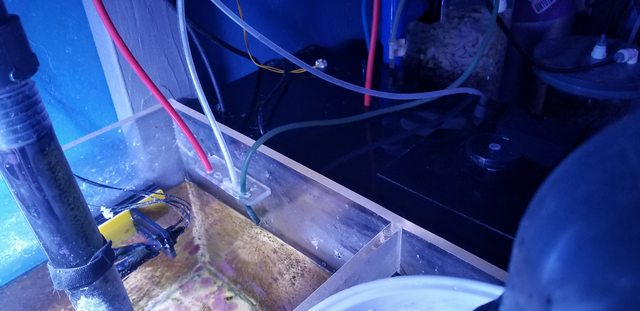

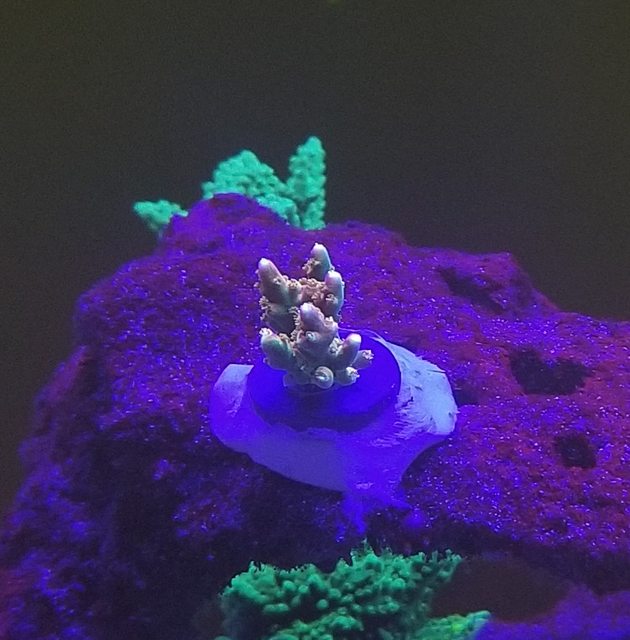

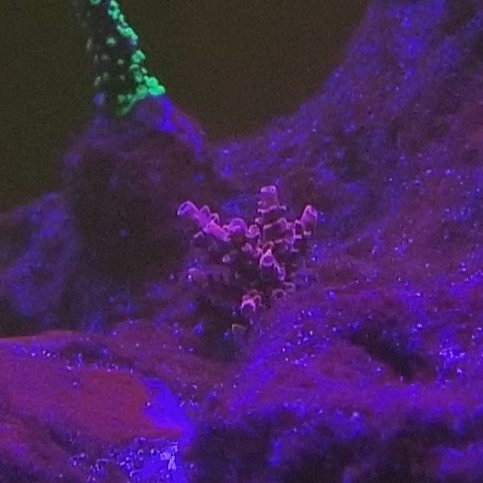

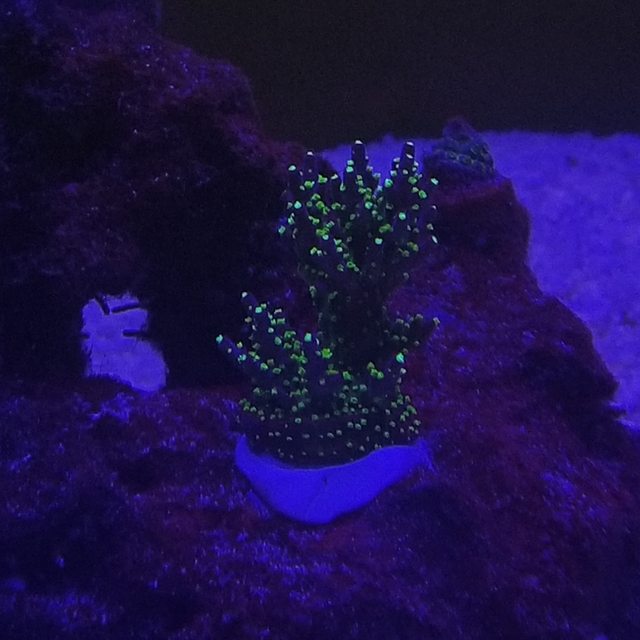

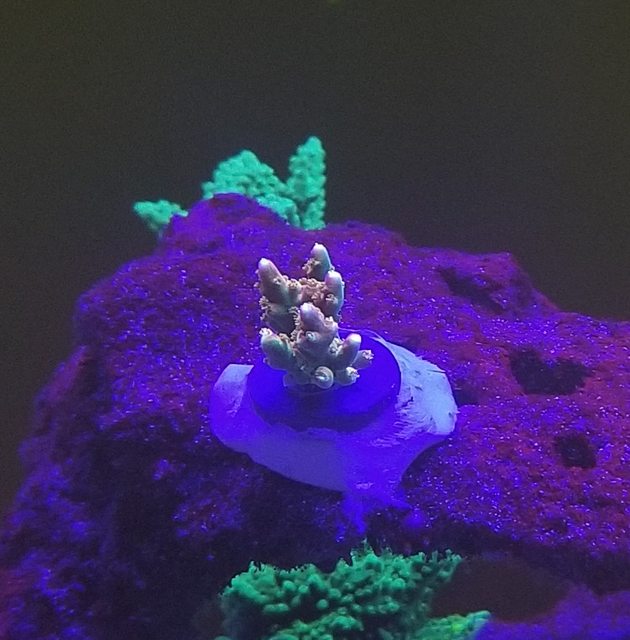

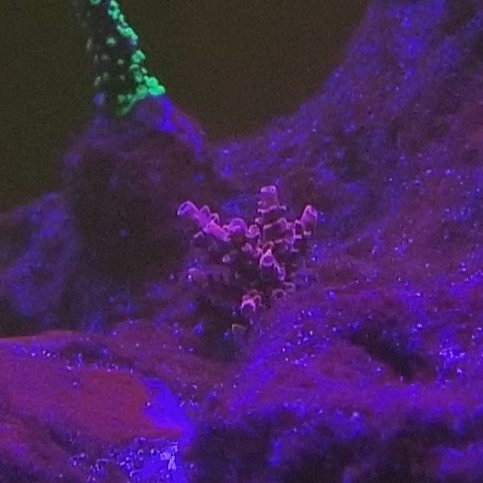

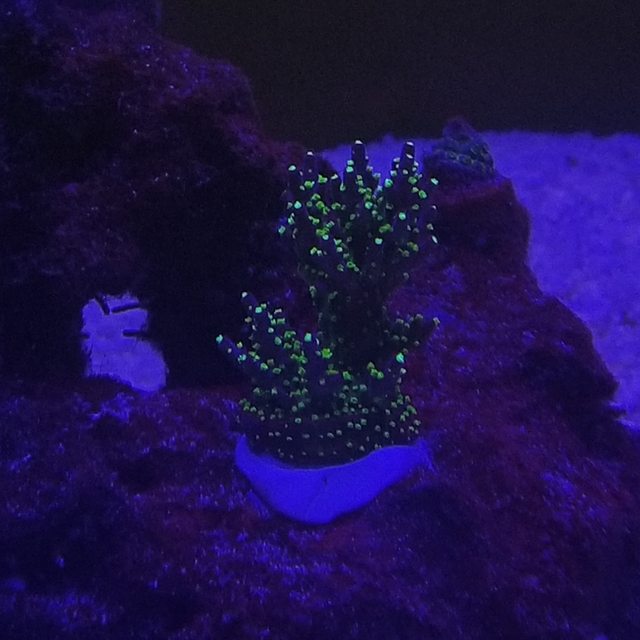

was a bit motivated the other night to snap some pictures:

One day I'll invest in a good lens for my DSLR, until then you get cellphone pics.

One day I'll invest in a good lens for my DSLR, until then you get cellphone pics.