New chapter... planning the new display tank.

The new house allows us to place a bigger display tank and so we will do!

and so we will do!

The original idea was to build an "aquarium room" next to the house and making a cut-out for the aquarium so we could view it from the living room. After discussion with construction workers; understanding the risks and finally hearing about the cost we decided it was not realistic for us. Therefore I decided to place the aquarium in the living room and the filter system in a "filter room" next to the house.

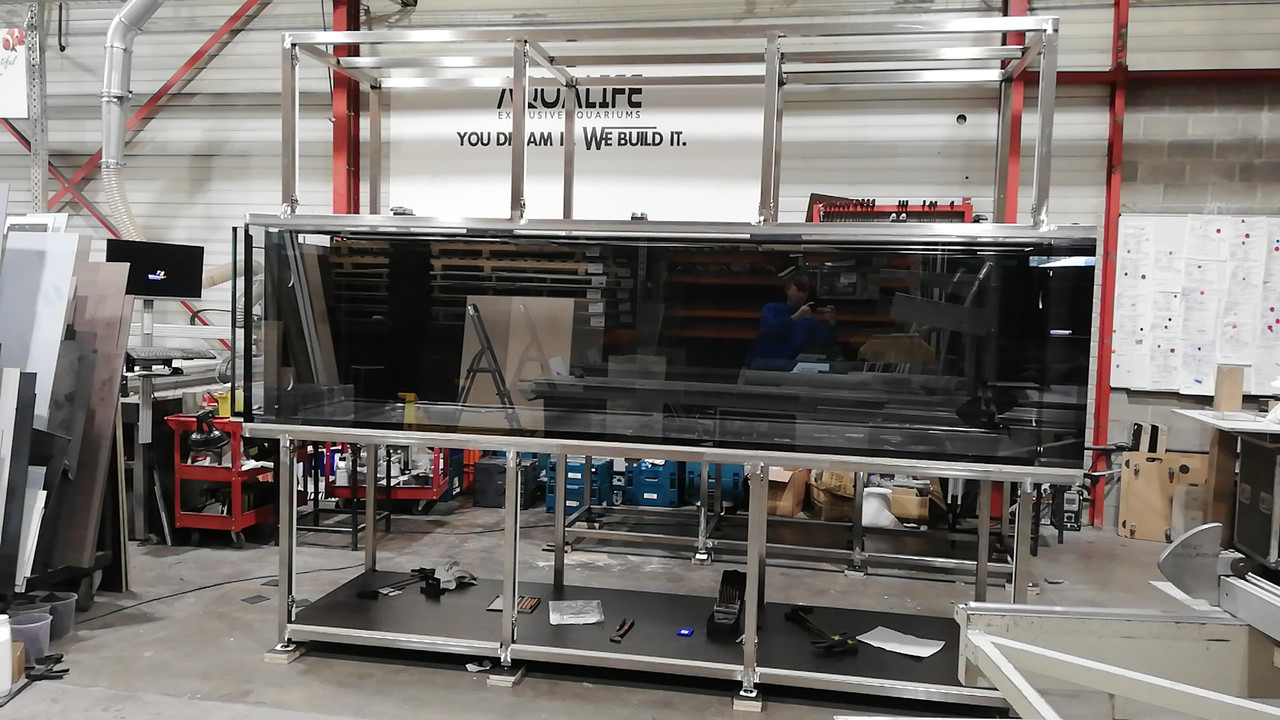

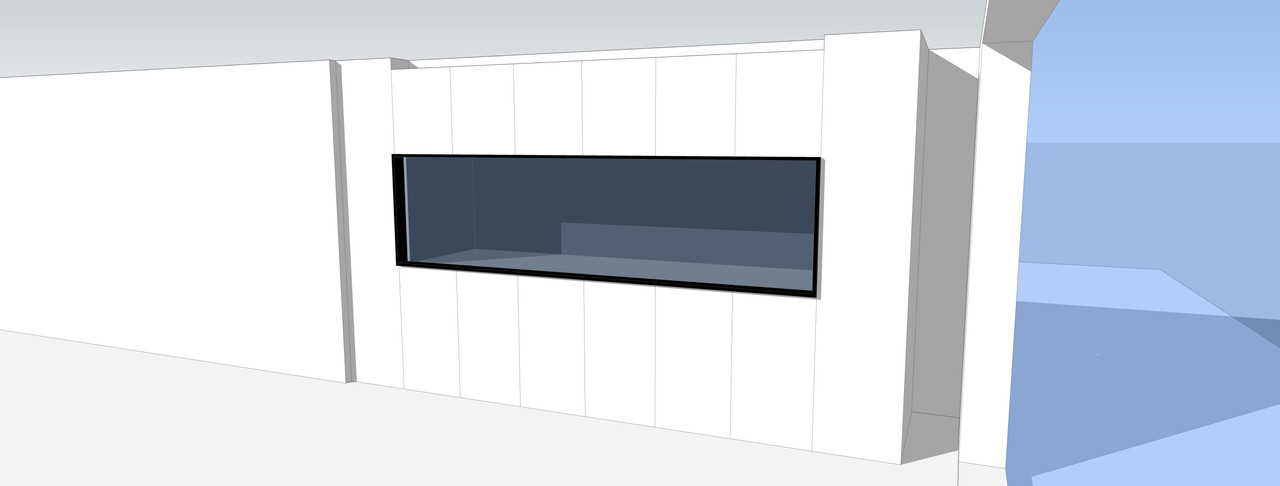

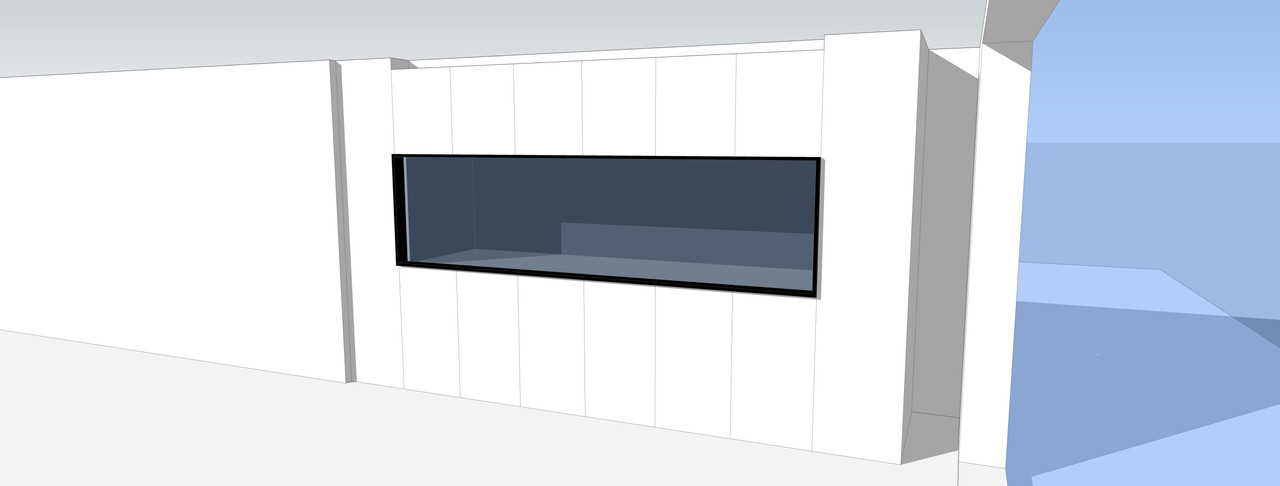

This was the first sketch of the tank:

Dimensions: 3.21 meter (the biggest they can cut from a single piece of standard aquarium glass)x80x80. ~2000 liters.

And a photo of the actual place (ignore the table and wood; I was still working on the living room furniture)

I agreed on the size of the tank and cabinet and continued planning the filter room.

I have a ~25m^2 area next to the house which was used for some garden waste and thought.. why not build the filter area over there. I start thinking about a simple construction and came across these pre-fab professional freezers. I managed to find one second hand (it was huge ~40m^2) but since it is modular i could reduce the size easily. Isolation properties are fantastic (15cm wall thickness) and the construction was strong enough to place it without additional support. It only had to be made wind/water proof with an outer shell.

So I bought it cheaply and dismantled it

The freezer still in the factory:

Inside the cell:

Disassembly was easy. Took us 2 days with 3 persons:

and almost done:

I also had to remove a small balcony next to the house because the height of the cell was ~3meters.

It was re-enforced concrete.. so it took some effort:

3 hours later:

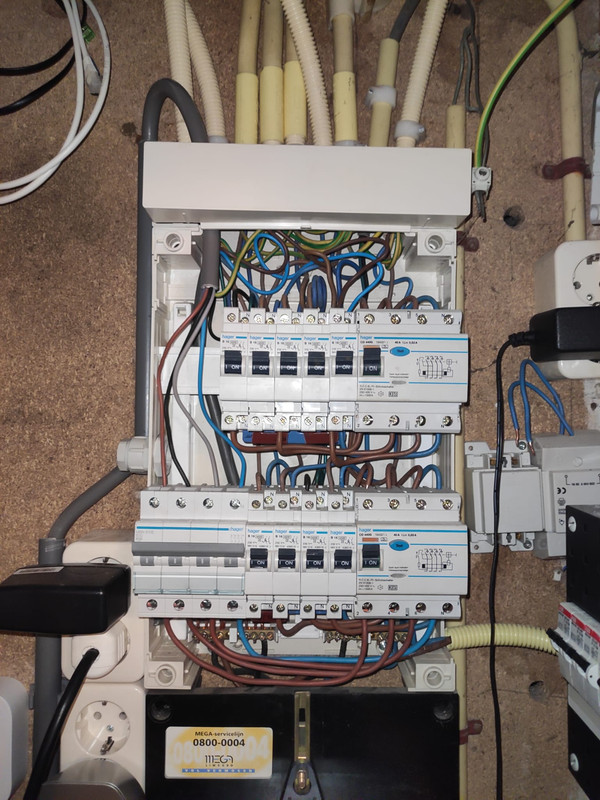

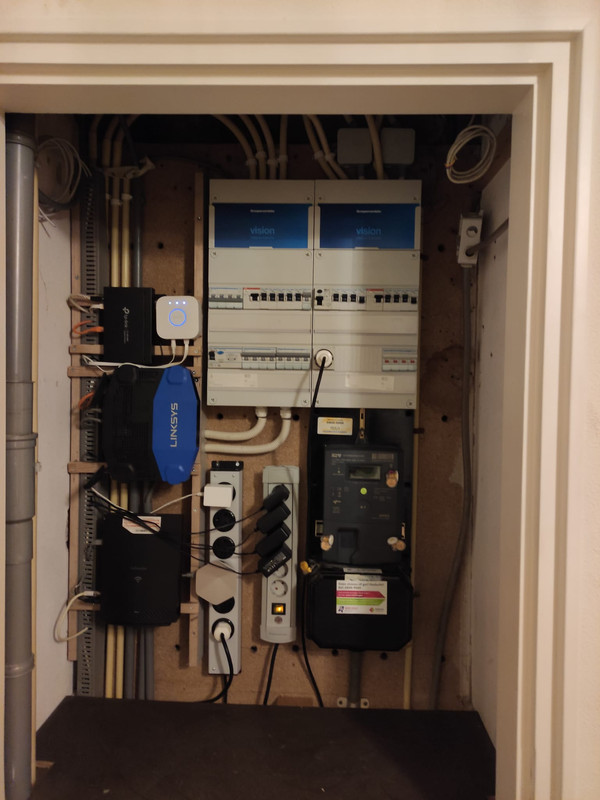

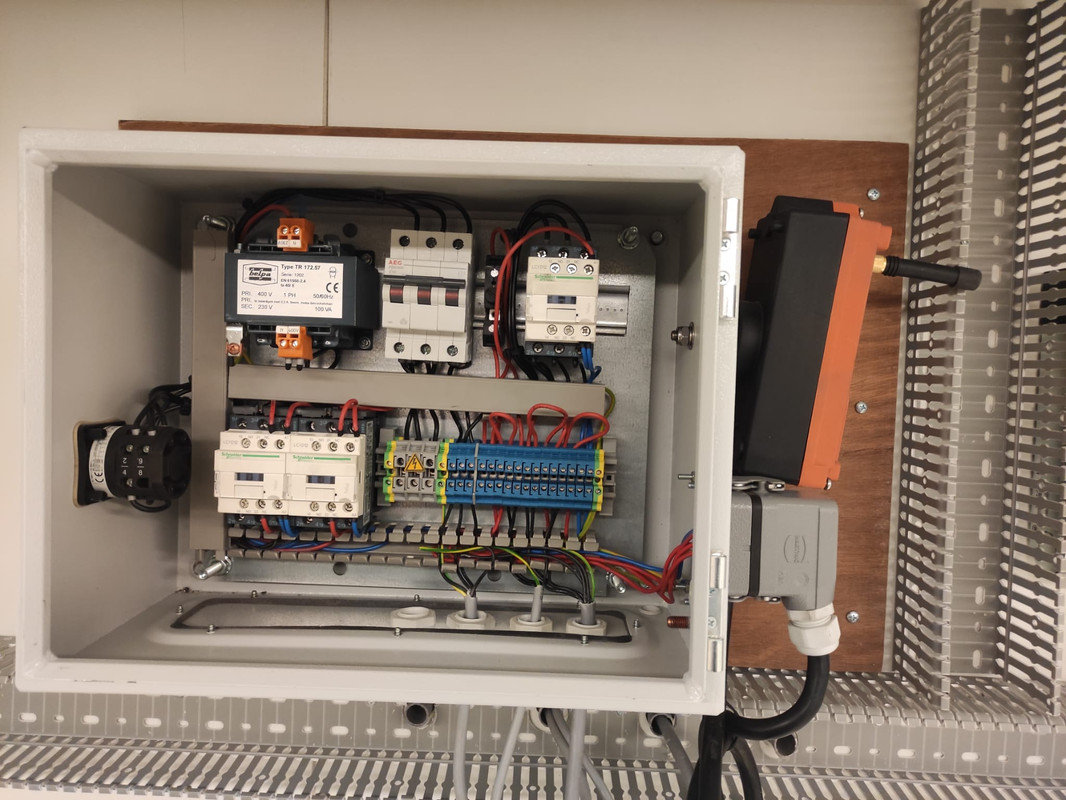

We then started with the base of the cell. We had to remove some sand (to stay under the starting point of the window on the first floor) and placed a cement gravel mix to harden the ground. I also made sure to add all plumbing for water (rain water/waste water); electricity etc.

Removal of the ground (~15kubics)

removed ground

pipework in place:

Gravel mix added:

and the final result including tiles which act as support for the construction

To be continued later!

The new house allows us to place a bigger display tank

The original idea was to build an "aquarium room" next to the house and making a cut-out for the aquarium so we could view it from the living room. After discussion with construction workers; understanding the risks and finally hearing about the cost we decided it was not realistic for us. Therefore I decided to place the aquarium in the living room and the filter system in a "filter room" next to the house.

This was the first sketch of the tank:

Dimensions: 3.21 meter (the biggest they can cut from a single piece of standard aquarium glass)x80x80. ~2000 liters.

And a photo of the actual place (ignore the table and wood; I was still working on the living room furniture)

I agreed on the size of the tank and cabinet and continued planning the filter room.

I have a ~25m^2 area next to the house which was used for some garden waste and thought.. why not build the filter area over there. I start thinking about a simple construction and came across these pre-fab professional freezers. I managed to find one second hand (it was huge ~40m^2) but since it is modular i could reduce the size easily. Isolation properties are fantastic (15cm wall thickness) and the construction was strong enough to place it without additional support. It only had to be made wind/water proof with an outer shell.

So I bought it cheaply and dismantled it

The freezer still in the factory:

Inside the cell:

Disassembly was easy. Took us 2 days with 3 persons:

and almost done:

I also had to remove a small balcony next to the house because the height of the cell was ~3meters.

It was re-enforced concrete.. so it took some effort:

3 hours later:

We then started with the base of the cell. We had to remove some sand (to stay under the starting point of the window on the first floor) and placed a cement gravel mix to harden the ground. I also made sure to add all plumbing for water (rain water/waste water); electricity etc.

Removal of the ground (~15kubics)

removed ground

pipework in place:

Gravel mix added:

and the final result including tiles which act as support for the construction

To be continued later!