jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

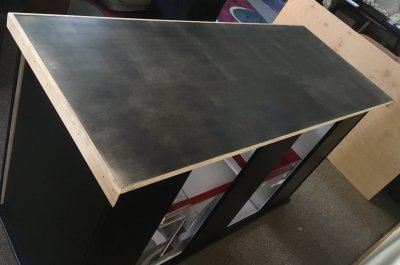

Here it is from the inside.... hope this helps

Looking at the picture, the seem come to my attention with the tank sitting in the middle of the cabinet. I would suggest installing a 2x4 along that seem and using spax washer head screws 3" and screwing two screws from the outside in, into the 2x4. you and use a little black paint to cover the screw. That would brace and support the tank propper. I like the idea of the 3/4 ply in top also since the cabinet is all MDF. It will look chunky but you can also bank around the top with trim wood and that would give you a modern look and a strong top, and if it got wet the cabinet would be sound.