Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NEW/OLD build 120g, 75sump,40frag tank

- Thread starter murphys_aquatics

- Start date

- Tagged users None

PAT!!! WELCOME!!!

Ok, I've read through and I've waited long enough. More, please...

Thanks for sharing.

Hit the Like button and Share often!

Ok, I've read through and I've waited long enough. More, please...

Thanks for sharing.

Hit the Like button and Share often!

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

It will get the countertop coating also. Outside paint for exteriorwhat will you clad the base in ?

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Alright here we go then..lolPAT!!! WELCOME!!!

Ok, I've read through and I've waited long enough. More, please...

Thanks for sharing.

Hit the Like button and Share often!

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

At this point I get the front, side, too and bottom face or planking in place and square it up. Used an air nail gun to attach the facings. So then I go ahead and proceed to fill in all the nail holes and sand the entire thing down

Once I finished sanding it was time to get this thing primed

After I put 2 layers of primer on I did the first top coat of countertop resurfacing resin

Here is the resin i.used to surface with, it is sold at Lowes. You can have it tinted in 16 different colors and is fairly cheap at $20 a canning I remember correct. I did NOT choose a tint

After the first coat of top surface I went ahead and painted two layers of paint to the outside skin/face of the stand

Then the final coat of countertop once that all dried

At that point the stand is complete, because I have not made doors still to this day..Haha

So let's get started with the DIY sump

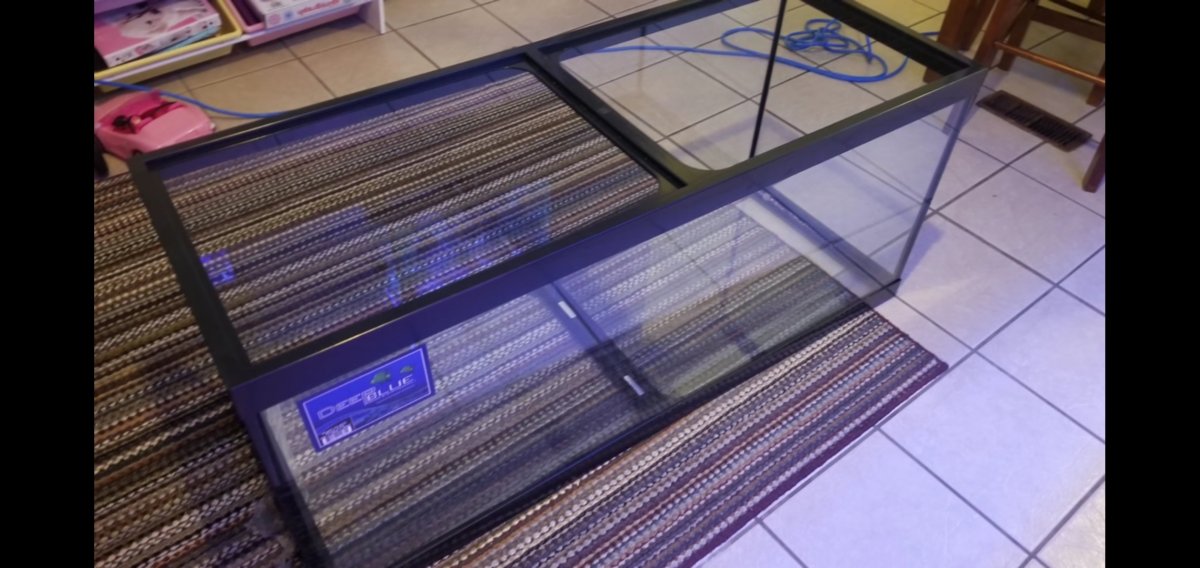

I started with a standard Deep Blue 75 gallon tank. Next thing I did was get ahold of the local glass place and have the baffles made to custom order. I cannot remember the exact sizes right off hand, cut if anyone really wants to know I can remeasure them

Now when I siliconed these baffles in i used ASI Black silicone. The trick I learned was to be quick and pretape every surface you will be using silicone on. Even pretaping the baffles so you can peel the tape off quickly after you apply your silicone bead and finger smooth it out.

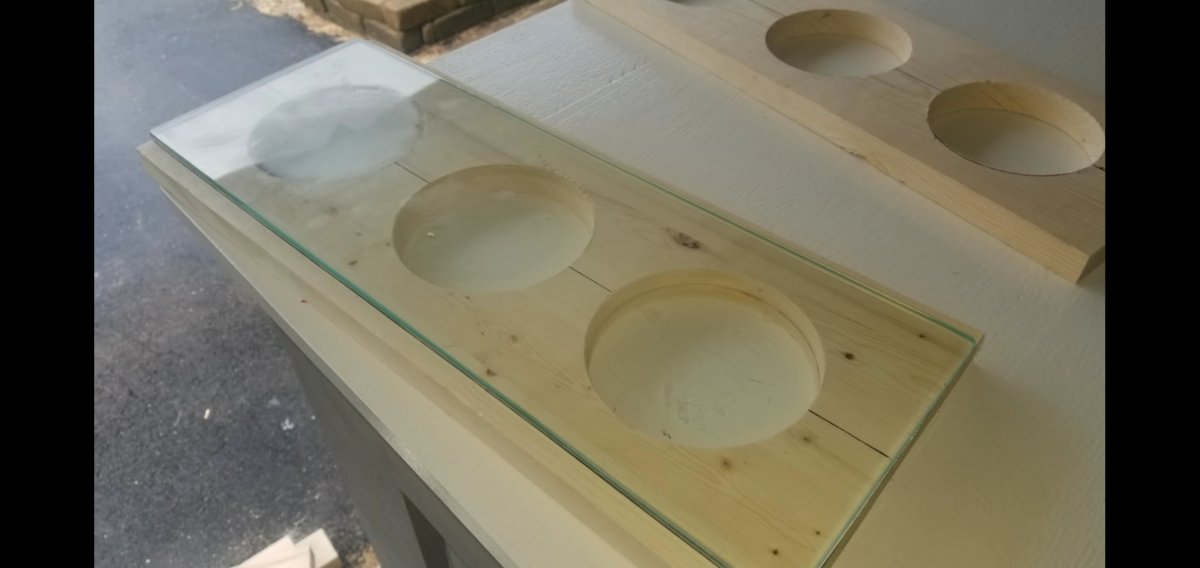

After I siliconed each baffle in place I started to get to work on the sump sock holder. I started with glass but ended up with Corian sump sock holder panel. It's pretty awesome how it is installed. You can take it out of you need to and is water tight. But first I will show you how I drilled the single pane of glass for sump socks

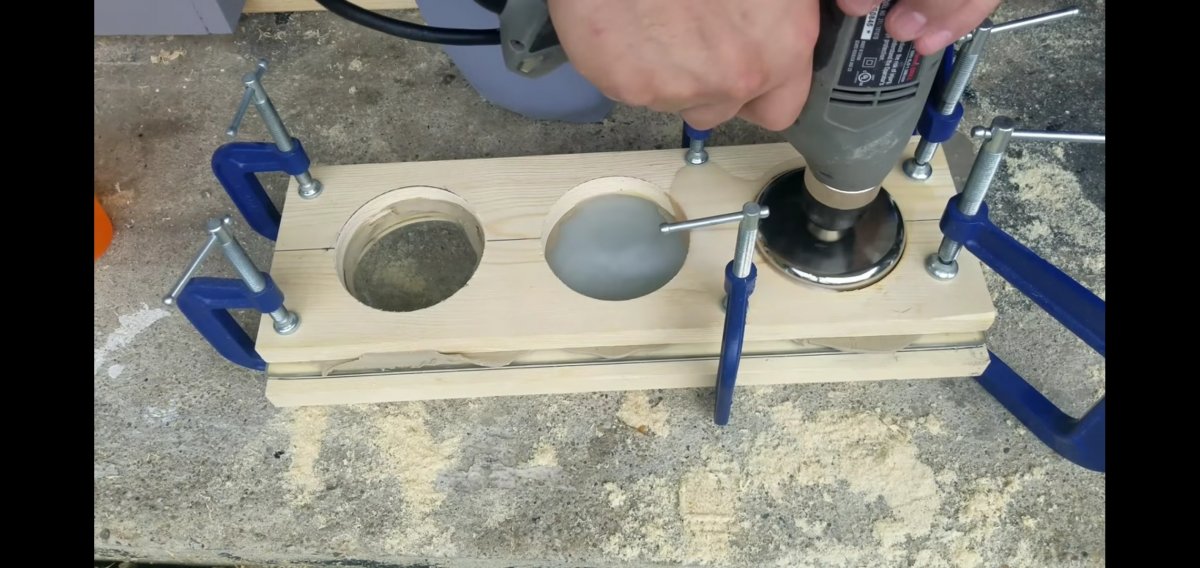

I started with a jig that I made remember 4" sump socks get a 3 3/4" hole

So I predrilled the template with a regular hole saw.. top side I used 3 3/4" bottom I used a 4" hole saw..there are 2 planks that I will sandwich the glass pane inbetween

The next step i took was to put plumbers putty down to create a water tight seal inside each hole

After I applied the plumbers putty and top template I went ahead and used C clamps at both end to smoosh it down

Once I finished sanding it was time to get this thing primed

After I put 2 layers of primer on I did the first top coat of countertop resurfacing resin

Here is the resin i.used to surface with, it is sold at Lowes. You can have it tinted in 16 different colors and is fairly cheap at $20 a canning I remember correct. I did NOT choose a tint

After the first coat of top surface I went ahead and painted two layers of paint to the outside skin/face of the stand

Then the final coat of countertop once that all dried

At that point the stand is complete, because I have not made doors still to this day..Haha

So let's get started with the DIY sump

I started with a standard Deep Blue 75 gallon tank. Next thing I did was get ahold of the local glass place and have the baffles made to custom order. I cannot remember the exact sizes right off hand, cut if anyone really wants to know I can remeasure them

Now when I siliconed these baffles in i used ASI Black silicone. The trick I learned was to be quick and pretape every surface you will be using silicone on. Even pretaping the baffles so you can peel the tape off quickly after you apply your silicone bead and finger smooth it out.

After I siliconed each baffle in place I started to get to work on the sump sock holder. I started with glass but ended up with Corian sump sock holder panel. It's pretty awesome how it is installed. You can take it out of you need to and is water tight. But first I will show you how I drilled the single pane of glass for sump socks

I started with a jig that I made remember 4" sump socks get a 3 3/4" hole

So I predrilled the template with a regular hole saw.. top side I used 3 3/4" bottom I used a 4" hole saw..there are 2 planks that I will sandwich the glass pane inbetween

The next step i took was to put plumbers putty down to create a water tight seal inside each hole

After I applied the plumbers putty and top template I went ahead and used C clamps at both end to smoosh it down

[...]

After I applied the plumbers putty and top template I went ahead and used C clamps at both end to smoosh it down

[...]

Thank you for the update! I appreciate all of the details in your thread and I enjoyed the relatable language like "smoosh"!

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Let's continue with the sump sock hole holder.

Once it was clamped down pretty tight I proceeded to drill each hole adding water to each hole first and using a diamond coated 3 3/4" hole saw

It went smooth really and came out pretty clean. I had one little blow out spot, I wonder it could have been avoided if I used a solid plank for the bottom? Idk so the next images will be of me scraping off the putty and showing ya what the final product looked like

Final product, remember I did end up going with corian so this was just a tutorial or mach run for the corian. I ended up doing corian because I feel like it is more superiojust in case there was any stress or pressure on the glass

Once it was clamped down pretty tight I proceeded to drill each hole adding water to each hole first and using a diamond coated 3 3/4" hole saw

It went smooth really and came out pretty clean. I had one little blow out spot, I wonder it could have been avoided if I used a solid plank for the bottom? Idk so the next images will be of me scraping off the putty and showing ya what the final product looked like

Final product, remember I did end up going with corian so this was just a tutorial or mach run for the corian. I ended up doing corian because I feel like it is more superiojust in case there was any stress or pressure on the glass

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Gotta keep it real..Haha fancy words dont mean anything if you dont even know what they mean.. thanks for giving this a lookThank you for the update! I appreciate all of the details in your thread and I enjoyed the relatable language like "smoosh"!

vetteguy53081

Well known Member and monster tank lover

View Badges

Partner Member 2024

Excellence Award

Reef Tank 365

RGB

Article Contributor

Tampa Bay Reef Keepers

West Palm Beach Reefer

Hospitality Award

Ocala Reef Club Member

305 Reef Club

Wisco Reefers

Midwest Reefer

Fish Medic

MAC of SW Florida

Rock Pool Reef Keepers

R2R Secret Santa 2023

My Tank Thread

My Aquarium Showcase

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Thanks for the welcome.. hopefully I can be a contributing member of this forum

LAReefer4Life

Lover of Angelfish

View Badges

Reef Squad

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Los Angeles Aquatics Club

My Tank Thread

Very cool! Keep us posted and Welcome to R2R!!

Thanks for the welcome.. hopefully I can be a contributing member of this forum

You already are - keep it up! I'm glad you're here!

Hi there! I'm glad you joined us. If you get the chance, you should place this information for your build thread under "member tanks": https://www.reef2reef.com/categories/members-aquarium-discussion.321/ . You will get lots of people following your tank progress that way. Welcome aboard!

Last edited:

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

I will do that buddy thanksHi there! I'm glad you joined us. If you get the chance, you should place this information for your build thread under "member tanks": https://www.reef2reef.com/categories/members-aquarium-discussion.321/ . You will get lots of people following your tank progress that way. Welcome aboard!

Welcome and ty.

I enjoy your content on youtube

I enjoy your content on youtube

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Thanks everyone, William I'm glad you like the content.Welcome and ty.

I enjoy your content on youtube

I cant wait to see all the fire to come

- Joined

- Jul 26, 2018

- Messages

- 127

- Reaction score

- 227

Theres been some significant color popping as of late..I cant wait to see all the fire to come

Similar threads

- Replies

- 20

- Views

- 138

- Replies

- 3

- Views

- 69

- Replies

- 1

- Views

- 98

New Posts

-

-

Anyone still around to accept me into the club?

- Latest: WalkerLoves_TheOcean

-

-

AIO Build steveschuergers 90 gallon Goni heavy mixed reef.

- Latest: steveschuerger