- Joined

- Jan 25, 2018

- Messages

- 54

- Reaction score

- 32

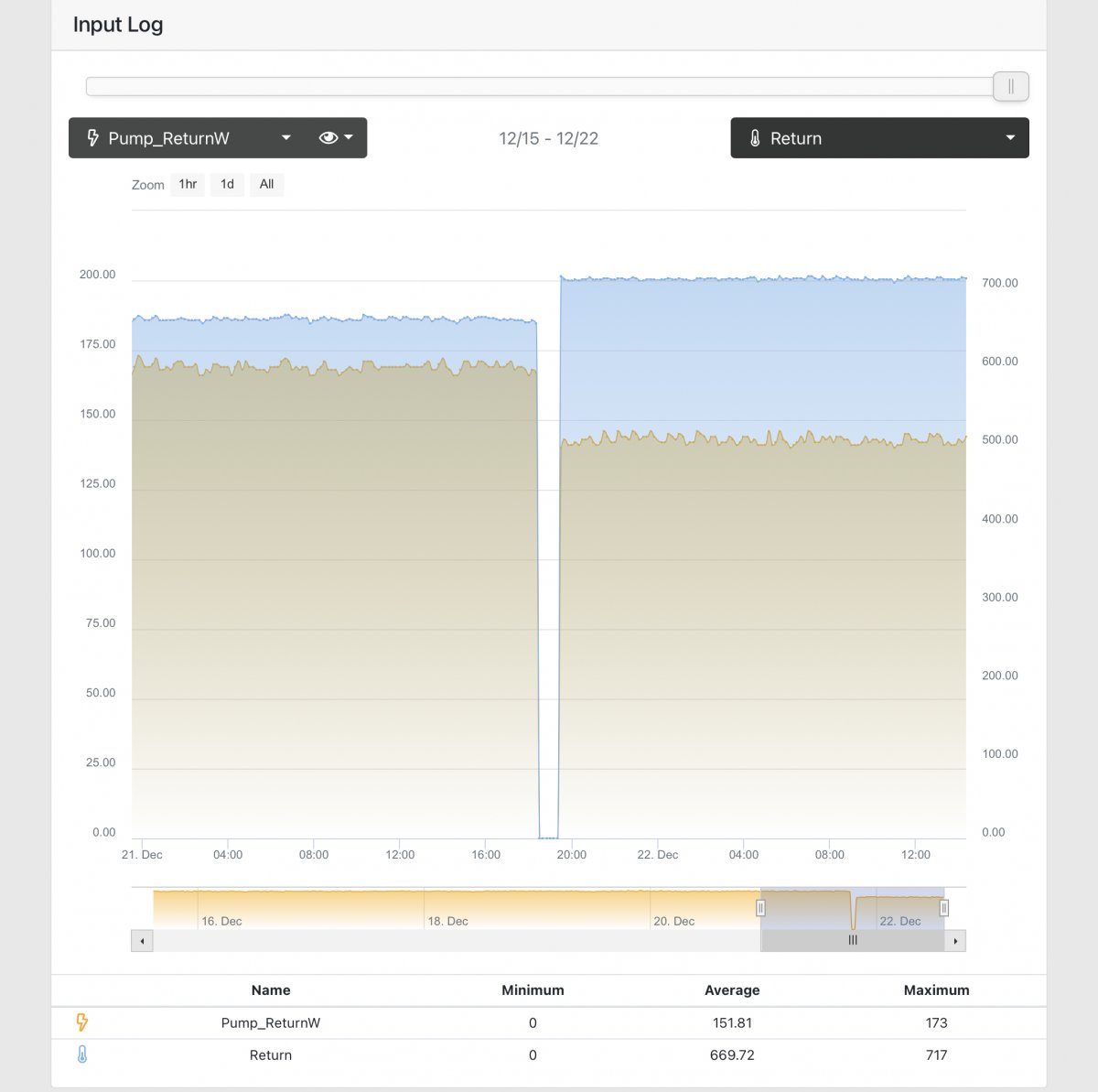

For those interested, captured below is the before and after for energy (watts) and flow rate (GPH) when cleaning return pump.

This energy reduction will save about $35 annually.

Granted have higher head pressure than some as it’s a basement sump going up about 10’.

Also it’s been a few years since a good cleaning.

But if you want to save a few bucks and get some additional water changeover, give your return a quick clean.

Pump is a Pam World 150PS, for what it’s worth. Thing is a champ.

This energy reduction will save about $35 annually.

Granted have higher head pressure than some as it’s a basement sump going up about 10’.

Also it’s been a few years since a good cleaning.

But if you want to save a few bucks and get some additional water changeover, give your return a quick clean.

Pump is a Pam World 150PS, for what it’s worth. Thing is a champ.