You are right, it would be more prone to flex, but in this case it would aslo kinda act like a gluelam beam and would have to comress that whole other layer in order to flex. But, youd have to glue it and fasten it solid or it would just be a 2x6. Or, if you ended up putting a wall in front of it, you could use a 'c' channel topper set flat that would be just about as rigid as possible. I think what you have will provide enough support though, i was just brain storming with you Engineering issues are fun! Love your progress and cant wait to see it done again!Thanks for the input all ideas are always welcome. I'm just not sure if this would add much additional structural strength especially if I use wood. Wood on its side like that does not really offer much stability it will most likely just flex. Not sure about some kind of metal? If metal I think it would need to be some type of angle or it would most likely just flex also. I have actually considered building a wall up the front so that I could have 2x4's or 2x6's perpendicular to the tank face around the opening.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mehaffy's 1100+ gallon Plywood display in North Alabama

- Monster Build

- Thread starter mehaffydr

- Start date

- Tagged users None

I added another layer of fiberglass today. This time I used my woven fiberglass. The first 2 layers were what is call strand matt which just has fibers going in every direction. This layer is more like a piece of fabric. It leaves a smoother finish and also by using both I should get good strength in all directions. This is dry before the resin just cutting to the right size.

This is after Resin is applied. You can see how smooth this is compared to the other layers.

This is after Resin is applied. You can see how smooth this is compared to the other layers.

I just used some real heavy duty scissors I have. They will cut heavy cloth and things like Burlap. They cut right through the fiberglass

Man I went out if town and didn't keep up with this thread and came back to your setback. Sorry to hear what happened but I'm glad you have brainstormed a solution and nearly fixed it. Hope you get everything epoxied so you can install the glass next weekend and let it sit for a week. Good luck!

I have been working on tank. I have spent the last three days just working to get all of the old Silicone removed. I now have that done and I will start repainting that front section over the weekend. I’m also thinking about adding the same brace I put on the front over on the side that has glass. It most likely is not needed but I didn’t think the front was needed either. If I do it after the glass is installed in the front it really won’t slow me down because I’ll have a few weeks waiting for silicone to cure anyway

I have been working on tank. I have spent the last three days just working to get all of the old Silicone removed. I now have that done and I will start repainting that front section over the weekend. I’m also thinking about adding the same brace I put on the front over on the side that has glass. It most likely is not needed but I didn’t think the front was needed either. If I do it after the glass is installed in the front it really won’t slow me down because I’ll have a few weeks waiting for silicone to cure anyway

Sorry to hear about your leak. What type of Silicone or RTV did you use for the first seal that had the leak?

Wow. I just spent the whole morning getting through 568 posts. Very grateful to you for sharing this. You should name this tank "Perseverance".

After looking this over the only thing I would consider is doubling the 3/4" on the front or adding another hardwood board over to stiffen the 3/4" plywood over the seal area but I can see how this beam should stiffen up that front.

I put the first coat of epoxy paint on the reinforced area today. This will takes 4-5 days as I need to get 4-5 coats and then I can install the glass.

I am also looking at a good way to reinforce that front with either hardwood or plywood just not sure yet how to do it and really get good support.Looking good. Looks like you will be back up and running in no time.

I put the second coat of epoxy paint on the repair area tonight. I will do at least 2 more before reinstalling glass. I will get these new couple coats done this week and then I'm going fishing for a few days next weekend so I will let the epoxy cure for about a week before reinstalling glass some time the first week of April which will get me back on a timeline to add water.

I have also decided to build some type of external brace to support the wood at the bottom of the glass. Still working on details. Maybe wood maybe aluminum maybe steel powder coated and maybe a combination of wood and metal. I will post some drawings tomorrow.

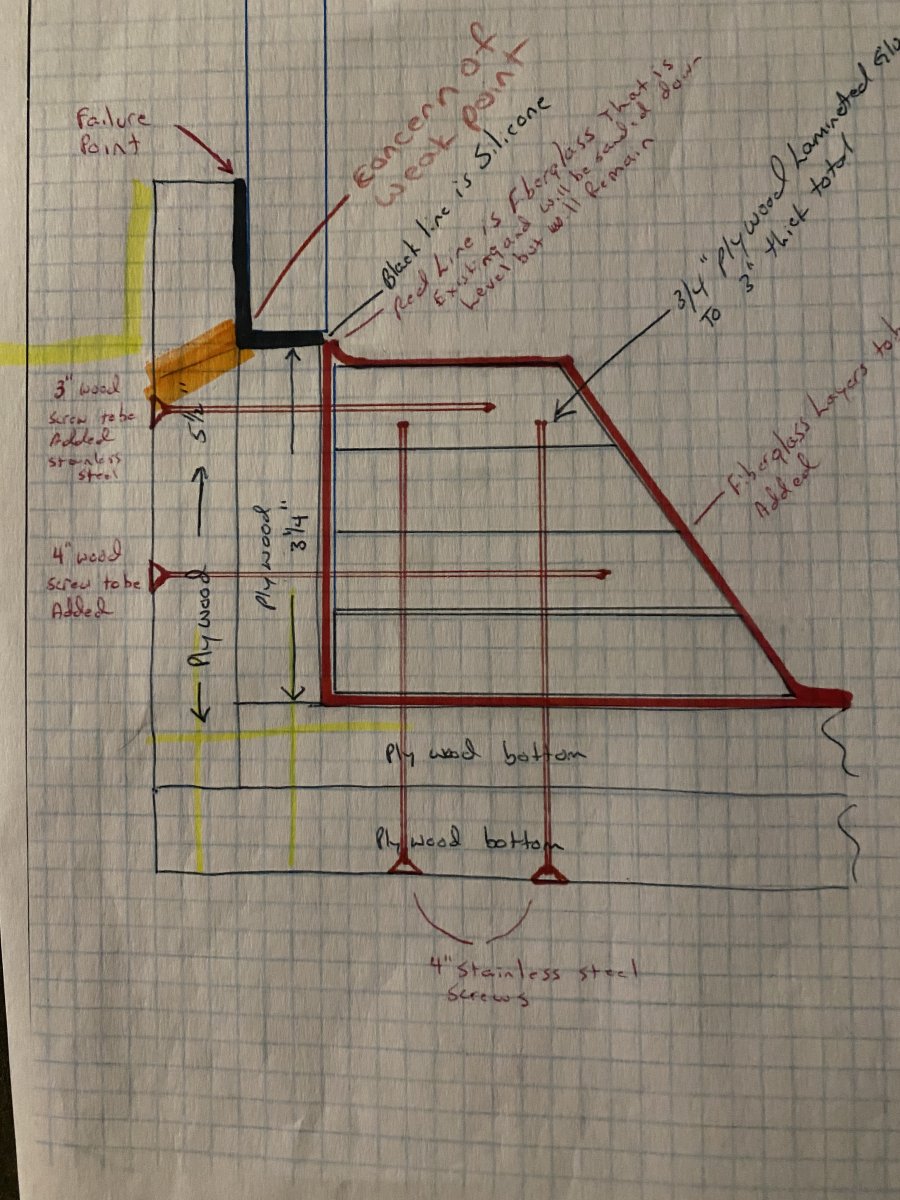

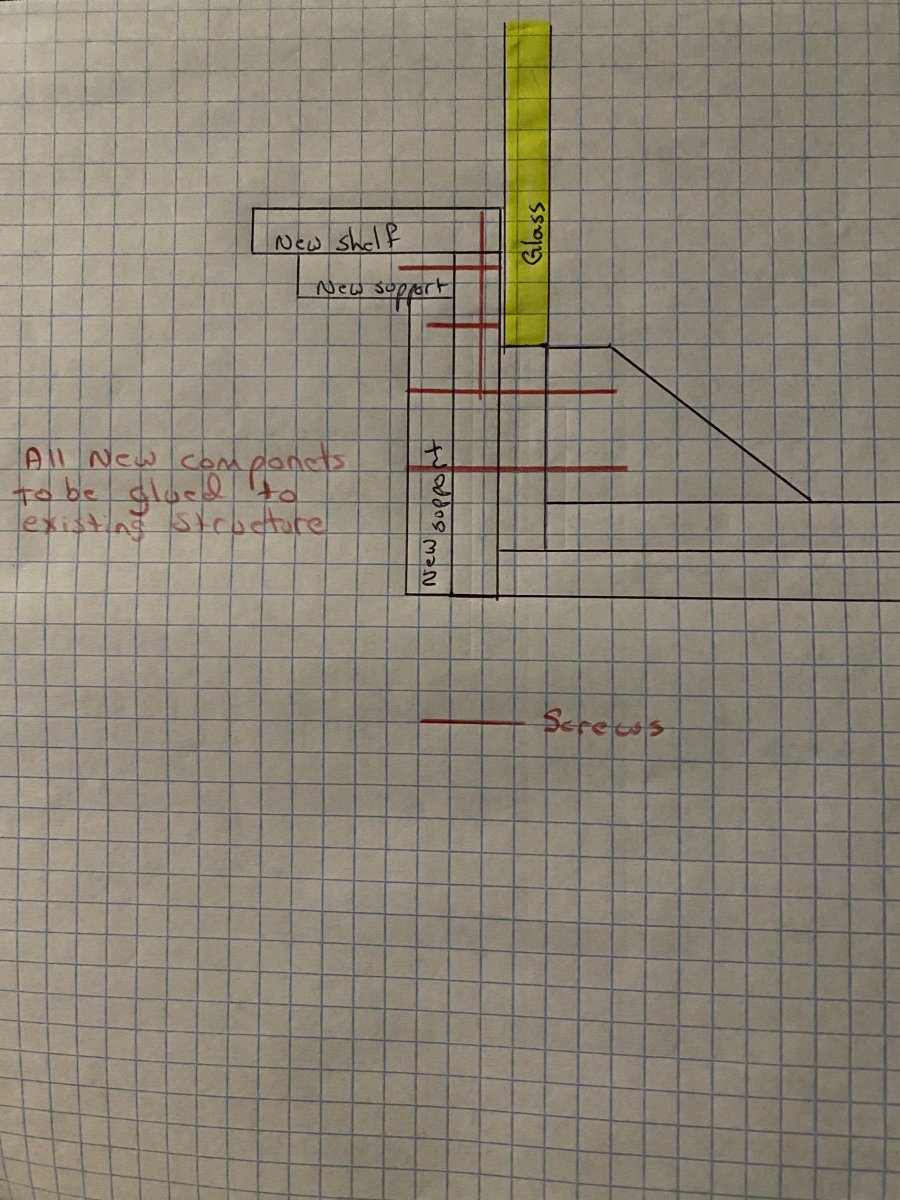

I had a couple of people suggest some extra reinforcing and as you all may have notice I am into overbuilding so as much as I think this current design will hold I have decided to add additional support. I am attaching a drawing I made below showing the added material which will all be Glued with Titebond 3 and screwed with structural screws. with this addition I think I can sleep easy.

I think the only real potential weak point is at the bottom of the glass where the plywood is only 1 layer. S I am reinforcing both ways making it thicker and also adding wood on edge to give structural strength to prevent bowing. First drawing is what I did to reinforce bottom seam and the Orange highlighted area is my point of concern. The second drawing is what I plan to add. Red lines are screws.

Let me know what you think?

I think the only real potential weak point is at the bottom of the glass where the plywood is only 1 layer. S I am reinforcing both ways making it thicker and also adding wood on edge to give structural strength to prevent bowing. First drawing is what I did to reinforce bottom seam and the Orange highlighted area is my point of concern. The second drawing is what I plan to add. Red lines are screws.

Let me know what you think?

While I am good at some stuff, I have in my years learned to consult "the engineers" as I m not a qualified engineer when pondering more extreme situations.

I have a mechanical engineer at my work and he says I'm overthinking it and it should not require this additional support but I need to be confident that my fish and corals are safe.While I am good at some stuff, I have in my years learned to consult "the engineers" as I m not a qualified engineer when pondering more extreme situations.

So now just have to decide what to use. I would like to use 3/4" plywood because the laminate structure of plywood would give more structural support but the only place I can find 10' plywood in Menards and the closest on to me is a 3 1/2 hour drive one way in Paducha KY. I'm thinking I may go with a good hardwood like Oak, Birch or Maple. But with solid wood there is a chance it could bow and actually aid the tank in bowing. @AlexG @Red_Beard what do you guys think

I love it, that little shelf is going to be handy and give it a load more strength. I put a lip on my stand and use it for all sorts of stuff. My opinion would be 10ft ply if you are still worried about it(if it was me and i had just re-done all of that work i would be paranoid), or even 8's as you are going to have them overlap, just make sure to offset the extra 2 ft section so the seams are opposite eachother and the whole mating surface glued. I think you are right about the hardwood, it could potentially bow given time and stress, but it isnt as likely given 2 lapping pieces on edge. Hardwood would look really good stained and marine epoxy coated But, I like to overbuild things too. If you cant park a truck on it, it isnt strong enoughSo now just have to decide what to use. I would like to use 3/4" plywood because the laminate structure of plywood would give more structural support but the only place I can find 10' plywood in Menards and the closest on to me is a 3 1/2 hour drive one way in Paducha KY. I'm thinking I may go with a good hardwood like Oak, Birch or Maple. But with solid wood there is a chance it could bow and actually aid the tank in bowing. @AlexG @Red_Beard what do you guys think

Similar threads

- Replies

- 117

- Views

- 3,131

- Replies

- 9

- Views

- 279