Hey friends,

Relatively new to this forum and returning with a passion to the reefing game. I grew up keeping aquariums in the late '80s, keeping it up through the early '00s, ultimately landing on a passion for reef ecosystems. In 2003 the reef tank I had crafted and matured over a number of years sprung a leak half way down the seam. It was heart breaking, and given other life pressures and expenses at the time (finishing up a degree, 2 young children) I decided to give it up for the time being.

Fast forward 18 years and my teenage son found a similar passion for aquatic life and spurred on by lockdown we decided to setup a pair of nano reef tanks. He has a 20g in his bedroom and I have a 15g in my home office. I have found that working from home has been the ultimate use case for enjoying and maintaining a tank. I enjoy watching my critters when I need a break from the screen and it's a great distraction to putz with in between meetings or when I just need a work break.

Given that it seems likely that I will be able to work remotely indefinitely I've decided to upgrade my nano reef to something more along the lines of a dream setup that I didn't have the resources to create when I was younger. I live in a relatively small house but I have the good fortune of my office being on top of our laundry room that has a fair bit of extra space so I've hatched a plan to put the business end of a tank in there. I've already hung my PC from the ceiling down there to avoid the space / noise / heat of having it in the office and I've already plumbed RO water through the floor to top off my nano.

I've spent the last 2 months binging BRSTV and trying to assemble an approach that will be as automated and bullet proof as possible. If anything I've had to check myself recently to make sure I'm not overdoing the various filtration methods. I also work in tech and have a passion for home automation so I'm excited to automate as much as possible.

I welcome any and all constructive feedback or advice as I am a sponge for information right now!

I spent the last couple of weeks taking advantage of all the holiday sales, placing numerous BRS and other orders. My wife just rolls her eyes every time another daily package shows up, I'm sure many of you can relate

At this point I've ordered the majority of my equipment and the tank and I've built out ~90% of the laundry room end of the equation. I ordered the Nuvo INT-75 gallon tank as that is the largest tank I can fit, nearly perfectly, next to my desk. A carpenter friend is building me a stand that fits with my office decor, and I have a garbage can full of marco rock curing. I aspire to build out something along the lines of the HNSA that BRS recently built / demoed for the 180 they gave away. That is my next project.

Here is a list of the major components I currently have:

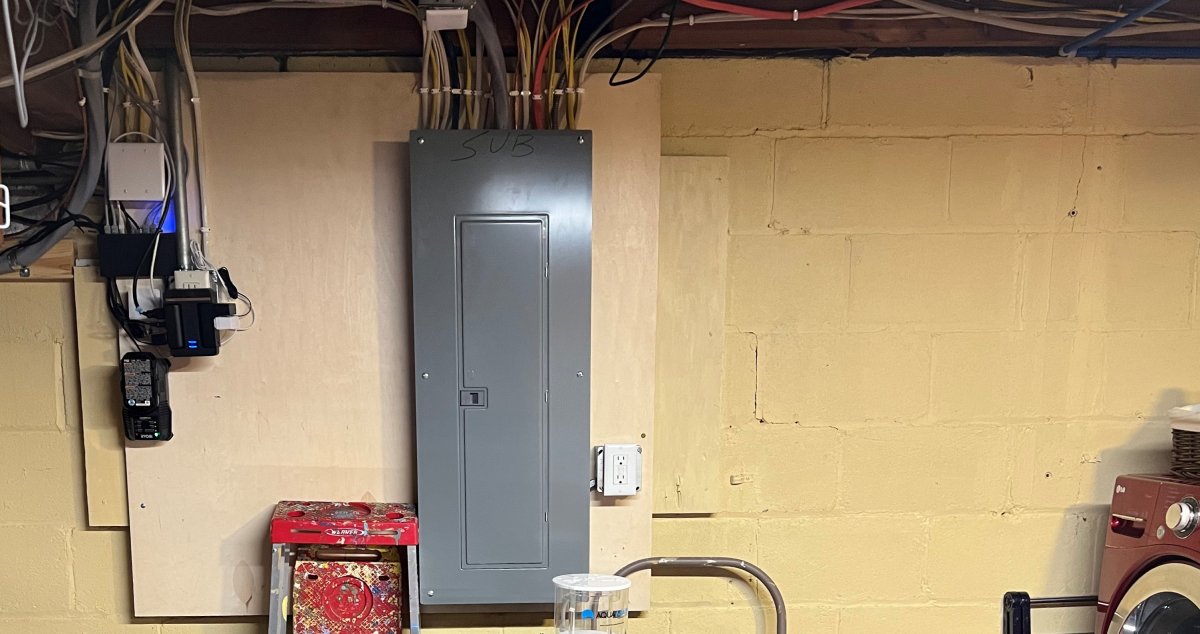

Here is the space before I started:

This is the palette I created for mounting all the gear, along with a stand I purchased for the sump:

This is after a weekend worth of build, about 90% complete:

This is how the tank showed up, it was a cool experience as I believe it's the first thing I've ever had delivered in a full on wood crate! I felt like Indiana Jones opening the crate with the ark

This is the tank after wrestling it into the basement, waiting for it's final home in my office to be ready:

If anyone has any suggestions for getting the paper off the acrylic, I'd appreciate it, it doesn't seem to want to peel cleanly without ripping and I'm concerned about what chemicals could do to the tank or the acrylic.

Anyhow, lots more to come, but I figured I'd get the build thread started and start to crowd source any feedback or advice, or share any nuggets of wisdom I learn along the way that could be useful for others!

Thanks!

Zach

Relatively new to this forum and returning with a passion to the reefing game. I grew up keeping aquariums in the late '80s, keeping it up through the early '00s, ultimately landing on a passion for reef ecosystems. In 2003 the reef tank I had crafted and matured over a number of years sprung a leak half way down the seam. It was heart breaking, and given other life pressures and expenses at the time (finishing up a degree, 2 young children) I decided to give it up for the time being.

Fast forward 18 years and my teenage son found a similar passion for aquatic life and spurred on by lockdown we decided to setup a pair of nano reef tanks. He has a 20g in his bedroom and I have a 15g in my home office. I have found that working from home has been the ultimate use case for enjoying and maintaining a tank. I enjoy watching my critters when I need a break from the screen and it's a great distraction to putz with in between meetings or when I just need a work break.

Given that it seems likely that I will be able to work remotely indefinitely I've decided to upgrade my nano reef to something more along the lines of a dream setup that I didn't have the resources to create when I was younger. I live in a relatively small house but I have the good fortune of my office being on top of our laundry room that has a fair bit of extra space so I've hatched a plan to put the business end of a tank in there. I've already hung my PC from the ceiling down there to avoid the space / noise / heat of having it in the office and I've already plumbed RO water through the floor to top off my nano.

I've spent the last 2 months binging BRSTV and trying to assemble an approach that will be as automated and bullet proof as possible. If anything I've had to check myself recently to make sure I'm not overdoing the various filtration methods. I also work in tech and have a passion for home automation so I'm excited to automate as much as possible.

I welcome any and all constructive feedback or advice as I am a sponge for information right now!

I spent the last couple of weeks taking advantage of all the holiday sales, placing numerous BRS and other orders. My wife just rolls her eyes every time another daily package shows up, I'm sure many of you can relate

At this point I've ordered the majority of my equipment and the tank and I've built out ~90% of the laundry room end of the equation. I ordered the Nuvo INT-75 gallon tank as that is the largest tank I can fit, nearly perfectly, next to my desk. A carpenter friend is building me a stand that fits with my office decor, and I have a garbage can full of marco rock curing. I aspire to build out something along the lines of the HNSA that BRS recently built / demoed for the 180 they gave away. That is my next project.

Here is a list of the major components I currently have:

- NUVO INT 75 Tank

- Trigger Triton 34 sump

- Reef Octopus Essence S-130 skimmer

- 2x BRS 200W titanium heater and Inkbird controller

- 2x Current USA eFlux DC return pumps

- Neptune Apex

- DOS pump (was thinking of getting another one and trying triton method or using one for auto water changes)

- Kessil AP9X

- AI Prime HD (planning to move from my nano to refugium once I transition to this tank)

- BRS Jumbo CO2 reactor (probably overkill but seems like they are potentially very useful and I don't want to change media all the time)

- BRS 6 stage RO/DI

- 2x Sicce Xstream wave pumps (not sure if this will be the final flow solution but BRS indicated a wide flow pattern good for mixed reefs and I wanted something I could attach the the back wall overflow so that ruled out Vortechs)

- 100ish lbs of Marco rock and lots of glue, epoxy, etc.

- 35 gallon Brute trash can that is my fresh salt water tanks (currently used for water changes on our nanos but may plumb in for auto water changes)

Here is the space before I started:

This is the palette I created for mounting all the gear, along with a stand I purchased for the sump:

This is after a weekend worth of build, about 90% complete:

This is how the tank showed up, it was a cool experience as I believe it's the first thing I've ever had delivered in a full on wood crate! I felt like Indiana Jones opening the crate with the ark

This is the tank after wrestling it into the basement, waiting for it's final home in my office to be ready:

If anyone has any suggestions for getting the paper off the acrylic, I'd appreciate it, it doesn't seem to want to peel cleanly without ripping and I'm concerned about what chemicals could do to the tank or the acrylic.

Anyhow, lots more to come, but I figured I'd get the build thread started and start to crowd source any feedback or advice, or share any nuggets of wisdom I learn along the way that could be useful for others!

Thanks!

Zach

Last edited: