- Joined

- Oct 3, 2015

- Messages

- 5,145

- Reaction score

- 8,759

Excellent @Sisterlimonpot !

I’m making something similar, though out of aluminum and delrin given I have access to a machine shop .

.

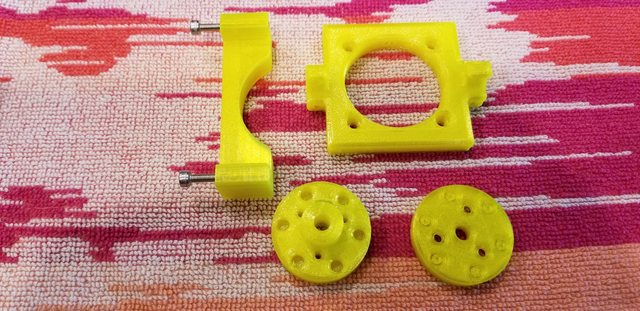

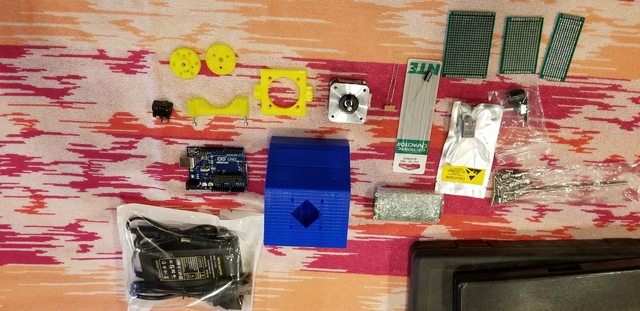

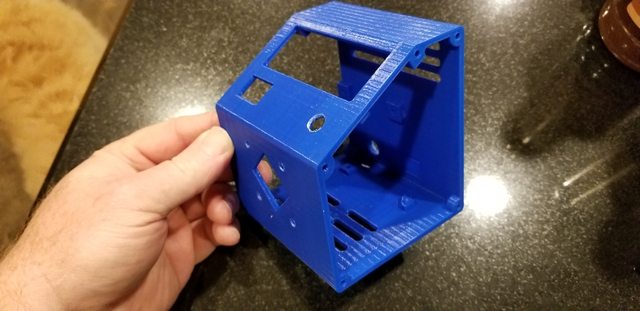

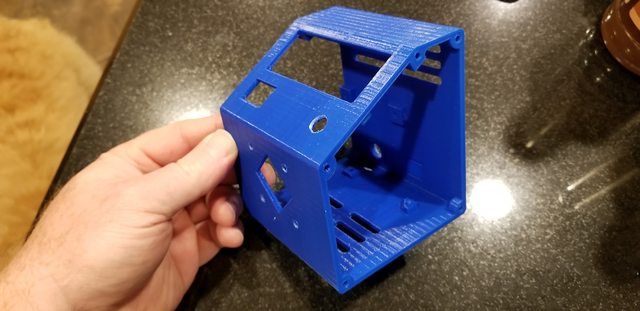

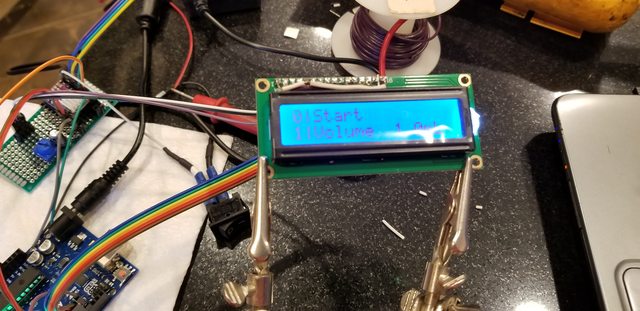

I already made a 3D printed 24x24 CNC, so am pretty familiar with steppers. But I want this one to be controller by apex 0-10v, which will be fun.

I’m making something similar, though out of aluminum and delrin given I have access to a machine shop

I already made a 3D printed 24x24 CNC, so am pretty familiar with steppers. But I want this one to be controller by apex 0-10v, which will be fun.