Or have it pumped out of the sump based on a float controlling the pump, then your relying 100% on float/level controllers but we use them in designing big water plants all the time with no issues as long as their maintained.Just add a solinoid valve based on float switch etc let it fill to a certain point and have the main line coming in close when the float is hit. Even if it's a backup to engineering it as a surge tank it would give me more peace of mind.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clever and/or engineer type people! Impossible or not, Can it be done??

- Thread starter Battlecorals

- Start date

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

- Joined

- Jan 20, 2019

- Messages

- 1,655

- Reaction score

- 1,831

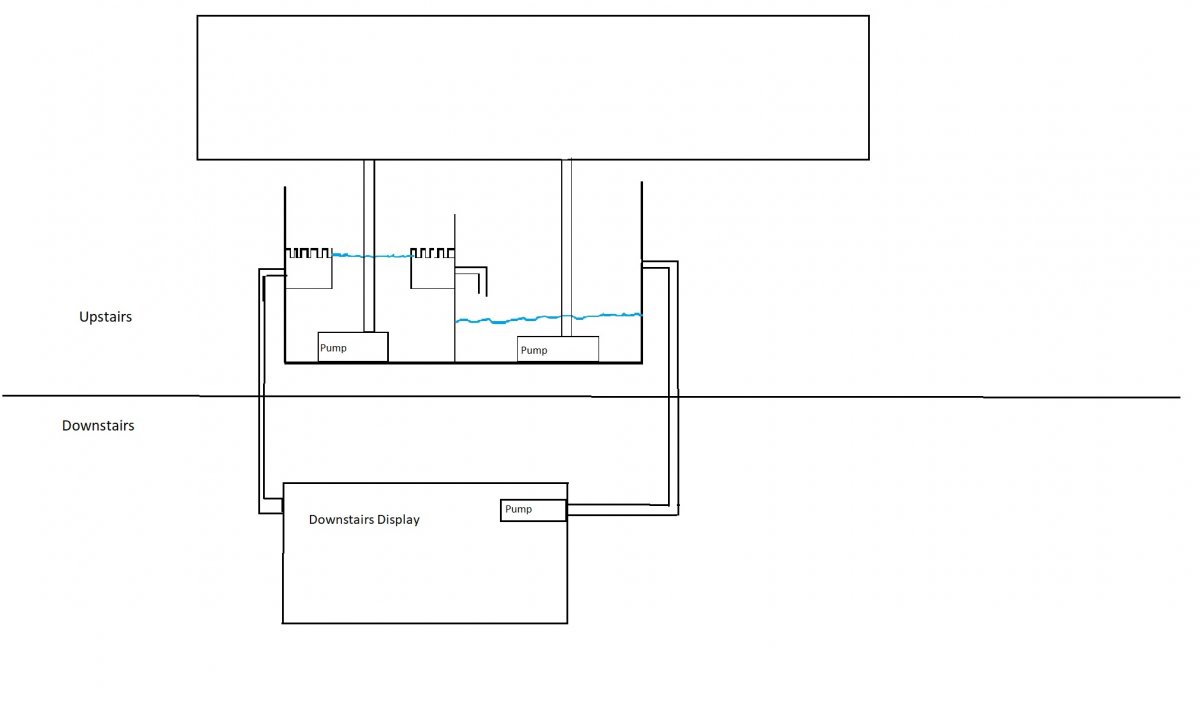

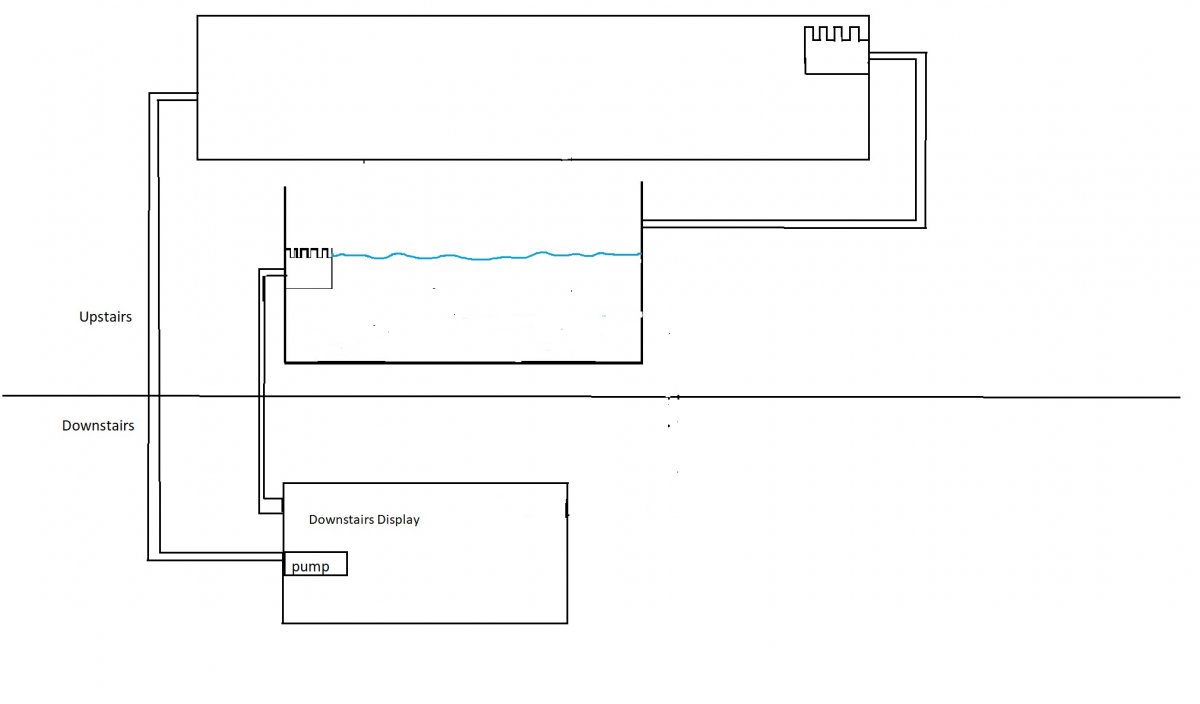

There are two options for a gravity failsafe overflow. Either:So, I've been seriously thinking about setting up another small display in my office which is underneath my grow-out facility. Been going back and forth on this a while actually, but what I'd love to do, if not just "possible" but 100% "floodproof possible", is have it connected to my main system upstairs. the plumbing will not be easy but that part I'm confident I can manage. The actual total execution, I'm not so sure about yet.

I'm sure I am not the first one to ponder this concept, but I'd like to know if anyone has either done this or may have some "smarts" on how I can pull it off. Sometimes in situations like this, someone will just say, "Oh sure, you just need a Blankety blank" and you're good to go. lol

The challenge clearly, is getting water to circulate safely, from my sump above to the tank below.

My first thought was modeled off of how a surge device works. Somehow have the water from the upper reservoir, circulate with sump water. maybe a separate overflow on the reservoir and it would continuously cycle water from the sump. And keep a minimum amount of water in the reservoir below the low drain point of the surge that would always be cycling sump water through. The turnover for the display would be pretty low but I think it may work, or some variation of this notion at least. And that's why I am reaching out on this one. I'm sure there's a way it could be done but I can't quite get there lol

The water level in the display tank would always fluctuate as the surge reservoir filled and drained, but I don't know that I'd really care so much. If that was the only snag id be very ok with it in fact. But I'd love to get some other ideas and concepts and really just spitball a little.

maybe ill work up a little diagram as well that might help to clarify the idea.

Ultimately in its simplest form, id like to plumb a new display to the sump on the floor above it rather than set up a whole new system

what do you guys think? can it be done?

- Use the downstairs display as the variable level overflow, or

- Add two tanks downstairs with the second smaller tank for the sole purpose of acting as the overflow.

Upstairs tanks become constant water level.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

Designing flood protection isn't too difficult. The challenge is balancing the 2 separate flow paths. Flow from the upstairs system into the surge must exactly match the flow to the upstairs system from the surge. Flow up from the downstairs tank must exactly match flow down to the downstairs tank.

This is the problem to solve. I don't believe it is possible without some from of measuring and adjustment.

This is the problem to solve. I don't believe it is possible without some from of measuring and adjustment.

Designing flood protection isn't too difficult. The challenge is balancing the 2 separate flow paths. Flow from the upstairs system into the surge must exactly match the flow to the upstairs system from the surge. Flow up from the downstairs tank must exactly match flow down to the downstairs tank.

This is the problem to solve. I don't believe it is possible without some from of measuring and adjustment.

Yeah I am starting to think you are right on this one. Believe me i thought about it long before i actually made the post and that was the best I could come up with. but I was not ready to go all-in on that concept at all lol. the whole idea seems simple at first, but when you really start to break it down it's got a trove of in's, outs and what have you's

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

I make a living of raining on other peoples parades. I try not to do that within the hobby, but in this case I can't help myself.Yeah I am starting to think you are right on this one. Believe me i thought about it long before i actually made the post and that was the best I could come up with. but I was not ready to go all-in on that concept at all lol. the whole idea seems simple at first, but when you really start to break it down it's got a trove of in's, outs and what have you's

If you decide you want to pull the trigger and do it using automation, I can probably help. Otherwise, it's best to put this plan on hold imo.

- Joined

- Jun 15, 2014

- Messages

- 208

- Reaction score

- 116

This is what i was thinking. If you have 2 return sections in the upstairs sump one section could overflow to the downstairs tank. The right side should evaporate and left would stay the same. The only problem with this is if both return pumps upstairs fail the sump level could raise too much.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

This was actually my first idea, but then I realized that in order to make it work the total system flow for the upstairs sump would have to flow through the DT. You could even add a sump below the downstairs DT to make the downstairs DT a constant level.Or this, but it would require the ATO to work off the downstairs display.

The problem happens when you only run partial flow through the downstairs system.

I make a living of raining on other peoples parades. I try not to do that within the hobby, but in this case I can't help myself.

If you decide you want to pull the trigger and do it using automation, I can probably help. Otherwise, it's best to put this plan on hold imo.

Lol Nah it's a clean, warm, welcome rain man, no worries there at all. And speaking of "warm" I'm starting to warm up more to the idea of having another separate system as a back up for growing out favorable pieces anyway

honestly,

i'd make them 2 seperate systems.

if you're concerned about keeping water quality the same, i think the easiest and cheapest way to do it would be to set up a AWC type of system, that would exchange 20 gal a day or so between the main system upstairs and the display system downstairs. ( i know you already said you don't want to do it that way) but 2 1/4" lines is easier and cheaper to run then all this plumbing, nevermind the risk of an overflow isn't really possible with peristaltic pumps as long as they're the high point of the loop.

i'd make them 2 seperate systems.

if you're concerned about keeping water quality the same, i think the easiest and cheapest way to do it would be to set up a AWC type of system, that would exchange 20 gal a day or so between the main system upstairs and the display system downstairs. ( i know you already said you don't want to do it that way) but 2 1/4" lines is easier and cheaper to run then all this plumbing, nevermind the risk of an overflow isn't really possible with peristaltic pumps as long as they're the high point of the loop.

* gets goofy idea * What if you just ran a small tank as if it were an inline reactor on a closed loop? Have one built out of thick acrylic with a flange at the top and a removeable, heavy-duty seal. On the inlet and outlet sides, put a ( high quality)ball valve, a tee leading to a gate valve, and another ball valve. That way you can close off incoming water and drain the tank when you want to service it.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

Love the idea! Lighting could be a challenge though. I'm not sure if an acrylic pressure rated lid would allow enough PUR through.* gets goofy idea * What if you just ran a small tank as if it were an inline reactor on a closed loop? Have one built out of thick acrylic with a flange at the top and a removeable, heavy-duty seal. On the inlet and outlet sides, put a ( high quality)ball valve, a tee leading to a gate valve, and another ball valve. That way you can close off incoming water and drain the tank when you want to service it.

Similar threads

- Replies

- 62

- Views

- 3,230

- Replies

- 6

- Views

- 200

- Replies

- 10

- Views

- 225