Curiosity got the best of me. So I got out of bed to check and sure enough, you are correct my friend . The input is after the ro membrane and just before the DI resin.I have the 4 stage BRS unit with the TDS meter but it has 2 meters, in and out. My in is after membrane and out is after resin. My water pressure is 45-60 and have not needed to change any of the filters after almost a year except resin. Tap is 55 TDS and after membrane it is 3

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help me understand when is best to change which filters on my RODI unit please.

- Thread starter fishbox

- Start date

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

- Joined

- Oct 6, 2017

- Messages

- 119

- Reaction score

- 191

Hey there,

It looks like you've gotten a number of helpful suggestions on here. A few things I would point out:

-With 6ppm breakthrough, it certainly is possible that some undesirable contaminants may be passing through which could contribute to algae growth, though it's hard to say for sure without testing the product water. A move and reset of the tank could also be a contributing factor.

-Sediment filters may not always change color as they clog; depends on your water. The primary concern is that they remove particulates, and should be replaced when they begin to clog, which would be indicated by a loss of pressure at the membrane.

-Carbon blocks typically will be good for a few thousand gallons, depending again on your municipal water, and testing for chlorine/chloramine breakthrough on your waste line on a regular basis is a good way to keep tabs on this. Keep in mind as well that all water, waste and product, are filtered by the carbon block. That means that if you are getting a 1:4 product to waste ratio, and produce 100 gallons of pure water, the carbon block has actually filtered about 500 gallons of water.

-DI resin usage will vary greatly by your source water and the contaminants. There isn't really a good way to give an accurate amount of time this should last, especially since everyone's water production needs will vary. I would focus more on the amount of water you're purifying and the level of starting TDS. In many cases (mine included) I'm lucky to have my DI last more than a few months. Others may get much more mileage. Ultimately, the goal when using DI resin is to get the water down to 0 TDS. If you have gone from 0 to 6, then this does suggest that the resin is no longer removing all impurities and needs to be replaced. The color change indicator is a nice convenience factor for visual monitoring, but TDS will be more accurate.

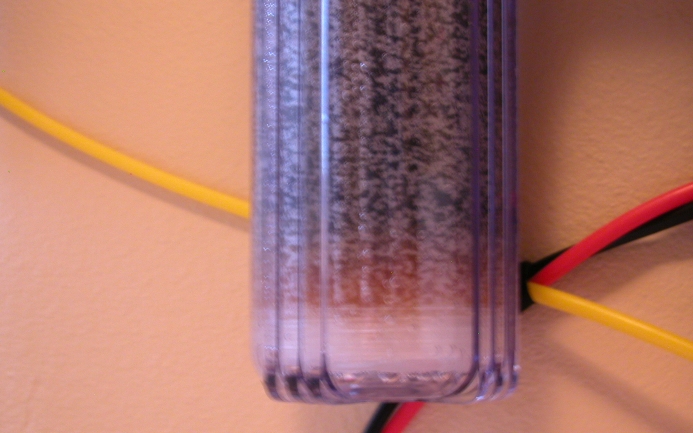

Looking at your DI resin cartridge, there does appear to be either some channeling going on, or stratification, both of which would suggest the DI resin is no longer tightly packed as it should be. Resin does shrink a small amount, and various other factors can affect settling inside of the cartridge, but I'd address this by replacing and re-packing your resin. This will likely return your final TDS to 0.

If your TDS is coming out at 27 after the membrane, I would be very curious to see what your tap TDS is. I would also ensure that your system's flush valve is not left in the open position, as this is a common issue and will cause higher TDS readings. Also, ensure that when you take readings, you do so after the unit has been running for a few minutes, in order to flush out the initial bit of higher TDS water from the lines. If you're still getting higher TDS readings after doing this, then I would be looking at the source water TDS (which would have to be pretty high to get that reading), as well as checking to see if the membrane came unseated in the housing and may be getting bypass. Sometimes even the jarring handling during shipping can cause the membranes to come a bit loose and they may need to be re-seated.

If you're still experiencing issues after looking into these things, you know you can always count on us for continued support. Our product experts in customer service are always happy to walk through issues with you and ensure that we get you a resolution.

It looks like you've gotten a number of helpful suggestions on here. A few things I would point out:

-With 6ppm breakthrough, it certainly is possible that some undesirable contaminants may be passing through which could contribute to algae growth, though it's hard to say for sure without testing the product water. A move and reset of the tank could also be a contributing factor.

-Sediment filters may not always change color as they clog; depends on your water. The primary concern is that they remove particulates, and should be replaced when they begin to clog, which would be indicated by a loss of pressure at the membrane.

-Carbon blocks typically will be good for a few thousand gallons, depending again on your municipal water, and testing for chlorine/chloramine breakthrough on your waste line on a regular basis is a good way to keep tabs on this. Keep in mind as well that all water, waste and product, are filtered by the carbon block. That means that if you are getting a 1:4 product to waste ratio, and produce 100 gallons of pure water, the carbon block has actually filtered about 500 gallons of water.

-DI resin usage will vary greatly by your source water and the contaminants. There isn't really a good way to give an accurate amount of time this should last, especially since everyone's water production needs will vary. I would focus more on the amount of water you're purifying and the level of starting TDS. In many cases (mine included) I'm lucky to have my DI last more than a few months. Others may get much more mileage. Ultimately, the goal when using DI resin is to get the water down to 0 TDS. If you have gone from 0 to 6, then this does suggest that the resin is no longer removing all impurities and needs to be replaced. The color change indicator is a nice convenience factor for visual monitoring, but TDS will be more accurate.

Looking at your DI resin cartridge, there does appear to be either some channeling going on, or stratification, both of which would suggest the DI resin is no longer tightly packed as it should be. Resin does shrink a small amount, and various other factors can affect settling inside of the cartridge, but I'd address this by replacing and re-packing your resin. This will likely return your final TDS to 0.

If your TDS is coming out at 27 after the membrane, I would be very curious to see what your tap TDS is. I would also ensure that your system's flush valve is not left in the open position, as this is a common issue and will cause higher TDS readings. Also, ensure that when you take readings, you do so after the unit has been running for a few minutes, in order to flush out the initial bit of higher TDS water from the lines. If you're still getting higher TDS readings after doing this, then I would be looking at the source water TDS (which would have to be pretty high to get that reading), as well as checking to see if the membrane came unseated in the housing and may be getting bypass. Sometimes even the jarring handling during shipping can cause the membranes to come a bit loose and they may need to be re-seated.

If you're still experiencing issues after looking into these things, you know you can always count on us for continued support. Our product experts in customer service are always happy to walk through issues with you and ensure that we get you a resolution.

Last edited:

Hey there,

It looks like you've gotten a number of helpful suggestions on here. A few things I would point out:

-With 6ppm breakthrough, it certainly is possible that some undesirable contaminants may be passing through which could contribute to algae growth, though it's hard to say for sure without testing the product water. A move and reset of the tank could also be a contributing factor.

-Sediment filters may not always change color as they clog; depends on your water. The primary concern is that they remove particulates, and should be replaced when they begin to clog, which would be indicated by a loss of pressure at the membrane.

-Carbon blocks typically will be good for a few thousand gallons, depending again on your municipal water, and testing for chlorine/chloramine breakthrough on your waste line on a regular basis is a good way to keep tabs on this. Keep in mind as well that all water, waste and product, are filtered by the carbon block. That means that if you are getting a 1:4 product to waste ratio, and produce 100 gallons of pure water, the carbon block has actually filtered about 500 gallons of water.

-DI resin usage will vary greatly by your source water and the contaminants. There isn't really a good way to give an accurate amount of time this should last, especially since everyone's water production needs will vary. I would focus more on the amount of water you're purifying and the level of starting TDS. In many cases (mine included) I'm lucky to have my DI last more than a few months. Others may get much more mileage. Ultimately, the goal when using DI resin is to get the water down to 0 TDS. If you have gone from 0 to 6, then this does suggest that the resin is no longer removing all impurities and needs to be replaced. The color change indicator is a nice convenience factor for visual monitoring, but TDS will be more accurate.

Looking at your DI resin cartridge, there does appear to be either some channeling going on, or stratification, both of which would suggest the DI resin is no longer tightly packed as it should be. Resin does shrink a small amount, and various other factors can affect settling inside of the cartridge, but I'd address this by replacing and re-packing your resin. This will likely return your final TDS to 0.

If your TDS is coming out at 27 after the membrane, I would be very curious to see what your tap TDS is. I would also ensure that your system's flush valve is not left in the open position, as this is a common issue and will cause higher TDS readings. Also, ensure that when you take readings, you do so after the unit has been running for a few minutes, in order to flush out the initial bit of higher TDS water from the lines. If you're still getting higher TDS readings after doing this, then I would be looking at the source water TDS (which would have to be pretty high to get that reading), as well as checking to see if the membrane came unseated in the housing and may be getting bypass. Sometimes even the jarring handling during shipping can cause the membranes to come a bit loose and they may need to be re-seated.

If you're still experiencing issues after looking into these things, you know you can always count on us for continued support. Our product experts in customer service are always happy to walk through issues with you and ensure that we get you a resolution.

Thanks for chiming in Zack. Looks like most of the info your giving me pretty much confirms what everyone else is giving me, but your info on my DI resin coloring puts me at ease. My new DI resin should be here any day from you guys. While I'm changing the DI, I'm gonna take the membrane out and check it's placement. I'll also order a handheld TDS and check the incoming. I know for a fact I shut off the flush kit after flushing for a minute because I have to stand there and hold the waste line in the washing machine. If not my waste water line goes flopping all over the place from the pressure lol.

Here's a question, did you flush the carbon blocks before connecting the prefilter stages to your RO membranes? The carbon blocks always have a decent amount of dust in them. Whenever I change mine I flow about 5 gallons through before I hook it back up to the RO membrane.

Knowing the TDS of your tap water is very important to make sure your filters are working properly. Don't worry about the amount of time or number of gallons. Your RO membrane should be rejecting 98-99%. So my tap is about 120, and out of my RO membrane, I get 1TDS after about 5 minutes of running. When it creeps up to 2, I change the sediment and carbon filters.

And it looks like your resin bed wasn't packed properly, the color change should be just about even all the way around as it goes up the canister. When you change the resin make sure it is packed tightly. If you close up the canister and it gives when you squeeze, it isn't packed tight enough.

Knowing the TDS of your tap water is very important to make sure your filters are working properly. Don't worry about the amount of time or number of gallons. Your RO membrane should be rejecting 98-99%. So my tap is about 120, and out of my RO membrane, I get 1TDS after about 5 minutes of running. When it creeps up to 2, I change the sediment and carbon filters.

And it looks like your resin bed wasn't packed properly, the color change should be just about even all the way around as it goes up the canister. When you change the resin make sure it is packed tightly. If you close up the canister and it gives when you squeeze, it isn't packed tight enough.

Here's a question, did you flush the carbon blocks before connecting the prefilter stages to your RO membranes? The carbon blocks always have a decent amount of dust in them. Whenever I change mine I flow about 5 gallons through before I hook it back up to the RO membrane.

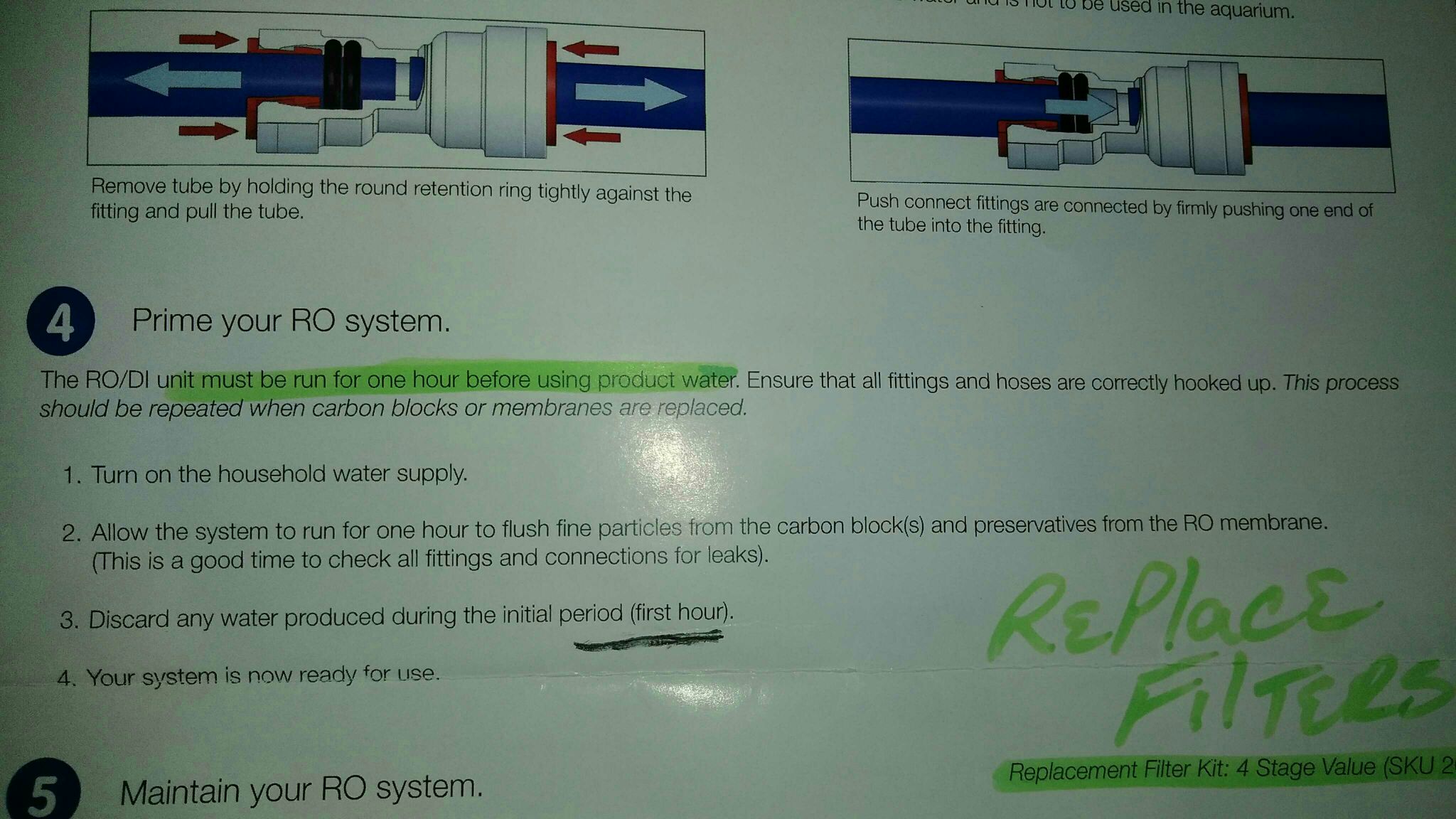

Everything came assembled from BRS. All I had to do was hook it up to a water source. Then I followed the instructions to Prime the RO which state I need to run for one hour and to discard any product water from that hour. It DOES NOT SAY whether or not to turn the flush valve on or off!!

Yeah I'm reading the big thread on them now.To address the diatoms or Dino a microscope is a must.

I measure my tds before it goes into the RO membrane and after. Mine runs at about 120 going in and 2 going out. It is always 0 tds after coming out of the resin. I use color change resin so I know when to change it. It does not sound as if your sediment filter or carbon filters are a problem. I doubt that your RO membrane would be a problem in the short time you have been running. The other thing is the DI resin. I get about 200 gallons per DI canister.

Unless you have a CO2 issue or really meant 2000 gallons, you have something wrong. A tds of 2 should get you around 2200 gallons of 0 tds water from the DI before it is depleted.

Looking at your DI resin cartridge, there does appear to be either some channeling going on, or stratification, both of which would suggest the DI resin is no longer tightly packed as it should be. Resin does shrink a small amount, and various other factors can affect settling inside of the cartridge, but I'd address this by replacing and re-packing your resin. This will likely return your final TDS to 0.

This... +1

Water is certainly channeling as I would expect to see a more gradual color change.

Also, keep in mind you are using a mixed DI resin. Cation and Anion pull out positive and negativity charged ions respectively. Anion resin typically goes first and once that depletes, it all needs to be replaced.

BRS has an exceptional video of this on their YouTube channel. Check it out.

- Joined

- Oct 6, 2017

- Messages

- 119

- Reaction score

- 191

BRS has an exceptional video of this on their YouTube channel. Check it out.

Thanks for the plug

In case you're interested, here's a recent video on the subject:

- Joined

- Oct 6, 2017

- Messages

- 119

- Reaction score

- 191

So my membrane could be jacked up?

While it's possible to do some harm to the membrane if you flush a lot of dust into it, this would cause premature clogging and would result in drastically reduced output. While it's not a bad idea to open the flush valve and run the initial water down the drain when installing new carbon blocks, I will say that most folks don't bother with this and it's very rare to hear of any issues resulting from it. It shouldn't result in an actual breakdown of the membrane or poorer rejection of impurities, so I doubt that's your issue here. Ultimately once you can test your tap water it'll be easier to diagnose if there's anything amiss with your system. In the mean time, if you wanted to open up your membrane housing and re-seat it just to be sure and eliminate that posssibility, it's not hard and couldn't hurt.

Quick update:

Changed the DI resin today. According to my inline tds meter, I am getting 0 tds in the product water. The old resin was definitely loose in the cartridge. I'm not sure if that's due to not being packed incorrectly before shipping or from shrinkage as Zack mentioned. However 0 TDs is the main goal and I'm happy.

I also changed the sediment filter just to be sure that I was remembering my pressure correctly. Sure enough after I changed it the pressure remained between 75 and 80. So again back to the waiting to be changed but I just wanted to verify my pressure.

I did take apart the RO membrane and everything seems to be installed correctly there. However, according to the inline TDS meter when switched to the output I'm still getting 27 TDS after the RO membrane before the DI cartridge. So I ordered a handheld TDS meter today and will follow up with you guys on that.

Changed the DI resin today. According to my inline tds meter, I am getting 0 tds in the product water. The old resin was definitely loose in the cartridge. I'm not sure if that's due to not being packed incorrectly before shipping or from shrinkage as Zack mentioned. However 0 TDs is the main goal and I'm happy.

I also changed the sediment filter just to be sure that I was remembering my pressure correctly. Sure enough after I changed it the pressure remained between 75 and 80. So again back to the waiting to be changed but I just wanted to verify my pressure.

I did take apart the RO membrane and everything seems to be installed correctly there. However, according to the inline TDS meter when switched to the output I'm still getting 27 TDS after the RO membrane before the DI cartridge. So I ordered a handheld TDS meter today and will follow up with you guys on that.

I've been using RODI systems for orchid horticulture for 10+ years, and more recently for aquaria.

Yup, definitely channeling and or stratification, as people have remarked. As the DI resin gets worn out, it should look something like this, and the margin should progressively and evenly march up the cannister.

Oh, one thing about channeling - If it's really bad, your resin may still be blue and apparently fine, but your product water has a TDS > 0. First thing to do here is repack that resin. BRS has a short video describing how to pack a DI resin cartridge well. If you've packed the cartridge really tightly, you might not see any increase in product water TDS until around 80% or so of the resin is worn out. Also, you can buy a second cannister for not that much, and put it after the first. That way, you can use up almost all of the resin in the first cannister, refill it, and then switch the first for the second. Very efficient.

I've kept the same sediment filter for as long as 5 years. Yes it turns extremely brown by that time, but that's ok, it's all microscopic sand and insoluble inorganics. As long as the pressure at the membrane stays at 50-60 or higher, I don't think you need to change it.

I've also kept the same RO membrane for as long as 5 years. Again, if it's functioning properly with a rejection rate of 98+% you don't need to change it, imo. I suspect membrane quality can make a difference in both rejection and longevity although I haven't researched it at all; fwiw I use Dow FilmTecs. I don't flush the membrane nearly as much as you do; once in a while, when I think of it, basically.

If you're really getting 27 TDS after the membrane, I would question whether that membrane is functioning properly.

Anything other than 0 TDS in the product water is unacceptable to me and if it ever hits 1, I discard that water and figure out what's happening before proceeding. I don't want whatever's breaking through to gradually accumulate in the aquarium.

Even with a TDS reading of 0 from an inline or handheld meter, in most cases, traces of this or that may still be getting through, most commonly silicon. To know whether this is the case, you may need to send the water in for professional testing.

Your DI resin was probably packed correctly but settled and stratified with storage and transportation.

In fairness, I should say that I'm very fortunate that our water where I live is completely untreated except for filtering, with TDS of 50-70. So if you're somewhere with high TDS and/or chloramine where the RODI system is really getting stressed out, you'll need to do everything just that much more often. I wouldn't just go by a schedule though, I'd go by whether the equipment is functioning or not. Of course if I'm clearly wrong on this for some reason I haven't considered, I'd love to be educated.

When the DI resin changes color, does it normally change all the bottom and work its way up? The reason I ask is if you look at my pic, the color change kind of swirls around the canister from bottom to top. It doesn't totally fill out the bottom. Is this an indication of channeling?

Yup, definitely channeling and or stratification, as people have remarked. As the DI resin gets worn out, it should look something like this, and the margin should progressively and evenly march up the cannister.

Oh, one thing about channeling - If it's really bad, your resin may still be blue and apparently fine, but your product water has a TDS > 0. First thing to do here is repack that resin. BRS has a short video describing how to pack a DI resin cartridge well. If you've packed the cartridge really tightly, you might not see any increase in product water TDS until around 80% or so of the resin is worn out. Also, you can buy a second cannister for not that much, and put it after the first. That way, you can use up almost all of the resin in the first cannister, refill it, and then switch the first for the second. Very efficient.

I've kept the same sediment filter for as long as 5 years. Yes it turns extremely brown by that time, but that's ok, it's all microscopic sand and insoluble inorganics. As long as the pressure at the membrane stays at 50-60 or higher, I don't think you need to change it.

I've also kept the same RO membrane for as long as 5 years. Again, if it's functioning properly with a rejection rate of 98+% you don't need to change it, imo. I suspect membrane quality can make a difference in both rejection and longevity although I haven't researched it at all; fwiw I use Dow FilmTecs. I don't flush the membrane nearly as much as you do; once in a while, when I think of it, basically.

If you're really getting 27 TDS after the membrane, I would question whether that membrane is functioning properly.

Anything other than 0 TDS in the product water is unacceptable to me and if it ever hits 1, I discard that water and figure out what's happening before proceeding. I don't want whatever's breaking through to gradually accumulate in the aquarium.

Even with a TDS reading of 0 from an inline or handheld meter, in most cases, traces of this or that may still be getting through, most commonly silicon. To know whether this is the case, you may need to send the water in for professional testing.

Your DI resin was probably packed correctly but settled and stratified with storage and transportation.

In fairness, I should say that I'm very fortunate that our water where I live is completely untreated except for filtering, with TDS of 50-70. So if you're somewhere with high TDS and/or chloramine where the RODI system is really getting stressed out, you'll need to do everything just that much more often. I wouldn't just go by a schedule though, I'd go by whether the equipment is functioning or not. Of course if I'm clearly wrong on this for some reason I haven't considered, I'd love to be educated.

You are welcome! Thanks for making the videos!Thanks for the plug

In case you're interested, here's a recent video on the subject:

Okay guys there's definitely a problem. My TDS meter came in today and the water from my tap is 172 TDS at 70 degrees. Now I'm no mathematician but me getting 27 TDS from my inline TDS meter after the RO membrane does not seem anywhere close to 98 % rejection. I still have to verify that 27 TDS with the handheld but I did verify that I'm getting 0 after the DI.

You might take the membrane cartridge apart (again - I think you did it once?), pull out the membrane, and inspect the two o-rings at the other end. Make sure they're both intact with no nicks. Rub them a bit with your thumb to restore their pliability a bit. Then put the membrane back in, really firmly; make sure both o-rings are seated. Close it up and see if you still get 27 TDS after it.

Similar threads

- Replies

- 2

- Views

- 127

- Replies

- 9

- Views

- 132

- Replies

- 7

- Views

- 317

- Replies

- 11

- Views

- 168

- Replies

- 17

- Views

- 370