Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my diy mesh screen tops....on the cheap

- Thread starter prime8reef

- Start date

- Tagged users None

Great thread, been a few years since I made one on my 90G. Had a fish jump out today.

I have a 40B, plan to go around HOB filter but looking for ideas for cutouts for powerhead cords etc. notching a corner piece work ok?

I have a 40B, plan to go around HOB filter but looking for ideas for cutouts for powerhead cords etc. notching a corner piece work ok?

I built one a few years ago with metal framing and it has done great, but it just sits on top of my rimless tank. When I added a new Radion with the arm it doesn't fit. I decided to start a new build. The problem is my return box is in the corner and it's round. I'm thinking about cutting the top of it so it fits when the screen is placed with plastic clips (https://smile.amazon.com/gp/product/B06XBL6893/ref=oh_aui_detailpage_o06_s00?ie=UTF8&psc=1) since it will be recessed into the inside of the glass. Any ideas on how to make it work?

I got the mesh from BRS. You can find it at https://www.bulkreefsupply.com/clear-netting.html.

I got the mesh from BRS. You can find it at https://www.bulkreefsupply.com/clear-netting.html.

Can You get the screen cover cover the overflow? It looks low enough . I assume the brackets you will use to set the cover on are too low for this . How about some egg crate?

This could be cut somewhat round maybe .

This could be cut somewhat round maybe .

Last edited:

The plastic clips sit below the overflow height. I need to cut the overflow on the edges so the screen frame can sit low enough to fit. The pic doesn't show it well. Egg crate is not an option due to the shading it would create, but it would be easier to cut it round.Can You get the screen cover cover the overflow? It looks low enough . I assume the brackets you will use to set the cover on are too low for this . How about some egg crate?

This could be cut somewhat round maybe .

- Joined

- Mar 30, 2018

- Messages

- 871

- Reaction score

- 723

Great call. I had a feeling I would find it at Joanne Fabrics. Now I just got to find it without some woman following me around thinking I'm creeping,lol.If you are referring to the railing, I found it at Lowe's. It's actually plastic with a metallic coating. I don't know if it's like powder coating or some metallic coating, but it comes in silver,and grey. Lowe's is closer to me than HD so I went there first and scored. The mesh is actually polyester material called 'tulle'. Used for making brides veils and wedding stuff. I found it at Joann fabrics but I'm sure any fabric store or craft store carries it. You CAN find 'bird netting' at HD and other home improvement stores. I wanted a finer mesh since sometimes when I order fish online I tend to get tiny or juvenile fish that could easily jump through the 1/2" mesh that bird netting has.

- Joined

- Mar 22, 2018

- Messages

- 444

- Reaction score

- 335

Great post. I did the same thing. I couldnt find the mesh material here in Jamaica so I bought a Loofa and unrolled it. Looks exactly like your project. Im thinking of changing the mesh though. My fans have not been as effective as they used to be and a lot if the wind is wasted bouncing off it and worse it tears easily. Gonna just go buy the 1/4 inch mesh. Oh and ive lost a visible amount of inrensity too. If you have none of those issues then thats great!

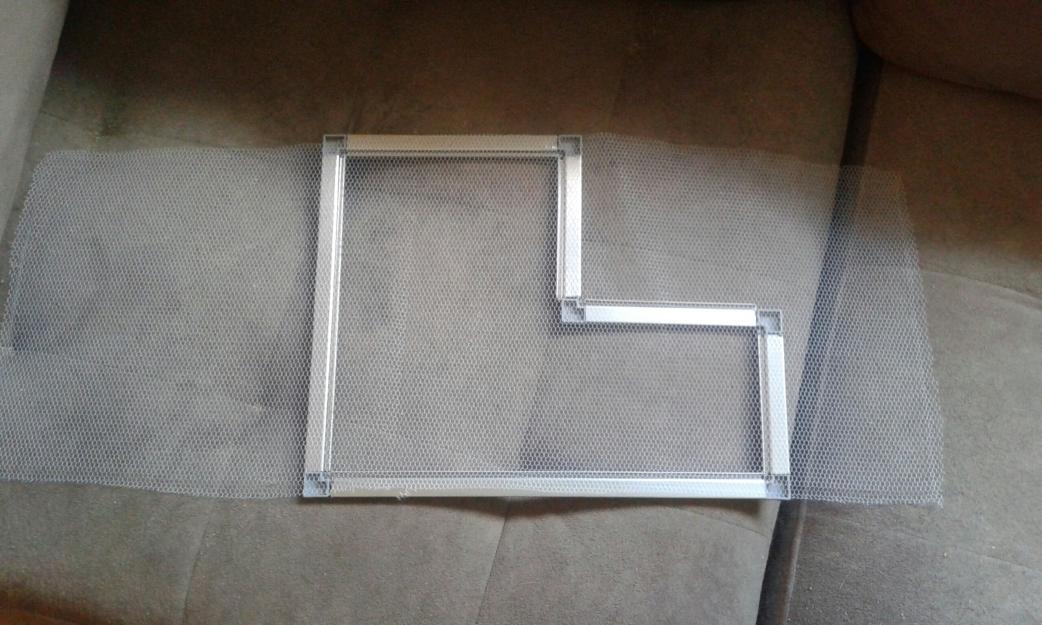

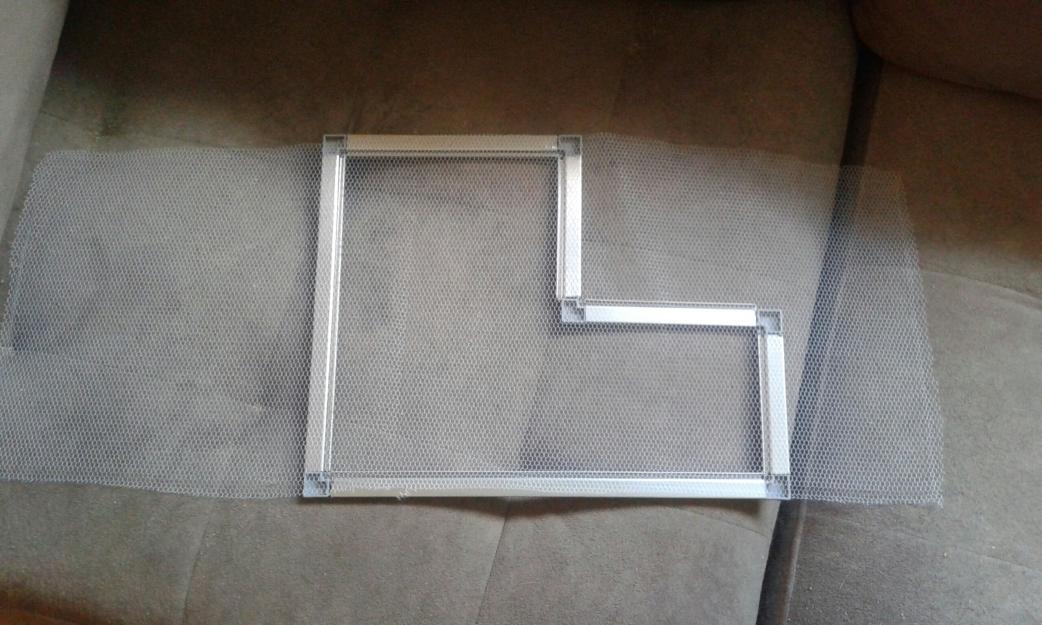

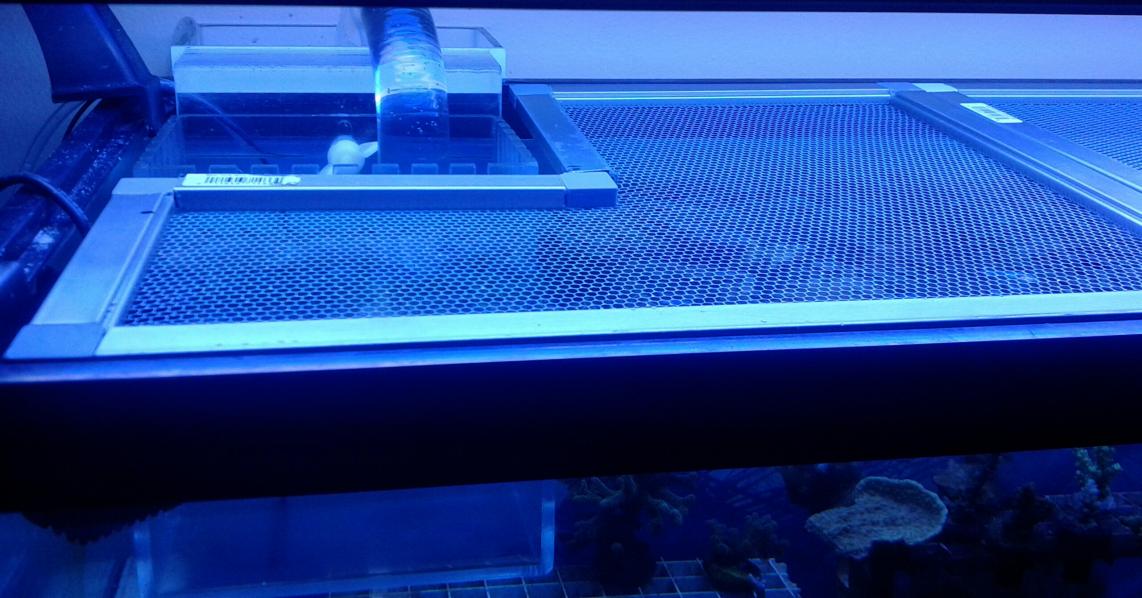

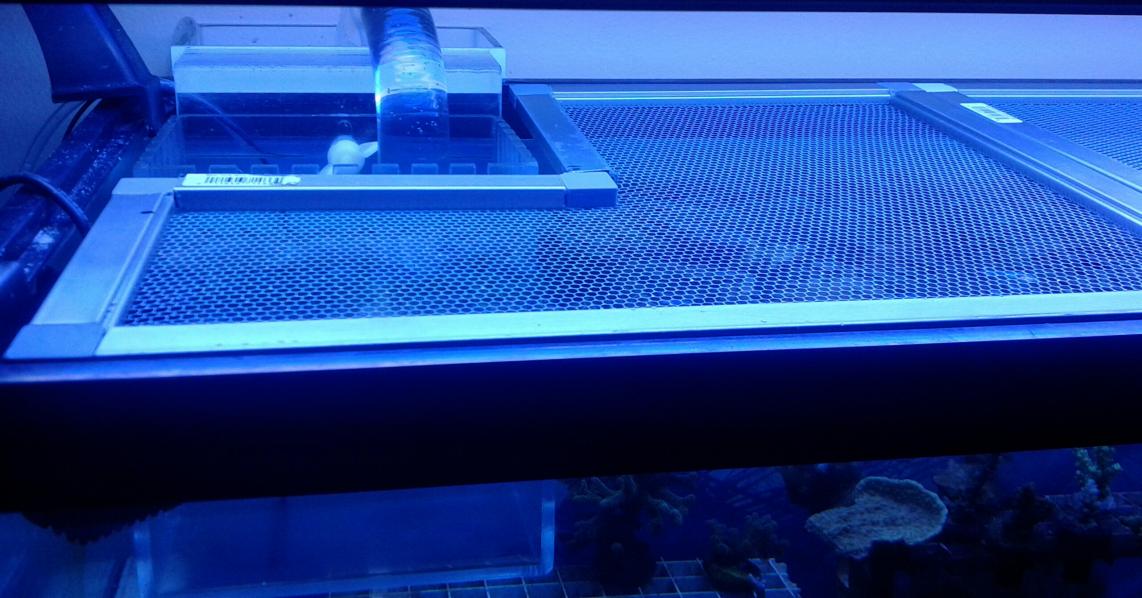

Thought I'd post my diy screen tops. Very inexpensive and super easy to do.

I found most all the parts at Lowe's and Joann fabrics. For under $25 I built mesh screen tops for two 20long aquariums and still had enough leftovers to make another screen top (25"x12").

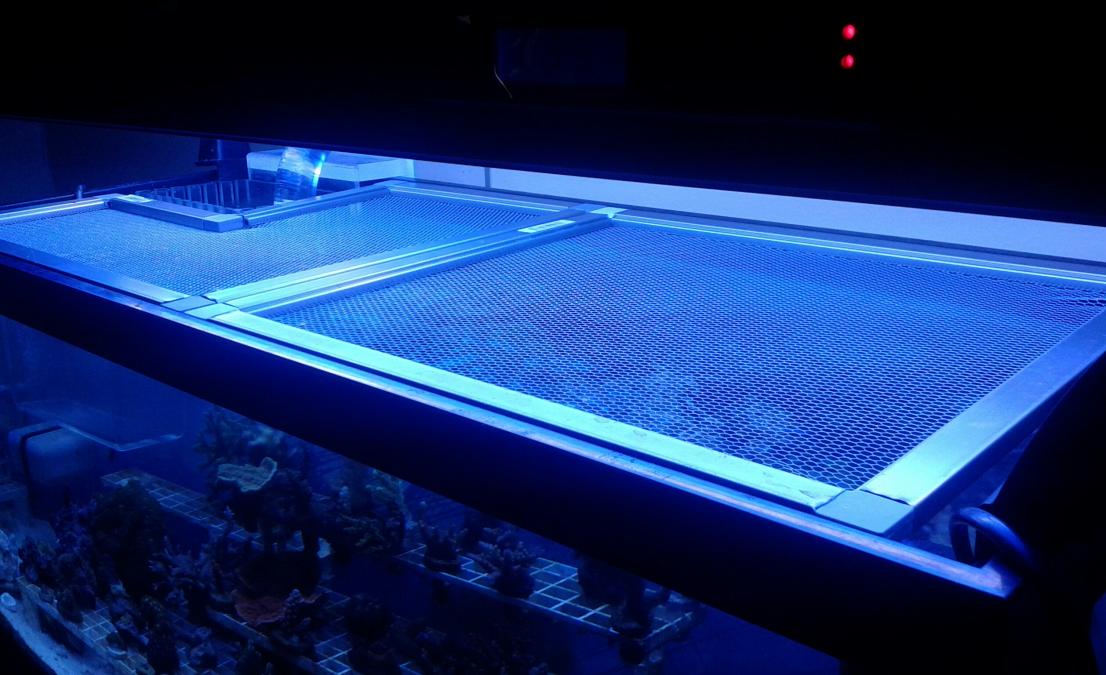

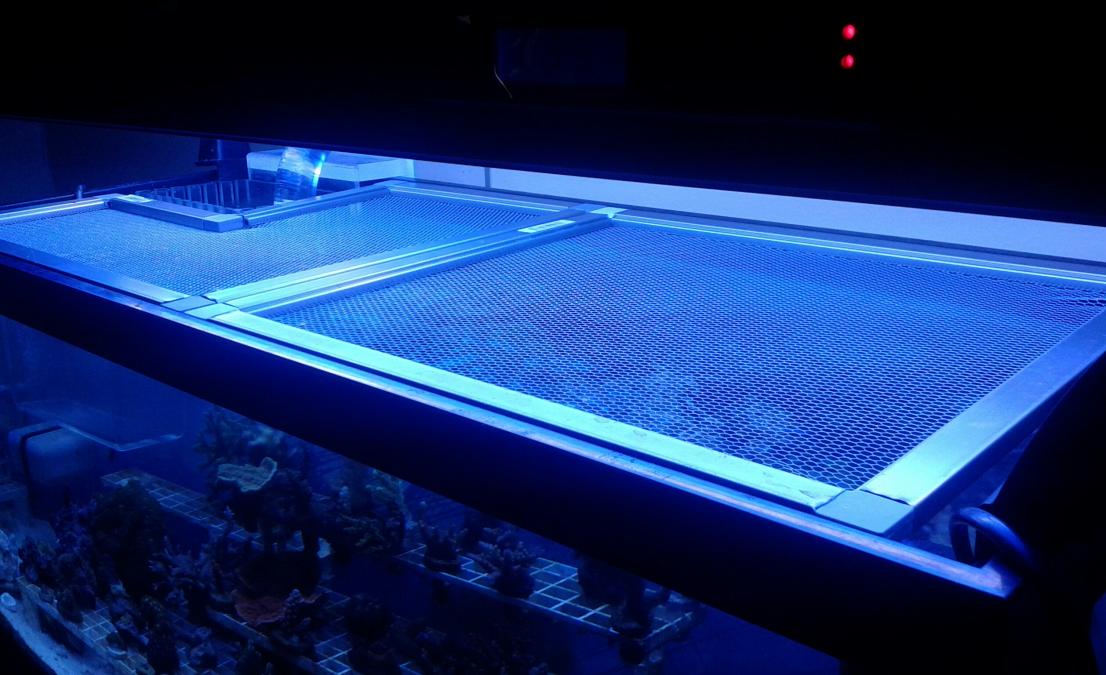

The framing is lightweight plastic with metallic finish. Measured properly it will fit snugly on the inside of your bracing and not get knocked off by jumping fish. The mesh screen is thin yet strong and there is no shadowing or diffusion of lights.

Completely corrosion free and looks very clean.

I chose to do two tops that sit side by side instead of one long rectangle cover for two reasons:

1) have partial protection against fish jumping out while working in the tank whether it be frag and coral placement or regular maintenance

2) didn't want to cover my overflow box/build around the overflow box due to the U-tube and keep a symmetric look to the cover.

List of parts& prices (may differ from city to city):

Screen railing: $4/8ft stick @Lowe's

Corner pieces: $2/4pack @Lowe's

Spline: $5/25ft bag @Lowe's

Mesh screen: $1.50/yard @Joann fabrics (72"x36")

Tools needed:

Mini hacksaw

Razor or exacto knife

Scissors

Marker or scratch awl

The build:

Measure the inside diameter of your aquariums bracing ring. The cover will sit on the inside lip of the bracing frame.

Be sure to subtract 3/4" from the ends of the screen frame 'railing' to allow for the slide in corner pieces.

Once all pieces are cut to desired length, snap in the corner pieces and assemble frame.

Make sure the rabbit/channel that the spline goes in are all on the same side. But this shouldn't be an issue as the corner pieces only slide in one way(one side of the clip is wider than the other)

Cut your mesh material(tulle fabric) to the size of the frame leaving about 1-2" larger than the area of the frame to allow for tightening or tautness.

Cut a length of spline to match the total length of the frame.

Starting at one end of the frame, push in the spline with your fingers or a spline roller. A spline roller isn't really needed as the spline snaps right into the rabbit easily with finger pressure. Rollers are good if you want to mash the spline into place. The spline is diff rubber and will deform to fill the rabbit but you really don't need to, the spline stays in good without it.

Work your way around the frame keeping the mesh tight as you insert the spline all the way around. You may want to slightly pinch the mesh material at the corners to avoid wrinkles in the final project.

Trim the excess mesh away using a razor blade or exacto knife. Cut along the outside of the spline carefully to remove excess mash and for a clean look.

If you feel that you want a more permanent frame, you can place a small thin bead of silicone in the rabbit/groove before inserting the screen and spline. Don't use super glue or you may get blushing on the frame( cloudy residue). You can, however, place a thin layer of super glue on the ends of the corner pieces before snapping into place in the frame.

Pretty much that's it! You're done.

Place on the inside lip of your aquarium's plastic brace and enjoy the peace of mind that none of your jumpers will end up on the floor.

I built two of these frames, for pieces in all, in under a few hours.

Great DIY. Thank you!

- Joined

- Aug 14, 2019

- Messages

- 4,198

- Reaction score

- 12,164

Some more views of the tops in action. In all actuality I think it took me a total of about half hour spent on each aquarium cover. I just take alot of breaks and measured twice, cut once.

The railing is easy to cut with a mini hacksaw but if you want a faster cut you can use a rotary tool. Just keep in mind that this material (railing) is hollow plastic and you don't want too much friction from, say, a table saw that may deform the hollow grove that the corner pieces slide into. I think the amount of strokes with a mini hacksaw to cut through the rail was, like, 10-15. You also don't have to cut completely through the rail as once you cut through the width of the sides, you can bend and snap it easily without any deforming of the groove.

Did you ever have any issues with the thin gap on the side where your chords go through?

I have about a 1/2” gap on either side for chords and had a tailspot jump through it today. Trying to plan better coverage with two additional tops or a new single one.

- Joined

- Feb 18, 2019

- Messages

- 5,105

- Reaction score

- 8,689

Did you ever have any issues with the thin gap on the side where your chords go through?

He hasn’t logged on 13 months

- Joined

- Aug 14, 2019

- Messages

- 4,198

- Reaction score

- 12,164

He hasn’t logged on 13 months

Well if he does, then I’m sure he’ll have an answer.

Similar threads

- Replies

- 6

- Views

- 337