All of my corals have graduated from Qt and are ready to go in my Dt. I am having designers block and am looking for opinions on placement.

The tank is going to be predominantly lps with the possibility of a toadstool leather coral at some point, and maybe a few sps.

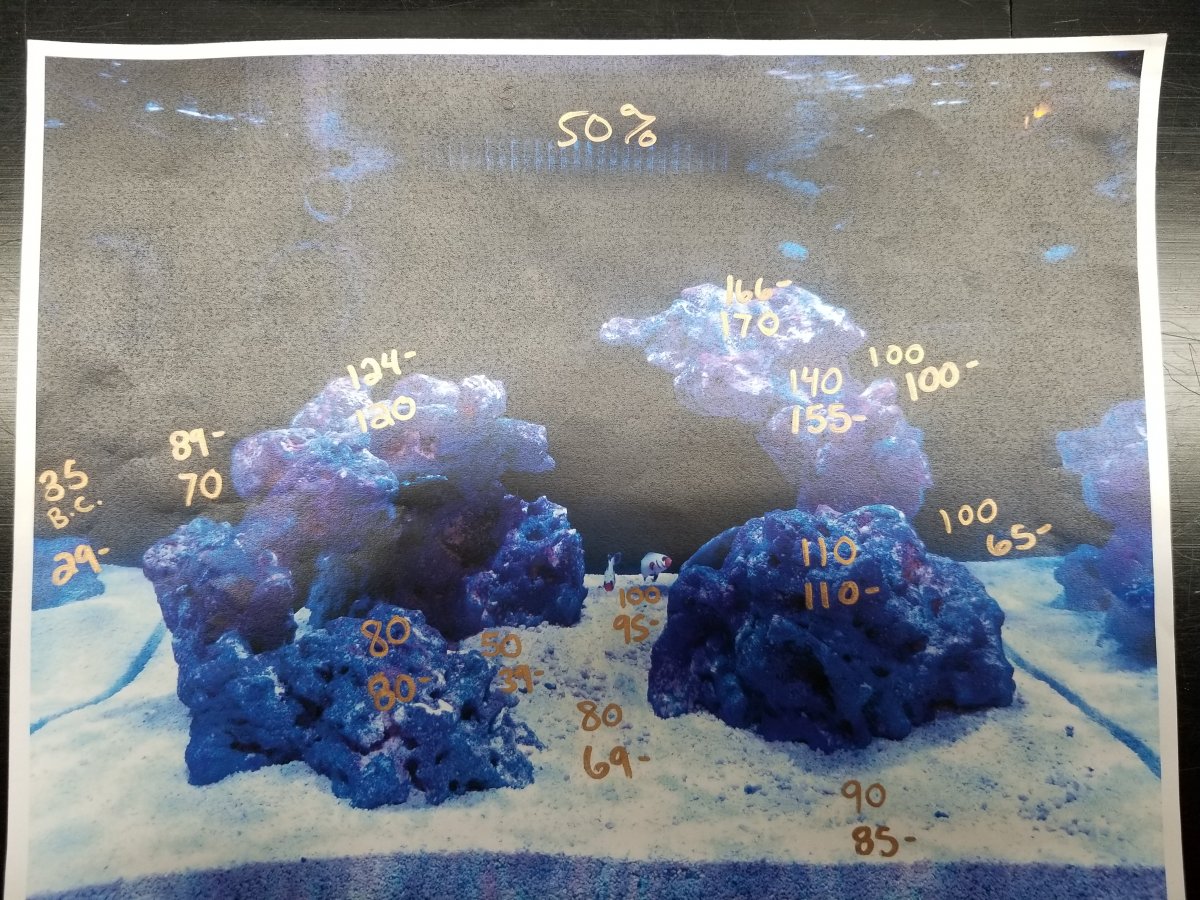

My light is going to have good par numbers for lps at only 50% so I will be able to turn it up or down if needed. Here are par numbers at 50%.

Here is a few pictures of my display

Front

Left side

Right side

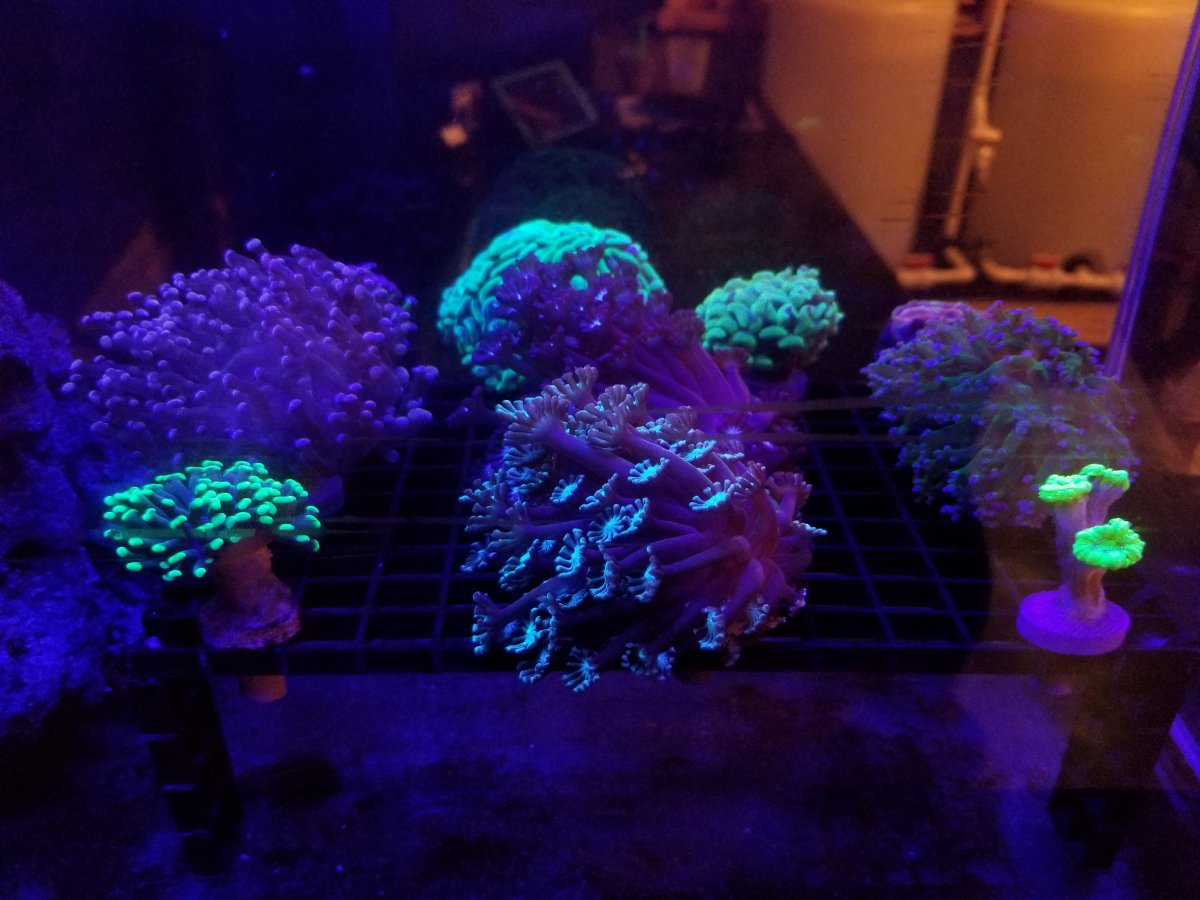

Corals shot

Thanks in advance

The tank is going to be predominantly lps with the possibility of a toadstool leather coral at some point, and maybe a few sps.

My light is going to have good par numbers for lps at only 50% so I will be able to turn it up or down if needed. Here are par numbers at 50%.

Here is a few pictures of my display

Front

Left side

Right side

Corals shot

Thanks in advance