Okay, complete post on my A.G.E tank/stand issue. The information in this post is either fact of my own situation, or public record. (@chefjpaul @Skep18 @KingJason)

Ever since i got the tank, i noticed a "tick" "tick" settling sounding noise coming from it every once in a while. It was clear it was due to the loading but i figured it might be the "leveling feet" (just upside down hex head structural bolts) being back driven by the load on them or the plywood deck on the top of the stand settling out any residual stresses etc... I reported this to Chris Brenes, Acrylic and glass exhibits / The Fish Gallery (AGE) sales rep, who didn't really make much of it so i let it go.

Fast forward to more recently. While measuring my home/tank/stand to build my lower cabinets, i noticed this:

Video showing light coming through, from the other side of the tank, between the bottom of the tank and the top of the stand deck:

Video showing the sagging PVC bottom of the tank. The edge of the PVC sheet is visible between the tank steel bracing and the top deck of the stand....

Video showing me pulling out a full sheet of paper i inserted between the tank and the stand. I can actually push this paper all the way through to the other side....

Edges of PVC tank bottom showing under the tank bracing...

Light shining through between the bottom of the tank and the top deck of the stand...

Measuring the gapping between the tank and stand...

So, basically, not good... I have ~ 4mm deflection. I decided to do hand calcs to see what the situation was with the stand, as built, assuming a very non-conservative (i.e. not safe because it is too small!) design load of the dry weight of the tank, plus the weight of saltwater to fill it.

In this situation, 100% fixity cannot be assumed! So the true situation exists somewhere in between 0%-100% fixity. Regardless, the safety factor in the best case, 100% fixity, is still MUCH MUCH too low for something that risks this level of hazard to life and property!

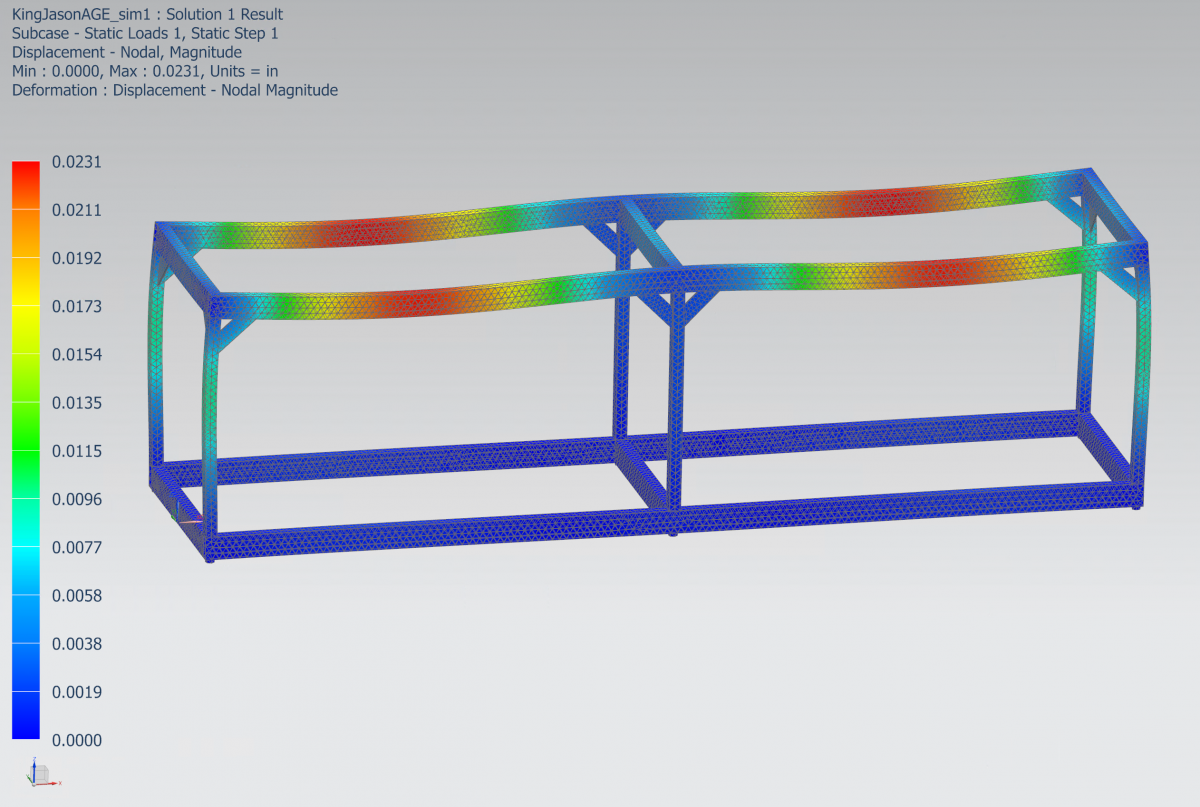

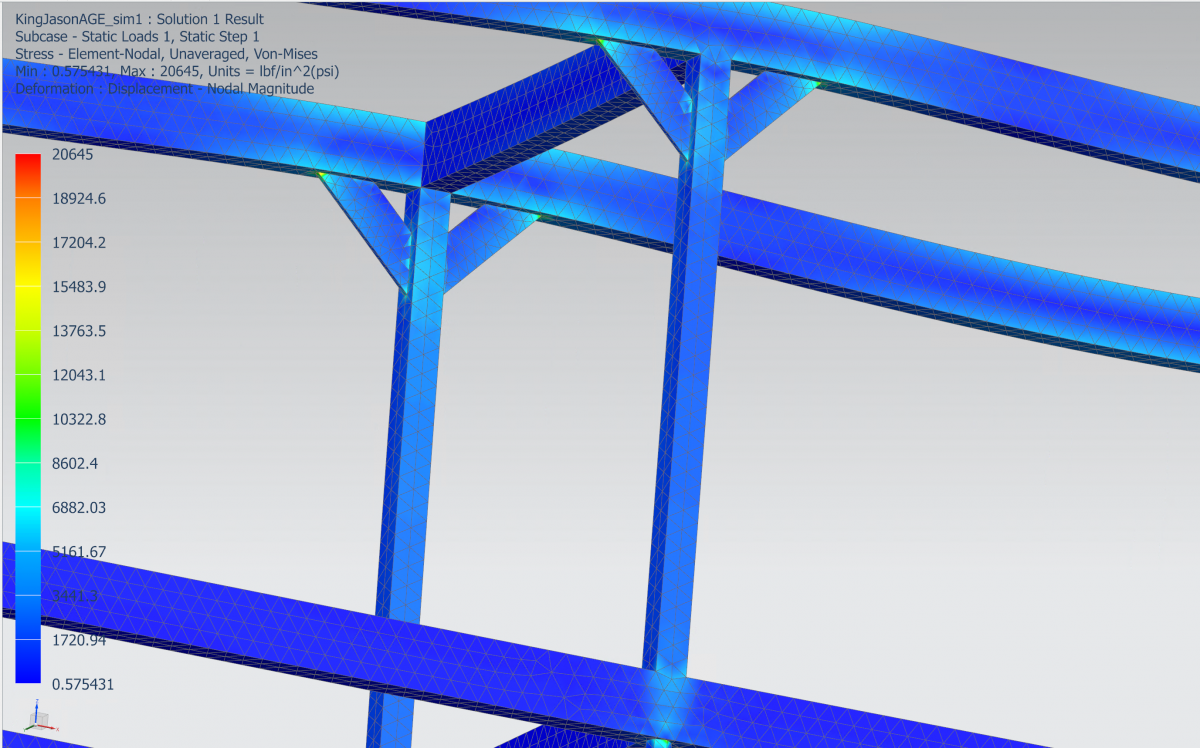

Okay, so for @Skep18 this probably makes loads of sense from statics and mech. of materials class, but for the rest of you, the next bit is probably better. I decided that hand calcs show a bad situation but it ultimately ignores the angled pieces between the vertical legs etc... so finite element analysis is an easier way to communicate the problem more accurately. So i built the stand in CAD and ran an FEA:

My setup: Feet are fully fixed. Top of stand is holding the weight of the dry tank, the saltwater to fill that tank, and the deck of plywood that sits on top of the stand, under the tank. No rocks, no equipment, nothing else.

Here is the displacement with visual-magnification factor set to 1x. You can see max deflection is 0.128in (3.2512mm). Scroll back up to my previous photos and you will see i am measuring 4mm. This is the difference between a "perfect" stand (no welds, no holes, just magically this structure exists in perfect world) and real life. This discrepancy is, in part, EXACTLY one of the reasons when designing things engineers add additional safety factor to designs. Explanation of safety factor is next.

Safety factors: A safety factor of 1 means the structure is just barely designed to hold the load you're putting on it. Factor of safety of 2 means the structure is designed to hold twice the load you're going to put on it. I.e. safety factors equal are a multiplier on the intended load that something can withstand).

Safety factor to yield: "Yielding" is an engineer's way of saying "permanently bent". It is when you bend something and it begins to deform plastically, meaning, you bend it, you let go, and it does NOT go back into its original shape: it yielded/ plastically deformed (vs elastically deformed like a rubber band, which goes right back to where it was before you bent it). Generally speaking, yielding is considered failure in almost all engineering disciplines.

For some perspective:

Considering we are talking about massive tanks, massive amounts of water, and putting it into peoples homes who then put massive amounts of money and time into them, I'd hazard a guess that if this was controlled by US code, the required safety factors for stands on tanks >100 gallons would have to be somewhere in the ballpark of 2.5 to 5.

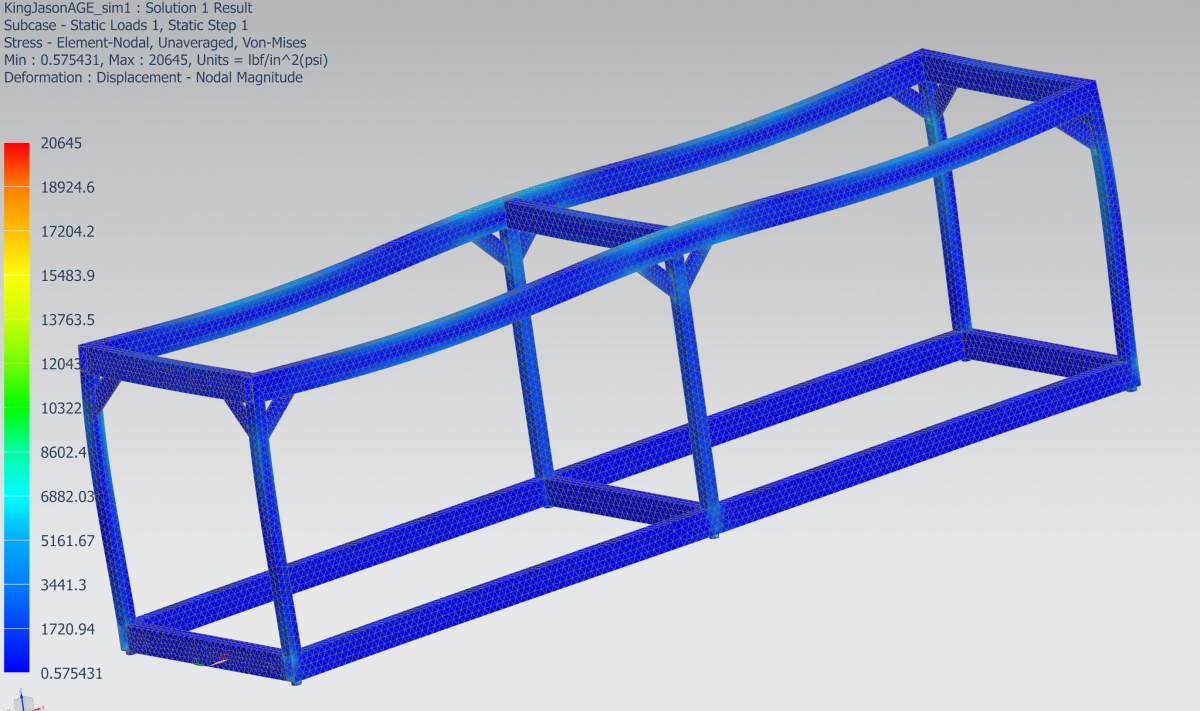

Stress: Now that i explained safety factors, let see what safety factor the simulation says the stand has to the weight of just the tank, the salt water to fill it, and the plywood top deck of the stand:

So, this is a little more complex to understand fully, so i'll try my best to keep you engaged as i explain: There is exists a small nodal region near where the angle supports meet the structure that's red. Stress level of 17.7 ksi. This might be an artifact of the simulation and geometry so lets give A.G.E the benefit of the doubt and ignore that. Everyone would agree that yellow is definitely in this structure though: 13.2886 ksi. The compressive yield strength of A36, common structural steel for square tube, is 22ksi (MATWEB). To calculate safety factor, we take the strength of the material and divide it by the max stress. Thus, if our stress is only half of the max strength of the material, then we have a nice safety factor of 2! So for this situation, we say our max stress is 13.2886 ksi (yellow color). And the material has a strength of 22ksi.

22ksi/13.2886ksi = 1.655 safety factor. In aerospace, we rarely have safety factors this low. And aerospace carries some of the lowest safety factors of ALL engineering. The reason why: we have to launch it into space so if it is too heavy, it won't get off the ground. So how does NASA get away with flying super expensive components with low safety factors? We test test test test test these pieces like crazy, then we analyze them like crazy with things like xrays etc.. to ensure that have testing them, they aren't damaged internally. Then we feel statistically safe they will perform in flight. This process is very expensive, hence why our projects cost so darn much. The cost and time to do this doesn't make sense for things like cars, tables, aquariums, so you over design them with a fat safety factor.

A safety factor of 1.655 on something that lives in peoples homes, exists in a corrosive environment (saltwater...), a dynamic environment (water motion), and risks serious hard to life and property, is insufficient and grossly negligent.

I emailed all this info to A.G.E, and the owner of The Fish Gallery / Acrylic and Glass Exhibits, Roger S Degregori (all this info is public fyi), told me that i am "over analyzing" this. We talked over the phone a few times and he admits that they have never engineered anything it is just based on his experience. He even went so far as to say he has a "sixth sense" for things like this. Kept saying if he had "seen anything concerning when [he] came to deliver the tank personally to my home he wouldn't have left it there risking failure". I repeatedly try to explain to him this isn't about a bad batch of metal or bad welds, it is about it just being under designed. He then went on to start blaming things i may have done etc... I don't want to go too far into this part of the issue. Suffice it to say, A.G.E takes responsibility for the failing stand and wants to try and "fix" it by either having me design a leg for them to make and on my time and dollar i'd have to attach it to the stand myself, OR, they send me a new stand and i have to break down my tank, which has that entire rock structure cemented to the overflow box, and swap it all out myself.... uhhh no thanks... not going to let them give it another "good ol' college try" at making a stand for me since by their owner's admission: no one over there knows how to use a calculator to design anything.

So now, now there is the issue of the tank. The center of the length of the tank is no longer supported, all the way across its width. As per A.G.E's warranty on their website:

http://www.acrylicandglassexhibits.com/About-Us

Thus, if this situation had been caused by another stand, the warranty on the tank would be null and void.

Multiple times i reiterated these points via email and over the phone:

Based on the above points, and the situation of my stand/tank, someone would be VERY VERY hard pressed to prove the joints of the tank have not been stressed beyond intent. Hence why this would void A.G.E warranty (if this hadn't been caused by AGE in the first place). Even with all of this, Roger maintains that because it is holding water presently, the tank is fine because it is built like “a brick s***house” (not a technical term so I have no idea what that means....). Roger also says that he “can’t promise it won’t break tomorrow” and he can’t show me any form of proof that it’s fine. I just have to take his unqualified-mechanical “word” for it.....

As everyone on here knows, even with a full refund, I have a LONG and likely expensive road ahead of me. I can't touch the stand to support it temporarily, and i can't go the route of designing something FOR AGE to fix this mess because my attorney has advised me not to as it risks producing a lack in clarity of culpability should damages need to be recouped legally. Makes sense.

I have found that Roger's attorney, or at least his attorney in a case in Texas court, is someone with the same last name (found via HCDistrictclerk.com case search). So it likely won't cost him to defend himself in court....which is probably why he is so brazen with me about not making good on their warranty, but I'm not worried.

On top of all of this, ever since i got the tank, and have been looking at other starphire tanks in person, i'm pretty sure i also didn't get the starphire glass i paid for on all sides:

Photo of my AGE glass edge on, camera right up against the cut edge of the glass with flash on:

A.G.E Glass again:

OCEANIC GLASS true starphire: edge on, camera right up against the cut edge of the glass with flash on:

OCEANIC GLASS (true starphire):

I have also done a similar FEA analysis on @KingJason 's tank stand. His deflection is much better than mine. Basically zero. But it looks like his safety factors are also around 1.5.... and his tank is nearly twice the size of mine

I'd hate to see what happens in an earthquake with our tanks....

....wonder if anyone actually will read all of this.... but this is why i now say NEVER BUY a tank from Acrylic and Glass Exhibits, The Fish Gallery, or anyone, for that matter,who doesn't say what the safety factor is on their stands.....especially if their response to that question is "huh?” ......ugh

What would you want if you found yourself in this situation?

..

Ever since i got the tank, i noticed a "tick" "tick" settling sounding noise coming from it every once in a while. It was clear it was due to the loading but i figured it might be the "leveling feet" (just upside down hex head structural bolts) being back driven by the load on them or the plywood deck on the top of the stand settling out any residual stresses etc... I reported this to Chris Brenes, Acrylic and glass exhibits / The Fish Gallery (AGE) sales rep, who didn't really make much of it so i let it go.

Fast forward to more recently. While measuring my home/tank/stand to build my lower cabinets, i noticed this:

Video showing light coming through, from the other side of the tank, between the bottom of the tank and the top of the stand deck:

Video showing the sagging PVC bottom of the tank. The edge of the PVC sheet is visible between the tank steel bracing and the top deck of the stand....

Video showing me pulling out a full sheet of paper i inserted between the tank and the stand. I can actually push this paper all the way through to the other side....

Edges of PVC tank bottom showing under the tank bracing...

Light shining through between the bottom of the tank and the top deck of the stand...

Measuring the gapping between the tank and stand...

So, basically, not good... I have ~ 4mm deflection. I decided to do hand calcs to see what the situation was with the stand, as built, assuming a very non-conservative (i.e. not safe because it is too small!) design load of the dry weight of the tank, plus the weight of saltwater to fill it.

In this situation, 100% fixity cannot be assumed! So the true situation exists somewhere in between 0%-100% fixity. Regardless, the safety factor in the best case, 100% fixity, is still MUCH MUCH too low for something that risks this level of hazard to life and property!

Okay, so for @Skep18 this probably makes loads of sense from statics and mech. of materials class, but for the rest of you, the next bit is probably better. I decided that hand calcs show a bad situation but it ultimately ignores the angled pieces between the vertical legs etc... so finite element analysis is an easier way to communicate the problem more accurately. So i built the stand in CAD and ran an FEA:

My setup: Feet are fully fixed. Top of stand is holding the weight of the dry tank, the saltwater to fill that tank, and the deck of plywood that sits on top of the stand, under the tank. No rocks, no equipment, nothing else.

Here is the displacement with visual-magnification factor set to 1x. You can see max deflection is 0.128in (3.2512mm). Scroll back up to my previous photos and you will see i am measuring 4mm. This is the difference between a "perfect" stand (no welds, no holes, just magically this structure exists in perfect world) and real life. This discrepancy is, in part, EXACTLY one of the reasons when designing things engineers add additional safety factor to designs. Explanation of safety factor is next.

Safety factors: A safety factor of 1 means the structure is just barely designed to hold the load you're putting on it. Factor of safety of 2 means the structure is designed to hold twice the load you're going to put on it. I.e. safety factors equal are a multiplier on the intended load that something can withstand).

Safety factor to yield: "Yielding" is an engineer's way of saying "permanently bent". It is when you bend something and it begins to deform plastically, meaning, you bend it, you let go, and it does NOT go back into its original shape: it yielded/ plastically deformed (vs elastically deformed like a rubber band, which goes right back to where it was before you bent it). Generally speaking, yielding is considered failure in almost all engineering disciplines.

For some perspective:

- Flight Spacecraft structures have design factors of safety to yield around 1.5 (they are EXTENSIVELY proof tested and post test analyzed with penetrating dyes, xray, etc... and only made from the highest grade materials available)

- For fixtures that hold personnel or flight hardware, the safety factors have to be 3.5 to yield and 5 to ultimate strength.

Applications Factor of Safety

For use with highly reliable materials where loading and environmental conditions are not severe and where weight is an important consideration 1.3 - 1.5

For use with reliable materials where loading and environmental conditions are not severe 1.5 - 2

For use with ordinary materials where loading and environmental conditions are not severe 2 - 2.5

For use with less tried and for brittle materials where loading and environmental conditions are not severe 2.5 - 3

For use with materials where properties are not reliable and where loading and environmental conditions are not severe, or where reliable materials are used under difficult and environmental conditions 3 - 4

Equipment Factor of Safety

Aircraft components 1.5 - 2.5

Boilers 3.5 - 6

Bolts 8.5

Cast-iron wheels 20

Engine components 6 - 8

Heavy duty shafting 10 - 12

Lifting equipment - hooks .. 8 - 9

Pressure vessels 3.5 - 6

Turbine components - static 6 - 8

Turbine components - rotating 2 - 3

Spring, large heavy-duty 4.5

Structural steel work in buildings 4 - 6

Structural steel work in bridges 5 - 7

Wire ropes 8 - 9

Considering we are talking about massive tanks, massive amounts of water, and putting it into peoples homes who then put massive amounts of money and time into them, I'd hazard a guess that if this was controlled by US code, the required safety factors for stands on tanks >100 gallons would have to be somewhere in the ballpark of 2.5 to 5.

Stress: Now that i explained safety factors, let see what safety factor the simulation says the stand has to the weight of just the tank, the salt water to fill it, and the plywood top deck of the stand:

So, this is a little more complex to understand fully, so i'll try my best to keep you engaged as i explain: There is exists a small nodal region near where the angle supports meet the structure that's red. Stress level of 17.7 ksi. This might be an artifact of the simulation and geometry so lets give A.G.E the benefit of the doubt and ignore that. Everyone would agree that yellow is definitely in this structure though: 13.2886 ksi. The compressive yield strength of A36, common structural steel for square tube, is 22ksi (MATWEB). To calculate safety factor, we take the strength of the material and divide it by the max stress. Thus, if our stress is only half of the max strength of the material, then we have a nice safety factor of 2! So for this situation, we say our max stress is 13.2886 ksi (yellow color). And the material has a strength of 22ksi.

22ksi/13.2886ksi = 1.655 safety factor. In aerospace, we rarely have safety factors this low. And aerospace carries some of the lowest safety factors of ALL engineering. The reason why: we have to launch it into space so if it is too heavy, it won't get off the ground. So how does NASA get away with flying super expensive components with low safety factors? We test test test test test these pieces like crazy, then we analyze them like crazy with things like xrays etc.. to ensure that have testing them, they aren't damaged internally. Then we feel statistically safe they will perform in flight. This process is very expensive, hence why our projects cost so darn much. The cost and time to do this doesn't make sense for things like cars, tables, aquariums, so you over design them with a fat safety factor.

A safety factor of 1.655 on something that lives in peoples homes, exists in a corrosive environment (saltwater...), a dynamic environment (water motion), and risks serious hard to life and property, is insufficient and grossly negligent.

I emailed all this info to A.G.E, and the owner of The Fish Gallery / Acrylic and Glass Exhibits, Roger S Degregori (all this info is public fyi), told me that i am "over analyzing" this. We talked over the phone a few times and he admits that they have never engineered anything it is just based on his experience. He even went so far as to say he has a "sixth sense" for things like this. Kept saying if he had "seen anything concerning when [he] came to deliver the tank personally to my home he wouldn't have left it there risking failure". I repeatedly try to explain to him this isn't about a bad batch of metal or bad welds, it is about it just being under designed. He then went on to start blaming things i may have done etc... I don't want to go too far into this part of the issue. Suffice it to say, A.G.E takes responsibility for the failing stand and wants to try and "fix" it by either having me design a leg for them to make and on my time and dollar i'd have to attach it to the stand myself, OR, they send me a new stand and i have to break down my tank, which has that entire rock structure cemented to the overflow box, and swap it all out myself.... uhhh no thanks... not going to let them give it another "good ol' college try" at making a stand for me since by their owner's admission: no one over there knows how to use a calculator to design anything.

So now, now there is the issue of the tank. The center of the length of the tank is no longer supported, all the way across its width. As per A.G.E's warranty on their website:

http://www.acrylicandglassexhibits.com/About-Us

Warranty Information - Glass & Acrylic Aquariums

- 3 years on approved A.G.E. or professionally built aquarium stands (other stand manufacturer with insurance)

- Warranty void on home built aquarium stands

Terms & Conditions

- Aquarium must be level from all angles

- Stands cannot have their structural integrity compromised through modification

- All intended structural support points must be in contact with their intended surface

- Aquarium must come flush to stand edges, they cannot hang over edges or be supported by undersized stands

Thus, if this situation had been caused by another stand, the warranty on the tank would be null and void.

Multiple times i reiterated these points via email and over the phone:

My reasons reiterated are as follows:

- The stand has failed. The longitudinal top beam of the stand is deflecting a full 4mm from its unstressed state. This deflection exists on both sides of the tank. Thus, the tank center is unsupported across the entire transverse-width of the tank, causing light to be able to be seen passing under the tank between the top of the stand and the bottom of the tank. The center of the tank is therefore no longer being supported. The cut edges of the PVC bottom of the tank are visible from the outside of the tank and are hanging below the bottom steel bracing of the tank indicating the expected additional stress on the silicone joints holding the tank glass walls to the PVC base.

- Being that the A.G.E tank is no longer supported on all of its edges due to the failing A.G.E stand, on the phone today you explicitly conceded that you are not able to produce a guarantee that the tank “won’t fail tomorrow” but rather based on your experience you “think it is okay”. If this situation had been the result of another manufacturer’s stand with an A.G.E tank, as per your company’s warranty policy, the warranty on the A.G.E tank would be void due to the failed condition of the stand. Therefore, the tank is deemed “compromised” under A.G.E’s warranty. Based on my engineering education, I am 100% certain that due to the off-nominal stress state imposed on the tank, the tank’s joints have been/are being subjected to a stress state above what the tank would see with a non-failing stand. There is no promise without analysis that these joints have not been overstrained, crazed, and or their strength compromised.

- Today on the phone you conceded that A.G.E tanks and stands are not a product of reasoned engineering thought and calculations as that would be prohibitively costly, but instead, their design is based your experience. In my experience with A.G.E, I received an under-designed stand. Based on remedial engineering calculations verified by my coworkers and as well by a computer simulation of the precise situation, I was able to clearly show that A.G.E provided a stand that is under-designed for the A.G.E tank provided with that stand. That result caused me to look at other A.G.E customers’ stands in my area and found similar results with their stands. Granted you claim a blemish free history, however, my history with A.G.E to this point has been the exact opposite. Thus, allowing A.G.E to attempt to remedy this situation by coming up with something else, is not an acceptable path towards a resolution of this problem.

When products are sold, in addition to any stated warranty by the seller/manufacturer, by law they have an implied warranty of merchantability and of fitness for a particular purpose. I purchased a tank and a stand for it, along with your time to fly out here to my home and deliver and place the items by hand to ensure the tank and stand would do what they are supposed to do, and are suitable for that particular purpose. Because of the aforementioned reasons I maintain that by implied warranties of merchantability and fitness, and by the warranty of your company, I am due for a full refund. Even with a full refund from A.G.E, fixing this problem is going to cost me an appreciable amount more time and money. The loss of my time and the additional money already spent (on top of what I paid your company) in putting this ecosystem together are lost.

- I paid a premium for your “white glove delivery service” to ensure your warranty would be in full force for my system, as it is a very large liability to property and life should there be a failure. Your warranty states several conditions needing to be met for the warranty to be valid. These conditions of your warranty practically require verification of said conditions by your personnel prior to the occurrence of a failure, should a warranty claim need to be made. The only ironclad verification is for A.G.E to come set up the system yourselves. Thus, I was persuaded to pay the premium for your white glove delivery service. You yourself came to my home for the delivery of my tank and stand and with your coworker you put the tank in its place in the center of my home.

Based on the above points, and the situation of my stand/tank, someone would be VERY VERY hard pressed to prove the joints of the tank have not been stressed beyond intent. Hence why this would void A.G.E warranty (if this hadn't been caused by AGE in the first place). Even with all of this, Roger maintains that because it is holding water presently, the tank is fine because it is built like “a brick s***house” (not a technical term so I have no idea what that means....). Roger also says that he “can’t promise it won’t break tomorrow” and he can’t show me any form of proof that it’s fine. I just have to take his unqualified-mechanical “word” for it.....

As everyone on here knows, even with a full refund, I have a LONG and likely expensive road ahead of me. I can't touch the stand to support it temporarily, and i can't go the route of designing something FOR AGE to fix this mess because my attorney has advised me not to as it risks producing a lack in clarity of culpability should damages need to be recouped legally. Makes sense.

I have found that Roger's attorney, or at least his attorney in a case in Texas court, is someone with the same last name (found via HCDistrictclerk.com case search). So it likely won't cost him to defend himself in court....which is probably why he is so brazen with me about not making good on their warranty, but I'm not worried.

On top of all of this, ever since i got the tank, and have been looking at other starphire tanks in person, i'm pretty sure i also didn't get the starphire glass i paid for on all sides:

Photo of my AGE glass edge on, camera right up against the cut edge of the glass with flash on:

A.G.E Glass again:

OCEANIC GLASS true starphire: edge on, camera right up against the cut edge of the glass with flash on:

OCEANIC GLASS (true starphire):

I have also done a similar FEA analysis on @KingJason 's tank stand. His deflection is much better than mine. Basically zero. But it looks like his safety factors are also around 1.5.... and his tank is nearly twice the size of mine

I'd hate to see what happens in an earthquake with our tanks....

....wonder if anyone actually will read all of this.... but this is why i now say NEVER BUY a tank from Acrylic and Glass Exhibits, The Fish Gallery, or anyone, for that matter,who doesn't say what the safety factor is on their stands.....especially if their response to that question is "huh?” ......ugh

What would you want if you found yourself in this situation?

..

Last edited: