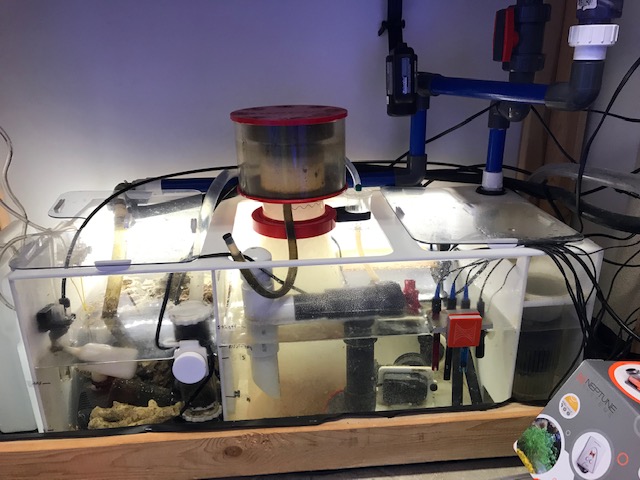

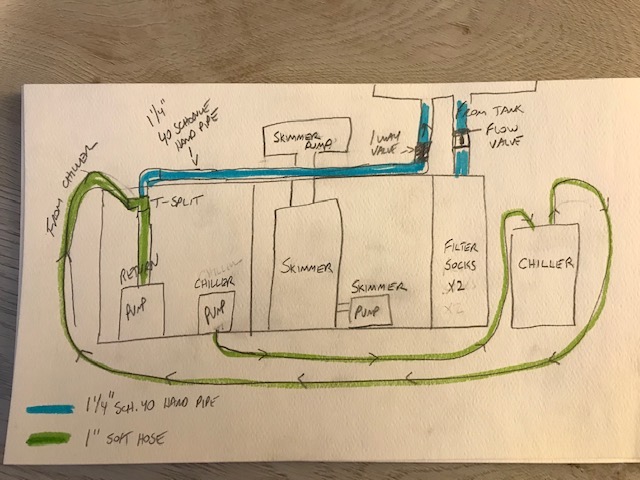

I had a custom sump that is reversed, filter socks on the right as you face the sump, because I have a dedicated sump room behind the tank. It has been running for about 14 months. I would like to replace the Sicce Syncra 4.0 with an Apex Cor-15 return pump. I also would like to add an Avast Zeovit reactor which has not been set up. I have hand drawn what I currently have and would like some help on adding the new equipment to the current one, but would like a nice manifold to have the sump look more organized. Any help, especially with a drawing or picture of a

set up would be greatly appreciated! I apologize in advance for the drawing, I did the best I could to keep it simple but complete. Ask any questions and I thank you in advance. I have a build thread but did not get many views so I decided to post here. Thanks again!

set up would be greatly appreciated! I apologize in advance for the drawing, I did the best I could to keep it simple but complete. Ask any questions and I thank you in advance. I have a build thread but did not get many views so I decided to post here. Thanks again!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have no idea but want to add a manifold...please help

- Thread starter Cristy17

- Start date

- Tagged users None

- Joined

- Apr 19, 2018

- Messages

- 1,454

- Reaction score

- 1,103

here's a good thread that discuss this. https://www.reef2reef.com/threads/designing-a-manifold.285166/

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

I would replace the 1" soft tubing coming out of the return pump with PVC(1" or bigger) and T off of that pipe to create the manifold. Use how man T's you need (1 for each output) and an end cap after them.

dbl

It Takes Less Energy to be Nice

View Badges

Excellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

Reef Squad Emeritus

Hospitality Award

My Tank Thread

Agree with @saltyhog, come off pump and Tee off to your manifold. I personally reduced my manifold down to 3/4" with 3/4" gate valves, but that's just me. Also agree with @Super Fly, use gate valves on the manifold. You'll want the precision when directing flow to various equipment.

Do you intend to feed the chiller off the manifold as well? If so, just make sure you'll have enough flow to feed the chiller properly. Also, I would just discharge the chiller in to the sump. It doesn't need to be tied in to the return line as your drawing shows.

My last comment is something I usually recommend for a manifold and have found useful. After coming off the return line, and before the gate valves, I installed a true union ball valve. I can literally remove the entire manifold (for whatever reason) without shutting the tank down. Just a suggestion.

Do you intend to feed the chiller off the manifold as well? If so, just make sure you'll have enough flow to feed the chiller properly. Also, I would just discharge the chiller in to the sump. It doesn't need to be tied in to the return line as your drawing shows.

My last comment is something I usually recommend for a manifold and have found useful. After coming off the return line, and before the gate valves, I installed a true union ball valve. I can literally remove the entire manifold (for whatever reason) without shutting the tank down. Just a suggestion.

Agree with @saltyhog, come off pump and Tee off to your manifold. I personally reduced my manifold down to 3/4" with 3/4" gate valves, but that's just me. Also agree with @Super Fly, use gate valves on the manifold. You'll want the precision when directing flow to various equipment.

Do you intend to feed the chiller off the manifold as well? If so, just make sure you'll have enough flow to feed the chiller properly. Also, I would just discharge the chiller in to the sump. It doesn't need to be tied in to the return line as your drawing shows.

My last comment is something I usually recommend for a manifold and have found useful. After coming off the return line, and before the gate valves, I installed a true union ball valve. I can literally remove the entire manifold (for whatever reason) without shutting the tank down. Just a suggestion.

Great points, I too used a true union valve before my outlets on the manifold. This will allow you to take it apart for moving/cleaning etc. and completely shut the manifold off in a heart beat if needed for any reason. Unions and union valves are your friend. Never have regretted any that I've installed on my system.

all good points here..only think I can add is a cheaper place to get some plumbing:

I got to T's elbows and unions from here:

supplyhouse.com

all schedule 80 too! I did end up getting true union ball valves as they did not have PVS gate valves but if I find them not to be up to par I can easily replace them. there I ton better than the ones from HD/lows .

I got to T's elbows and unions from here:

supplyhouse.com

all schedule 80 too! I did end up getting true union ball valves as they did not have PVS gate valves but if I find them not to be up to par I can easily replace them. there I ton better than the ones from HD/lows .

dbl

It Takes Less Energy to be Nice

View Badges

Excellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

Reef Squad Emeritus

Hospitality Award

My Tank Thread

Another great source is www.pvcfittingsonline.com. Here are the gate valves I ended up using, from them.

https://www.pvcfittingsonline.com/3-4-pvc-threaded-gate-valve-spears-2021-007.html

https://www.pvcfittingsonline.com/3-4-pvc-threaded-gate-valve-spears-2021-007.html

Thank you! Yes I plan on getting rid of all the soft tubing except coming from the Avast and the possibly the chiller depending on every ones ideas.here's a good thread that discuss this. https://www.reef2reef.com/threads/designing-a-manifold.285166/

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

here's a good thread that discuss this. https://www.reef2reef.com/threads/designing-a-manifold.285166/

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

Thank you! Gate valves are a great idea!here's a good thread that discuss this. https://www.reef2reef.com/threads/designing-a-manifold.285166/

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

- Joined

- Oct 1, 2017

- Messages

- 3,060

- Reaction score

- 2,521

Would disagree with some members here. Think a short piece of soft tubing coming off pump is a good idea. Will give some flexibility and isolate pump vibration

In drawing, chiller pump feeding chiller and returning to flow off return pump will create Venturi effect. Just have chiller return to water where return pump sits. You could use return pump to feed chiller, and eliminate the separate chiller pump too.

Use 1 1/4 x 1 1/4 x 3/4 tee’s, then get a bunch of these 3/4 slip to 3/4 barb for each run.

Good idea to make an extra tee/outlet for future expansion, and one for water that could go back to sump, that you could control orbit use with a valve

In drawing, chiller pump feeding chiller and returning to flow off return pump will create Venturi effect. Just have chiller return to water where return pump sits. You could use return pump to feed chiller, and eliminate the separate chiller pump too.

Use 1 1/4 x 1 1/4 x 3/4 tee’s, then get a bunch of these 3/4 slip to 3/4 barb for each run.

Good idea to make an extra tee/outlet for future expansion, and one for water that could go back to sump, that you could control orbit use with a valve

Yes I am hoping to get rid of all the soft hose and use 1 1/4” pipe. I guess I am confused because my return line goes across the sump from left to right and back to the tank. So this means the manifold will be after the return pump, connect to all the equipment and then back to the tank. Does that sound correct?I would replace the 1" soft tubing coming out of the return pump with PVC(1" or bigger) and T off of that pipe to create the manifold. Use how man T's you need (1 for each output) and an end cap after them.

I have heard that soft hose will help with vibration, but does it? I guess I was hoping for a uniform look but noise would trump that. I like your idea to run the soft hose uniformily to the equipment coming off the manifold...thank you for your suggestion and the picture of what I will need. I am trying to get all the plumbing parts at one time so once I begin to build it, Incan have it up and running as quickly as possible. Also, what is the Venturi effect that I have created now with the current set up? I am not sure I understand.Would disagree with some members here. Think a short piece of soft tubing coming off pump is a good idea. Will give some flexibility and isolate pump vibration

In drawing, chiller pump feeding chiller and returning to flow off return pump will create Venturi effect. Just have chiller return to water where return pump sits. You could use return pump to feed chiller, and eliminate the separate chiller pump too.

Use 1 1/4 x 1 1/4 x 3/4 tee’s, then get a bunch of these 3/4 slip to 3/4 barb for each run.

Good idea to make an extra tee/outlet for future expansion, and one for water that could go back to sump, that you could control orbit use with a valve

Thank you!Let me get some help for you...

#reefsquad

Would disagree with some members here. Think a short piece of soft tubing coming off pump is a good idea. Will give some flexibility and isolate pump vibration

In drawing, chiller pump feeding chiller and returning to flow off return pump will create Venturi effect. Just have chiller return to water where return pump sits. You could use return pump to feed chiller, and eliminate the separate chiller pump too.

Use 1 1/4 x 1 1/4 x 3/4 tee’s, then get a bunch of these 3/4 slip to 3/4 barb for each run.

Good idea to make an extra tee/outlet for future expansion, and one for water that could go back to sump, that you could control orbit use with a valve

I've done it both ways and couldn't tell any difference in sound/vibration and either way will work fine. The only reason I changed was due to changing return pumps to one that came set up for hard plumbing (Vectra M1). Still pretty easy to break down, just unscrew the effluent connection.

- Joined

- Oct 1, 2017

- Messages

- 3,060

- Reaction score

- 2,521

Far as the noise, guess it depends on the pump. Have seen it work big time on some, not so much on other. Know it can’t hurt.I have heard that soft hose will help with vibration, but does it? I guess I was hoping for a uniform look but noise would trump that. I like your idea to run the soft hose uniformily to the equipment coming off the manifold...thank you for your suggestion and the picture of what I will need. I am trying to get all the plumbing parts at one time so once I begin to build it, Incan have it up and running as quickly as possible. Also, what is the Venturi effect that I have created now with the current set up? I am not sure I understand.

Venturi effect is when water is rushing by the tee where chiller returns to return line, it creates s vacuum. Most skimmer pumps pull air into skimmer in this, venturi way. Not necessarily a bad thing, unless it pulls a lot faster than the pump pushing it through the chiller on the other side can’t keep up. Then that pump gets “dragged”, and could make noise, and won’t be good for it’s lifespan. Just don’t see why you wouldn’t just return chiller to section that houses return pump. Would also eliminate the chiller pump, since you’re doing a manifold.

Well really, would keep the return pump for tank separate. So you have a better idea of what your gph is making it to tank. But that’s not what you were asking, and many people have very successful tanks with the return on a manifold

Last edited:

Just finished reading the thread you sent. Great information! Thank you so much! It seems most are saying to use gate valves. I think that is how I am going to go.here's a good thread that discuss this. https://www.reef2reef.com/threads/designing-a-manifold.285166/

I'd recommend using gate valves as they are easier and more precise to control. I regret going cheap and not using gate valves

Agree with @saltyhog, come off pump and Tee off to your manifold. I personally reduced my manifold down to 3/4" with 3/4" gate valves, but that's just me. Also agree with @Super Fly, use gate valves on the manifold. You'll want the precision when directing flow to various equipment.

Do you intend to feed the chiller off the manifold as well? If so, just make sure you'll have enough flow to feed the chiller properly. Also, I would just discharge the chiller in to the sump. It doesn't need to be tied in to the return line as your drawing shows.

My last comment is something I usually recommend for a manifold and have found useful. After coming off the return line, and before the gate valves, I installed a true union ball valve. I can literally remove the entire manifold (for whatever reason) without shutting the tank down. Just a suggestion.

Yes! I should have just let the chiller line dump into the return pump area! I am hoping to feed everything off the return pump, if I have enough power. I also need to decide if I will use the current 1 1/4” hard pipe to 1” soft tubes to each piece of equipment or downsize even more to 3/4”.. this is where I get really confused. The thread I just read had a calculator I will try to use. The union to be able to remove the entire manifold is a must! Thank you for suggesting it!

I will be using the Neptune Cor-15 and it appears to be set up for hard plumbing, I think..I was a little concerned with the 1” hose I purchased at Home Depot because I was just reading that some soft tubing has Chlorine in it. Do you know anything about this? Does anyone?I've done it both ways and couldn't tell any difference in sound/vibration and either way will work fine. The only reason I changed was due to changing return pumps to one that came set up for hard plumbing (Vectra M1). Still pretty easy to break down, just unscrew the effluent connection.

Similar threads

- Replies

- 3

- Views

- 109