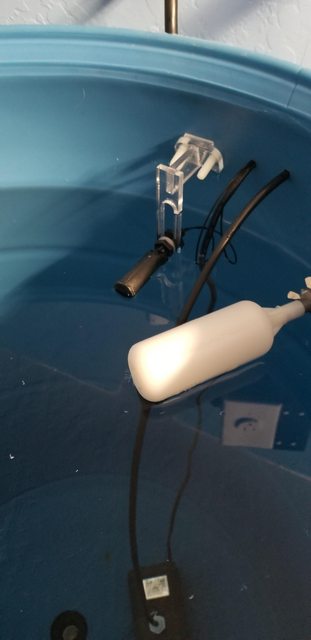

I never thought that I would be this excited to have the lights working!!! I finally made progress.

After getting back into the hobby I started catching up on equipment room builds and one that has stood out for me is a thread by halmus his attention to detail is awe-inspiring and that even if you tried you couldn't come close to his perfection. One thing in his build that really stood out for me was how he used a cable drag chain to carry the cords. After seeing that, I knew that I had to incorporate one of those chains into my build. Without even having a plan, I hopped on the internet and prematurely order one big enough to to house 8 radion cords. I guess I have to confess that there were many ways to get my lights out of the way for maintenance, but I wanted to use it.

It was extremely user friendly how you can place the cable in the drag chain and snap the pieces into place.

The cross pieces have a plastic hinge on one side and snaps into place on the other

After everything was locked in and tied into place..... we have light!!!

And cue the curious cat, she enjoyed the last tank, there's no reason why she's not going to pester the fish.

The build isn't over by a long shot however, at this point the tank is cycled and I can start turning my attention to stocking the tank with live stock. Now i'm on the hunt for a qt tank.. nothing so far... so the search continues.

After getting back into the hobby I started catching up on equipment room builds and one that has stood out for me is a thread by halmus his attention to detail is awe-inspiring and that even if you tried you couldn't come close to his perfection. One thing in his build that really stood out for me was how he used a cable drag chain to carry the cords. After seeing that, I knew that I had to incorporate one of those chains into my build. Without even having a plan, I hopped on the internet and prematurely order one big enough to to house 8 radion cords. I guess I have to confess that there were many ways to get my lights out of the way for maintenance, but I wanted to use it.

It was extremely user friendly how you can place the cable in the drag chain and snap the pieces into place.

The cross pieces have a plastic hinge on one side and snaps into place on the other

After everything was locked in and tied into place..... we have light!!!

And cue the curious cat, she enjoyed the last tank, there's no reason why she's not going to pester the fish.

The build isn't over by a long shot however, at this point the tank is cycled and I can start turning my attention to stocking the tank with live stock. Now i'm on the hunt for a qt tank.. nothing so far... so the search continues.