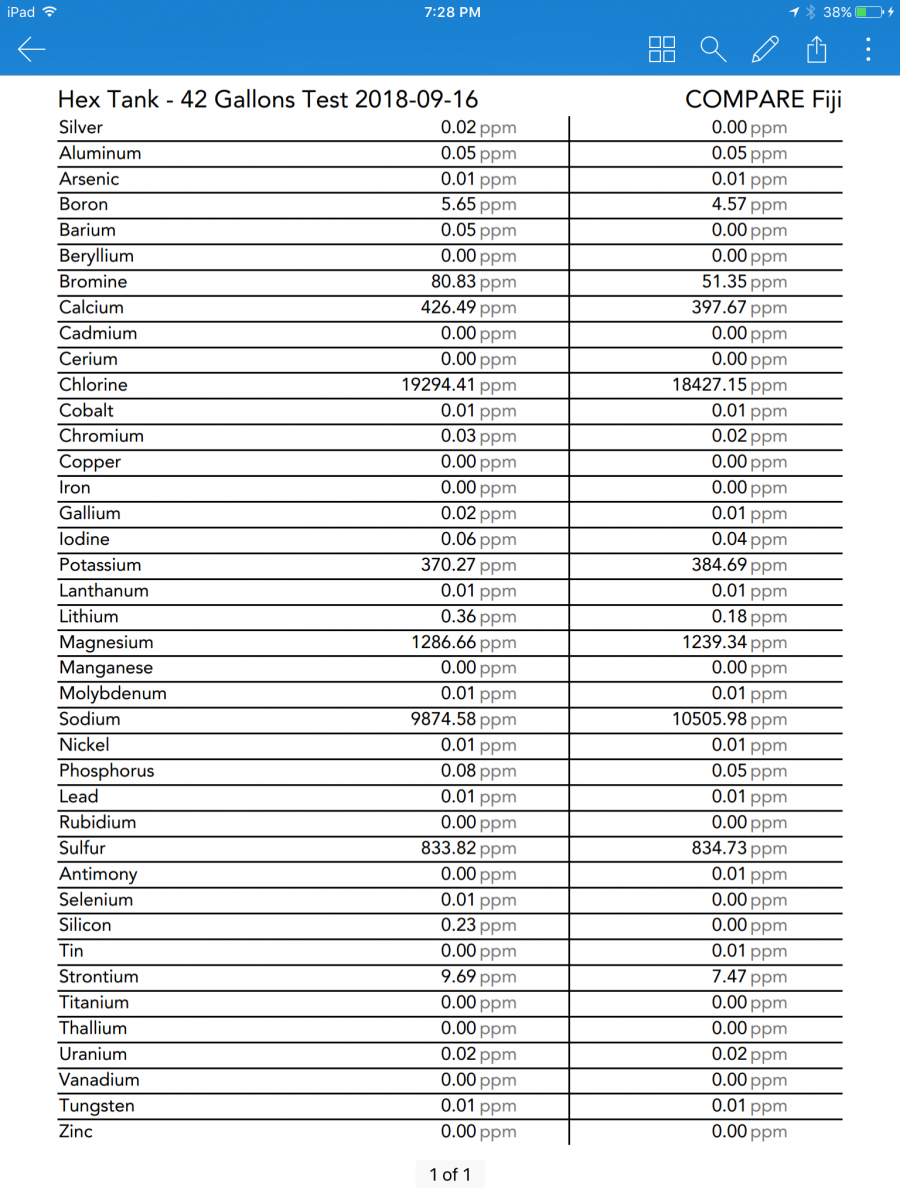

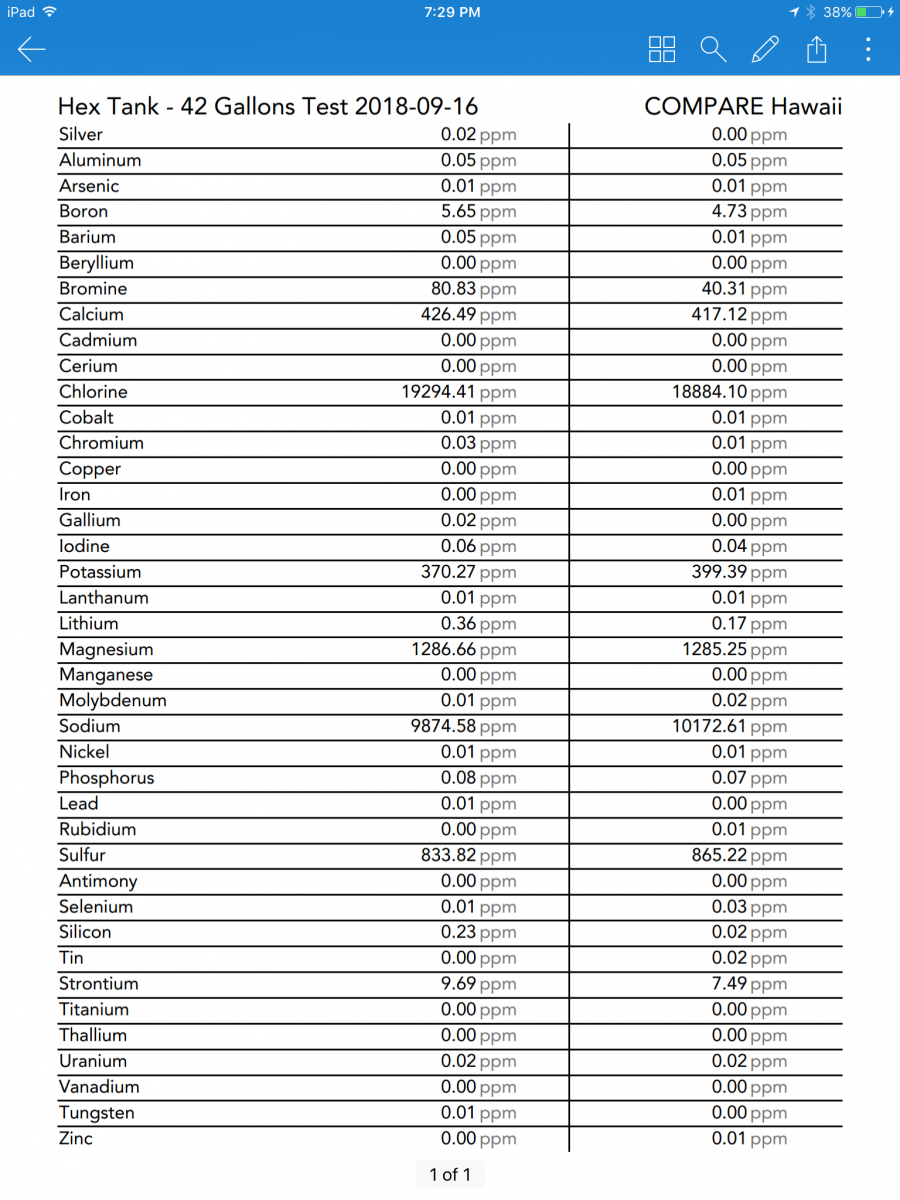

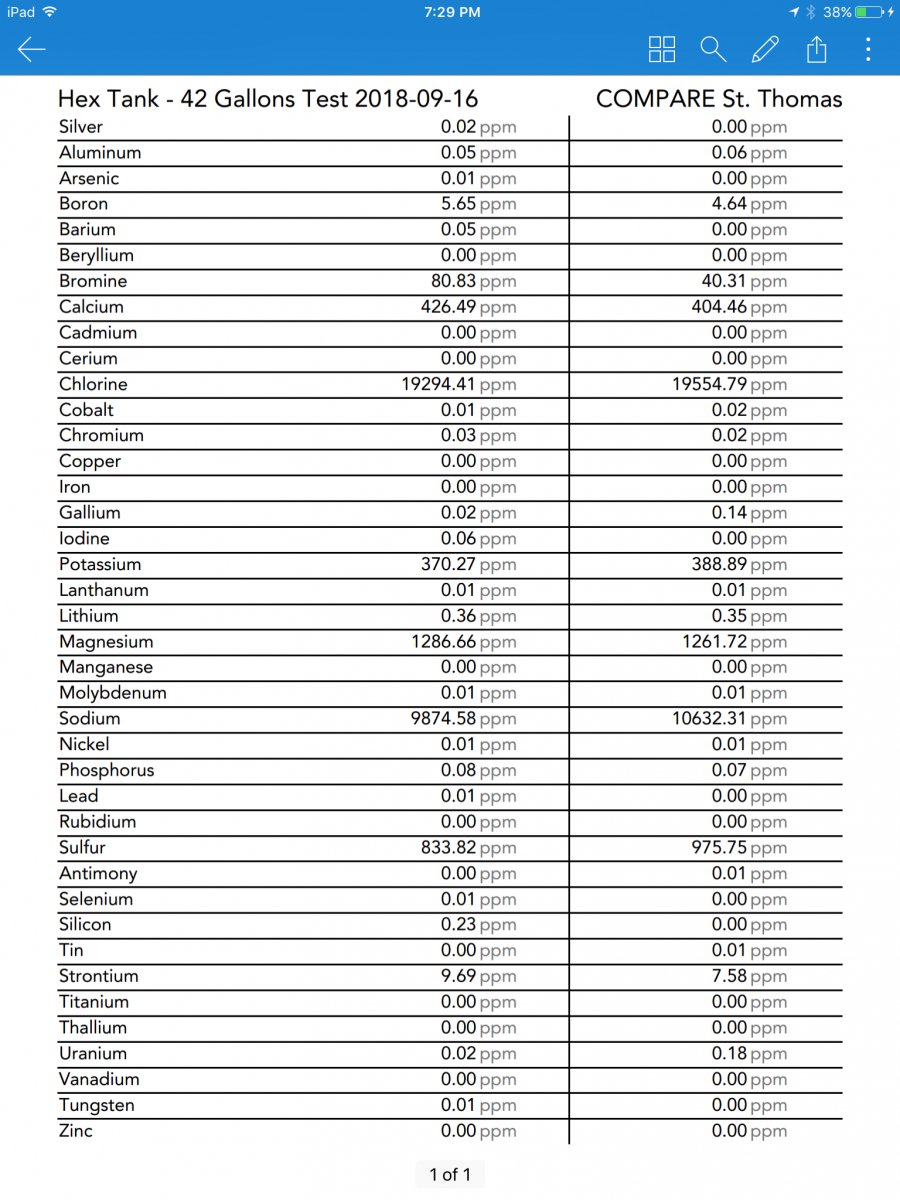

They also have comparisons to 4 different areas of the world. Below is the download of all 4. These are rounded to the hundredths where above there rounded to the thousands. These are downloaded in PDF form so I did screenshots on the iPad to import them here as a image.

On the same day as the sample I tested the following. They do seem close to my results. I did not expect them to match.

Salinity on The Archon .. 34.9ppt

Calcium Nyos kit ............ 435ppm

Magnesium Nyos kit ...... 1305ppm

They also have comparisons to 4 different areas of the world. Below is the download of all 4. These are rounded to the hundredths where above there rounded to the thousands. These are downloaded in PDF form so I did screenshots on the iPad to import them here as a image.

Last edited:

WOW, beautifulI wanted to get back into the hobby and try out LED's as a light source. I had a 42 gallon hex tank on hand to use as a test tank for this. My better half had a few requirements if I set this tank back up. She did not want to see a water line or the gravel or sand below the suface level on the glass sides of the tank. Also she did not want to see any equipment hanging off or under the tank. So I had to come up with a way to accomplish this and still have a working tank. I got her to compromise on 5 1/4" tubes from the wall plate to the tank along with the backup battery for the Vortech pumps. Otherwise I believe I have met her original conditions. I did not want it in a corner due to how it was built, but that was the only location I was allowed to use. But I did get a compromise on allowing it to be out from the wall enough to allow access to the back of the stand and canopy. There was carpet in the room where it was to be install. It was rather old carpet so I was allowed to cut the squares enough to allow the stand to sit on the concrete slab. I do plan on replacing the carpet squares in this room in the future. The photo below is of the finished product. The stand and canopy is made from pine like you can get from Lowes or Home Depot.

There was no plywood used in this project. Lots of screws though. I think it was close to 800 of them. The doors are raised panel doors that are 5 seperate pieces.

The canopy

I will start with the canopy build. Below are the pieces of wood for the project. This photo was taken after the teardown from the inital build. After the inital build the stand and canopy was tested in the garage for about 4 weeks before it was torn down for the final assembly where the parts were glued sanded, stained and final touches were added. This project was started in 2008, so it has been going on for a long time. My saws are in the garage and in Texas there are only a few days that are comfortable to work for any length of time in there. Also I have had limited free time for the project.

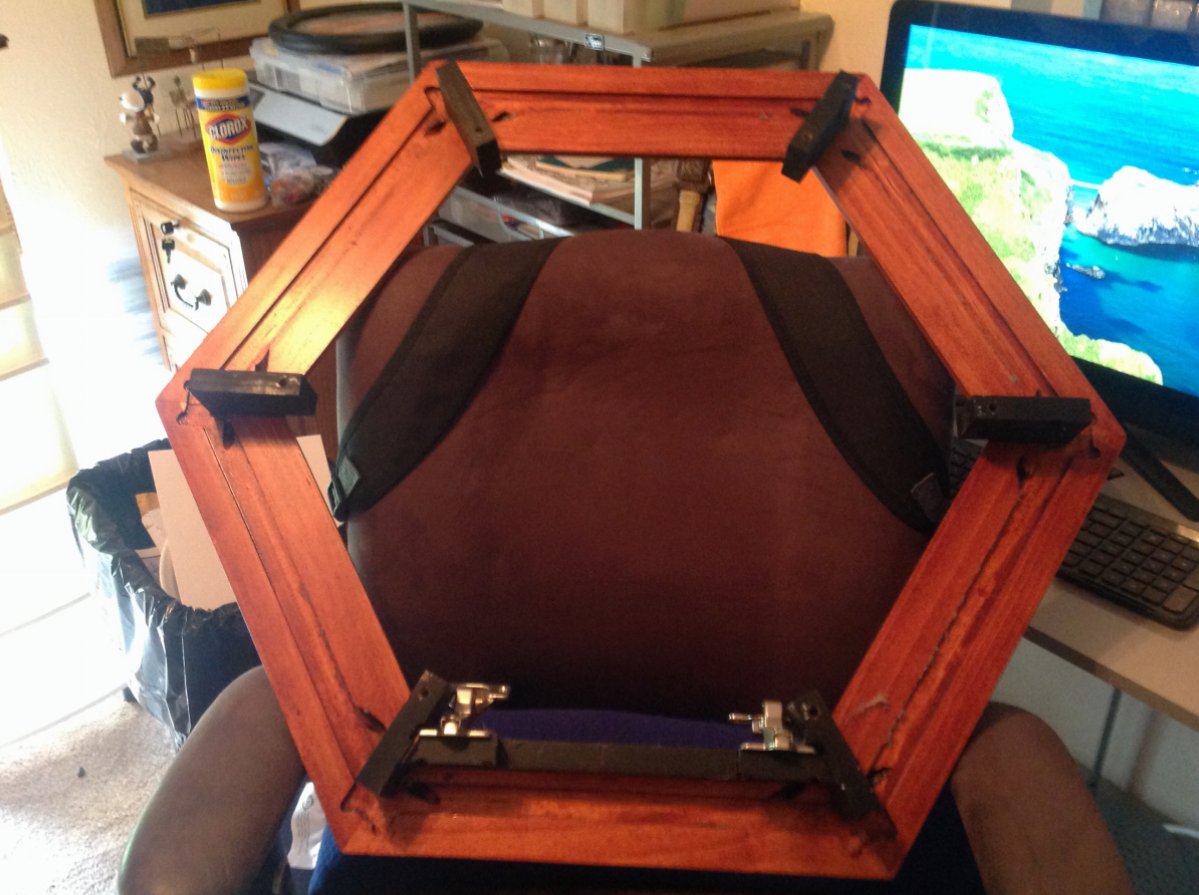

The canopy consist of a inner frame that has side panels, bottom outer frame, top outer frame and lid attached. Below is the top inner frame after it was glued and had a couple coats of primer. This view is from the top. The large rectangular hole is for the acrylic cover for the LED's. The LED's and other electronics are not exposed to the area above the tank. The pocket holes drilled at angles at the corners are how the side panels are attached at the top.

Below is the bottom view of the inner frame. The open section is to allow a overflow box on the back of the tank. This tank is not drilled so I decided to use an overflow instead of drilling the tank.

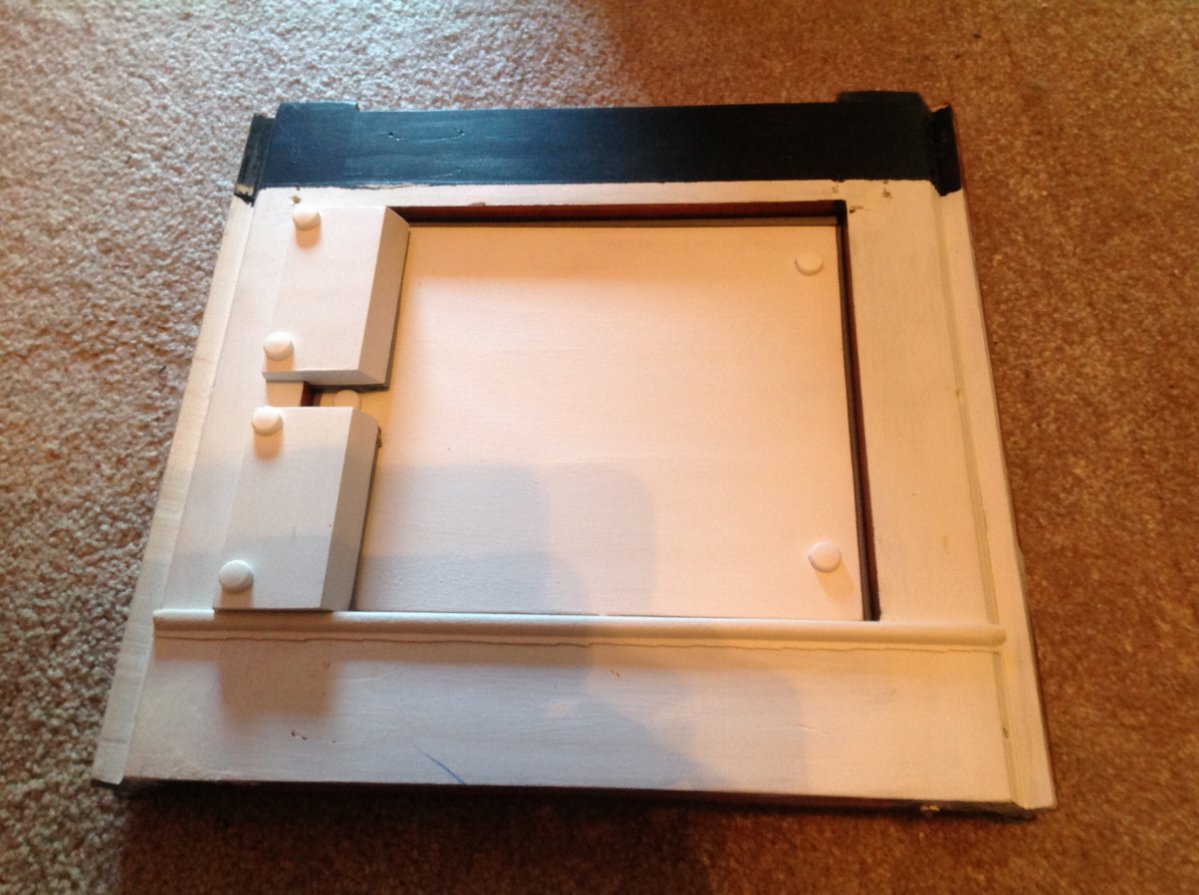

The bottom outer frame holds the panels together at the bottom. It is attached to each panel with 2 screws. Below is a photo of the assembled bottom outer frame. This is a top view. There is a pattern cut out of it that matches the bottom edge of the side panels.

Below is a photo of a single section of the bottom outer frame that shows the pattern a little better.

Below is the top outer frame bottom view. This also has a pattern cut out to match the top of the side panels.

Below is a photo of a single section of the top outer frame. It is a little easer to see the pattern in this photo.

Below is an assembled side panel with door attached. The door is not completly done at the time of the photo.

The parts of a side panel and door are in the photo below.

Below is a picture of the top rail on the side panel it has a pattern cut into it to allow ventilation of the compartment where the LED's and electronics will be kept. Also the bottom is cut at a 15 degree angle so that water drips are kept in the canopy and not on the floor the bottom rail has the same 15 degree cut on the top. Both slant down toward the inside of the canopy.

The corner view below will show the slits that are used for ventilation in the top of the side panel. Also it gives a good view of the insert at the corner where the side panels come together. I think this was purchase from Home Depot. It does add to the overall appeal of the project.

I guess this is a long enough post for now. More to come.

Thank you.WOW, beautiful

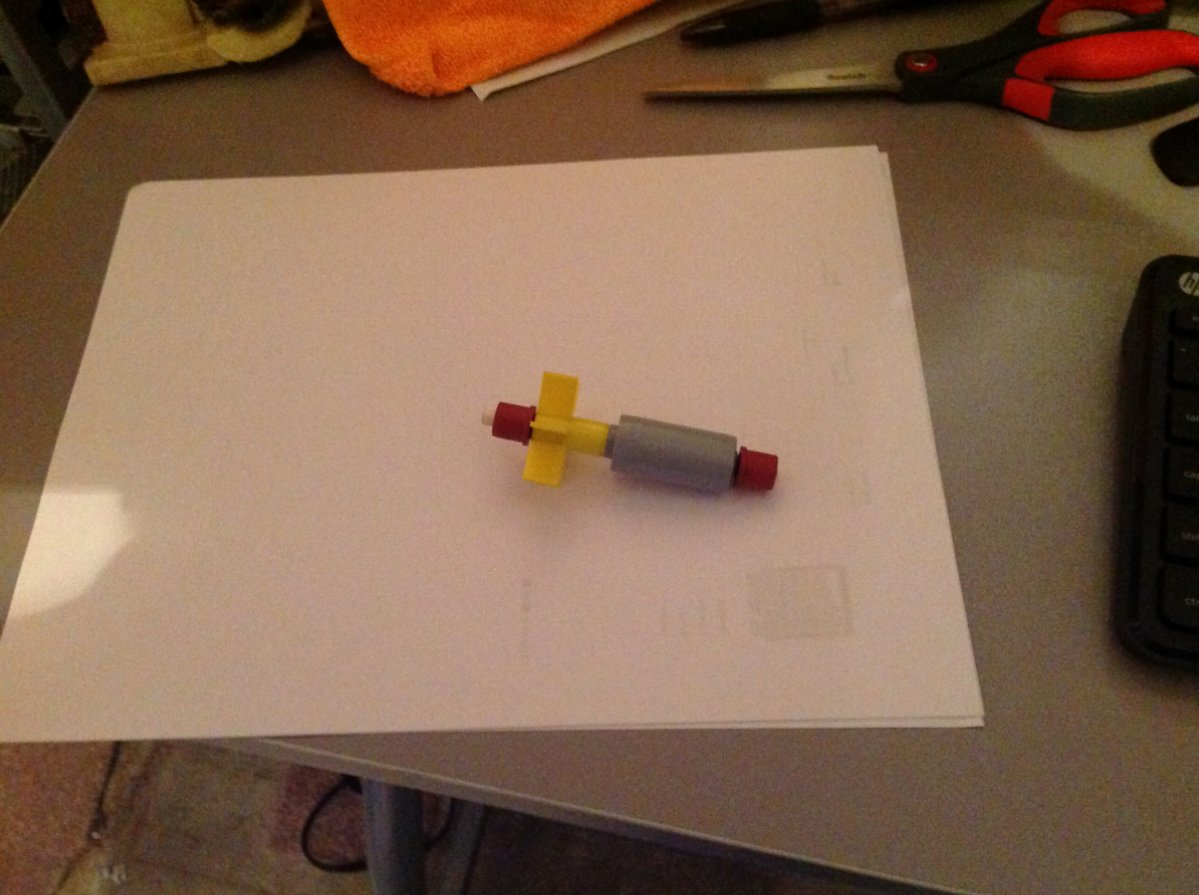

I finally ordered the replacement impeller for my return pump. It has been installed and the pump returned to service. It has more flow than the backup even when dialed back some. The cost was $70 and some change. Photo of new impeller below.

Canopy Update

I had some time off from work so I decided to finish the back panels for the canopy doors and the covers for the hinges. I decided to remove each panel one at a time. To do this I had to remove the top lid and top outer frame from the canopy. The canopy remained in use through the process. Below three photos of the removal of the lid and top outer frame. Other than some dust every thing looks good.

Below is a photo with the top frame and lid removed.

Below is a photo with the front side panel removed from the canopy.

Below is a photo of the removed front side panel. The hinges were also being replaced. Not too bad for 3 years of use.

Below is a photo of the hinge covers in various stages. Next to them are the templates used to get the router pattern cut into the hinge cover. Next to those are the three parts to the door cover before they are glued together. Below the hinge covers and parts for the door cover are two finished covers.

Below is the finished front side panel ready for reattachment to the canopy. There was water that was leaking between the panel and the canopy inner frame so I decided to add some stripping at that contact point on the panel assembly.

Below is the photo of the panel with the door open.

Below is a better photo of the canopy with the front side panel removed.

Below is a photo with the front side panel reinstalled.

Below is a photo of a side panel with the hinge on the opposite side from the front side panel. Below that a photo with the door open.

Below is a side panel ready for new hinges and the door panel and hinge covers installed. The two hinge covers, door panel, two hinges along with the hardware for mounting the parts.

The remaining photos are of the canopy with all side panels completed and re installed. The top outer frame and lid are also reinstalled.

Now just the back cover is left needing the door panels and hinge covers. I am hoping this will also limit the air flow through the canopy via the doors and allow more flow through the stand where the evaporative cooling is performed. I do want some flow through the canopy via the bottom of the door. The flow for the canopy and stand is done via the fans in the top of the back cover. The fans at top center of the canopy are for cooling the LED heat sink only.

I had some time off from work so I decided to finish the back panels for the canopy doors and the covers for the hinges. I decided to remove each panel one at a time. To do this I had to remove the top lid and top outer frame from the canopy. The canopy remained in use through the process. Below three photos of the removal of the lid and top outer frame. Other than some dust every thing looks good.

Below is a photo with the top frame and lid removed.

Below is a photo with the front side panel removed from the canopy.

Below is a photo of the removed front side panel. The hinges were also being replaced. Not too bad for 3 years of use.

Below is a photo of the hinge covers in various stages. Next to them are the templates used to get the router pattern cut into the hinge cover. Next to those are the three parts to the door cover before they are glued together. Below the hinge covers and parts for the door cover are two finished covers.

Below is the finished front side panel ready for reattachment to the canopy. There was water that was leaking between the panel and the canopy inner frame so I decided to add some stripping at that contact point on the panel assembly.

Below is the photo of the panel with the door open.

Below is a better photo of the canopy with the front side panel removed.

Below is a photo with the front side panel reinstalled.

Below is a photo of a side panel with the hinge on the opposite side from the front side panel. Below that a photo with the door open.

Below is a side panel ready for new hinges and the door panel and hinge covers installed. The two hinge covers, door panel, two hinges along with the hardware for mounting the parts.

The remaining photos are of the canopy with all side panels completed and re installed. The top outer frame and lid are also reinstalled.

Now just the back cover is left needing the door panels and hinge covers. I am hoping this will also limit the air flow through the canopy via the doors and allow more flow through the stand where the evaporative cooling is performed. I do want some flow through the canopy via the bottom of the door. The flow for the canopy and stand is done via the fans in the top of the back cover. The fans at top center of the canopy are for cooling the LED heat sink only.

Last edited:

Back Cover Update

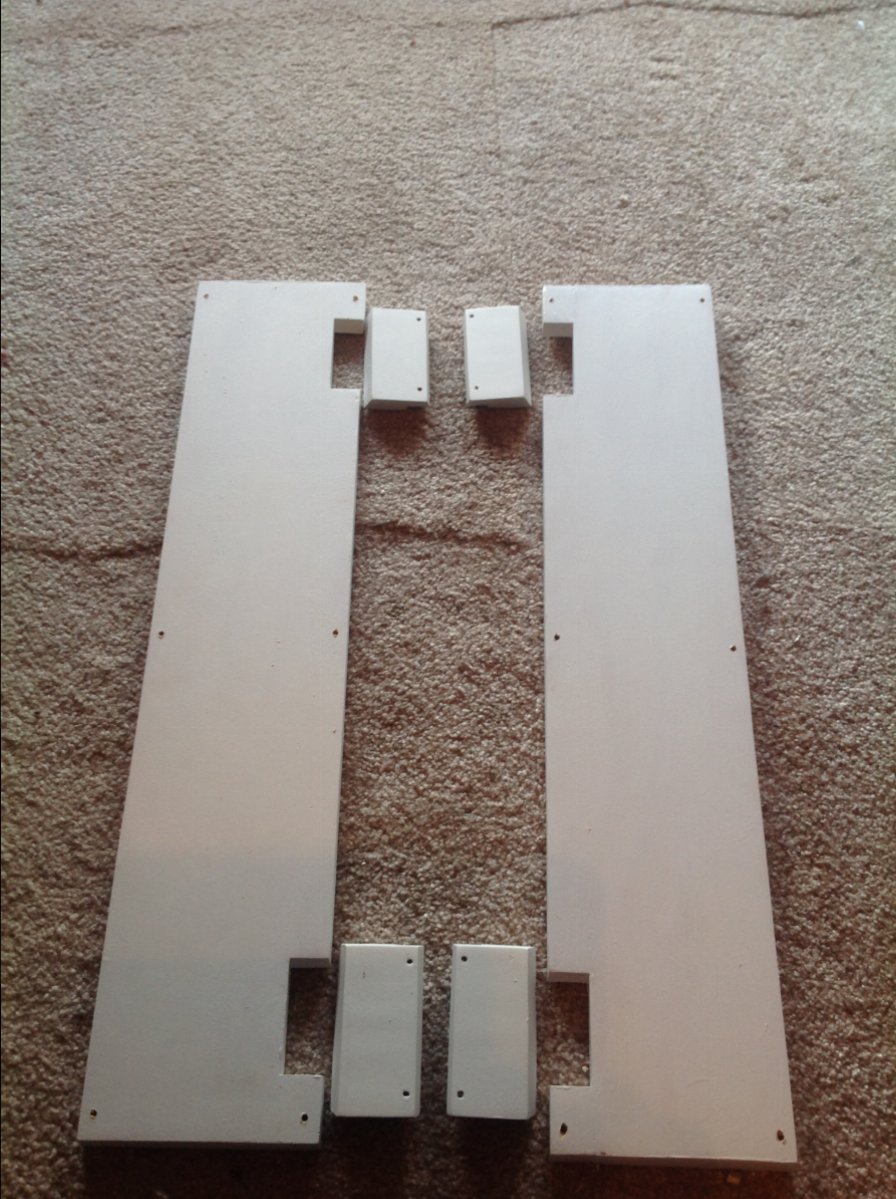

I had a chance to build the inner panels and hinge covers for the back cover. Below is a photo of a partially completed inner panels and the parts for a second one.

Below is both inner panels and the four hinge covers complete and ready to install.

Below is a photo of the back cover with both inner panels and the four hinge covers installed.

Below is with the doors closed.

This did make it a little quieter. Hopefully it will help divert more flow through the sump area to help with the evaporative cooling.

I had a chance to build the inner panels and hinge covers for the back cover. Below is a photo of a partially completed inner panels and the parts for a second one.

Below is both inner panels and the four hinge covers complete and ready to install.

Below is a photo of the back cover with both inner panels and the four hinge covers installed.

Below is with the doors closed.

This did make it a little quieter. Hopefully it will help divert more flow through the sump area to help with the evaporative cooling.

Last edited:

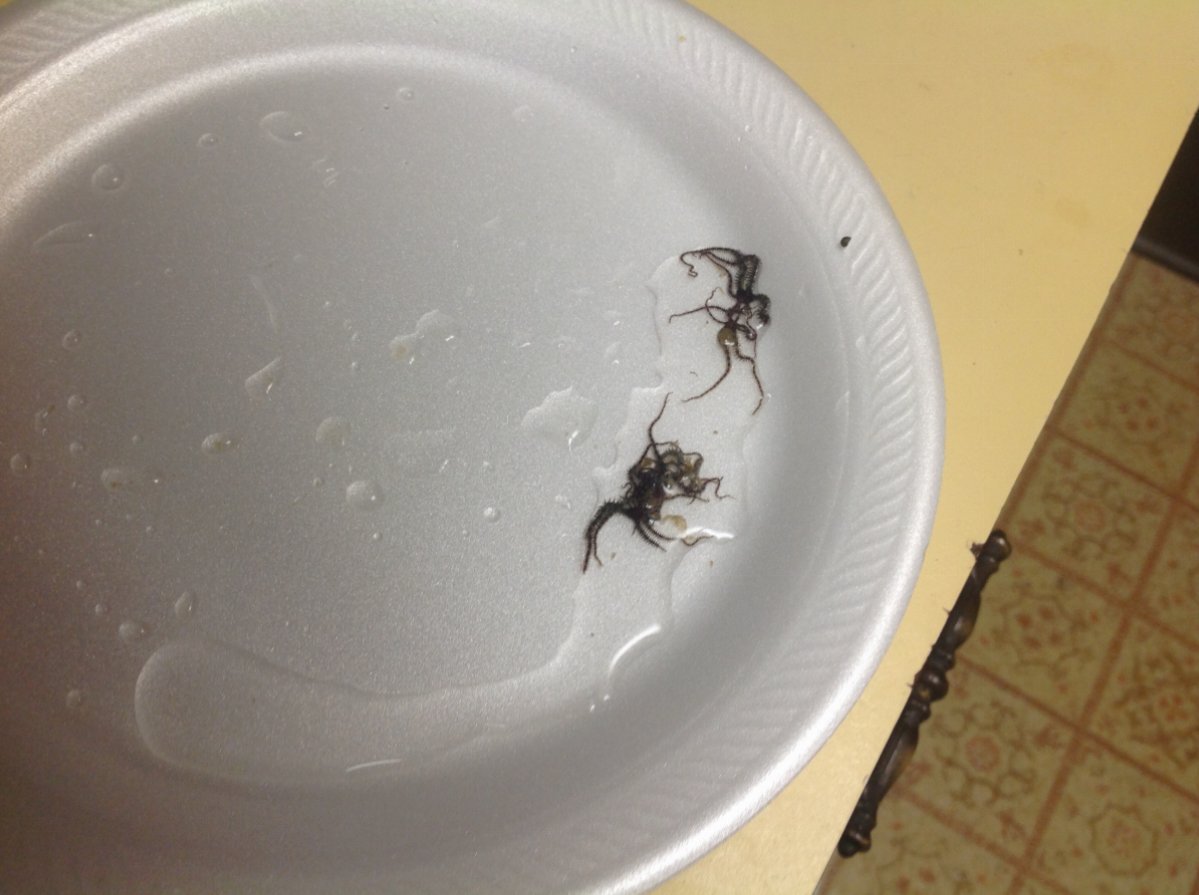

I got these out of one of my MP10's while cleaning. I always have to check them before I dump them in the cleaning solution. I have not figured out how they stay alive with the impeller spinning so fast. I have hundreds of these in my tank. They must have been hitch hicking on something to get in.

Recent photos of the tank.

Recent photos of the tank.

- Joined

- Jan 11, 2019

- Messages

- 54

- Reaction score

- 23

Let me start by saying that I have never liked hex-tank. After seeing the work you put into your tank and not buying a plug and play tank{like I did}. I find your work of art to be beautiful. You must be so very proud of yourself and your tank. Enjoy it.

Thank you, I am very happy with how it turned out. Welcome to R2R.Let me start by saying that I have never liked hex-tank. After seeing the work you put into your tank and not buying a plug and play tank{like I did}. I find your work of art to be beautiful. You must be so very proud of yourself and your tank. Enjoy it.

I managed to get a backup for my Archon head unit and IOE module. At this point I have a backup module for every module in the system.

There is not much going on with the tank. I did start a non tank related project. I started making a cabinet for the garage. One side goes agsinst a wall. It has doors and drawers on both front and back. It looks like kitchen cabinets are next. After that I may be able to start on the build for the 110.

There is not much going on with the tank. I did start a non tank related project. I started making a cabinet for the garage. One side goes agsinst a wall. It has doors and drawers on both front and back. It looks like kitchen cabinets are next. After that I may be able to start on the build for the 110.

I got the candy cane coral in Oct 2016

I took a recent photo below. It has grown quite a bit. I moved it forward some to get it away from the zoa's

Below is a duncan I got Nov 2017.

This is a recent photo of the same duncan

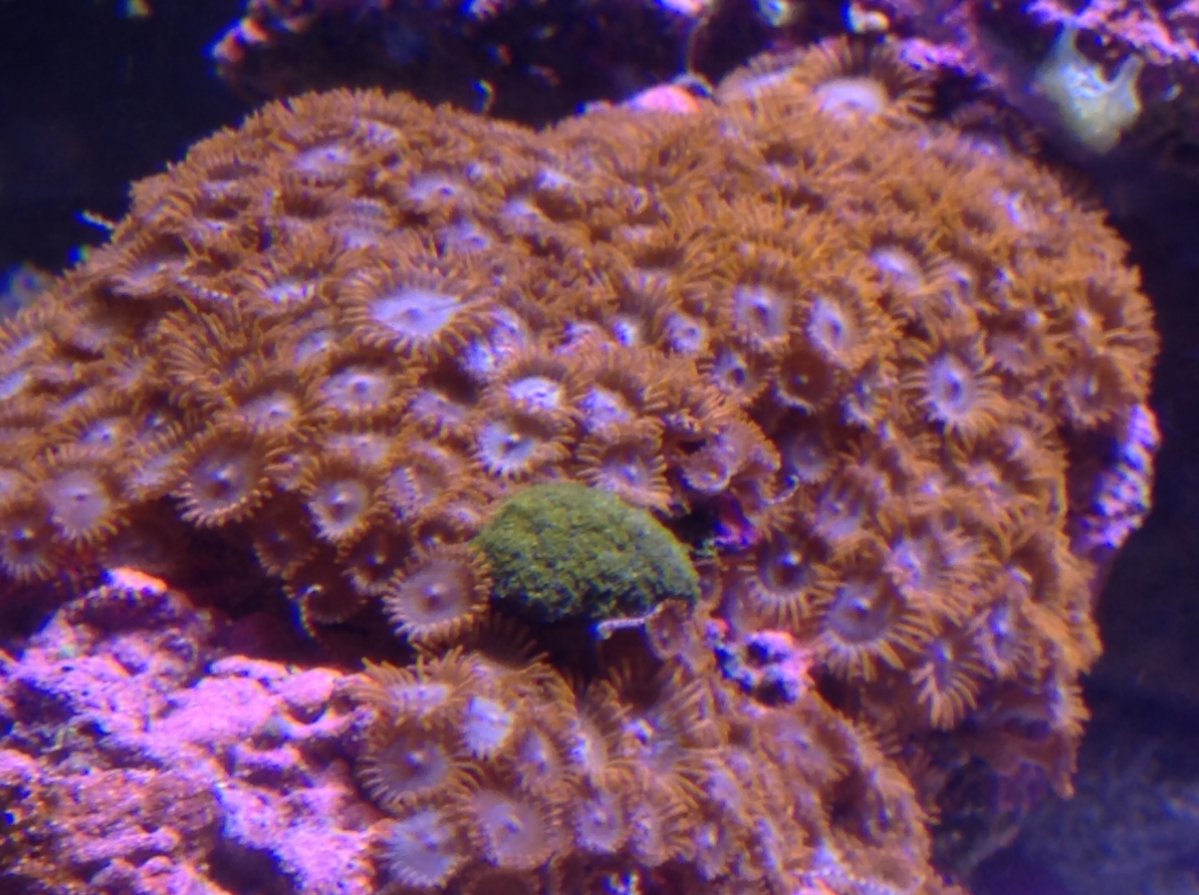

Below is a photo of some zoanthids I got in Oct 2016.

Below is a current photo of the same zoanthids. The green ones did not make it but these seem to be thriving.

Not much going on with the tank otherwise.

I took a recent photo below. It has grown quite a bit. I moved it forward some to get it away from the zoa's

Below is a duncan I got Nov 2017.

This is a recent photo of the same duncan

Below is a photo of some zoanthids I got in Oct 2016.

Below is a current photo of the same zoanthids. The green ones did not make it but these seem to be thriving.

Not much going on with the tank otherwise.

Two new additions to the tank.

The goby out just chillin.

Similar threads

- Price: 500

- Shipping NOT Available

- Replies

- 0

- Views

- 276

- Replies

- 1

- Views

- 76

- Replies

- 27

- Views

- 957

- Replies

- 5

- Views

- 275

- Replies

- 24

- Views

- 685