- Joined

- May 20, 2018

- Messages

- 303

- Reaction score

- 75

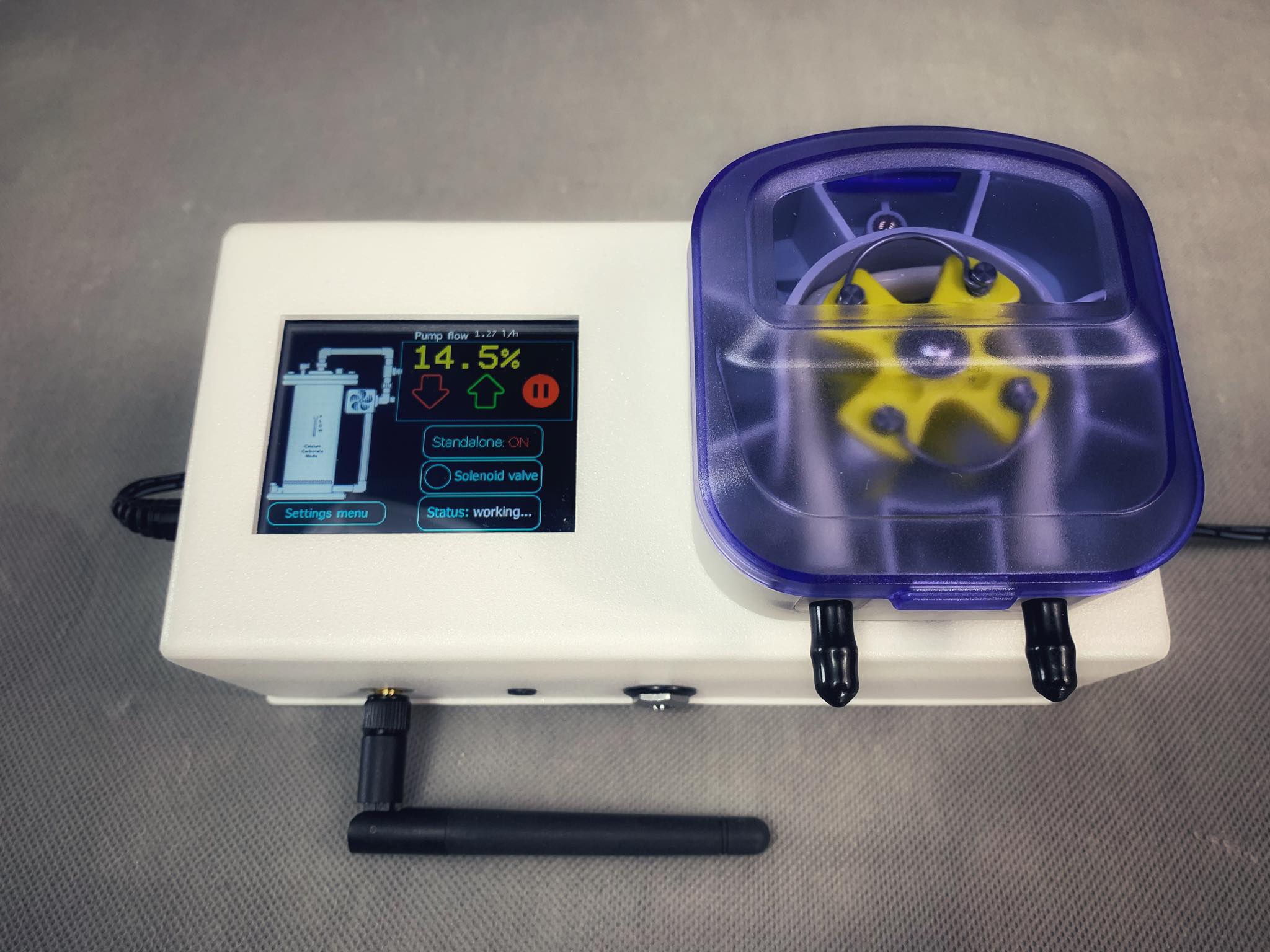

Hi, I've seen few videos and threads with people using either peristaltic pumps or DC pumps, some people say that have to migrate to DC pumps because peristatic pumps leak or don't have enough pressure or the output effluent is not enough, also they say that you have to change the tubing twice or at least once a year.

By the way on DC pumps, I think one of those new ones from current usa have a very good way to control the output and I don't have plans to use it with a needle valve so clogging won't be an issue.

So, which one do you guys still think are the reasons why should I get a DC pump or a Peristatic pump?

By the way on DC pumps, I think one of those new ones from current usa have a very good way to control the output and I don't have plans to use it with a needle valve so clogging won't be an issue.

So, which one do you guys still think are the reasons why should I get a DC pump or a Peristatic pump?