I love my new Kamoer X2SR water change system - however I was not satisfied with their use of 1/2” vinyl tubing to run the unit. This unit IMO is too flexible/bendable for such a purpose on a high end tank and I noticed problems with the initial setup in the vinyl tubing bending too much at the entrance to the tank - restricting the flow

Because of this (and having to run the line through a wall a considerable distance from the tank) I decided to convert the cheap 1/2” ID vinyl tubing setup to high quality 1/2” ID LLDPE/Polyethylene tubing with push-fit fittings. As a note: The system is substantially more accurate with this new tubing vs the vinyl tubing!

Here’s how I did it:

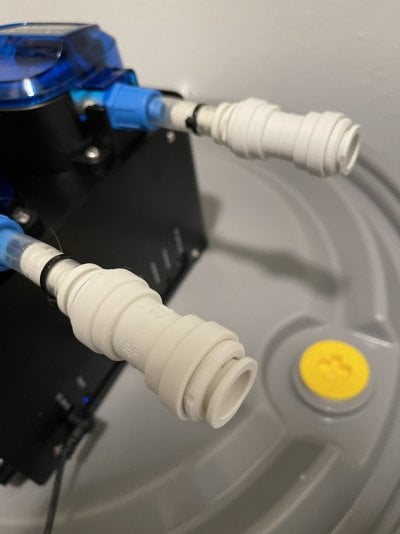

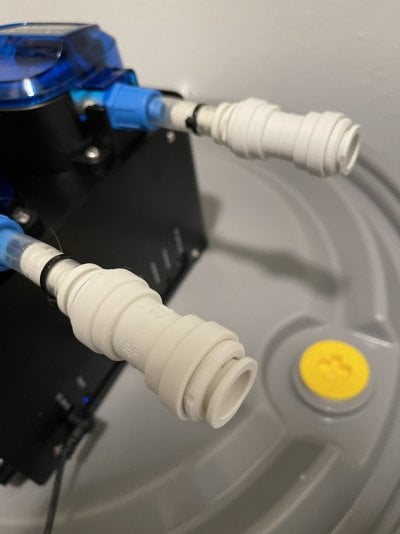

The inlet/outlet feeds still have to be adapted to the Kamoer with vinyl tubing, so I cut 2-3” leaders of tubing, which connect to the X2SR pump barbs like normal.

On the other end of the 1/2” tubing, I installed a John Guest 1/2” OD Stem x 3/8 ID Barb (Part PP251612W)

Now the inlets/outlets can accommodate any 1/2” push-fit fitting, so I added JG 1/2” union connectors (Part PP0416W). From there, I can securely push-fit any standard 1/2” ID hard tubing (available at any HD/Lowes)

The feeds then go through my utility room wall to the tank in the other room. I have an acrylic tank, so I drilled holes through the back of the sump area to securely anchor the lines (with corresponding 1/2" union elbows). If you were dealing with glass, you could easily just create a hook with union elbows to to over the top of the tank. You could obviously run the X2SR much closer to your tank and avoid long runs of tubing, but it is pretty loud (its pushing a lot of water compared to a normal dosing pump!) and I installed it in the other room with my water reservoirs to keep it quiet.

The X2SR also has a built in ATO feature (using included float valves) that I installed. While Id prefer my optical ATO on my controller, the ATO integrated into the X2SR prevents RODI water from feeding to the tank while a water change is in progress. I directly plumbed a 1/4” LLDPE line from my 55g RODI barrel to the tank using the same methods, and the included ATO pump has no problem pushing the water about 15ft to the tank. Because it is directly attached to my RO barrel, I essentially never have to refill an ATO chamber again!

I am thrilled with the new system - the tank does automated daily water changes and ATO virtually silently, and I am already seeing an increase in system stability, cleanness and nitrate reduction!

If you are interested in refitting an X2SR using these methods, here are the primary parts I used:

John Guest Stem Barb Connector Polypro - 1/2 OD Stem x 3/8 ID Barb

www.freshwatersystems.com

www.freshwatersystems.com

John Guest Union Connector Polypro - 1/2

www.freshwatersystems.com

www.freshwatersystems.com

John Guest Locking Clip - 1/2

www.freshwatersystems.com

www.freshwatersystems.com

Because of this (and having to run the line through a wall a considerable distance from the tank) I decided to convert the cheap 1/2” ID vinyl tubing setup to high quality 1/2” ID LLDPE/Polyethylene tubing with push-fit fittings. As a note: The system is substantially more accurate with this new tubing vs the vinyl tubing!

Here’s how I did it:

The inlet/outlet feeds still have to be adapted to the Kamoer with vinyl tubing, so I cut 2-3” leaders of tubing, which connect to the X2SR pump barbs like normal.

On the other end of the 1/2” tubing, I installed a John Guest 1/2” OD Stem x 3/8 ID Barb (Part PP251612W)

Now the inlets/outlets can accommodate any 1/2” push-fit fitting, so I added JG 1/2” union connectors (Part PP0416W). From there, I can securely push-fit any standard 1/2” ID hard tubing (available at any HD/Lowes)

The feeds then go through my utility room wall to the tank in the other room. I have an acrylic tank, so I drilled holes through the back of the sump area to securely anchor the lines (with corresponding 1/2" union elbows). If you were dealing with glass, you could easily just create a hook with union elbows to to over the top of the tank. You could obviously run the X2SR much closer to your tank and avoid long runs of tubing, but it is pretty loud (its pushing a lot of water compared to a normal dosing pump!) and I installed it in the other room with my water reservoirs to keep it quiet.

The X2SR also has a built in ATO feature (using included float valves) that I installed. While Id prefer my optical ATO on my controller, the ATO integrated into the X2SR prevents RODI water from feeding to the tank while a water change is in progress. I directly plumbed a 1/4” LLDPE line from my 55g RODI barrel to the tank using the same methods, and the included ATO pump has no problem pushing the water about 15ft to the tank. Because it is directly attached to my RO barrel, I essentially never have to refill an ATO chamber again!

I am thrilled with the new system - the tank does automated daily water changes and ATO virtually silently, and I am already seeing an increase in system stability, cleanness and nitrate reduction!

If you are interested in refitting an X2SR using these methods, here are the primary parts I used:

John Guest Stem Barb Connector Polypro - 1/2 OD Stem x 3/8 ID Barb

John Guest Polypro Tube to Hose Stem - 1/2 OD Stem x 3/8 ID Barb

The John Guest tube to hose stems are used to connect hose to Push-fit fittings. Manufactured in polypropylene, these fittings were developed for the filtered pure water market.Features: Push-fit Technology creates reliable, leak-free connections For connecting hose to Push-fit fittings...

John Guest Union Connector Polypro - 1/2

John Guest Union Connector Polypro - 1/2

The John Guest union makes connecting OD tubing sizes to female NPT threads quick and easy. Manufactured in polypropylene with food grade EDPM O-ring, these fittings were developed for the filtered pure water market.Features: Push-fit Technology creates reliable, leak-free connections Used to...

John Guest Locking Clip - 1/2

John Guest Locking Clip - 1/2

The John Guest locking clip secures the collet in a locked position after the tubing has been inserted. This prevents the accidental release of tubing. The clip is easy to remove if the tubing needs to be released. Features: Used to secure the collet in a locked position Prevents accidental...

Last edited: