It should be a tapered pipe thread fitting and not need anything to to seal. Unless its british parallel pipe thread, that is not likely. Orko doesn't understand how pipe threads work. Do not shorten the fittings. It relies on thread pitch and taper to seal. Hence why the teflon tape caused the break.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crack in bulk head threads on return.

- Thread starter Wick

- Start date

- Tagged users None

Flippers4pups

Fins up since 1993

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Reef Squad Emeritus

Hospitality Award

Looking at the threads and cracks, I'd replace it.

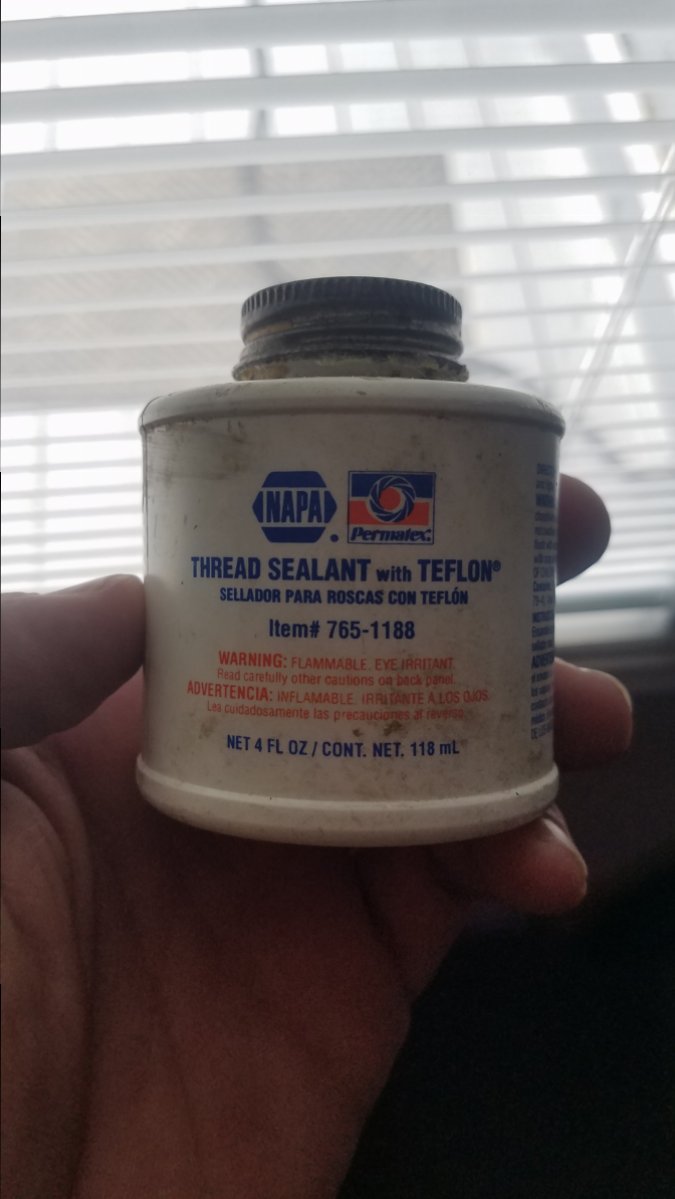

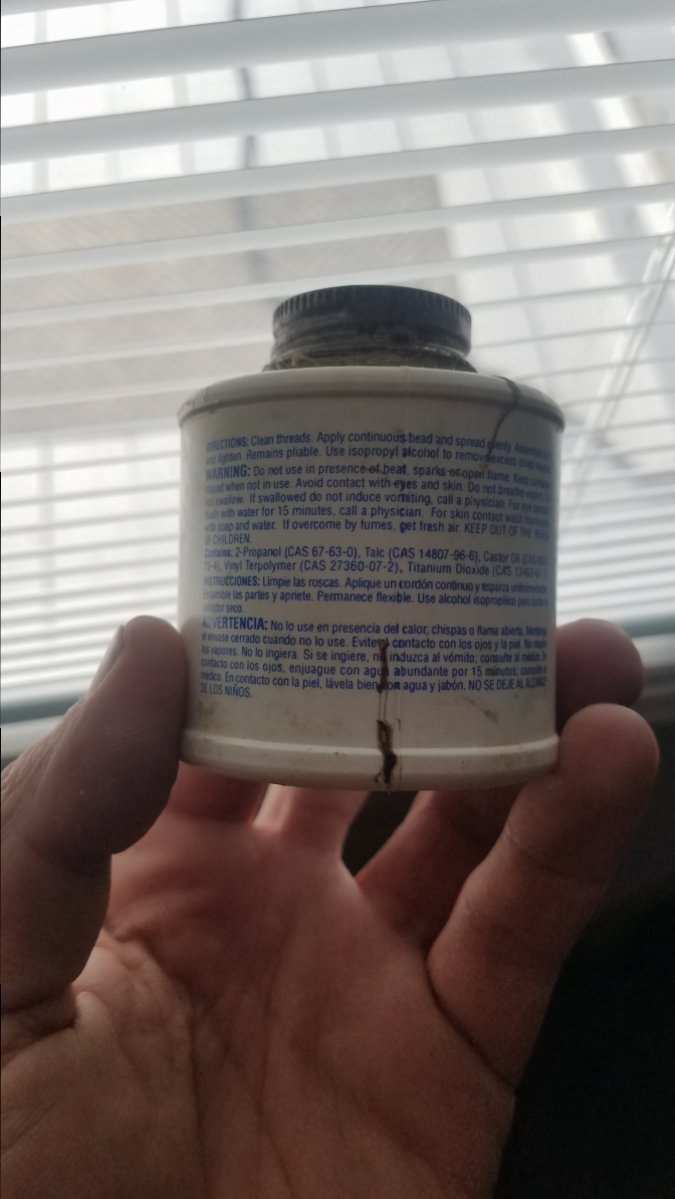

Don't use that you have. This.

That is threaded, so it will not be in the fitting itself, just clogging up the gaps in the threads. Or get a slip bulkhead and glue it.

i ended up using that item number and bought it from the store, however when i got home read the back and it says not to use on pvc. does yours say it any where on the back about that?

thanks! going to order it since im in no rush lol

It says nothing about PVC.

- Joined

- Mar 12, 2019

- Messages

- 82

- Reaction score

- 164

It should be a tapered pipe thread fitting and not need anything to to seal. Unless its british parallel pipe thread, that is not likely. Orko doesn't understand how pipe threads work. Do not shorten the fittings. It relies on thread pitch and taper to seal. Hence why the teflon tape caused the break.

Yep too many wraps of Teflon tape. The main job of Teflon tape is lubrication to prevent galling of the threads only a couple wraps are needed otherwise it will increase the diameter of the male threads. NPT (National Pipe Thread) threads are a taper fit to mechanically seal the joint. Save yourself the trouble and replace it because it will leak sooner or later. Oh and also don’t over tighten the joint or it will bust again looks like this is what happened. There should be a couple threads or so showing when tightened properly.

Last edited:

My part # is 765-1188. Permatex

I googled that and the one you showed is the one that popped up for it. Idk if they changed something or what lol. But i will probably just bring it back next trip there.My part # is 765-1188. Permatex

This one is ok for both pvc pipe and potable water applications:

Thanks big g!This one is ok for both pvc pipe and potable water applications:

Yea i ordered a new bulkhead and think im going to cut the end off the off to get some new threads too. Not a big fan of the 90 degree bend and was thinking about maybe a 45 into the bulkhead for a smoother flow? Or am i over thinking here.

Mastiffsrule

Where ever you go, there you are, so be nice 2 you

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Reef Squad Emeritus

Hospitality Award

My Tank Thread

This really helped me

http://www.lascofittings.com/threads

http://www.lascofittings.com/threads

- Don't wrap Teflon tape or Teflon paste or pipe dope to add bulk to or to lubricate the joint. Do use a sealant for threaded joints.

- Because the threads are tapered, additional turns cause the female part to stretch or undergo "strain." This will split the female fitting just as a wedge, driven by a sledgehammer, will split a tree stump.

- When Teflon tape is wrapped around plastic male threads it adds to the strain and tensile stress. The tendency of most installers is to incorrectly wrap several thickness of tape around the male threads, increasing stain and stress further.

Teflon paste and pipe dope, just like Teflon tape, make threaded joints slippery. Their use on PVC fittings can be an invitation to over-torque.

When working with threaded plastic fittings do use a proper sealant. The right sealant for threaded joints is non-hardening, compatible with plastic and doesn't add slipperiness

- The procedure to make leak free joints that will not cause split fittings is simple! Make-up the joint to finger-tight, not hand tight, then tighten 1 to 2 more turns. This method will provide a joint that is leak tight without causing excessive stress within the connection. It is important to realize that pipe thread sealant; especially those made with Teflon®, lubricate the threads and mislead the installer to believe the joint is not tight.

I use silicone o-ring lubricant on plastic threads on bulkheads. It makes them easy to hand tighten and they don’t over tighten and they don’t leak.

Any cracked plastic fitting is a problem. You did good for yourself getting a new one. Don’t over tighten it and it will last many years. GL!

Any cracked plastic fitting is a problem. You did good for yourself getting a new one. Don’t over tighten it and it will last many years. GL!

Some comments on bulkheads:

There are standard duty bulkheads: http://www.buckeyehydro.com/bulkheads/

and there are heavy duty bulkheads: http://www.buckeyehydro.com/bulkheads-heavy-duty/

In applications where a crack in the bulkhead or something similar would be a pain in the neck, use the heavy duty variety.

If you are going to use a lubricant/sealant on the threads, make sure it is intended for use on plastic, and with potable water. Teflon tape may be a safer bet.

Whenever you screw taped male threads into a poly female fitting you run the risk of the female cracking. One thing we do is to put a band clamp on the outside of the female part before screwing in the male. Also consider using a bulkhead with a slip female rather than a threaded female.

Remember the flange and gasket go on the wet side.

And yes - absolutely replace that cracked bulkhead.

Russ

There are standard duty bulkheads: http://www.buckeyehydro.com/bulkheads/

and there are heavy duty bulkheads: http://www.buckeyehydro.com/bulkheads-heavy-duty/

In applications where a crack in the bulkhead or something similar would be a pain in the neck, use the heavy duty variety.

If you are going to use a lubricant/sealant on the threads, make sure it is intended for use on plastic, and with potable water. Teflon tape may be a safer bet.

Whenever you screw taped male threads into a poly female fitting you run the risk of the female cracking. One thing we do is to put a band clamp on the outside of the female part before screwing in the male. Also consider using a bulkhead with a slip female rather than a threaded female.

Remember the flange and gasket go on the wet side.

And yes - absolutely replace that cracked bulkhead.

Russ

Similar threads

- Replies

- 8

- Views

- 166

- Replies

- 12

- Views

- 171

- Replies

- 2

- Views

- 124

- Replies

- 20

- Views

- 509

- Replies

- 6

- Views

- 176

New Posts

-

Markings on Gem Tang I can only see at night?

- Latest: onlyreefers

-

-

-

-