- Joined

- May 14, 2008

- Messages

- 323

- Reaction score

- 426

Welcome to my build thread!

I had a 70 gallon mixed reef while I was in grad school from 2008 to 2011. I started that tank with Tampa Bay Saltwater live rock. I took the tank down and sold all the livestock locally because I was moving often and because the price of the coral I really wanted to keep was out of my price range. I used to dream of an aquarium with all the bells and whistles and a basement sump room. Well fast forward 14 years and I'm now in a place to set up my "dream tank".

The Aquarium

I had the aquarium built by Coast to Coast Custom Aquariums (CTC) in New Jersey. It's 153 gallons based on the external dimensions and 138 gallons actual water volume based on the internal dimensions. The tank is 49.5" x 31" x 23". It's eurobraced and has an external overflow box with three 1.5" drains and two 1" return bulkheads.

The Stand

The stand is an aluminum 80/20 stand built by Framing Tech. I had the stand skinned with removable stained oak panels by Chris McGrody Fine Furniture.

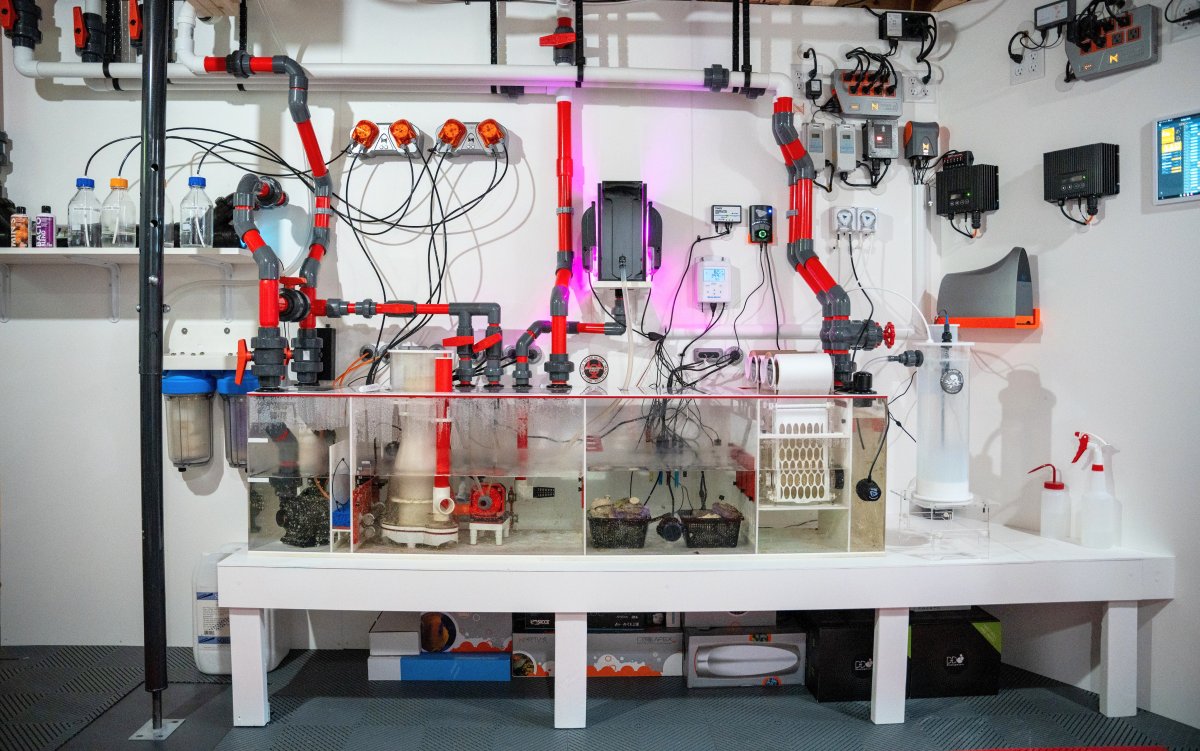

The Sump and Filtration

The sump is a Synergy Reef SK72 (72" x 18" x 18") sump with Dual Gen 3 Clearisea SK5000 Brackets.

Filtration consists of two Gen 3 Clearisea SK5000's, a Bubble King Double Cone 180 skimmer, a Clear Water CW-200 Algae Scrubber V2, a Lifegard Aquatics Pro Max 40 watt UV sterilizer, an Ozotech Poseidon 200 ozone generator and two Dreambox media filters for carbon and Rowaphos when needed. Rock is Marco Reesaver Rock.

Lighting

Two Kessil A500X, one Kessil A360X, and four 24" ReefBrite Bars.

Flow

Two EcoTech Vortec MP40's

Return Pumps

Dual Abyzz A200 IPUs, one plumbed to each return bulkhead.

Heating

Two Aqualogic controllers each controlling one 200 watt and one 300 watt titanium heating element.

Control

Neptune Apex System

Trident

Tunze Osmolator

Aqualogic controllers

Supplementation

Avast Marine K2 Kalk stirrer

Neptune DOS

Reef Moonshiners elements

Livestock

Currently an LPS heavy mixed reef dominated by Euphilia, Micromussa, and Zoanthids. Also included is Trachyphyllia, Duncans, Fungia, Favia, Goniopora, Chalice, Blastomussa, Pectinia, and others. I have an upper section of assorted Acropora species and some Montipora. Also included are some select Ricordea and other mushrooms on isolated sections of the aquascape.

Fish currently include a Gem Tang, Yellow Tang, Kole Tang, Convict Tang, a pair of clowns, a Royal Gramma, a pair of Banggai cardinalfish, a Midas Blenny, five Lyretail Anthias, a pair of Bluestar Leopard Wrasse, a Ruby Red Dragonet, a Yellow Coris Wrasse, a McCosker's Flasher Wrasse, and two Zebra Goby's.

I had a 70 gallon mixed reef while I was in grad school from 2008 to 2011. I started that tank with Tampa Bay Saltwater live rock. I took the tank down and sold all the livestock locally because I was moving often and because the price of the coral I really wanted to keep was out of my price range. I used to dream of an aquarium with all the bells and whistles and a basement sump room. Well fast forward 14 years and I'm now in a place to set up my "dream tank".

The Aquarium

I had the aquarium built by Coast to Coast Custom Aquariums (CTC) in New Jersey. It's 153 gallons based on the external dimensions and 138 gallons actual water volume based on the internal dimensions. The tank is 49.5" x 31" x 23". It's eurobraced and has an external overflow box with three 1.5" drains and two 1" return bulkheads.

The Stand

The stand is an aluminum 80/20 stand built by Framing Tech. I had the stand skinned with removable stained oak panels by Chris McGrody Fine Furniture.

The Sump and Filtration

The sump is a Synergy Reef SK72 (72" x 18" x 18") sump with Dual Gen 3 Clearisea SK5000 Brackets.

Filtration consists of two Gen 3 Clearisea SK5000's, a Bubble King Double Cone 180 skimmer, a Clear Water CW-200 Algae Scrubber V2, a Lifegard Aquatics Pro Max 40 watt UV sterilizer, an Ozotech Poseidon 200 ozone generator and two Dreambox media filters for carbon and Rowaphos when needed. Rock is Marco Reesaver Rock.

Lighting

Two Kessil A500X, one Kessil A360X, and four 24" ReefBrite Bars.

Flow

Two EcoTech Vortec MP40's

Return Pumps

Dual Abyzz A200 IPUs, one plumbed to each return bulkhead.

Heating

Two Aqualogic controllers each controlling one 200 watt and one 300 watt titanium heating element.

Control

Neptune Apex System

Trident

Tunze Osmolator

Aqualogic controllers

Supplementation

Avast Marine K2 Kalk stirrer

Neptune DOS

Reef Moonshiners elements

Livestock

Currently an LPS heavy mixed reef dominated by Euphilia, Micromussa, and Zoanthids. Also included is Trachyphyllia, Duncans, Fungia, Favia, Goniopora, Chalice, Blastomussa, Pectinia, and others. I have an upper section of assorted Acropora species and some Montipora. Also included are some select Ricordea and other mushrooms on isolated sections of the aquascape.

Fish currently include a Gem Tang, Yellow Tang, Kole Tang, Convict Tang, a pair of clowns, a Royal Gramma, a pair of Banggai cardinalfish, a Midas Blenny, five Lyretail Anthias, a pair of Bluestar Leopard Wrasse, a Ruby Red Dragonet, a Yellow Coris Wrasse, a McCosker's Flasher Wrasse, and two Zebra Goby's.

Last edited: