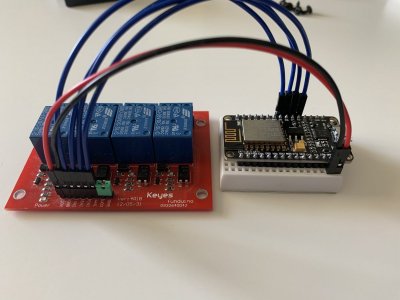

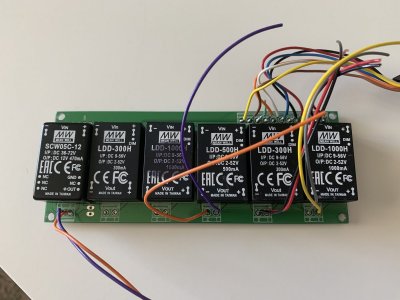

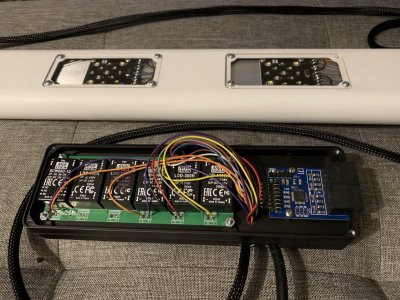

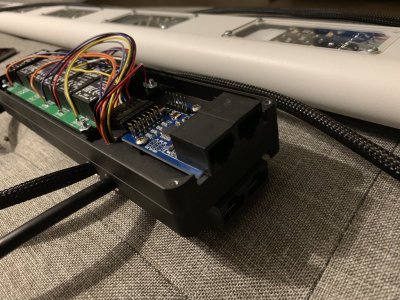

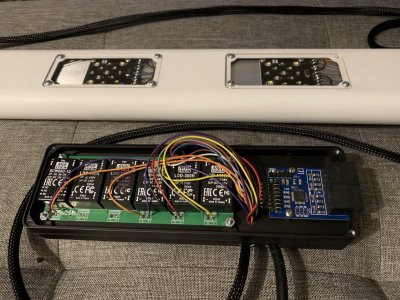

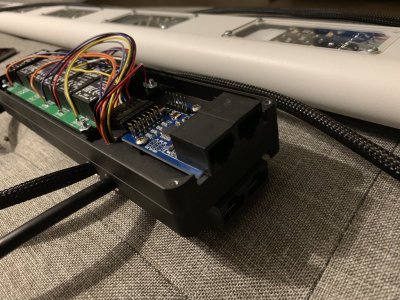

Started thinking through how I’ll be implementing the Nanobox LED over this tank. Originally, the plan was to run it with 0-10V from either an Apex/GHL so Dave outfitted the power supply with a PWM to 0-10V converter. I really like how compact these buckpuck boards are...

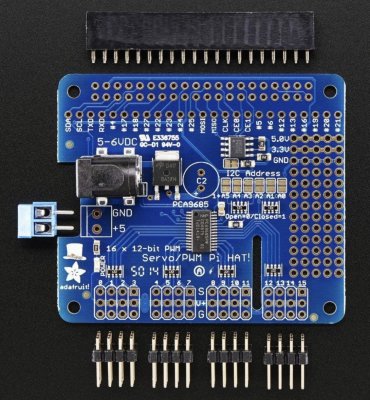

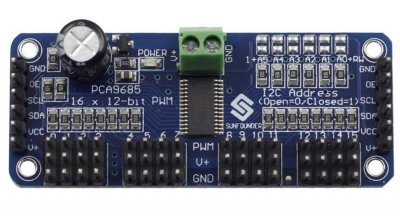

But now that this controller is Raspberry Pi based, it’ll be easier going straight to the PWM with a multi-channel PWM hat for the LED channels. The converters will be used to interface the 0-10V pumps.

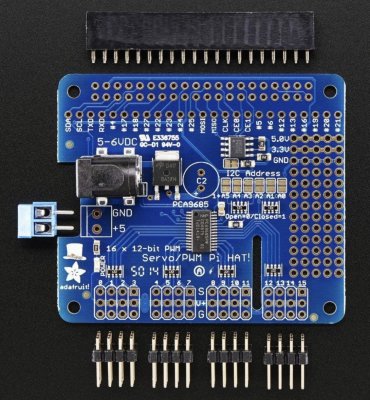

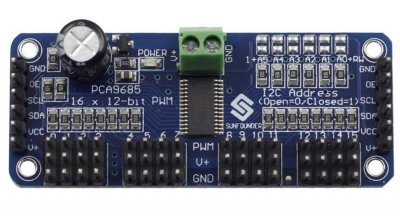

One of these should do for PWM control...

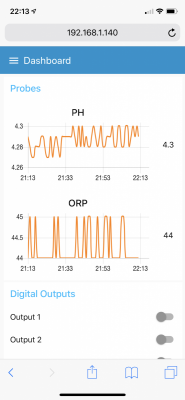

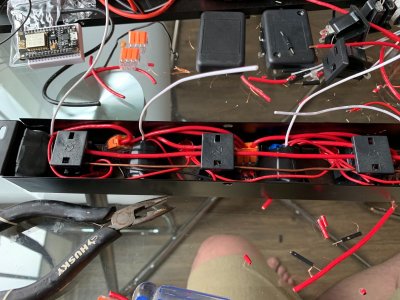

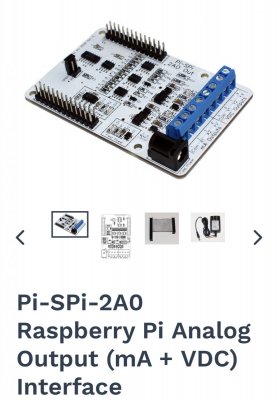

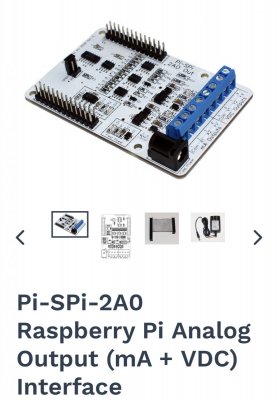

In addition, I’ve ordered a couple of analog input/output boards to see if the PLC is even needed. Node-Red offers well built PID nodes so the control needed for regulating the drain valve should be possible directly from Pi and these boards.

Once the valve shows up from the UK, I’ll set the concept tanks up to run a PID loop controlled by Node-Red to verify it performs adequately. Depending on performance and how accurately the failsafes respond to simulated failures, testing of the PLC will be evaluated.

But now that this controller is Raspberry Pi based, it’ll be easier going straight to the PWM with a multi-channel PWM hat for the LED channels. The converters will be used to interface the 0-10V pumps.

One of these should do for PWM control...

In addition, I’ve ordered a couple of analog input/output boards to see if the PLC is even needed. Node-Red offers well built PID nodes so the control needed for regulating the drain valve should be possible directly from Pi and these boards.

Once the valve shows up from the UK, I’ll set the concept tanks up to run a PID loop controlled by Node-Red to verify it performs adequately. Depending on performance and how accurately the failsafes respond to simulated failures, testing of the PLC will be evaluated.