Hi everyone! This is a great site, and wonderful thread for ideas.

I would greatly appreciate as much feedback as I can get in the next 24 hrs as I plan to get the remaining parts I need and begin assembly over the next few days!

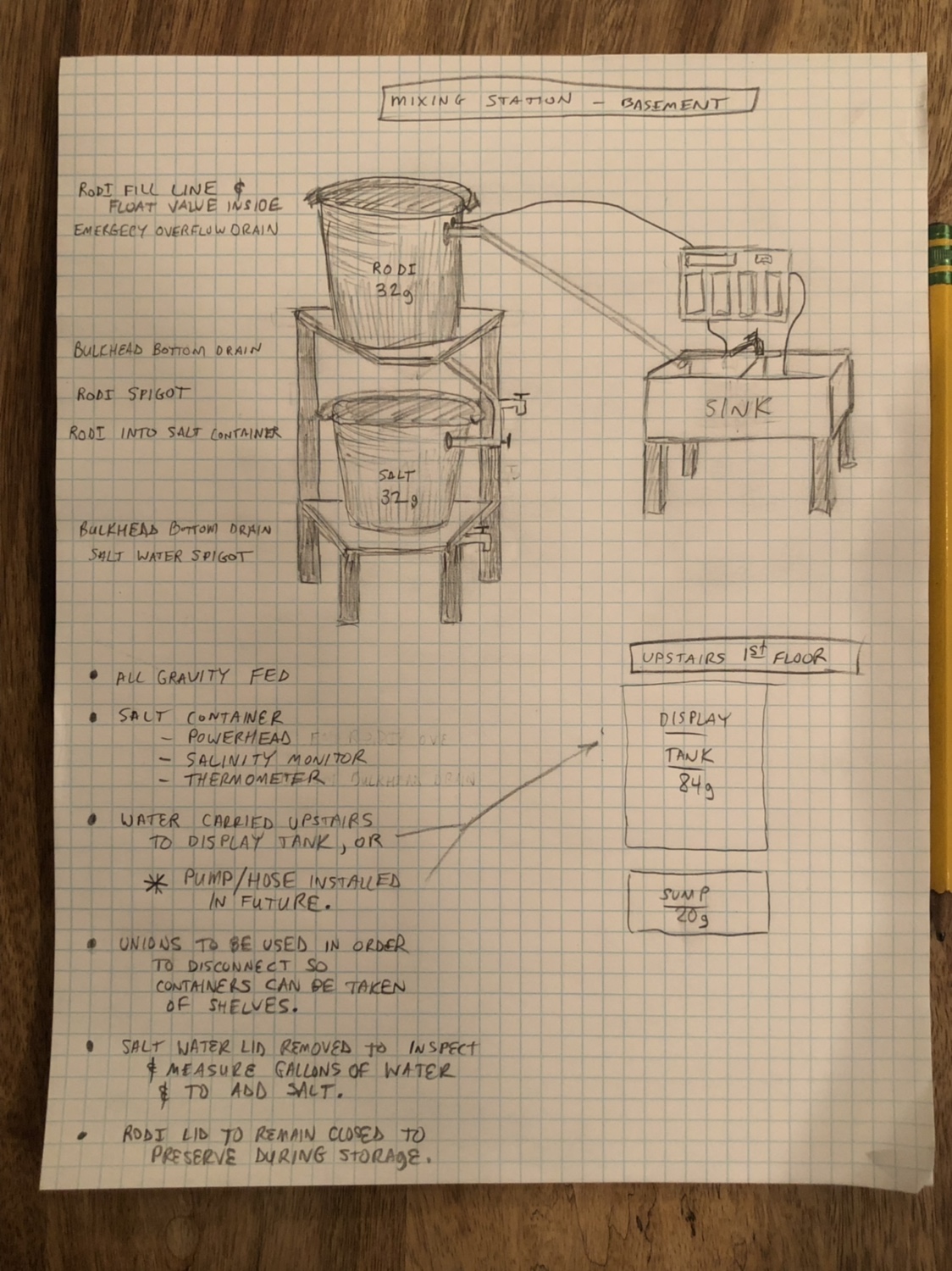

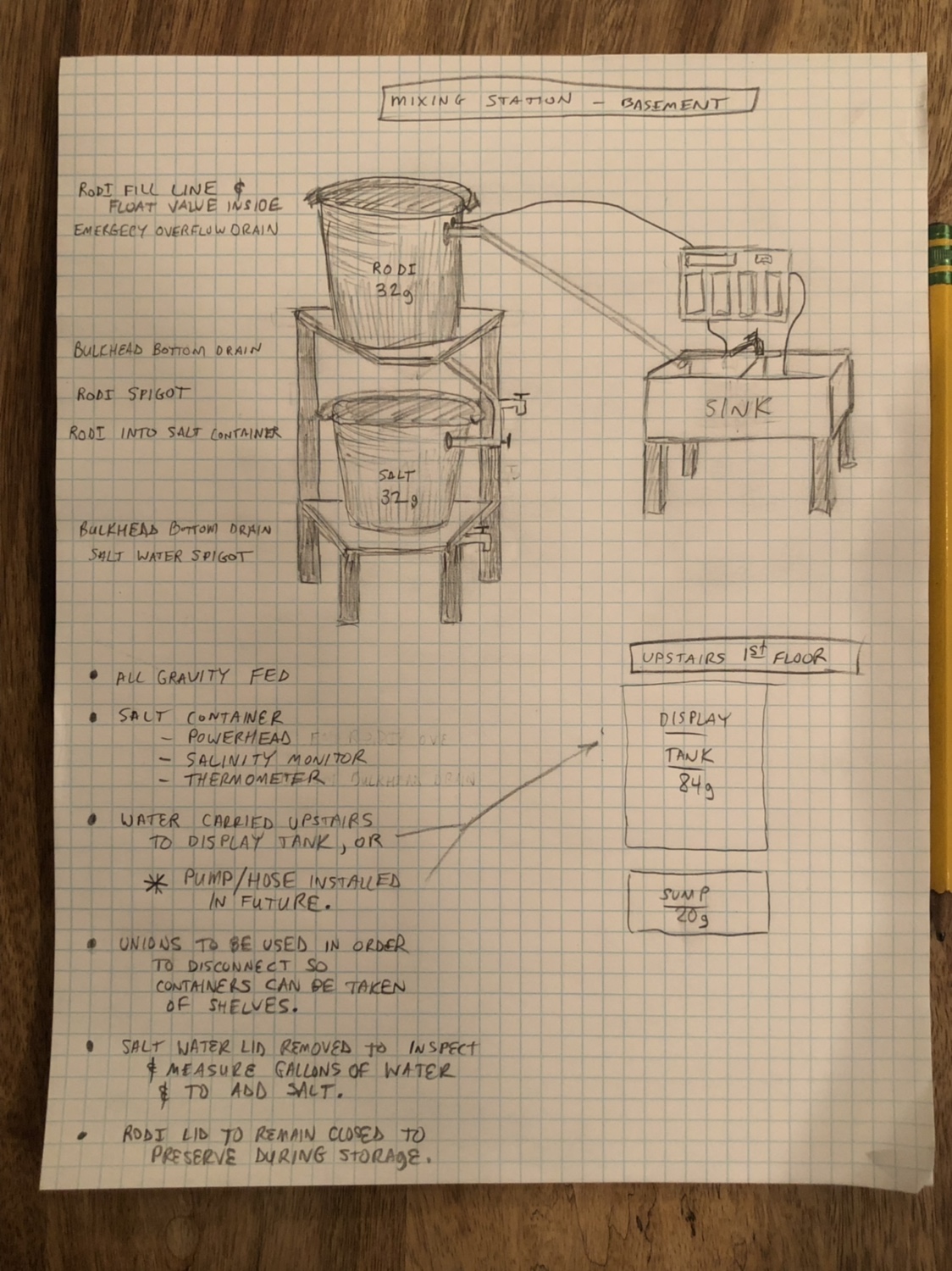

I attached a sketch plan and thank you in advance for any and all feedback!!

-Matt

I would greatly appreciate as much feedback as I can get in the next 24 hrs as I plan to get the remaining parts I need and begin assembly over the next few days!

I attached a sketch plan and thank you in advance for any and all feedback!!

-Matt