Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jason's 467 Gallon (120x30x30) Tank Build in SoCal

- Monster Build

- Thread starter KingJason

- Start date

- Tagged users None

- Joined

- Sep 26, 2016

- Messages

- 845

- Reaction score

- 861

Ahh steel! it looked like wood!AGE's design and build and it's solid steel. I trust they know what they are doing.

Ahh steel! it looked like wood!

Haha. Yes, if it were wood that would be problematic!

Looks amazing. Can't wait to watch this fill up.

Are you planning for water changes?

Yes, I'll implement an auto water change system. Not sure how much right now but the less I can get away with the better.

The tank is about 450 gallons which makes it roughly 4500 lbs. which equates to 750 lbs. on each leg.

hrmm... this is easy to calculate....if given some numbers...

A.G.E. Generally has 1.5"x1.5" and 3"X1.5" steel 1/8" wall thickness. Lets assume we are working with the 3"x1.5" because thats what it's looking like on his stand from the photos. @KingJason can correct me if i'm wrong here.

Area moment of inertia for this is then: 0.396 [in^4] (assuming bending in the weakest direction of the cross section)

Young's Modulus is about: 180 [GPa] = 26.11E+6 [PSI] for steel

Looks like approximately ~36" tall stand. So to be conservative, lets say that the stand legs are each 36" tall. (longer legs = more prone to buckling)

Assume both ends of each leg are fixed (seems like a fair assumption to me!)

If I didn't botch these numbers while sitting here at the vet, critical buckling load for each leg is about: 300,000 lbs. Put a safety factor of 10 on that and say 30,000 lbs.

the tank, glass plus salt water weights (assuming .75 thick glass and dimensions of 120x30x30 with a 1" pvc base) = 4364 [lbs]

i see 6 legs which means if they are all weighted equally each leg is only seeing ~727.33 [lbs]

that means you are well within the overkill range of safety.

Even if i misjudged what i'm looking at in the picture and @KingJason has 1.5"x1.5" legs on his stand, critical buckling load for each of those legs still is a whopping: 173,000[lbs]. Still mega overkill.

Awesome plumbing Jason. I'm toying with mine right now too!

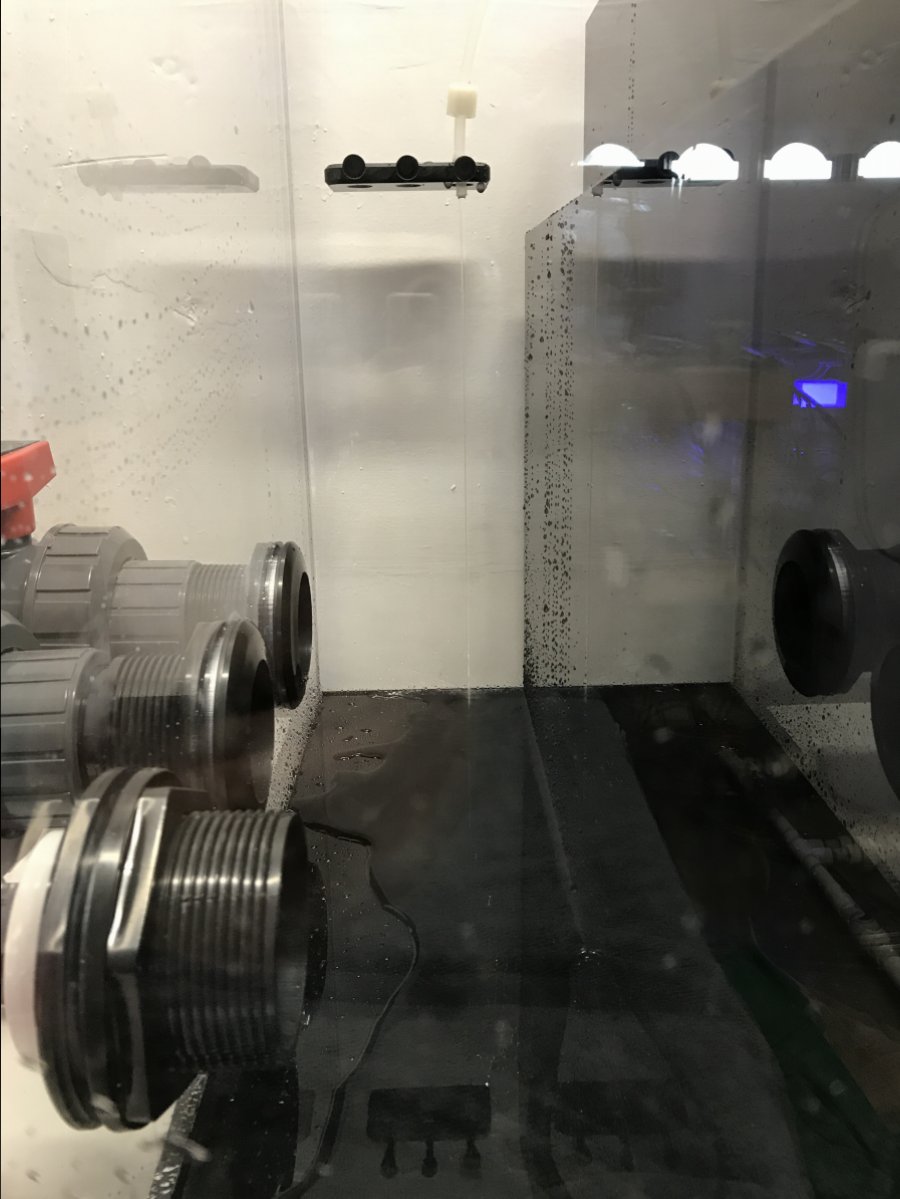

Made some nice progress over the the weekend. I have the overflow lines and main return plumbing through the wall finished and glued. Also patched the wall to seal around where I cut through for the return PVC. I still need to do the plumbing for the return over the tank itself as well as the manifold, skimmer and other misc. I started doing some targeted water testing. Bulkheads in the sump are all fine. I have one bulkhead in the Synergy overflow that's giving me a hard time. I've taken it out and re-seated it twice now and it still has a slow leak. I even took off all the connected plumbing to see if it was pressure and it's still dripping on me. Going to give it another shot in the morning. Hoping I don't have to replace it...I hate bulkheads...

First tank that I've chamfered all the PVC edges with a router. Took a lot of extra time, but makes for very easy and nice connections.

Main return line on the left from the Abyzz up to the top of the tank's right side (if you're looking at it). Have a 2" flow sensor for the Apex FMM module hooked in.

All 3 overflow lines for the Bean Animal style return. Installed a 2" flow monitor on the emergency line so I can setup an alert if water starts to flow through it and of course the gate valve on the primary. In my setup it goes (left to right): secondary, emergency, primary.

First tank that I've chamfered all the PVC edges with a router. Took a lot of extra time, but makes for very easy and nice connections.

Main return line on the left from the Abyzz up to the top of the tank's right side (if you're looking at it). Have a 2" flow sensor for the Apex FMM module hooked in.

All 3 overflow lines for the Bean Animal style return. Installed a 2" flow monitor on the emergency line so I can setup an alert if water starts to flow through it and of course the gate valve on the primary. In my setup it goes (left to right): secondary, emergency, primary.

Hey @KingJason ,

shouldn't you have a gate valve on your secondary also?

Original BeanAnimal post shows valves on all three, during nominal operations, emergency is wide open, full siphon valve is used to control flow (generally adjusted to control height of waterlevel in overflow), and the secondary "open channel" has a trickle going through it (generally wide open).

It didn't make sense to me why there would be valves on all three at first but i figured it could help with getting the full siphon started to be able to stop all flow through the secondary. Unless your secondary's opening is located sufficiently higher than your primary?

Also, those apex flow sensors, can you show me what the ends of the wires look like?

I was considering buying these for my DIY controller but if i recall correctly, the output is a "headphone" jack connector and i don't know what the output from the flow sensor is....probably just voltage....but i didn't want to spend the $$ and not be sure.

shouldn't you have a gate valve on your secondary also?

Original BeanAnimal post shows valves on all three, during nominal operations, emergency is wide open, full siphon valve is used to control flow (generally adjusted to control height of waterlevel in overflow), and the secondary "open channel" has a trickle going through it (generally wide open).

It didn't make sense to me why there would be valves on all three at first but i figured it could help with getting the full siphon started to be able to stop all flow through the secondary. Unless your secondary's opening is located sufficiently higher than your primary?

Also, those apex flow sensors, can you show me what the ends of the wires look like?

I was considering buying these for my DIY controller but if i recall correctly, the output is a "headphone" jack connector and i don't know what the output from the flow sensor is....probably just voltage....but i didn't want to spend the $$ and not be sure.

Hey @KingJason ,

shouldn't you have a gate valve on your secondary also?

Original BeanAnimal post shows valves on all three, during nominal operations, emergency is wide open, full siphon valve is used to control flow (generally adjusted to control height of waterlevel in overflow), and the secondary "open channel" has a trickle going through it (generally wide open).

It didn't make sense to me why there would be valves on all three at first but i figured it could help with getting the full siphon started to be able to stop all flow through the secondary. Unless your secondary's opening is located sufficiently higher than your primary?

Also, those apex flow sensors, can you show me what the ends of the wires look like?

I was considering buying these for my DIY controller but if i recall correctly, the output is a "headphone" jack connector and i don't know what the output from the flow sensor is....probably just voltage....but i didn't want to spend the $$ and not be sure.

This is an instruction video by Synergy for this overflow. I followed it to start and we'll see if I need go make any adjustments.

http://synergyreef.com/2017/02/16/how-to-plumb-the-shadow-overflow/

The plugs are headphone style jacks on the Apex flow sensors.

Impressive build for sure!

revhtree

Owner Administrator

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

RGB

Photo of the Month

Article Contributor

R2R TV Featured

Hospitality Award

Article Administrator

Black Friday Sponsor

Partner Sponsor 2023

Industry Professional

My Aquarium Showcase

- Joined

- May 8, 2006

- Messages

- 47,739

- Reaction score

- 86,877

Very nice!

- Joined

- May 16, 2017

- Messages

- 28

- Reaction score

- 20

Perfect dimensions on this size tank

This is an instruction video by Synergy for this overflow. I followed it to start and we'll see if I need go make any adjustments.

http://synergyreef.com/2017/02/16/how-to-plumb-the-shadow-overflow/

The plugs are headphone style jacks on the Apex flow sensors.

Right on! Just wanted to make sure

Also, after I posted that last thing, I just went and bought 4 of those flow meters. Figured, worst case I'll cut the connectors and splice them into my custom controller.

- Joined

- Apr 29, 2016

- Messages

- 604

- Reaction score

- 381

Young's Modulus is about: 180 [GPa] = 26.11E+6 [PSI] for steel

Hahahaha about time someone pulled some science into building a stand! Haven't touched Young's modulus since college.

Hahahaha about time someone pulled some science into building a stand! Haven't touched Young's modulus since college.

**clears throat** excuse me.....it's engineering....THERES A DIFFERENCE!!!

Yeah well, I've been helping Chris at AGE design a crazy stand (cantilever....wut.....) and I figured I might as well slap some knowledge down to back up my man's jason!

Last edited:

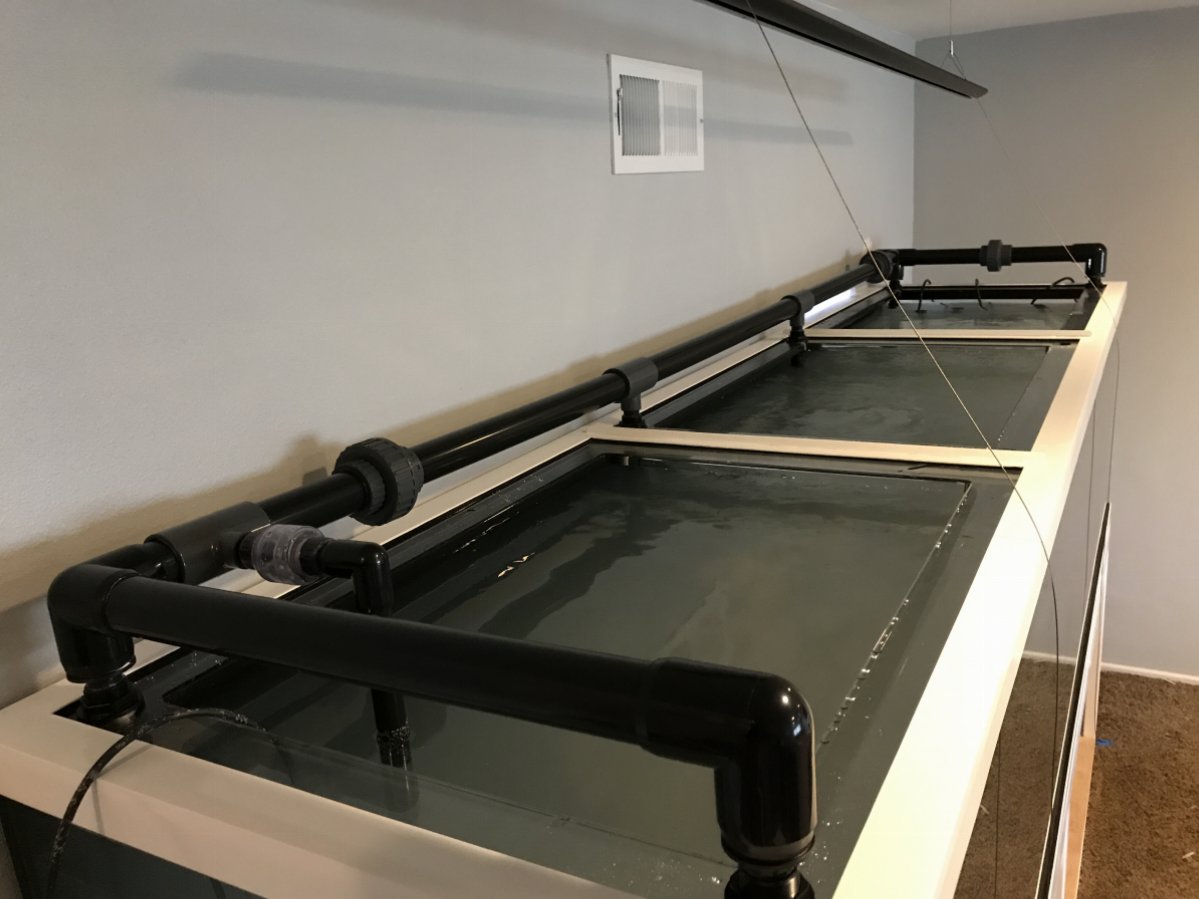

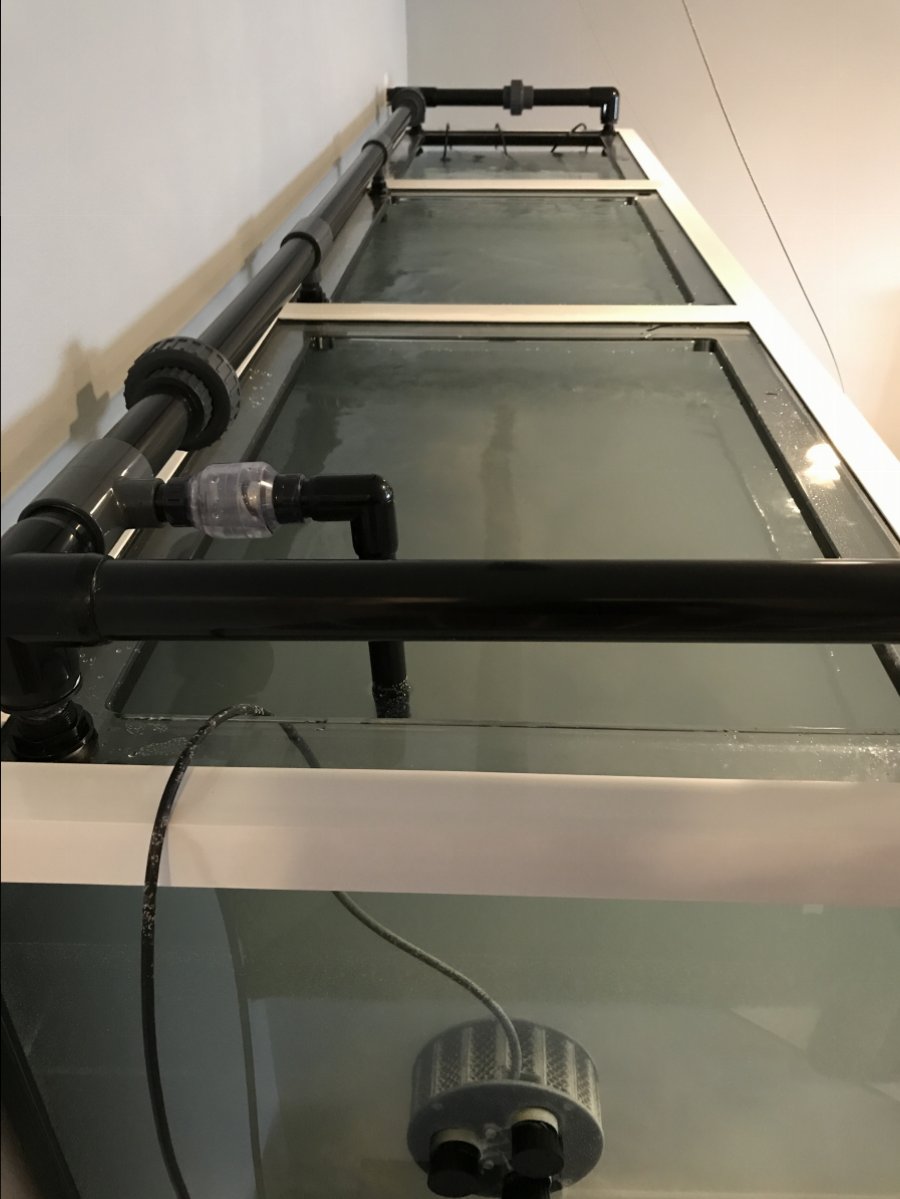

Got a few things done over the weekend and had a big day yesterday.

Plumbing done on the tank side of the return. All 1.5" pipe going into 3/4" bulkheads and loc-line. 6 exit points in total all with adjustable ball values so I can adjust the flow as needed. Also put in a reverse check valve to break the siphon when the pump is turned off. Works like a charm! Only thing left to do is paint around the hole for the return.

As you can see we have WATER! It took about 6 days, but it's now full and salty.

I hooked up the two Panta Rhei 63's once I had enough water and have started to play around with them. You can see one of them in the pic above. The wave action it produces is legit. Each unit can easily push a wave across 10ft of tank at 60%. I haven't turned it up past that yet since I think it would actually push water out of the tank from 10ft away. I have some more dialing in to do and Unique is sending me a sync cable which I didn't know I needed until I hooked them up. They definitely don't have all the easy programming already setup like a Vortech but they have the ability to program it yourself. Their advantage is they are insanely powerful pumps and push a literal wave of water across the tank which is super cool to see and mimics what you'd see while diving and having current push back and forth across the reef. Once I get the lighting done and something in the tank to see move I'll do a video of it.

The Abyzz 200 is running and we're pushing water through the entire system. The flow monitor on the APEX says I'm pushing about 1100 with the Abyzz at 46%. I'm not using it up to it's potential at all, yet. Right now I have it running at a comfortable speed that the overflow is dialed in to. Based on how much water is moving in the sump, it seems like a TON of flow but my goal is to push this up to get more turnover through the sump since I know it's only 1100. If it wasn't for the APEX telling me the flow number I would have said it looked like double that amount. I guess I have been conditioned into thinking I was pushing more flow until now w/ data telling me otherwise. The pump is also dead silent. You can't hear a thing or really even feel that it is running if you put your hand on it. The only way I know it is on is that water is flowing in the sump. It's insane how silent it is.

I'm sure some of you noticed the murky water in the pic above. That is because our Part 1 of "The Package" from Tampa Bay Saltwater yesterday. We picked up 20 50# boxes from John Wayne airport yesterday afternoon. Dan shipped them out around 4AM Florida time and we picked them up around 2PM our local time. The first part of "The Package" is the sand and base rock and in this shipment we got about 400# of sand and 250# of rock. I went with a little less rock then they recommend so I keep enough room in the tank and it doesn't look too full of rock. I think I made the right move so far. At this point it's basically just pilled into the tank. I had to let the water clear so I could arrange it a little better to see how much more of the "nicer" rock I'll have them ship in Part 2. This is our second time using Tampa Bay and my wife and I really enjoy opening it up and seeing all the life on the rocks. A lot of great color and fun shapes even on our base rock so we're very happy. Lots of crabs, snails, some coral, a few anemones, worms, sponges, macro, tons of color, etc.

I was up in the attic last week hanging the lines for the 6 Radion lights. Along with going under the house to reinforce the floor, going in the attic is now also on my list of things I never want to have to do again. The studs that the lighting is hanging from are up against a corner of the roof so I had to lay on my chest in nasty attic mess to get them screwed in. I unfortunately have to go up one or two more times to mount the motor that will raise and lower the lights electronically. More or that when that project starts.

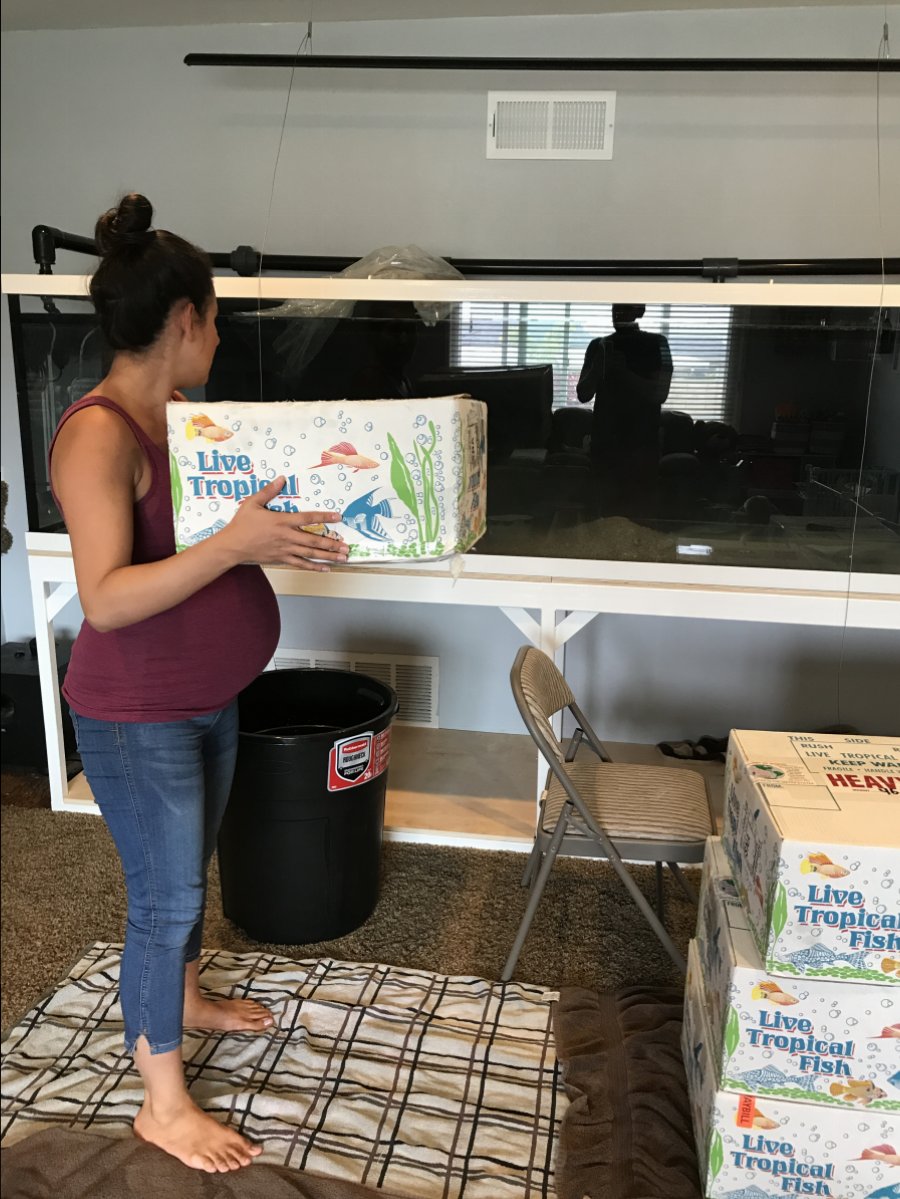

Here is a picture of my beautiful wife helping with the Tamp Bay boxes yesterday (her box is empty...) Pretty sure she planned the whole pregnancy thing out so she wouldn't have to carry twenty 50# boxes to our cars from the cargo terminal and then from the cars to the the house

And here is the aftermath once all the boxes were opened and contents moved into the tank. That was a big project but we had a good time doing it.

Lastly I got the plumbing on the skimmer cut and dry fitted. I have to glue it tonight when I get home so I can get it running and start pulling junk out of the water.

So there we are!

Plumbing done on the tank side of the return. All 1.5" pipe going into 3/4" bulkheads and loc-line. 6 exit points in total all with adjustable ball values so I can adjust the flow as needed. Also put in a reverse check valve to break the siphon when the pump is turned off. Works like a charm! Only thing left to do is paint around the hole for the return.

As you can see we have WATER! It took about 6 days, but it's now full and salty.

I hooked up the two Panta Rhei 63's once I had enough water and have started to play around with them. You can see one of them in the pic above. The wave action it produces is legit. Each unit can easily push a wave across 10ft of tank at 60%. I haven't turned it up past that yet since I think it would actually push water out of the tank from 10ft away. I have some more dialing in to do and Unique is sending me a sync cable which I didn't know I needed until I hooked them up. They definitely don't have all the easy programming already setup like a Vortech but they have the ability to program it yourself. Their advantage is they are insanely powerful pumps and push a literal wave of water across the tank which is super cool to see and mimics what you'd see while diving and having current push back and forth across the reef. Once I get the lighting done and something in the tank to see move I'll do a video of it.

The Abyzz 200 is running and we're pushing water through the entire system. The flow monitor on the APEX says I'm pushing about 1100 with the Abyzz at 46%. I'm not using it up to it's potential at all, yet. Right now I have it running at a comfortable speed that the overflow is dialed in to. Based on how much water is moving in the sump, it seems like a TON of flow but my goal is to push this up to get more turnover through the sump since I know it's only 1100. If it wasn't for the APEX telling me the flow number I would have said it looked like double that amount. I guess I have been conditioned into thinking I was pushing more flow until now w/ data telling me otherwise. The pump is also dead silent. You can't hear a thing or really even feel that it is running if you put your hand on it. The only way I know it is on is that water is flowing in the sump. It's insane how silent it is.

I'm sure some of you noticed the murky water in the pic above. That is because our Part 1 of "The Package" from Tampa Bay Saltwater yesterday. We picked up 20 50# boxes from John Wayne airport yesterday afternoon. Dan shipped them out around 4AM Florida time and we picked them up around 2PM our local time. The first part of "The Package" is the sand and base rock and in this shipment we got about 400# of sand and 250# of rock. I went with a little less rock then they recommend so I keep enough room in the tank and it doesn't look too full of rock. I think I made the right move so far. At this point it's basically just pilled into the tank. I had to let the water clear so I could arrange it a little better to see how much more of the "nicer" rock I'll have them ship in Part 2. This is our second time using Tampa Bay and my wife and I really enjoy opening it up and seeing all the life on the rocks. A lot of great color and fun shapes even on our base rock so we're very happy. Lots of crabs, snails, some coral, a few anemones, worms, sponges, macro, tons of color, etc.

I was up in the attic last week hanging the lines for the 6 Radion lights. Along with going under the house to reinforce the floor, going in the attic is now also on my list of things I never want to have to do again. The studs that the lighting is hanging from are up against a corner of the roof so I had to lay on my chest in nasty attic mess to get them screwed in. I unfortunately have to go up one or two more times to mount the motor that will raise and lower the lights electronically. More or that when that project starts.

Here is a picture of my beautiful wife helping with the Tamp Bay boxes yesterday (her box is empty...) Pretty sure she planned the whole pregnancy thing out so she wouldn't have to carry twenty 50# boxes to our cars from the cargo terminal and then from the cars to the the house

And here is the aftermath once all the boxes were opened and contents moved into the tank. That was a big project but we had a good time doing it.

Lastly I got the plumbing on the skimmer cut and dry fitted. I have to glue it tonight when I get home so I can get it running and start pulling junk out of the water.

So there we are!

Excellent jason! I got rocks today too. But you have me beat on filling! I'm a little off from that.

Please, don't trust that check valve to save you. They are notorious for getting stuck after months of being open during normal

Operations.

I highly recommend something in addition to that check valve such has the hole drilling idea. Something more to break the siphon.

Please, don't trust that check valve to save you. They are notorious for getting stuck after months of being open during normal

Operations.

I highly recommend something in addition to that check valve such has the hole drilling idea. Something more to break the siphon.

Similar threads

- Replies

- 115

- Views

- 2,898

- Replies

- 28

- Views

- 350

- Replies

- 2

- Views

- 88