- Joined

- Apr 14, 2015

- Messages

- 126

- Reaction score

- 23

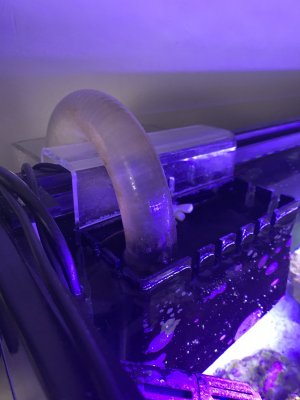

I have a 40B with a HOB Eshopps pf300 overflow, down to a small 10gal sump. The consistent water level in the sump is at 6", the return section (separated by two baffles) is about an inch lower than that and has a Jebao DC3000 return pump.

I've been having some issues dialing the return pump in to match the overflow (without triggering the float valve in the DT which shuts off the return pump as a failsafe). Even though I have a DC pump and a gate valve on my return plumbing (and a gate valve on the overflow!?, but that's a separate issue). Due to this issue I've unplugged my ATO (Tunze Osmolator) because when I'm not home and DT fills a little too much, the float triggers a shutoff and drains a portion of the DT water down to the sump, triggering the ATO alarm which no one appreciates haha.

While searching for a permanent solution to this (pls chime in on this if possible too) I've been topping off the sump by hand every day.

MY QUESTION I THIS.... why does my overflow box get low and make a gurgling noise when my return section of the sump drops due to evaporation!? I'm very new to all this stuff, but was under the impression that the display/overflow portion of the system should all be consistent and that any evaporation is only noticed in the return section of the sump..

PLEASE HELP EXPLAIN THIS TO ME, or maybe direct me to a solution

I've been having some issues dialing the return pump in to match the overflow (without triggering the float valve in the DT which shuts off the return pump as a failsafe). Even though I have a DC pump and a gate valve on my return plumbing (and a gate valve on the overflow!?, but that's a separate issue). Due to this issue I've unplugged my ATO (Tunze Osmolator) because when I'm not home and DT fills a little too much, the float triggers a shutoff and drains a portion of the DT water down to the sump, triggering the ATO alarm which no one appreciates haha.

While searching for a permanent solution to this (pls chime in on this if possible too) I've been topping off the sump by hand every day.

MY QUESTION I THIS.... why does my overflow box get low and make a gurgling noise when my return section of the sump drops due to evaporation!? I'm very new to all this stuff, but was under the impression that the display/overflow portion of the system should all be consistent and that any evaporation is only noticed in the return section of the sump..

PLEASE HELP EXPLAIN THIS TO ME, or maybe direct me to a solution