The gold standard for bonding acrylic to itself in larger aquarium builds is polymerizable cement bonding. It is the go to method when joining pieces greater than 1 inch in thickness and some cases, as thin as 1/2 inch. Polymerizable cements are those in which a catalyst is added to an already thick monomer/polymer syrup to promote rapid hardening. Cements PS-30 and Weld-On 40 or 42 are polymerizable cements of this type. They are suitable for cementing all types of acrylic sheet.

At room temperature, these cements harden (polymerize) in the container in about 45 minutes after the components are mixed. They will harden more rapidly at higher temperatures. The cement joints are usually strong enough for handling one to two hours after assembly depending upon part configuration. The joints may be machined four hours after assembly, but it is better to wait 24 hours.

PS-30 and Weld-On 40 or 42 joints retain excellent appearance and color stability after outdoor exposure. These cements produce clear, transparent joints and should be used when the clarity and appearance of the joints are important.

PS-30 and Weld-On 40 or 42 should be used at temperatures no lower than 65°F. If cementing is done in a room cooler than 65°F, it will require a longer time to harden and the joint strength will be reduced. The cement should be prepared with the correct proportions of components as recommended by the manufacturer and thoroughly mixed. Make sure neither the mixing container nor mixing paddle adds color or affects the hardening of the cement. Clean glass or polyethylene mixing containers are preferred.

PRO TIP >>> PS-30 may be thinned by adding up to 25 percent MMA inhibited monomer to Component A to minimize bubbles when laminating. Up to twice the normally recommended amount of Component B may be used to increase the polymerizing rates.

PRO TIP >>> Adding about 10 percent (by weight) Plexiglas® VS-100 acrylic molding resin will reduce shrinkage of the cement during polymerization. However this will also slightly decrease joint strength. The pellets must be thoroughly dissolved before mixing the components.

Because of their short pot life (approximately 45 minutes), Cements PS-30 and Weld-On 40 or 42 must be used quickly once the components are mixed. Time consumed in preparation shortens the effective working time, making it necessary to have everything ready to be cemented before the components are mixed.

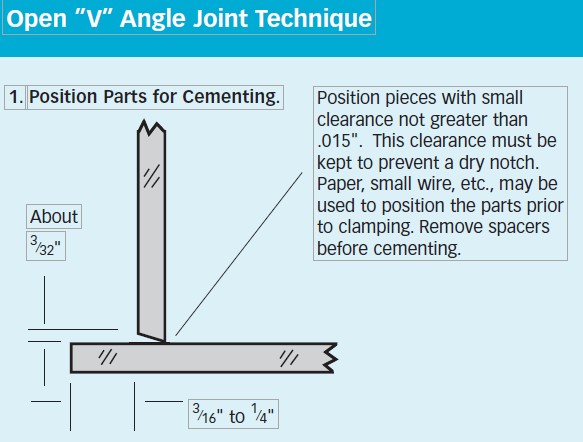

Bonding Techniques. There are several bonding techniques and for our purposes, I will focus on the most common one suitable for aquarium manufacture. I call it the "Open V Angle Joint" technique. It is described below.

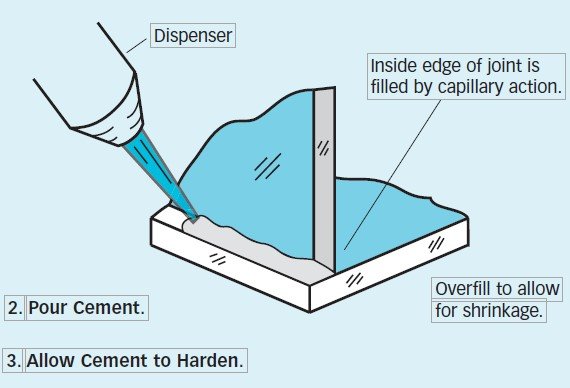

The hardest step is making an accurate "V" cut. Notice how the piece with the "V" cut sits directly on the piece it will be cemented to. No need for pins. The edge of the cut acts as a perimeter for the cement. However, if the cut is not accurate, cement will pass beyond the inside edge to the vertical piece.

As stated earlier, the cement will set in approximately 2 hours and cure to 80% strength in about 24 hours. Do not attempt the secondary finishing operations until at least 24 hours have passed. Four hours is usually enough but longer wait times are better.

In summary, this is a high level description of the Open V Gap technique, the most common polymerizable bonding technique. This technique is significantly superior than solvent bonding when working with thicker gauges and/or larger tanks. I will discuss more advanced polymerizable bonding techniques in future posts. All the best.

At room temperature, these cements harden (polymerize) in the container in about 45 minutes after the components are mixed. They will harden more rapidly at higher temperatures. The cement joints are usually strong enough for handling one to two hours after assembly depending upon part configuration. The joints may be machined four hours after assembly, but it is better to wait 24 hours.

PS-30 and Weld-On 40 or 42 joints retain excellent appearance and color stability after outdoor exposure. These cements produce clear, transparent joints and should be used when the clarity and appearance of the joints are important.

PS-30 and Weld-On 40 or 42 should be used at temperatures no lower than 65°F. If cementing is done in a room cooler than 65°F, it will require a longer time to harden and the joint strength will be reduced. The cement should be prepared with the correct proportions of components as recommended by the manufacturer and thoroughly mixed. Make sure neither the mixing container nor mixing paddle adds color or affects the hardening of the cement. Clean glass or polyethylene mixing containers are preferred.

PRO TIP >>> PS-30 may be thinned by adding up to 25 percent MMA inhibited monomer to Component A to minimize bubbles when laminating. Up to twice the normally recommended amount of Component B may be used to increase the polymerizing rates.

PRO TIP >>> Adding about 10 percent (by weight) Plexiglas® VS-100 acrylic molding resin will reduce shrinkage of the cement during polymerization. However this will also slightly decrease joint strength. The pellets must be thoroughly dissolved before mixing the components.

Because of their short pot life (approximately 45 minutes), Cements PS-30 and Weld-On 40 or 42 must be used quickly once the components are mixed. Time consumed in preparation shortens the effective working time, making it necessary to have everything ready to be cemented before the components are mixed.

Bonding Techniques. There are several bonding techniques and for our purposes, I will focus on the most common one suitable for aquarium manufacture. I call it the "Open V Angle Joint" technique. It is described below.

The hardest step is making an accurate "V" cut. Notice how the piece with the "V" cut sits directly on the piece it will be cemented to. No need for pins. The edge of the cut acts as a perimeter for the cement. However, if the cut is not accurate, cement will pass beyond the inside edge to the vertical piece.

As stated earlier, the cement will set in approximately 2 hours and cure to 80% strength in about 24 hours. Do not attempt the secondary finishing operations until at least 24 hours have passed. Four hours is usually enough but longer wait times are better.

In summary, this is a high level description of the Open V Gap technique, the most common polymerizable bonding technique. This technique is significantly superior than solvent bonding when working with thicker gauges and/or larger tanks. I will discuss more advanced polymerizable bonding techniques in future posts. All the best.

Last edited by a moderator: