Does the reactor has a closed-loop?The issue I described having with the SD is happening at the moment.

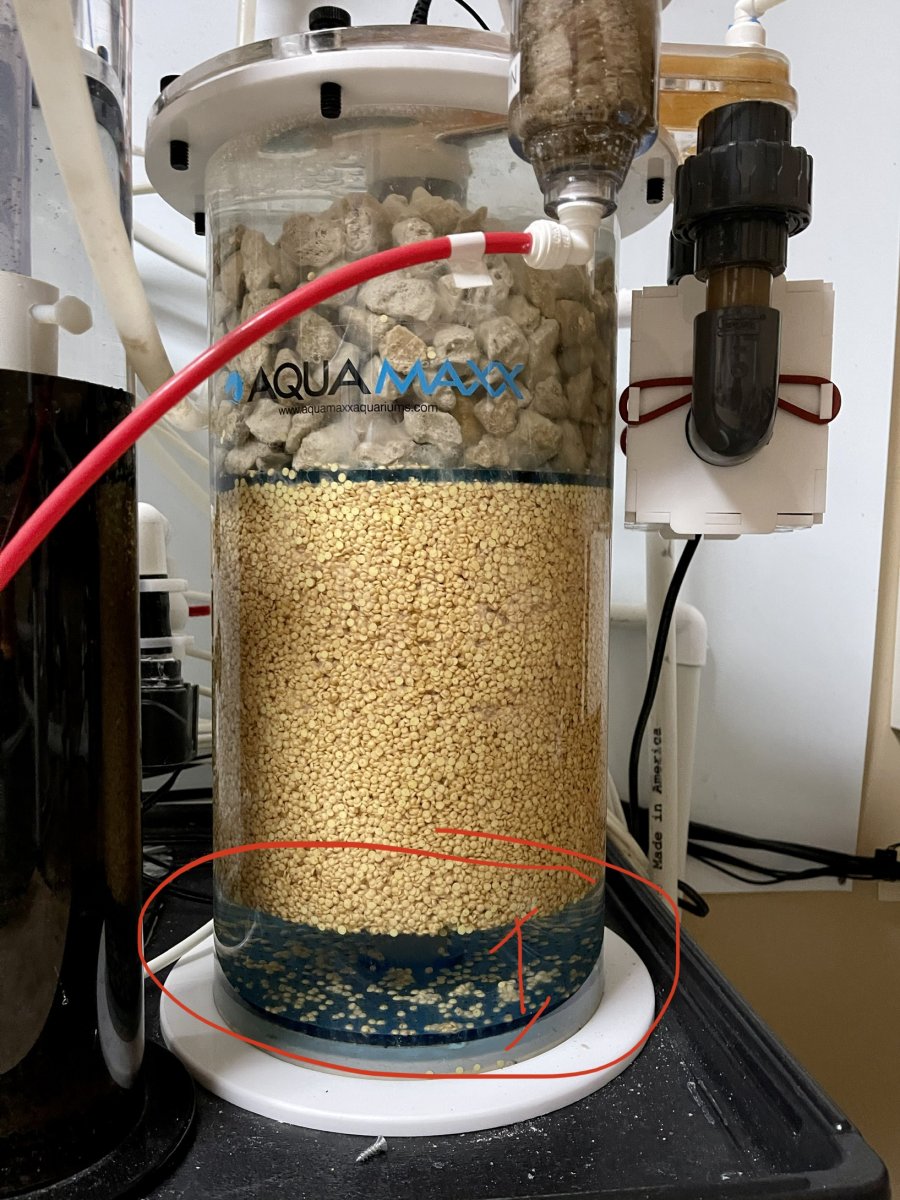

After about 6 months, I start to notice the formation of a form of mulm in the reactor and it starts to coat and eventually bind and clump the sulfur beads together. When this happens, the water no longer flows through the sulfur beads and the pressure of the circulating pump “lifts” the entire sulfur and calcium carbonate media off the bottom plate of the reactor, as shown in the picture.

This forces me to open the reactor and wash the sulfur media, killing the bacteria in the process and restarting the colonization process in the reactor from scratch (just in case, there’s way too much mulm to rinse with aquarium water and requires a lot of water to rinse). In the past, I have noticed the corals don’t like this.

Has anyone experienced this or have any thoughts as to how to prevent this from happening?

A closed-loop makes it possible to manage the internal flow without influencing the actual effluent flow rate and may prevent this to happen. Another closed-loop on the pump itself makes it possible to manage the internal flow of the reactor running the circulation pump at normal speed.

Another reason may be the effluent flow rate is controlled by a valve in the outflow instead of the inflow. In this case, one may try to solve it by fully open the outflow valve or disconnect the outflow from the restrictor. Clean the clogged outflow valve. The reactor disconnected from the system.

Using the reactor as an MBR ( moving bed reactor) will solve this. Pressure should not be able to build up in the reactor.

If the reactor has a closed-loop one just has to increase the internal flow in a way the media moves around removing created tunnels and any blockages. One can also back-wash the reactor, disconnected from the system, without opening it.

In an MBR the media moves around very slowly, not too fast to prevent too much biofilm erosion, preventing clogging.

What is the actual flow rate? What is the max flow rate for the normal operation of this reactor?

Last edited: