- Joined

- Sep 18, 2017

- Messages

- 5,590

- Reaction score

- 3,440

In europe...

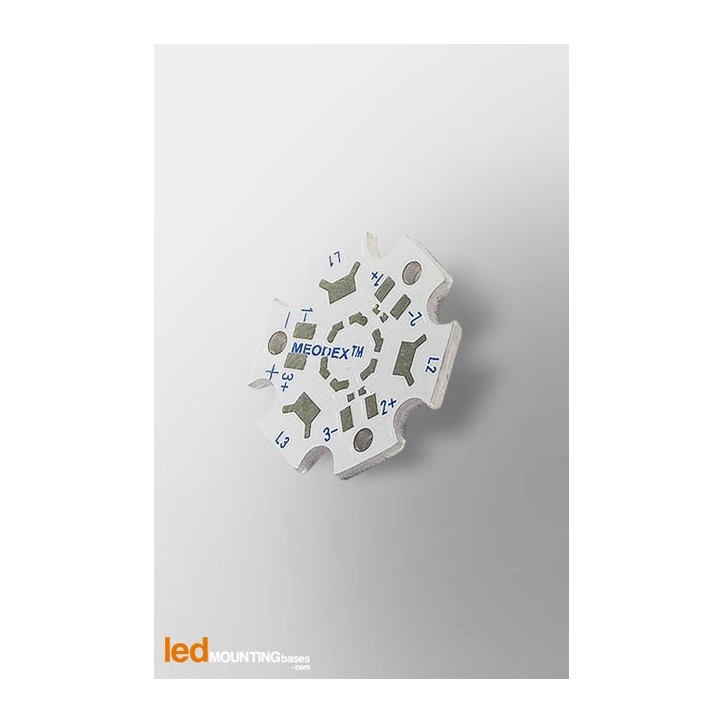

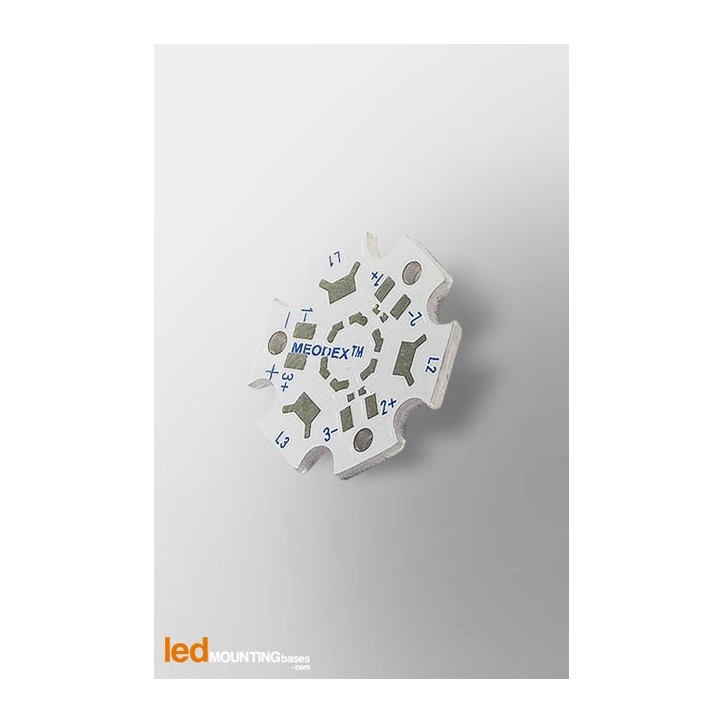

led-mounting-bases.com

led-mounting-bases.com

Reflowing leds is not for the faint of heart.

Besides Steves led price is about what you would pay price-wise in getting the parts. You would need a pretty specific reason for it.

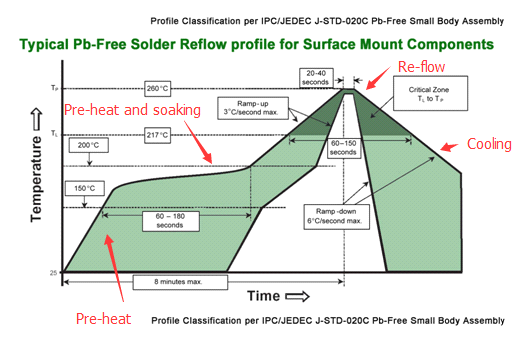

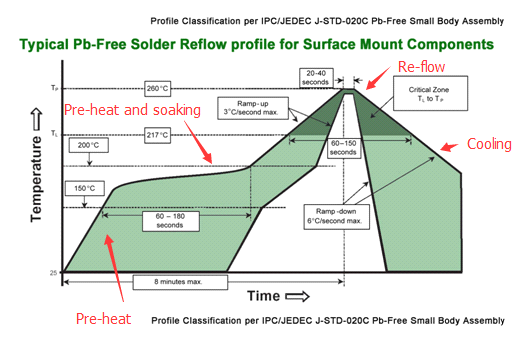

Example of how its done in industry, That said one can use an electric fry pan.

STAR PCB for 3 LED Lumileds Luxeon Rebel / Carclo LED lens compatib...

STAR PCB for 3 LED Lumileds Luxeon Rebel / Carclo LED lens compatible - Led Mounting Bases - STAR PCB for 3 LED Lumileds Luxeon Rebel / Carclo LED lens compa...

Reflowing leds is not for the faint of heart.

Besides Steves led price is about what you would pay price-wise in getting the parts. You would need a pretty specific reason for it.

Example of how its done in industry, That said one can use an electric fry pan.

How to optimize the reflow profile? - Bittele

This page lists the things you need to do to optimize a reflow profile of a target board, including making a virtual reflow profile, checking solder joint quality, testing the board's thermal shock and mechanical reliability, and adjusting parameter set up.

www.7pcb.com