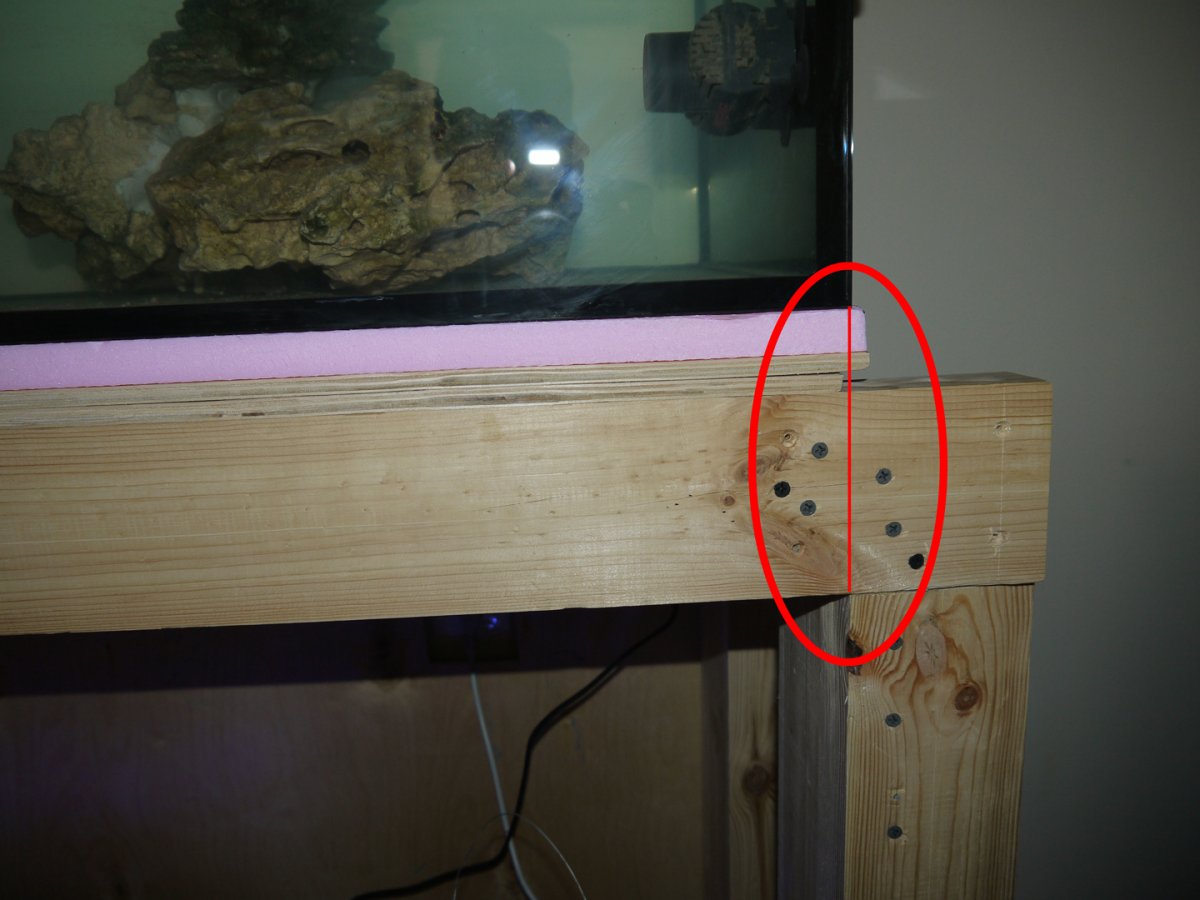

The stand is made of 3,9 x 1,9" pine wood (100x50mm). It's typical DIY 43x20x35" stand my for 70g build, https://www.reef2reef.com/threads/70g-diy-peninsula-40x20x20.390761 .

The only difference is that my tank is sitting between vertical supports, not directly above them:

I do understand this stand is way overbuild, compared to MDF cabinets sold everywhere. I realize that horizontal rails purpose is to distribute weight between vertical supports and nothing much else. I know two 4 feet long 2x4s should hold equally distributed weight of 70g tank with ease.

Still, I really need someone to convince me this is absolutely 100% safe So, сan I sleep soundly or should be worried?

So, сan I sleep soundly or should be worried?

The only difference is that my tank is sitting between vertical supports, not directly above them:

I do understand this stand is way overbuild, compared to MDF cabinets sold everywhere. I realize that horizontal rails purpose is to distribute weight between vertical supports and nothing much else. I know two 4 feet long 2x4s should hold equally distributed weight of 70g tank with ease.

Still, I really need someone to convince me this is absolutely 100% safe