Because I have about 1000 gph pumping through my 125 gal basement sump to my 200 Gal DD tank upstairs I had to wait for the DI-7. It finally was released a couple weeks ago and I bought mine from BRS. I have contacted CloralVue on my apparent faulty controller. I am sure they will replace it. I am not worried about that.

After following the video install and the online installation steps correctly, I have realized a few flaws that will not deter me from keeping this BUT I do want to bring these up in a public way to discuss. I just want others input on this also as someone may have already pointed these things out or have solutions.

After following the video install and the online installation steps correctly, I have realized a few flaws that will not deter me from keeping this BUT I do want to bring these up in a public way to discuss. I just want others input on this also as someone may have already pointed these things out or have solutions.

- First, the obvious, the controller is a toy. While I don't doubt the component board inside is up to par (even though mine is faulty) it just feels incredibly cheap. it feels like a happy meal toy.

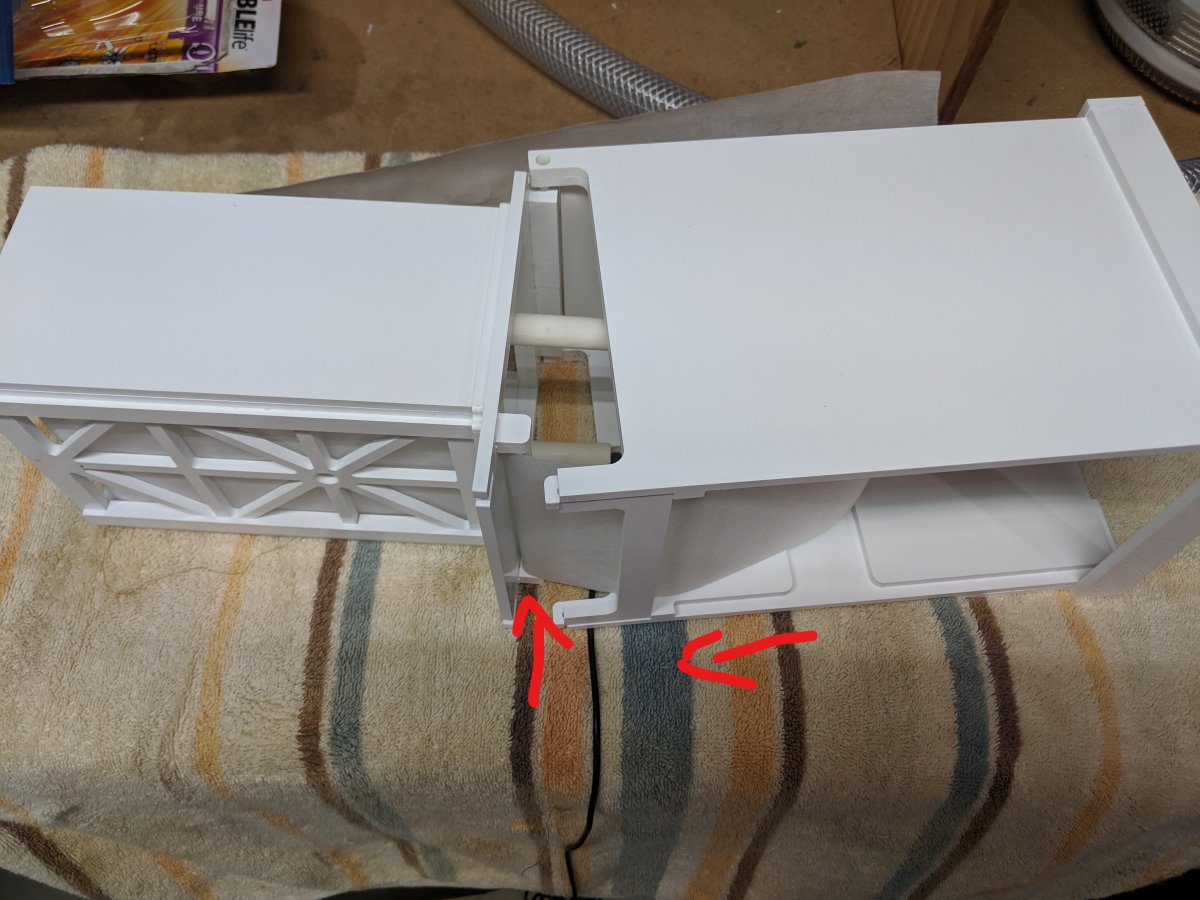

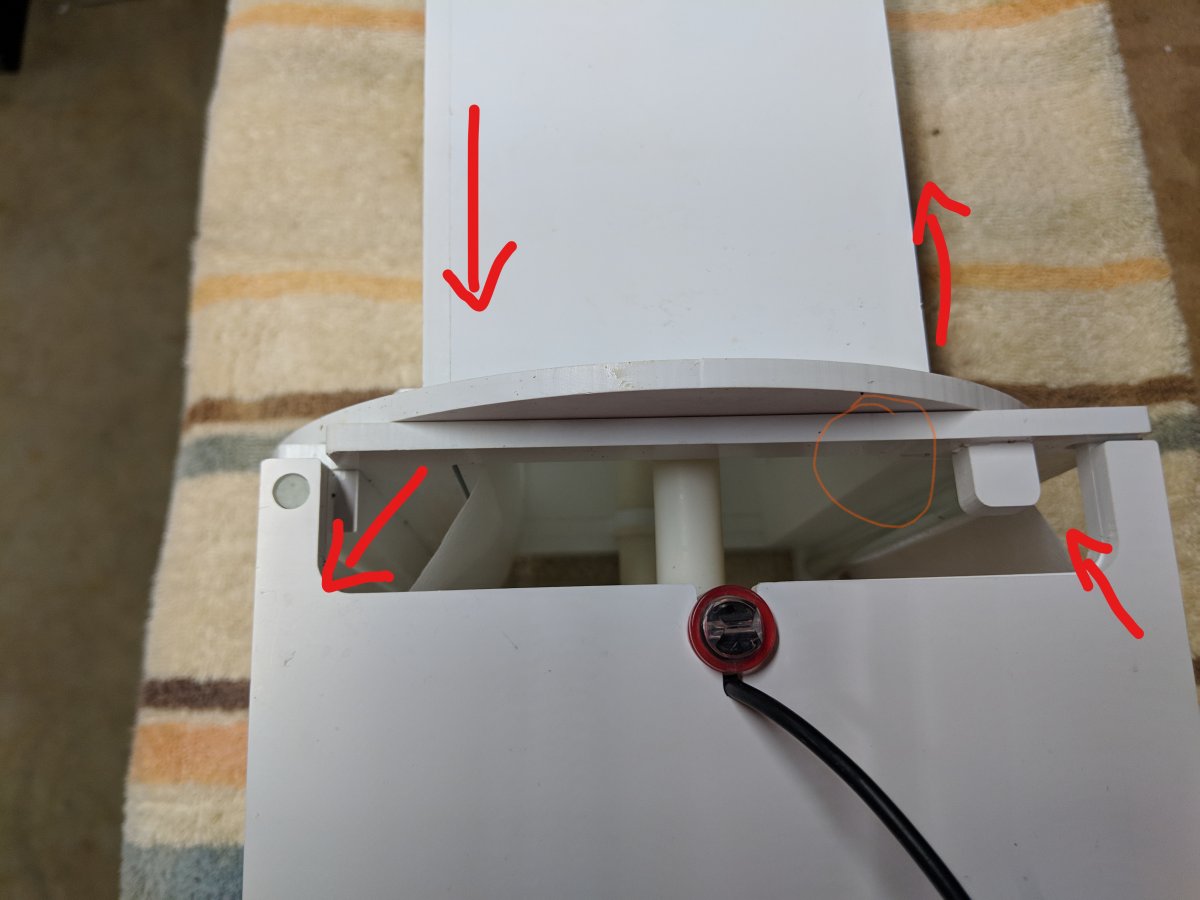

- Next, the path that the filter media goes through from the top to the bottom is incredibly flawed in my opinion. The path takes it over the first roller on the outside then to the 90deg roller at the junction of the top to the bottom part THEN it lays against the edge of the part that goes to the bottom creating a huge binding point. See pics attached. It needed another roller RIGHT a the edge so the media could roll easily not bound by that corner.

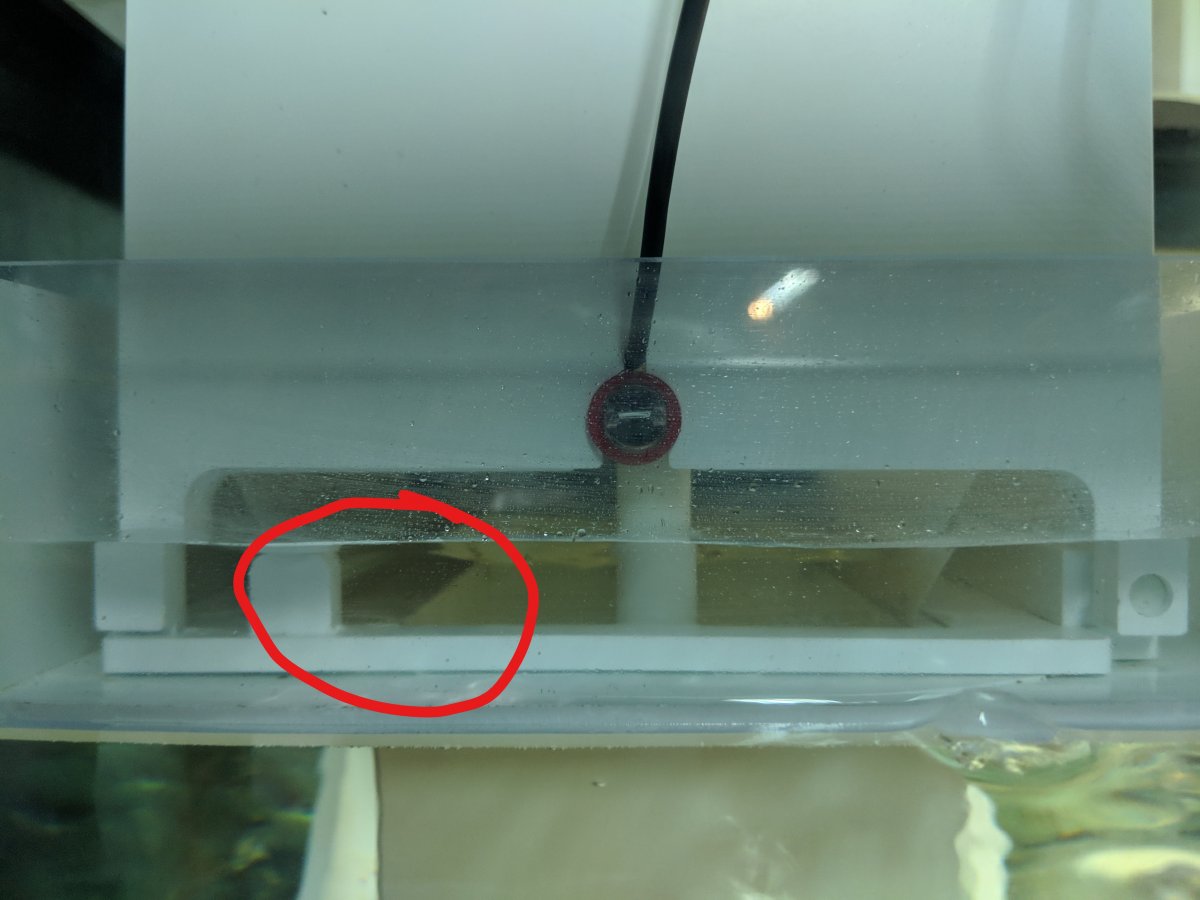

- I am sure others have had this happen, but if the water flows over the edge due to the motor not working/controller not working/etc (like mine) the unused roll of media gets soaking wet, so wet I had to remove it and use the spare. Yes I can dry it out, but very annoying that it is so close to the highest water level that it can get that wet.