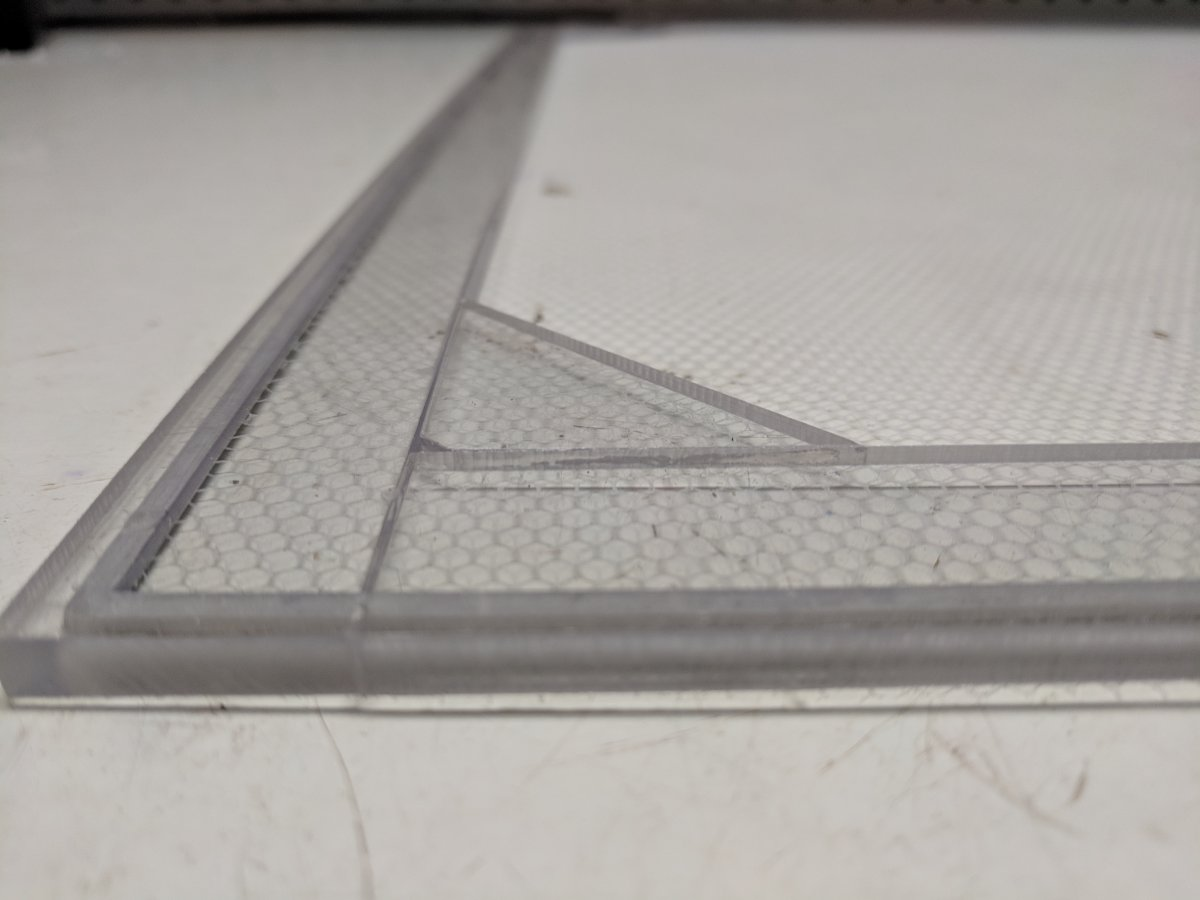

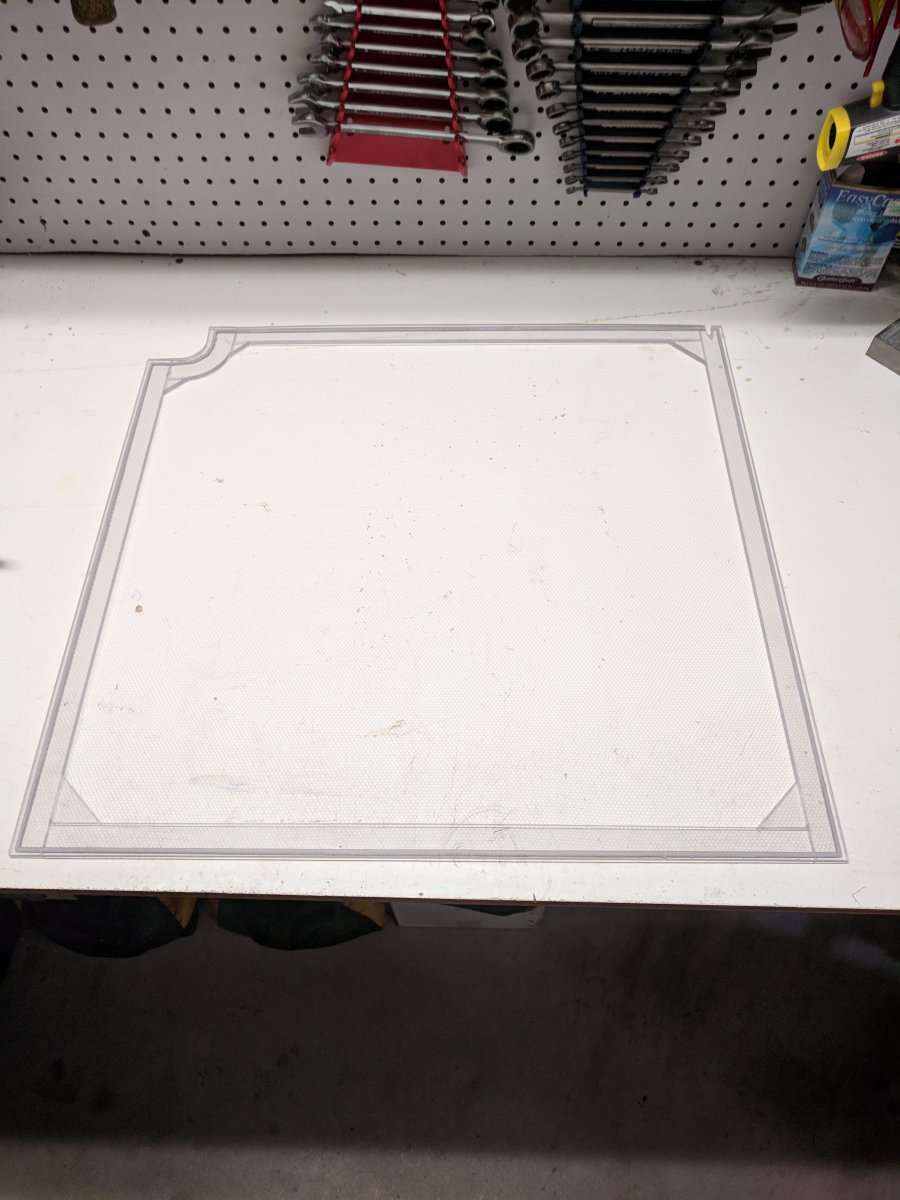

I made lids out of 1.5" strips of 6mm acrylic glued together. I used clear, but any color would work.

I originally made these with a 1" frame, but they were too flimsy and eventually broke in the corners. The 1.5" strips are way stronger and have been problem free.

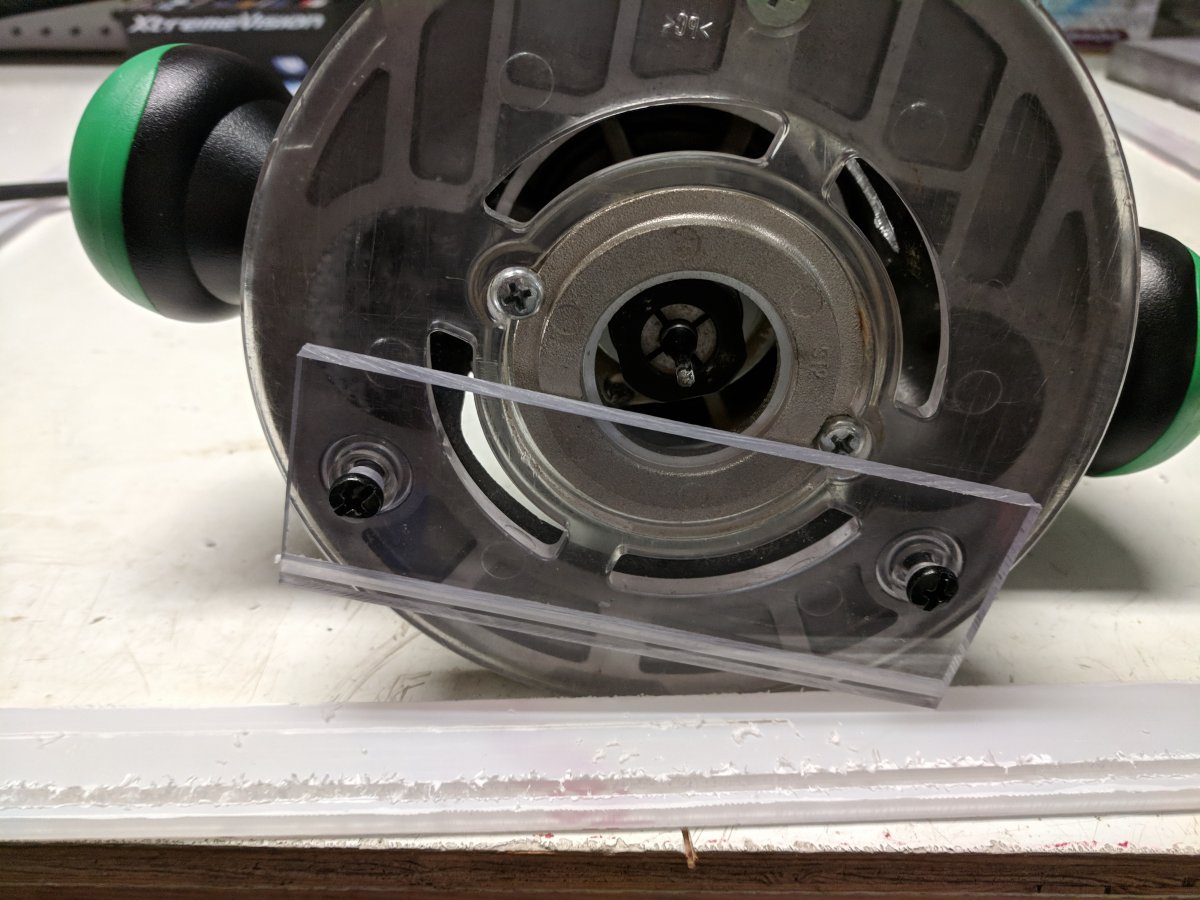

I then made a fence jig for my router to cut an 1/8" slot. It's made from the same acrylic strips scraps and a 1/8" straight flute carbide router bit. They do make specific acrylic router bits, but they cost a lot more and the wood bit worked fine.

I then used mosquito netting I got at a local fabric store for $1 and window screen spline to hold them together.

One of the major advantages of using acrylic over the aluminum window screen kits is you can cut out grooves for cords and rounded parts for plumbing, overflows, bowfronts, etc. My return line hangs over the back and wraps around my center brace. I used a hole saw to cut a radius into a small square, that I was able to use in the corner. It's also the reason I cut the slot for the spline with a router instead of a table saw, so I could follow the radius of the cutout.

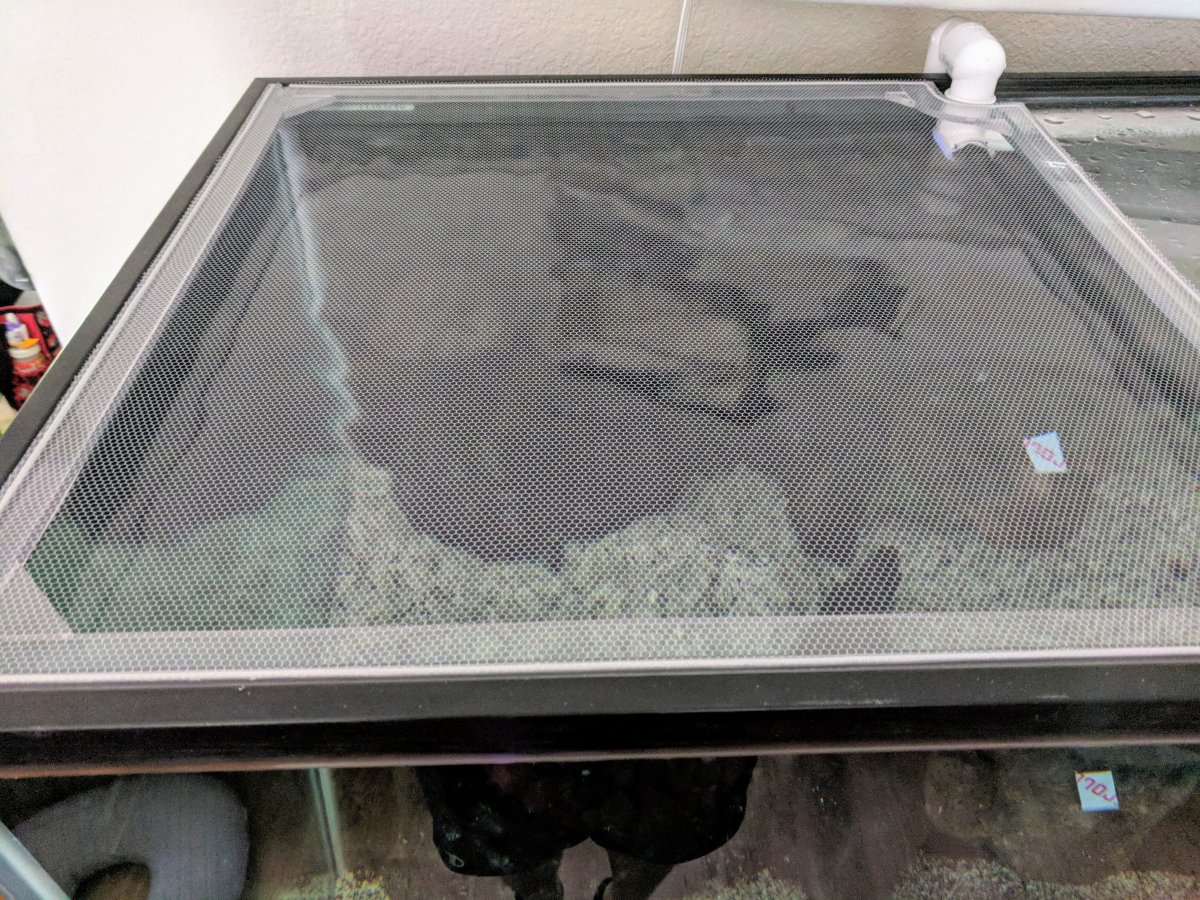

First Install on the tank.

2 Years later, still going strong.

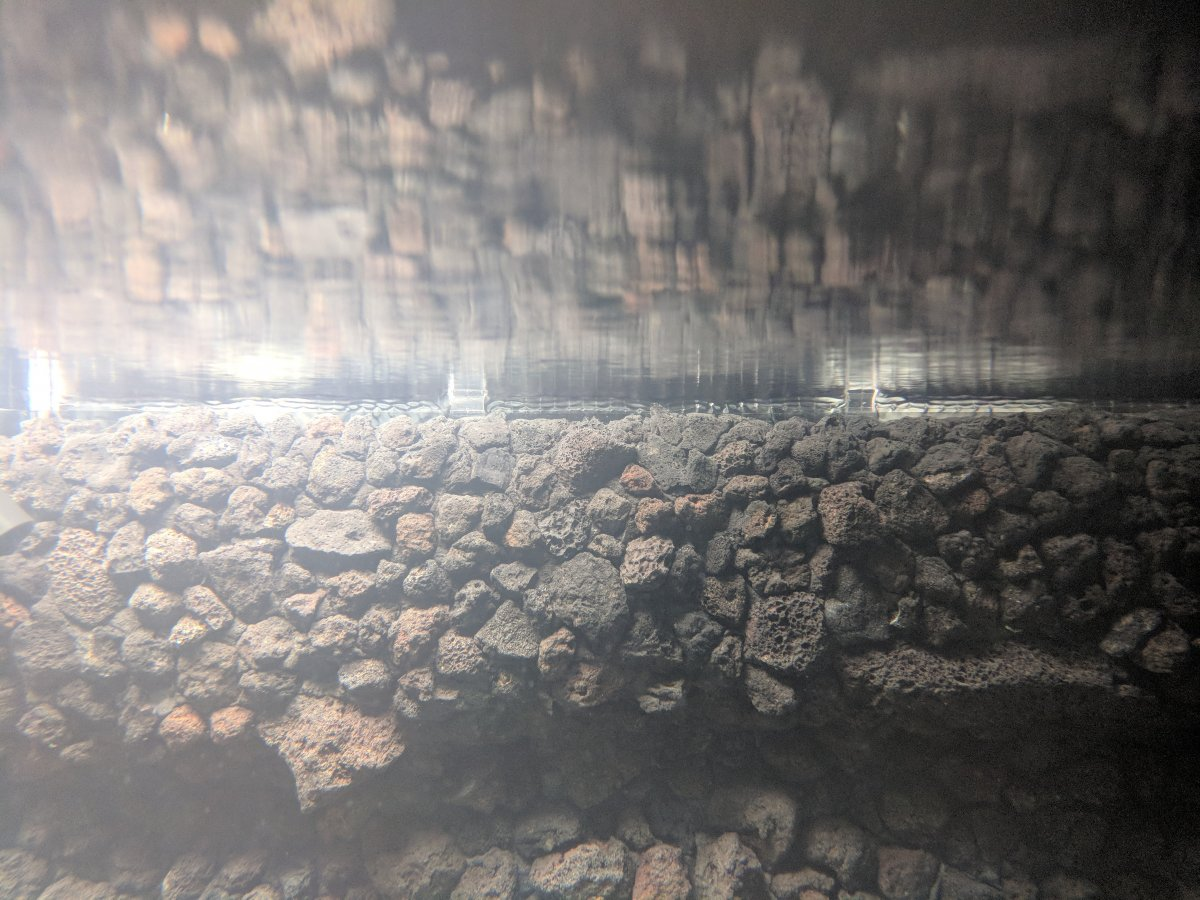

I made my overflow out of glass, so I couldn't cut any teeth into the weir. I figured it was only a matter of time before some snails or fish ended up in the overflow. So I used the same method to make a screen for the overflow. The only difference was using black for the top to block light/algae and 1/4" nylon mesh instead of mosquito netting.

I added a lid for the external portion of the overflow to block light for algae. It also quiets the noise and contains any splashes.

It's barely visible when viewing the front of the tank.

I originally made these with a 1" frame, but they were too flimsy and eventually broke in the corners. The 1.5" strips are way stronger and have been problem free.

I then made a fence jig for my router to cut an 1/8" slot. It's made from the same acrylic strips scraps and a 1/8" straight flute carbide router bit. They do make specific acrylic router bits, but they cost a lot more and the wood bit worked fine.

I then used mosquito netting I got at a local fabric store for $1 and window screen spline to hold them together.

One of the major advantages of using acrylic over the aluminum window screen kits is you can cut out grooves for cords and rounded parts for plumbing, overflows, bowfronts, etc. My return line hangs over the back and wraps around my center brace. I used a hole saw to cut a radius into a small square, that I was able to use in the corner. It's also the reason I cut the slot for the spline with a router instead of a table saw, so I could follow the radius of the cutout.

First Install on the tank.

2 Years later, still going strong.

I made my overflow out of glass, so I couldn't cut any teeth into the weir. I figured it was only a matter of time before some snails or fish ended up in the overflow. So I used the same method to make a screen for the overflow. The only difference was using black for the top to block light/algae and 1/4" nylon mesh instead of mosquito netting.

I added a lid for the external portion of the overflow to block light for algae. It also quiets the noise and contains any splashes.

It's barely visible when viewing the front of the tank.