Hello R2R , I'm a long time lurker, first time poster. I just felt others would like to follow this crazy "project" of mine.

I'm currently running a 6ft 125 gallon, but always felt something a bit bigger would allow me to have more of the fish I love, this combined with my desire to have a fish room is a recipe to blow all my spending money. I have tossed the idea of a larger tank/fish room around with my girlfriend a few times over the last year to less then stellar results... After checking out some used tanks from various sellers just to see whats out there, she really liked the height on a 36" tank we saw... at first I was not a fan, being my reach is about 33" if i'm lucky, and lighting corals gets a bit harder, but after some thought, I started to think "she likes a tank type... This is great news, and LPS / Softies are my coral of choice anyways!!" now to convince her on a fish room. At first I wanted to re-purpose one of the downstairs rooms... it just wasn't in the cards. then it came to me, the garage! My garage is a tinkers paradise that I built from the ground up to do anything I could ever think of in climate controlled comfort. It's the perfect place to section off an area the fish room... except it is not attached to the house...

After letting the thought die for a few months, a tank/stand came up on Facebook for $700, and they lived like 2 blocks from me. we checked it out, and determined this is the tank. It's a 72"L x 24"W x 36"H acrylic monster of a tank, and was a pain to get home. thankfully owning an old forklift paid off again for unloading.

once home I cleaned it out, and started the long process of polishing out the years of scratches.

to break up the monotony of tank prep and polishing I started on the process of getting plumbing to the garage... The current tank(which is where the new tank will go) shares a wall with the kitchen which is very close to the garage. I started thinking about how to get plumbing out under the house, and to the garage. After some thought I determined I would remove a cabinet and make a hole in the foundation under it, that way if we ever sell, or I get out of the hobby again, I can cap it off and no one is the wiser. This spot will allow me to put the cabinet back over the plumbing when I'm done, while passing everything through the wall to the new tank. holy cow this was a lot of work! but after a long day of digging I did it. I got my plumbing under the house. I went with 1" 1/2 PVC for my return line which will get split off to 2 x 3/4" lines on the tank, and 2" for my overflow, which gets split off to 2 x 1" lines. I wanted to go with 3" PVC for my overflow, but due to the location of my driveway, the 3" PVC would have been almost impossible to get under the house. I also ran some 10 conductor sprinkler wire along with my pipes, as I plan to run an Apex with everything, and will need it for light control, and other tank side goodies. I have such a loving girlfriend... when I told her the details of how I was going to pull off a garage sump, she let out a little sigh, and said "I love you, what can I do to help"

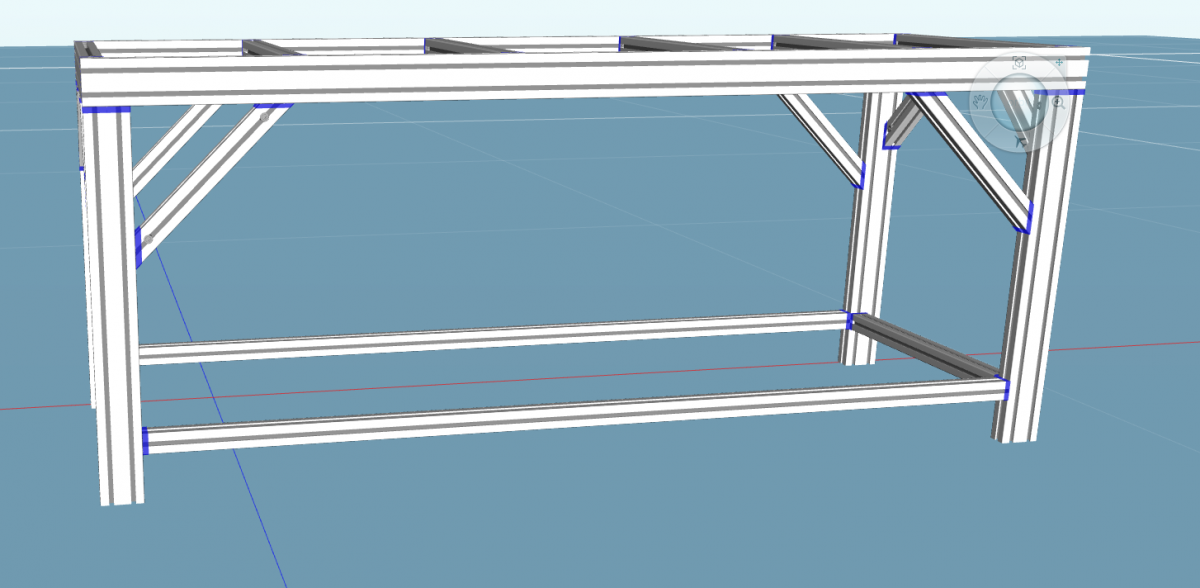

I also started to design a stand, as the wood one that came with the tank just wasn't going to suit our needs. After some calculations, a few talks with some engineering friends, and an order to Tnuntz I ordered the parts to make this, using a combination of 1530 and 1515 extruded aluminum. the math says she will hold, but I will be doing a water-filled deflection test before she goes into the house.

Stay tuned, the next steps are to finish the tank polishing, Painting the back of the tank black, and moving all my current stock to a garage tank, so that I can break down the 125. (which will become the future sump for this monster) and the fun part of building out my future fish room.

I'm currently running a 6ft 125 gallon, but always felt something a bit bigger would allow me to have more of the fish I love, this combined with my desire to have a fish room is a recipe to blow all my spending money. I have tossed the idea of a larger tank/fish room around with my girlfriend a few times over the last year to less then stellar results... After checking out some used tanks from various sellers just to see whats out there, she really liked the height on a 36" tank we saw... at first I was not a fan, being my reach is about 33" if i'm lucky, and lighting corals gets a bit harder, but after some thought, I started to think "she likes a tank type... This is great news, and LPS / Softies are my coral of choice anyways!!" now to convince her on a fish room. At first I wanted to re-purpose one of the downstairs rooms... it just wasn't in the cards. then it came to me, the garage! My garage is a tinkers paradise that I built from the ground up to do anything I could ever think of in climate controlled comfort. It's the perfect place to section off an area the fish room... except it is not attached to the house...

After letting the thought die for a few months, a tank/stand came up on Facebook for $700, and they lived like 2 blocks from me. we checked it out, and determined this is the tank. It's a 72"L x 24"W x 36"H acrylic monster of a tank, and was a pain to get home. thankfully owning an old forklift paid off again for unloading.

once home I cleaned it out, and started the long process of polishing out the years of scratches.

to break up the monotony of tank prep and polishing I started on the process of getting plumbing to the garage... The current tank(which is where the new tank will go) shares a wall with the kitchen which is very close to the garage. I started thinking about how to get plumbing out under the house, and to the garage. After some thought I determined I would remove a cabinet and make a hole in the foundation under it, that way if we ever sell, or I get out of the hobby again, I can cap it off and no one is the wiser. This spot will allow me to put the cabinet back over the plumbing when I'm done, while passing everything through the wall to the new tank. holy cow this was a lot of work! but after a long day of digging I did it. I got my plumbing under the house. I went with 1" 1/2 PVC for my return line which will get split off to 2 x 3/4" lines on the tank, and 2" for my overflow, which gets split off to 2 x 1" lines. I wanted to go with 3" PVC for my overflow, but due to the location of my driveway, the 3" PVC would have been almost impossible to get under the house. I also ran some 10 conductor sprinkler wire along with my pipes, as I plan to run an Apex with everything, and will need it for light control, and other tank side goodies. I have such a loving girlfriend... when I told her the details of how I was going to pull off a garage sump, she let out a little sigh, and said "I love you, what can I do to help"

I also started to design a stand, as the wood one that came with the tank just wasn't going to suit our needs. After some calculations, a few talks with some engineering friends, and an order to Tnuntz I ordered the parts to make this, using a combination of 1530 and 1515 extruded aluminum. the math says she will hold, but I will be doing a water-filled deflection test before she goes into the house.

Stay tuned, the next steps are to finish the tank polishing, Painting the back of the tank black, and moving all my current stock to a garage tank, so that I can break down the 125. (which will become the future sump for this monster) and the fun part of building out my future fish room.

Last edited: