Hi all! I've been madly bored while everything is shut down to mitigate the pandemic, so I finally gave in and decided to set up a build for some random acros. I used to sell commercially years ago back in highschool, and I haven't had a proper tank to grow things out in since. I'm a huge wild Acropora collector, so this tank should fill in quickly. The plan is to grow out frags/chunks from different colonies and see what I can turn them into alongside some old classics. The other gimmick that I'm sticking with for this build is that I'm trying to scavenge/repair/recycle as much equipment as possible. Thankfully, I have plenty of old equipment sitting around, but I've already got to meet with other local reefers and had to dig around on Craigslist for other materials.

Here are some specs of what this build will include!

3' x 2' x 1' Shallow Lagoon Peninsula

Custom T5/LED Lights

Two Maxpect Gyre XF250

50ish Pounds of Pukani

40 Breeder Sump

Ecotech Vectra M1

Reef Octopus 150 NWB Skimmer

Neptune Apex Classic

Ancient Geo's Reef (I think?) Calcium Reactor with Milwaukee Regulator

So here's where things get fun. I've been building tanks for years, but my long-time reefing buddy convinced me to try to cut my own glass for a small desktop build. Small is boring and I had some glass laying around, so I decided to cut apart some tanks that I had laying around, which was moderately successful? I broke some tanks, and I was lucky enough to have some local reefers bail me out with extra tanks . I used 40 Breeders for the 36" long panels and a 20 Long for the 24" long panels. Cutting 1/4" glass is easy when it decides to break where it's supposed to. That doesn't always happen.

A sacrificial 40 Breeder:

Cutting apart the rim:

Rimless (right before I tore the panels apart):

Cutting a 36" long strip of 4" wide glass from my 36" x 16" 40 Breeder panels didn't go well and left jagged edges on my 36" x 12" peninsula panels:

Two 30" x 12" panels from a 20 Gallon that I tore apart:

Cutting 6" off of the 30" panel to get to my 24"x12" side panel:

I ground the few jagged edges on my 36" panels and clamped my four sides together. The grinding isn't perfect, but it's good enough.

I also drilled some holes for the plumbing on the 20" back panel. The 1.5" hole is for the overflow box. There are two 3/4" drain holes.

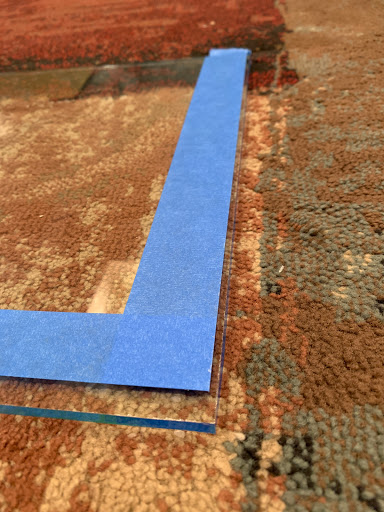

I took the tank apart and taped up all of the edges so that I can silicone it nice and cleanly! I'm using the injection method of building this tank, which is why the taping is 1/4" off on the sides of the short panels (pictured):

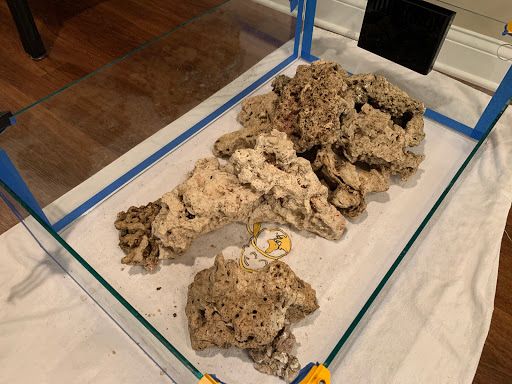

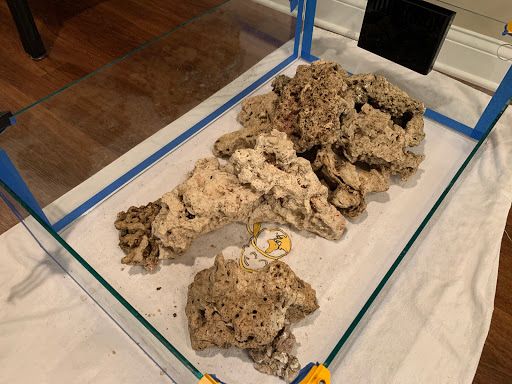

So! At this point, the tank was all taped up and I was using 90º clamps to hold the panels in place, so I decided to do some dry scaping with my rock. A friend is getting to ready to move out of town, so I snagged a bunch of bleached/cleaned Pukani rock for dirt cheap. Here's what I had to work with:

And this is what I ended up with. Top view:

Front left:

Front right:

Right side:

Front:

Left (there's more room between the rock and the glass than the picture shows; the extra-wide painter's tape hides the gap)

This tank is only 12" deep (11 3/4" when I finally get the bottom panel), so I wanted to keep the rockwork low so that my acros have room to grow vertically. Here's a rim-level side profile showing how I did. The tallest point of the scape is exactly 3" below the rim. After I subtract for the bottom panel and water level, I'll still have about 2" of water from the absolute top of the rocks and closer to 6" throughout the rest of the tank.

For the sump, I was going to build a custom 30"x18"x14" tank and throw in baffles and a sock holder, but I'm thoroughly tired of taking tanks apart. I caved and bought a 40 Breeder (after I destroyed two of them getting the glass for the DT. Oops). I'm going to use some scrap glass as a lid for the drain/filter sock chamber, and I have oversized skimmer and return chambers. I had the Reef Octopus and Vectra sitting around from my 24G nano build from two years ago, and I can always use even larger equipment with this sump in the future.

Putting in an 8" bubble trap:

Putting in two baffles for my filter sock holder. I'm going to cut the holder itself from some acrylic that should be arriving later today:

For lights, I have a super old 48x3W LED board that I originally ordered back in 2011ish. Two years ago, I cut it in half to fit into my Nanocube hood. Now I'm going to lay the two halves of the board into the middle of a custom hybrid fixture, but first I have to replace some of the broken LEDs. Luckily, I found some replacement diodes for $0.80 apiece on Amazon.

For the T5 part, I had an old 4x39W retrofit kit left over from my old growout tank that I took down in 2014. I managed to ruin the reflectors, so I got a 4' Aquaticlife T5 fixture from another local that I gutted for the reflectors and fans. I'm going to cut the center channel in half and end up with two 36" T5s on either side of my rebuilt LEDs. Check out this wild three-piece four bulb reflector:

That's where I'm at for today. I ordered the bottom tank panel from a glass shop because I couldn't find any 36" x 24" glass locally, and that should be done by the weekend. Once it is, I can silicone the tank together and let it sit for a few days before I leak test it. In the mean time, I need to build a stand and canopy, cut my filter sock holder, and get my lights put together. With any luck, I can get this tank fully up and running by next weekend. I already have my eye on some nice Aussie colonies and I have a store owner tracking me down some fish; this should all progress quickly. I'll leave you all with a picture of my old nano before from before it crashed out. Too many corals, not enough water volume.

(Also I swear the next round of posts will have better photo quality. I just realized that the forum isn't running vBulletin anymore and I guess I have to stop hosting my photos on Facebook. I used Blogger for this post, and the compression is wild.)

Here are some specs of what this build will include!

3' x 2' x 1' Shallow Lagoon Peninsula

Custom T5/LED Lights

Two Maxpect Gyre XF250

50ish Pounds of Pukani

40 Breeder Sump

Ecotech Vectra M1

Reef Octopus 150 NWB Skimmer

Neptune Apex Classic

Ancient Geo's Reef (I think?) Calcium Reactor with Milwaukee Regulator

So here's where things get fun. I've been building tanks for years, but my long-time reefing buddy convinced me to try to cut my own glass for a small desktop build. Small is boring and I had some glass laying around, so I decided to cut apart some tanks that I had laying around, which was moderately successful? I broke some tanks, and I was lucky enough to have some local reefers bail me out with extra tanks . I used 40 Breeders for the 36" long panels and a 20 Long for the 24" long panels. Cutting 1/4" glass is easy when it decides to break where it's supposed to. That doesn't always happen.

A sacrificial 40 Breeder:

Cutting apart the rim:

Rimless (right before I tore the panels apart):

Cutting a 36" long strip of 4" wide glass from my 36" x 16" 40 Breeder panels didn't go well and left jagged edges on my 36" x 12" peninsula panels:

Two 30" x 12" panels from a 20 Gallon that I tore apart:

Cutting 6" off of the 30" panel to get to my 24"x12" side panel:

I ground the few jagged edges on my 36" panels and clamped my four sides together. The grinding isn't perfect, but it's good enough.

I also drilled some holes for the plumbing on the 20" back panel. The 1.5" hole is for the overflow box. There are two 3/4" drain holes.

I took the tank apart and taped up all of the edges so that I can silicone it nice and cleanly! I'm using the injection method of building this tank, which is why the taping is 1/4" off on the sides of the short panels (pictured):

So! At this point, the tank was all taped up and I was using 90º clamps to hold the panels in place, so I decided to do some dry scaping with my rock. A friend is getting to ready to move out of town, so I snagged a bunch of bleached/cleaned Pukani rock for dirt cheap. Here's what I had to work with:

And this is what I ended up with. Top view:

Front left:

Front right:

Right side:

Front:

Left (there's more room between the rock and the glass than the picture shows; the extra-wide painter's tape hides the gap)

This tank is only 12" deep (11 3/4" when I finally get the bottom panel), so I wanted to keep the rockwork low so that my acros have room to grow vertically. Here's a rim-level side profile showing how I did. The tallest point of the scape is exactly 3" below the rim. After I subtract for the bottom panel and water level, I'll still have about 2" of water from the absolute top of the rocks and closer to 6" throughout the rest of the tank.

For the sump, I was going to build a custom 30"x18"x14" tank and throw in baffles and a sock holder, but I'm thoroughly tired of taking tanks apart. I caved and bought a 40 Breeder (after I destroyed two of them getting the glass for the DT. Oops). I'm going to use some scrap glass as a lid for the drain/filter sock chamber, and I have oversized skimmer and return chambers. I had the Reef Octopus and Vectra sitting around from my 24G nano build from two years ago, and I can always use even larger equipment with this sump in the future.

Putting in an 8" bubble trap:

Putting in two baffles for my filter sock holder. I'm going to cut the holder itself from some acrylic that should be arriving later today:

For lights, I have a super old 48x3W LED board that I originally ordered back in 2011ish. Two years ago, I cut it in half to fit into my Nanocube hood. Now I'm going to lay the two halves of the board into the middle of a custom hybrid fixture, but first I have to replace some of the broken LEDs. Luckily, I found some replacement diodes for $0.80 apiece on Amazon.

For the T5 part, I had an old 4x39W retrofit kit left over from my old growout tank that I took down in 2014. I managed to ruin the reflectors, so I got a 4' Aquaticlife T5 fixture from another local that I gutted for the reflectors and fans. I'm going to cut the center channel in half and end up with two 36" T5s on either side of my rebuilt LEDs. Check out this wild three-piece four bulb reflector:

That's where I'm at for today. I ordered the bottom tank panel from a glass shop because I couldn't find any 36" x 24" glass locally, and that should be done by the weekend. Once it is, I can silicone the tank together and let it sit for a few days before I leak test it. In the mean time, I need to build a stand and canopy, cut my filter sock holder, and get my lights put together. With any luck, I can get this tank fully up and running by next weekend. I already have my eye on some nice Aussie colonies and I have a store owner tracking me down some fish; this should all progress quickly. I'll leave you all with a picture of my old nano before from before it crashed out. Too many corals, not enough water volume.

(Also I swear the next round of posts will have better photo quality. I just realized that the forum isn't running vBulletin anymore and I guess I have to stop hosting my photos on Facebook. I used Blogger for this post, and the compression is wild.)